ASTM B467-14(2022)

(Specification)Standard Specification for Welded Copper-Nickel Pipe

Standard Specification for Welded Copper-Nickel Pipe

ABSTRACT

This specification covers welded copper-nickel alloy pipes produced from Copper Alloy UNS Nos. C70600 and C71500 for general engineering applications. Pipes may be produced in any one of the following tempers: as-welded from annealed sheets, strips, or plates (WM50); as-welded from cold-worked sheets, strips, or plates (WM00, WM01, WM02, and so forth); welded and annealed (WO50); welded, light cold drawn (WR00) or hard cold drawn (WR04), and stress relieved; or fully finished as annealed, light drawn (WH00) or hard drawn (WH04), and stress relieved. Products shall be sampled and prepared, then tested accordingly to examine their conformance to dimensional (outside diameter, specific and stock lengths, wall thickness, squareness of cut, and roundness), mechanical (tensile and yield strengths, and elongation), and chemical composition requirements. Specimens shall also undergo nondestructive tests such as radiographic examination, eddy-current test, and hydrostatic test.

SIGNIFICANCE AND USE

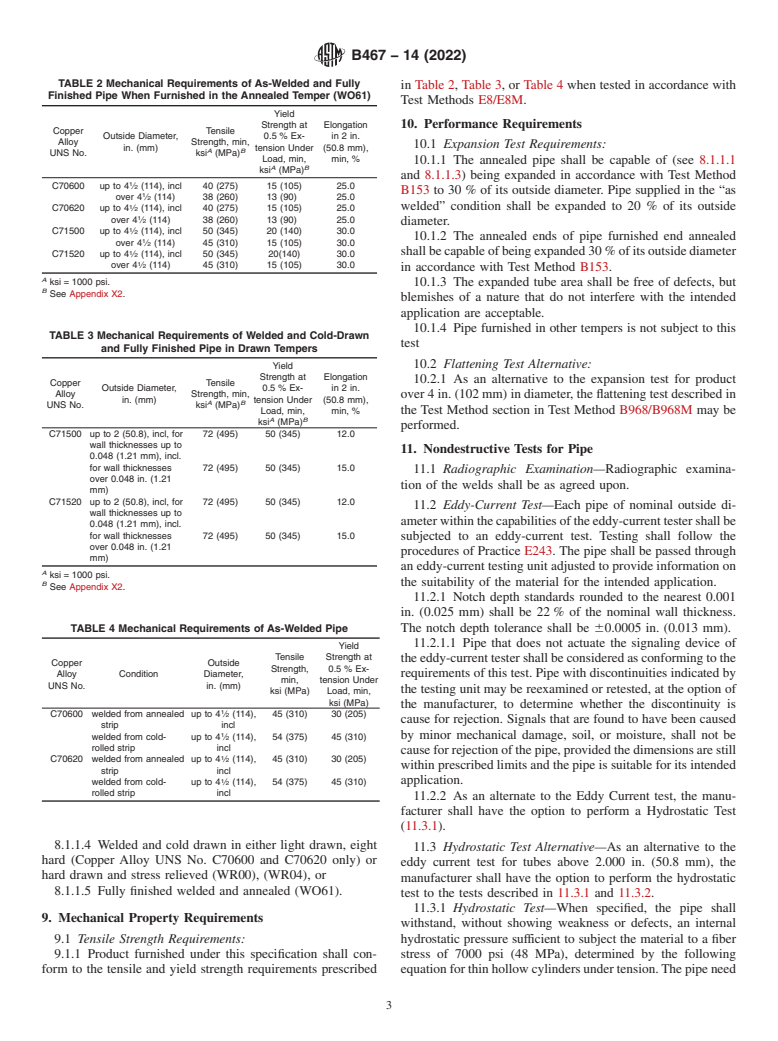

18.1 For purposes of determining compliance with the specified limits for requirements of the properties listed in the following table, and observed value or a calculated value shall be rounded as indicated in accordance with the rounding method of Practice E29.

Property

Rounded Unit for Observed or Calculated Value

Chemical composition

nearest unit in the last right-hand place of figures of the specified limit

Tensile strength

Yield strength

nearest ksi (nearest MPa up to 10 ksi, incl, nearest 5 MPa over 10 ksi)

Elongation

nearest 1 %

SCOPE

1.1 This specification establishes the requirements for welded copper-nickel alloy pipe for general engineering purposes. The following alloys are covered:2

Copper Alloy

UNS No.2

Type of Metal

C70600

90-10 copper-nickel

C70620

90-10 copper-nickel

(Modified for Welding)

C71500

70-30 copper-nickel

C71520

70-30 copper-nickel

(Modified for Welding)

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B467 −14 (Reapproved 2022)

Standard Specification for

1

Welded Copper-Nickel Pipe

This standard is issued under the fixed designation B467; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Specifications for Copper and Copper Alloys

B968/B968M Test Method for Flattening of Copper and

1.1 This specification establishes the requirements for

Copper-Alloy Pipe and Tube

welded copper-nickel alloy pipe for general engineering pur-

2 E8/E8M Test Methods for Tension Testing of Metallic Ma-

poses. The following alloys are covered:

terials

Copper Alloy Type of Metal

E29 Practice for Using Significant Digits in Test Data to

2

UNS No.

Determine Conformance with Specifications

C70600 90-10 copper-nickel

E54 Test Methods for ChemicalAnalysis of Special Brasses

C70620 90-10 copper-nickel

4

and Bronzes (Withdrawn 2002)

(Modified for Welding)

C71500 70-30 copper-nickel E62 Test Methods for Chemical Analysis of Copper and

4

C71520 70-30 copper-nickel

CopperAlloys(PhotometricMethods)(Withdrawn2010)

(Modified for Welding)

E243 Practice for Electromagnetic (Eddy Current) Examina-

1.2 Units—The values stated in inch-pound units are to be

tion of Copper and Copper-Alloy Tubes

regarded as standard. The values given in parentheses are

E255 Practice for Sampling Copper and Copper Alloys for

mathematical conversions to SI units that are provided for

the Determination of Chemical Composition

information only and are not considered standard.

E478 Test Methods for ChemicalAnalysis of CopperAlloys

5

1.3 This international standard was developed in accor-

2.2 ASME Code:

dance with internationally recognized principles on standard-

ASME Boiler and Pressure Vessel Code Application

ization established in the Decision on Principles for the

6

2.3 AWS Standards:

Development of International Standards, Guides and Recom-

A5.6/A5.6M Specification for Copper and Copper - Alloy

mendations issued by the World Trade Organization Technical

Electrodes for Shielded Metal Arc Welding

Barriers to Trade (TBT) Committee.

A5.7/A5.7M Specification for Copper and Copper - Alloy

Bare Welding Rods and Electrodes

2. Referenced Documents

3

2.1 ASTM Standards:

3. Terminology

B153 Test Method for Expansion (Pin Test) of Copper and

3.1 For the definitions of terms related to copper and copper

Copper-Alloy Pipe and Tubing

alloys, refer to Terminology B846.

B601 ClassificationforTemperDesignationsforCopperand

Copper Alloys—Wrought and Cast

4. Types of Welded Pipe

B846 Terminology for Copper and Copper Alloys

B950 Guide for Editorial Procedures and Form of Product 4.1 As-Welded—Pipe that has been welded with no further

workperformedotherthanstraighteningorcuttingtolength,or

both.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.2 Welded and Annealed—Welded pipe that has been

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

annealed to produce a uniform grain size appropriate to the

and Tube.

Current edition approved May 1, 2022. Published June 2022. Originally specified annealed temper.

approved in 1986. Last previous edition approved in 2014 as B467 – 14. DOI:

10.1520/B0467-14R22.

2

The UNS system for copper and copper alloys is a simple expansion of the

4

former standard designation system accomplished by the addition of a prefix “C” The last approved version of this historical standard is referenced on

and a suffix “00.” The suffix can be used to accommodate composition variations of www.astm.org.

5

the base alloy. Available from American Society of Mechanical Engineers (ASME), ASME

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

6 th

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Welding Society (AWS), 8669 NW 36 Street, #130,

the ASTM website. Miami, FL 33166, http://www.aws.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B467−14 (2022)

4.3 Welded and Cold Drawn—Welded pipe with internal 6.2 Manufacture:

flash removed by scarfing, and subsequently cold drawn to

6.2.1 The product shall be manufactured by form

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.