ASTM C1236-99(2005)

(Guide)Standard Guide for In-Plant Performance Evaluation of Automatic Vehicle SNM Monitors (Withdrawn 2014)

Standard Guide for In-Plant Performance Evaluation of Automatic Vehicle SNM Monitors (Withdrawn 2014)

SIGNIFICANCE AND USE

SNM monitors are an effective and unobtrusive means to search for concealed SNM, and facility security plans use them to prevent SNM theft or unauthorized removal from SNM access areas. Functional testing of monitors on a daily basis with radioactive sources can assure that they are in good working order. The significant use of a less frequent, in-plant evaluation of an SNM monitor is to verify that the monitor achieves an expected probability of detection for an SNM or alternative test source.

Note 1—An SNM test source used for in-plant evaluation is normally shielded only by protective encapsulation and the parts of a vehicle that may lie between the source and the monitor’detectors. However, the evaluation procedure could just as well be used to verify an expected level of detection for SNM inside of containers or shields.

SCOPE

1.1 This guide is one of a series on special nuclear material (SNM) monitors and their performance evaluation. Others in the series provide information on SNM monitoring, monitor calibration, and methods of evaluation (see ), but Guide C 993, in particular, provides much of the basis for this guide. The purpose for a guide to in-plant performance evaluation is to provide a comparatively rapid way to verify whether SNM monitors perform as expected for detecting SNM or an alternative test source.

1.2 Guide C 993 points out that in-plant evaluation is one part of a program to keep SNM monitors in proper operating condition and that in-plant evaluation can be used as a routine operational evaluation or can be used to verify performance after a monitor is calibrated.

1.3 This guide is based on ASTM standards that describe applying and evaluating SNM monitors.

WITHDRAWN RATIONALE

This guide is one of a series on special nuclear material (SNM) monitors and their performance evaluation. Others in the series provide information on SNM monitoring, monitor calibration, and methods of evaluation, but Guide C993, in particular, provides much of the basis for this guide. The purpose for a guide to in-plant performance evaluation is to provide a comparatively rapid way to verify whether SNM monitors perform as expected for detecting SNM or an alternative test source.

Formerly under the jurisdiction of C26 on Nuclear Fuel Cycle, this practice was withdrawn in January 2014 in accordance with section 10.6.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1236 − 99 (Reapproved2005)

Standard Guide for

In-Plant Performance Evaluation of Automatic Vehicle SNM

Monitors

This standard is issued under the fixed designation C1236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1.1 Discussion—These monitors are described in 5.3.2

of Guide C1112.

1.1 This guide is one of a series on special nuclear material

3.1.2 vehicle portal monitor—an automatic vehicle SNM

(SNM) monitors and their performance evaluation. Others in

monitor that monitors moving vehicles as they pass through

the series provide information on SNM monitoring, monitor

radiation detectors during their approach to an entry/exit

calibration, and methods of evaluation (see 1.3), but Guide

station.

C993, in particular, provides much of the basis for this guide.

3.1.2.1 Discussion—These monitors are described in 5.3.1

The purpose for a guide to in-plant performance evaluation is

of Guide C1112.

to provide a comparatively rapid way to verify whether SNM

monitors perform as expected for detecting SNM or an

3.2 Terminology for confidence coefficient, confidence

alternative test source.

interval, detection probability, evaluations, nuisance alarm,

SNM,SNMmonitor,andtestsourcesisdefinedordescribedin

1.2 Guide C993 points out that in-plant evaluation is one

Section 3 of Guide C993.

part of a program to keep SNM monitors in proper operating

condition and that in-plant evaluation can be used as a routine

operational evaluation or can be used to verify performance 4. Summary of Guide

after a monitor is calibrated.

4.1 The monitor to be evaluated is a vehicle SNM portal

1.3 This guide is based on ASTM standards that describe monitor (see 3.1.1) or a vehicle SNM monitoring station (see

3.1.2).

applying and evaluating SNM monitors.

4.2 As a first step, the monitor’s indicated background

2. Referenced Documents

measurement value is recorded for possible future use in

2.1 ASTM Standards:

troubleshooting.

C993 Guide for In-Plant Performance Evaluation of Auto-

4.3 If the monitor is being evaluated in routine operation,

matic Pedestrian SNM Monitors

the number of nuisance alarms since the last evaluation is

C1112 Guide for Application of Radiation Monitors to the

examined for evidence of possible misoperation.

Control and Physical Security of Special Nuclear Material

4.4 The detection probability for a test source is evaluated

C1189 Guide to Procedures for Calibrating Automatic Pe-

by repeatedly transporting a test source through the monitor.

destrian SNM Monitors

4.5 The results of the evaluation are analyzed and recorded.

3. Terminology

3.1 Definitions:

5. Significance and Use

3.1.1 vehicle monitoring station—a type of vehicle SNM

5.1 SNM monitors are an effective and unobtrusive means

monitor that monitors vehicles while they are stopped, await-

to search for concealed SNM, and facility security plans use

ing clearance at an entry/exit station.

themtopreventSNMtheftorunauthorizedremovalfromSNM

access areas. Functional testing of monitors on a daily basis

This guide is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel with radioactive sources can assure that they are in good

Cycle and is the direct responsibility of Subcommittee C26.12 on Safeguard

working order. The significant use of a less frequent, in-plant

Applications.

evaluation of an SNM monitor is to verify that the monitor

Current edition approved June 1, 2005. Published October 2005. Originally

achieves an expected probability of detection for an SNM or

approved in 1993. Last previous edition approved in 1999 as C1236 - 99. DOI:

10.1520/C1236-99R05.

alternative test source.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—An SNM test source used for in-plant evaluation is normally

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on shielded only by protective encapsulation and the parts of a vehicle that

the ASTM website. may lie between the source and the monitor’s detectors. However, the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

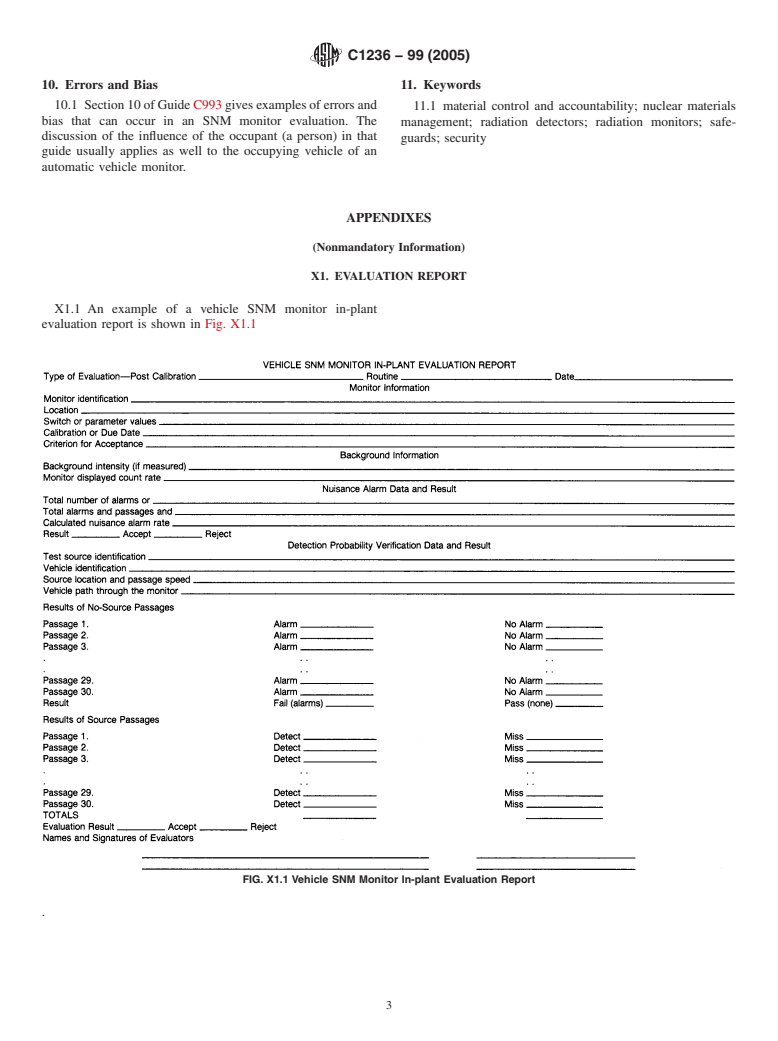

C1236 − 99 (2005)

evaluation procedure could just as well be used to verify an expected level

does not cause alarms. A possible choice for assurance during

of detection for SNM inside of containers or shields.

an evaluation is the following:

8.2.2.1 The individual who will drive the vehicle during the

6. Apparatus

evaluation can first drive it into or through the monitor, as

6.1 Gamma-Ray Survey Meter (Nonmandatory

appropriate, without a source. The chosen manner of passage

Information)—Historical records of gamma-ray background

and the chosen number of passages should be used, and the

intensity may provide useful information for troubleshooting

results (alarm or not for each passage) should be recorded.Any

future monitoring problems. An evaluation offers a good

alarms that occur disqualify the vehicle from further use; select

opportunity to record both the monitor’s indicated background

another vehicle and restart the evaluation.

count and the gamma-ray background intensity. If desired,

8.2.3 Next,theindividualshoulddrivethevehicletransport-

gamma-ray intensity can be measured with a survey meter and

ingthesourceintoorthroughthemonitor,asappropriate.After

recorded during the evaluation. The gamma-ray survey meter

each passage, record the results (detection or miss), and move

should have a NaI(Tl) or plastic scintillator capable of mea-

the vehicle well away from the monitor before making the next

suring environmental gamma radiation in the range from 60

passage. Allow the monitor’s background measurement to

keV to 3 MeV at background intensities that normally range

update after each passage, or after each 20 % of passages when

between 5 and 25 µR/h (1.3 and 6.5 nC/kg h or 0.36 and 1.8

10 or more passages are used.

pA/kg).

8.2.4 When the total number of passages with the source is

complete, tally the results and analyze them by using Table 1.

7. Test Materials

Record the analysis result, acceptance, or rejection.

8.2.5 The acceptance criteria in Table 1 provides at least

7.1 The required material is a test source that may be

95 % confidence that the probability of detection for the test

standard SNM, process SNM, or an alternative test source as

source used in the evaluation is greater than 0.50. Therefore,

described in Section 7 of Guide C993.

the hypothesis that the monitor is operating as expected is

8. Procedure accepted. Rejection criteria does not provide 95 % confidence

that the probability of detection is greater than 0.50, so the

8.1 Procedure for Nuisance Alarm Evaluation:

hypothesisisrejected.Inthatcase,themonitorcanberepaired,

8.1.1 Examine records of nuisance alarms when evaluating

recalibrated, and evaluated again. See 8.2.5 through 8.2.7 of

a monitor in routine service.

Guide C993 for a discussion of the criteria.

8.1.2 The record of alarms should be one generated at the

8.2.6 Other criteria (for more passages, different detection

m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.