ASTM D7477-08(2013)

(Test Method)Standard Test Method for Determining the Area Stability of Wet Blue Submersed in Boiling Water

Standard Test Method for Determining the Area Stability of Wet Blue Submersed in Boiling Water

SIGNIFICANCE AND USE

4.1 Determination of the hydro-thermal area stability of wet blue provides information concerning the efficacy of the tanning process as well as the adequacy of the wet blue for intended end use applications where area stability is a particular requirement. Relative area stability of chrome-tanned leather is a requirement for many applications such as bookbinding, shoe and boot components, upholstery, seals and gaskets, etc.

4.2 This test method is suitable for use in development work and process control in the tannery and for specification testing of wet blue for domestic and international commercial purposes.

SCOPE

1.1 This test method provides a standard procedure for determination of the dimensional stability or area shrinkage of a specimen of wet blue that is submersed in boiling water for a specified time period. This test method is applicable to all types of wet blue.

1.2 The values given in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7477 − 08(Reapproved 2013)

Standard Test Method for

Determining the Area Stability of Wet Blue Submersed in

1

Boiling Water

This standard is issued under the fixed designation D7477; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope reaches 100°C and begins to re-boil. As soon as the specimen

has cooled sufficiently to allow comfortable handling the area

1.1 This test method provides a standard procedure for

loss is determined.

determination of the dimensional stability or area shrinkage of

a specimen of wet blue that is submersed in boiling water for

4. Significance and Use

a specified time period. This test method is applicable to all

4.1 Determination of the hydro-thermal area stability of wet

types of wet blue.

blue provides information concerning the efficacy of the

1.2 The values given in SI units are to be regarded as the

tanning process as well as the adequacy of the wet blue for

standard. The inch-pound units given in parentheses are for

intended end use applications where area stability is a particu-

information only.

lar requirement. Relative area stability of chrome-tanned

1.3 This standard does not purport to address all of the

leather is a requirement for many applications such as

safety concerns, if any, associated with its use. It is the

bookbinding, shoe and boot components, upholstery, seals and

responsibility of the user of this standard to establish appro-

gaskets, etc.

priate safety and health practices and determine the applica-

4.2 Thistestmethodissuitableforuseindevelopmentwork

bility of regulatory limitations prior to use.

and process control in the tannery and for specification testing

of wet blue for domestic and international commercial pur-

2. Referenced Documents

poses.

2

2.1 ASTM Standards:

D6659Practice for Sampling and Preparation of Wet Blue 5. Apparatus

for Physical and Chemical Tests

5.1 Beaker, standard, IL capacity. Other suitable containers

E691Practice for Conducting an Interlaboratory Study to

may be used so long as the dimensions are sufficiently large to

Determine the Precision of a Test Method

enable suspension of the completely immersed test specimen

E177Practice for Use of the Terms Precision and Bias in

with no contact occurring with the sides and bottom of the

ASTM Test Methods

container during the test. Particularly when non-standard test

specimens are used, the size and shape requirements of the

3. Summary of Test Method

container are dependent on the dimensions of the specimen to

3.1 Asample cutting of wet blue is either taken directly out be tested.

of the tanning drum or else is pre-soaked in water for 30 min

5.2 Thermometer,withaminimumscalereadingto+110°C,

or until it is completely re-hydrated (see 9.1 for details on

graduated in 1°C, and having a 0.5°C tolerance.

re-hydration). The specimen to be tested is cut out from this

5.3 Timer, with minimum 3 min capacity and 1.0 s resolu-

thoroughly hydrated sample cutting. The test specimen is then

tion.

totally submerged and suspended in boiling water. The test

specimen is removed 3.0 min after the water temperature

5.4 Metal die, to cut specimens. The die should be con-

structed of highly corrosion resistant alloy metal and must be

maintained in a clean and sharp condition to minimize distor-

1

tionofthewetbluesamplethatmayoccurduringthespecimen

This test method is under the jurisdiction ofASTM Committee D31 on Leather

and is the direct responsibility of Subcommittee D31.02 on Wet Blue.

cuttingoperation.Therecommendedspecimenisasquare76.2

Current edition approved May 1, 2013. Published July 2013. Originall approved

by 76.2 mm (3.00 by 3.00 in.). However, other size and shape

in 2008. Last previous edition approved in 2008 as D7477- 08. DOI: 10.1520/

specimens can be used so long as the requirements of Section

D7477-08R13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 8 are met.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.5 Measuring scale, ruler longer than the greatest dimen-

Standards volume information, refer to the standard’s Document Summary page on

1

the ASTM website. sion of the test specimen, divided in millimeters ( ⁄32 in.).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7477 − 08 (2013)

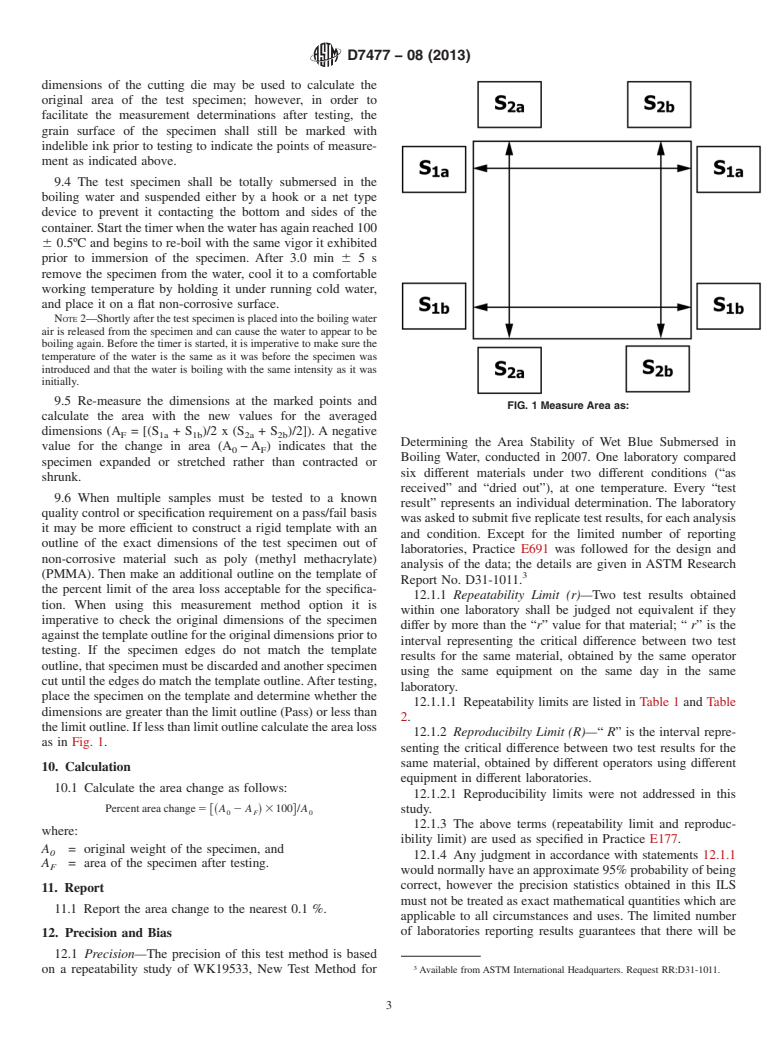

through the mathematical calculations.

5.6 Marking pen, Suitable water-proof marker or pen for

marking the indicator points, on the hydrated wet blue grain

8.3 Appropriate small holes may be punched in t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.