ASTM D5709-09

(Test Method)Standard Test Method for Sieve Analysis of Petroleum Coke

Standard Test Method for Sieve Analysis of Petroleum Coke

SIGNIFICANCE AND USE

The test method concerns the sieving of coke into designated size fractions for the purpose of characterizing the material as to its particle size distribution. It requires the use of standard sieves, standard sampling methods, standard sample preparation methods, and a minimum initial sample mass based on lot topsize. Suggestions are given for industry typical sieve stacks for both green and calcined petroleum coke.

Particle size distribution is significant in that many physical characteristics of a coke are related to such a distribution including bulk density and surface area. Nuisance characteristics, such as excessive fines in a lot, can also be controlled.

Results from this test method are useful in determining whether a coke lot meets purchase specifications, for classification purposes, and for quality control. The results of this test method can also be used to predict the performance of a particular lot of coke in a process.

SCOPE

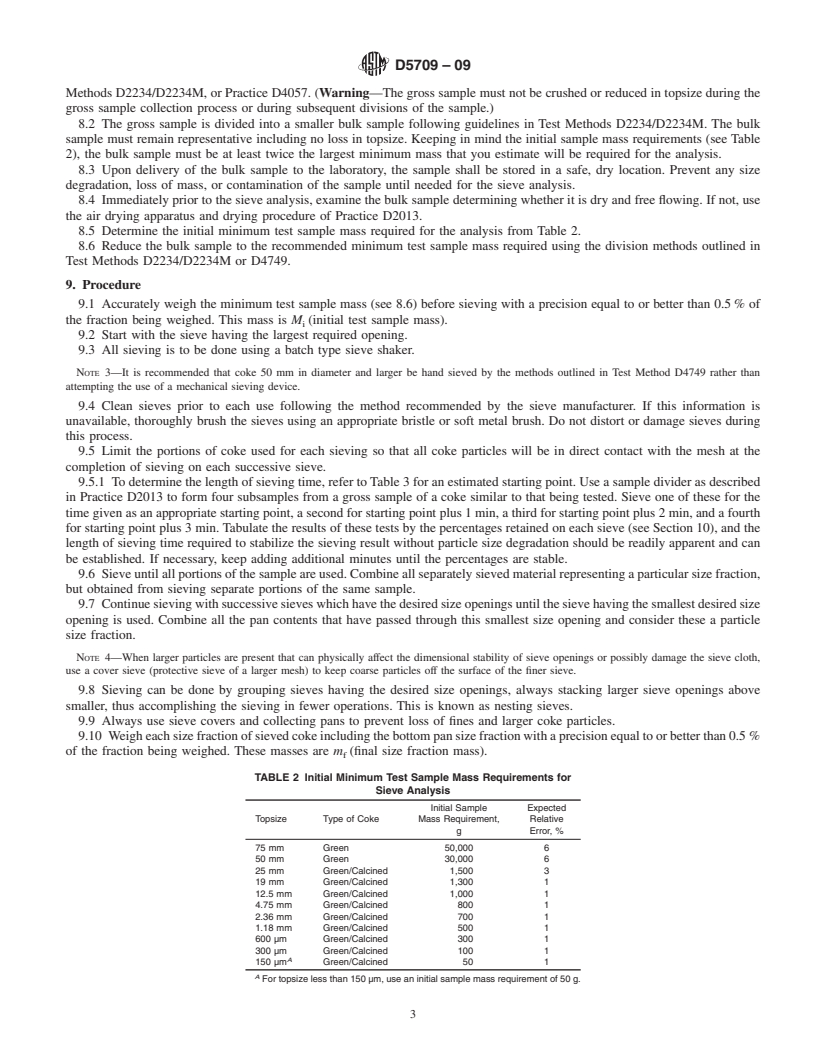

1.1 This test method details a procedure for performing particle size distribution analysis by dry sieve testing on green petroleum coke with a topsize of no more than 75 mm and calcined petroleum coke with a topsize of no more than 25 mm. Size fractions go down to and include 4.75 mm for green petroleum coke and 75 μm for calcined petroleum coke.

Note 1—To convert units, see Table 1 on nominal dimensions in Specification E11. For example, 75 mm is approximately equivalent to a nominal sieve opening of 3 in. and 25 mm to a nominal sieve opening of 1 in. Likewise, 4.75 mm can be converted to approximately 0.187 in. and 75 microns to 0.0029 in.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 The sieve size is reported as U.S.A. standard test series in any units listed in Table 1 on nominal dimensions of Specification E11, or their commercial size equivalents.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5709 − 09

StandardTest Method for

1

Sieve Analysis of Petroleum Coke

This standard is issued under the fixed designation D5709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D4749 Test Method for Performing the Sieve Analysis of

Coal and Designating Coal Size

1.1 This test method details a procedure for performing

E11 Specification for Woven Wire Test Sieve Cloth and Test

particle size distribution analysis by dry sieve testing on green

Sieves

petroleum coke with a topsize of no more than 75 mm and

calcinedpetroleumcokewithatopsizeofnomorethan25mm.

3. Terminology

Size fractions go down to and include 4.75 mm for green

3.1 Definitions of Terms Specific to This Standard:

petroleum coke and 75 µm for calcined petroleum coke.

3.1.1 bulk sample, n—the reduced and divided representa-

NOTE 1—To convert units, see Table 1 on nominal dimensions in

tiveportionofthegrosssampleaspreparedforshipmenttoand

Specification E11. For example, 75 mm is approximately equivalent to a

received by a laboratory, to be prepared for analysis.

nominal sieve opening of 3 in. and 25 mm to a nominal sieve opening of

1 in. Likewise, 4.75 mm can be converted to approximately 0.187 in. and

3.1.2 gross sample, n—the original, uncrushed, representa-

75 microns to 0.0029 in.

tive portion taken from a shipment or lot of coke.

1.2 The values stated in SI units are to be regarded as

3.1.3 lot, n—a quantity of coke to be represented by a gross

standard. No other units of measurement are included in this

sample.

standard.

3.1.4 representative sample, n—a sample collected in such a

1.2.1 The sieve size is reported as U.S.A. standard test

manner that every particle in the lot to be sampled is equally

series in any units listed in Table 1 on nominal dimensions of

represented in the gross sample.

Specification E11, or their commercial size equivalents.

3.1.5 topsize, n—the size of the smallest opening of one

1.3 This standard does not purport to address all of the

sieve of a series upon which is cumulatively retained a total of

safety concerns, if any, associated with its use. It is the

less than 5 % of the sample. This defined topsize is not to be

responsibility of the user of this standard to establish appro-

confused with the size of the largest particle in a lot.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

4.1 A representative coke sample is divided into ranges of

2. Referenced Documents

particle size by the use of a series of square-holed sieves.

2

2.1 ASTM Standards:

D346 Practice for Collection and Preparation of Coke

5. Significance and Use

Samples for Laboratory Analysis

5.1 The test method concerns the sieving of coke into

D2013 Practice for Preparing Coal Samples for Analysis

designated size fractions for the purpose of characterizing the

D2234/D2234M Practice for Collection of a Gross Sample

material as to its particle size distribution. It requires the use of

of Coal

standard sieves, standard sampling methods, standard sample

D4057 Practice for Manual Sampling of Petroleum and

preparationmethods,andaminimuminitialsamplemassbased

Petroleum Products

on lot topsize. Suggestions are given for industry typical sieve

stacks for both green and calcined petroleum coke.

5.2 Particle size distribution is significant in that many

1

This test method is under the jurisdiction of ASTM Committee D02 on

physical characteristics of a coke are related to such a

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

distribution including bulk density and surface area. Nuisance

Current edition approved Dec. 1, 2009. Published February 2010. Originally

characteristics, such as excessive fines in a lot, can also be

approved in 1995. Last previous edition approved in 2005 as D5709–95(2005).

controlled.

DOI: 10.1520/D5709-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 Results from this test method are useful in determining

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

whether a coke lot meets purchase specifications, for classifi-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cation purposes, and for quality control. The results of this test

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-------------------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5709–95 (Reapproved 2005) Designation:D5709–09

Standard Test Method for

1

Sieve Analysis of Petroleum Coke

This standard is issued under the fixed designation D5709; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method details a procedure for performing particle size distribution analysis by dry sieve testing on green

petroleum coke with a topsize of no more than 75 mm and calcined petroleum coke with a topsize of no more than 25 mm. Size

fractions go down to and include 4.75 mm for green petroleum coke and 75 µm for calcined petroleum coke.

NOTE 1—To convert units, see Table 1 on nominal dimensions in Specification E11. For example, 75 mm is approximately equivalent to a nominal

sieve opening of 3 in. and 25 mm to a nominal sieve opening of 1 in. Likewise, 4.75 mm can be converted to approximately 0.187 in. and 75 microns

to 0.0029 in.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 The sieve size is reported as U.S.A. standard test series in any units listed in Table 1 on nominal dimensions of

Specification E11, or their commercial size equivalents.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D346 Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

D2013 Practice for Preparing Coal Samples for Analysis

D2234/D2234M Practice for Collection of a Gross Sample of Coal

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4749 Test Method for Performing the Sieve Analysis of Coal and Designating Coal Size

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bulk samplebulk sample, n—the reduced and divided representative portion of the gross sample as prepared for shipment

to and received by a laboratory, to be prepared for analysis.

3.1.2 gross samplegross sample, n—the original, uncrushed, representative portion taken from a shipment or lot of coke.

3.1.3 lotlot, n—a quantity of coke to be represented by a gross sample.

3.1.4 representative samplerepresentative sample, n—a sample collected in such a manner that every particle in the lot to be

sampled is equally represented in the gross sample.

3.1.5 topsize, n—the size of the smallest opening of thatone sieve of a series with the smallest opening upon which is

cumulatively retained a total of less than 5 % of the sample. This defined topsize is not to be confused with the size of the largest

particle in a lot.

4. Summary of Test Method

4.1 A representative coke sample is divided into ranges of particle size by the use of a series of square-holed sieves.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.05 on

Properties of Fuels, Petroleum Coke and Carbon Material.

´1

Current edition approved May 1, 2005. Published June 2005. Originally approved in 1995. Last previous edition approved in 2000 as D5709–95(2000) . DOI:

10.1520/D5709-95R05.

Current edition approved Dec. 1, 2009. Published February 2010. Originally approved in 1995. Last previous edition approved in 2005 as D5709–95(2005). DOI:

10.1520/D5709-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5709–09

5. Significance and Use

5.1 The test method concerns the sieving of coke into designated size fractions for the purpose of characterizing the material

as to its particle size distribution. It requires the use of standard sieves, standard sampling methods, s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.