ASTM B913-00

(Test Method)Standard Test Method for Evaluation of Crimped Electrical Connections to 16-Gauge and Smaller Diameter Stranded and Solid Conductors

Standard Test Method for Evaluation of Crimped Electrical Connections to 16-Gauge and Smaller Diameter Stranded and Solid Conductors

SCOPE

1.1 This test method establishes the requirements for a standardized method of evaluating the quality of crimped-type electrical connections to solid or stranded conductors. This test method applies to 16-gauge and smaller diameter copper wire, coated or uncoated.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 913 – 00

Standard Test Method for

Evaluation of Crimped Electrical Connections to 16-Gauge

and Smaller Diameter Stranded and Solid Conductors

This standard is issued under the fixed designation B 913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope has a ring, fork, spade, tab, or related configuration designed to

attach to another connection such as a screw or terminal block.

1.1 This test method establishes the requirements for a

standardized method of evaluating the quality of crimped-type

4. Summary of Test Method

electrical connections to solid or stranded conductors. This test

4.1 A test lot of test specimens of the crimp terminal

method applies to 16-gauge and smaller diameter copper wire,

crimped to a short length of wire is prepared. The wire is pulled

coated or uncoated.

from a group of the specimens in a tensile pull and the force

2. Referenced Documents compared to set requirements based on wire diameter. A

separate group of specimens is subjected to an electrical test

2.1 ASTM Standards:

where resistance stability of the specimen is evaluated during

B 8 Specification for Concentric-Lay-Stranded Copper

2 deflection of the wire at the exit of the crimped connection. The

Conductors, Hard, Medium-Hard, or Soft

group is then aged for 33 days at 118°C and periodically

B 258 Specification for Standard Nominal Diameters and

retested in the electrical test. The electrical test results are

Cross-Sectional Areas of AWG Sizes of Solid Round Wires

compared to a standard value based on wire diameter. A test lot

Used as Electrical Conductors

passes the evaluation if it passes both the mechanical pull test

B 542 Terminology Relating to Electrical Contacts and

and the electrical test. In Method B, additional pull tests are

Their Use

performed on subgroups of parts during and after the aging test

3. Terminology

to provide information on progressive degradation in perfor-

mance.

3.1 Definitions—Many terms related to electrical contacts

used in this test method are defined in Terminology B 542.

5. Significance and Use

3.2 Definitions of Terms Specific to This Standard:

5.1 This test method establishes the requirements for a

3.2.1 crimp, v—to establish an electrical and mechanical

standardized method of evaluating the performance of

attachment between the two members by mechanically deform-

crimped-type electrical connections having solid or stranded

ing one contact member around another. In most cases, one

conductors.

member is a wire or group of wires, the other is a hollow

5.2 In order to achieve a successful crimped connection, the

cylinder or partial cylinder that is deformed around the wires.

crimping tool must deform the material of the crimp barrel or

3.2.2 crimp barrel, crimp tab—the portion of the crimp

barrel tab(s) around the conductor. As a consequence, the

terminal that is deformed in the crimping operation.

conductor surfaces are placed under compression by the crimp

3.2.3 crimped connection—a mechanical and electrical con-

terminal and areas of contact are established between the

nection between a conductor and a component. The connection

conductor and the crimp barrel. These areas provide the desired

is made by compressing (crimping) the component (crimp

electrical connection. A reliable crimped connection is one that

barrel) or tab(s) of the component about the conductor using a

is capable of maintaining the contact between the conductor

tool specifically designed for the purpose

and crimp barrel so that a stable electrical connection is

3.2.4 crimp terminal—an electrical component designed to

maintained when it is exposed to the conditions it was designed

be electrically and mechanically attached to a wire by deform-

to endure during its useful life.

ing a portion of the component in a crimping operation to form

5.3 Evaluation testing is designed to ensure that a particular

an attachment to the wire. The other end of the terminal usually

design crimped connection system consisting of conductor and

component and associated tooling is capable of achieving a

This test method is under the jurisdiction of ASTM Committee B02 on

reliable electrical and mechanical connection. After the evalu-

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

ation is completed, if any change in the system parts is made,

B02.11 on Electrical Contact Test Methods.

Current edition approved Oct. 10, 2000. Published December 2000.

the system should be reevaluated using the same procedures.

Annual Book of ASTM Standards, Vol 02.03.

5.4 After completion of the evaluation test, the tensile pull

Annual Book of ASTM Standards, Vol 02.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 913

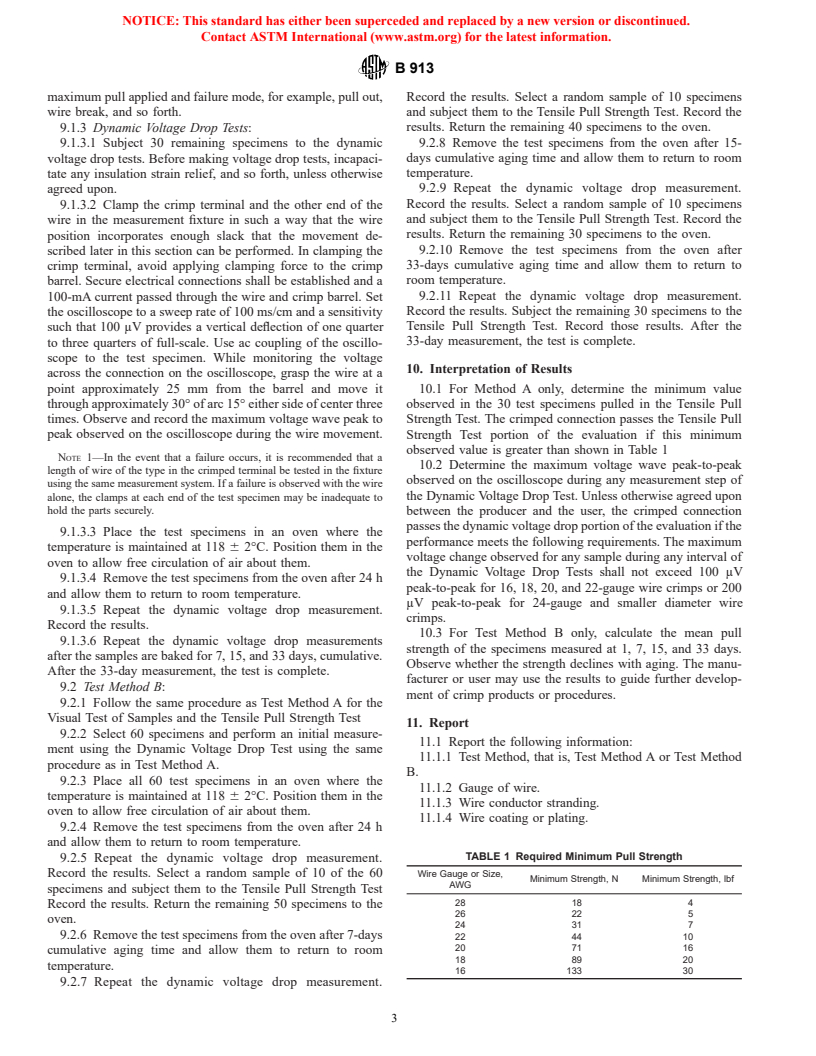

strength results may be used to develop acceptance require- 8.2.10 Crimping tool supplier part number, and

ments to be used in inspection of subsequent production lots of 8.2.11 Crimping tool die setting (if applicable).

crimped connections. An example of such an acceptance 8.3 The test specimens shall meet the following require-

requirement is shown in Appendix X1. ments:

8.3.1 All strands of the conductor(s) shall be in the crimp

6. Interferences

barrel and there shall be no evidence of missing, broken,

6.1 The wire strain relief included in some crimp terminals

damaged, or loose strands of the conductor(s).

may mask the performance of the crimped connection to the 8.3.2 Conductors shall not be pre-soldered or solder-dipped

wire. The strain relief shall be disabled prior to testing the

prior to crimping.

specimens in this test method. 8.3.3 Wire is to be stripped immediately before crimping for

a distance that is proper to full insertion into the crimp barrel.

7. Apparatus

Strip the other end of the wire for 25 mm to allow for

7.1 Tensile Test Stand, Load cell and grips, or Holding

connection to electrical measuring devices.

Fixtures, adequate to measure the force required to pull the

8.3.4 The crimp indent shall be in the intended position and

crimp terminal off the wire at the speed specified in this test

orientation on the barrel in accordance with the design intent of

method.

the manufacturer’s die set and crimp barrel.

7.2 Oscilloscope, with adequate preamplifiers to measure

8.3.5 There shall be no cracking or rupture in any portion of

dynamic change of 100 6 10 μV. An oscilloscope with a

the barrel, tabs, and so forth.

recording device is preferred as it can provide a permanent

8.3.6 The crimp barrel shall show no evidence of re-

record of the results.

crimping (double crimping) in the same location. Barrels may

7.3 Fixture with Two Clamps, to securely hold the crimp

be crimped in more than one location in accordance with the

terminal and end of the wire while making an electrical

manufacture’s design.

connection to each, and allow for manual deflection of the wire

8.3.7 When a terminal is equipped with an insulation grip or

at the exit of the crimp terminal through 15° in all directions.

support, the wire insulation shall be in its intended position

A fixture with two vise-like clamps mounted about 80 mm

within the grip or support after crimping. The grip or support

apart on an insulating base has proved suitable. Spring clips

shall, as designed, mechanically secure or support the wire

often used with 16 to 24-gauge wire are not adequate; a higher

insulation.

force clamp is needed.

8.3.8 On pre-insulated terminals or splices, the insulated

7.4 dc Power Supply, capable of providing 100-mA milli-

sleeve shall remain in its proper position on the crimp barrel

amps current through the sample with noise or ripple less than

after crimping and shall not show evidence of cracking or

10 μV on the measured sample

spalling.

8.3.9 When sleeving is used to insulate uninsulated crimped

8. Test Specimen

barrels, the sleeving shall be a snug fit and shall cause no

8.1 Prepare the following quantities of test specimens of the

evidence of damage to the wire insulation.

crimped connection made with the wire and crimp component

8.3.10 The conductor must be fully seated in the barrel and

to be evaluated. For Test Method A, prepare 64 specimens, for

may extend beyond the barrel but not into the tongue area or

Test Method B, prepare 94 test specimens. For crimped

plug end of terminal lugs to the extent that it will interfere with

connections that will be manufactured with adjustable crimp

proper connection of the terminal to another part in the manner

dies, prepare 64 (Test Method A) or 94 (Test Method B) test

intended.

specimens each made with the smallest and largest die setting

8.3.11 If more than one conductor is crimped in a single

to which the dies will be set in the manufacture of the actual

crimp terminal, the wires must not be twisted together before

connections. The wire length beyond the crimp barrel shall be

crimping.

200 mm (8 in.), minimum. In each test method, the 64 or 94

9. Procedure

specimens provide four extra specimens beyond those actually

required for testing, the remaining four can be used in test set 9.1 Test Method A:

up or retained as examples of the manufactured test specimens 9.1.1 Visual Test of Samples—Visually inspect all test speci-

since the testing is destructive. Specifications B 8 and B 258 mens to determine if they meet the applicable requirements of

define wire gauge (diameter) and wire stranding. the Test Specimens section of this test method.

8.2 Document the following items at the time that the 9.1.2 Tensile Pull Strength Test—Perform the tensile (pull)

specimens are prepared: strength tests on 30 test specimens in the as-received condition.

8.2.1 Gauge of wire, For multiple wire crimped connections, test (pull) the smallest

8.2.2 Wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.