ASTM C1237-99(2005)

(Guide)Standard Guide to In-Plant Performance Evaluation of Hand-Held SNM Monitors (Withdrawn 2014)

Standard Guide to In-Plant Performance Evaluation of Hand-Held SNM Monitors (Withdrawn 2014)

SIGNIFICANCE AND USE

Hand-held SNM monitors are an effective and unobtrusive means to search pedestrians or vehicles for concealed SNM when automatic SNM monitors are not available or have sounded an alarm. Facility security plans apply SNM monitors as one means to prevent theft or unauthorized removal of SNM from designated areas. Functional testing of monitors on a daily basis with radioactive sources can assure they are in good working order. The significance of a less frequent, in-plant evaluation of an SNM monitor is to verify that the monitor achieves an expected probability of detection for an SNM or alternative test source.

The evaluation verifies acceptable performance or discloses faults in hardware or calibration.

The evaluation uses test sources shielded only by normal source encapsulation. However, shielded SNM test sources could be used as well.

The evaluation, when applied as a routine operational evaluation, provides evidence for continued compliance with the performance goals of security plans or regulatory guidance.

Note 1—It is the responsibility of the users of this guide to coordinate its application with the appropriate regulatory authority so that mutually agreeable choices for evaluation frequency, test sources, detection criteria (whether a single or multiple alarms constitute detection), minimum distance for first detection, number of trials, and reporting procedures are used. Regulatory concurrence should be formally documented.

SCOPE

1.1 This guide is one of a series on the application and evaluation of special nuclear material (SNM) monitors. Other guides in the series are listed in Section 2, and the relationship of in-plant performance evaluation to other procedures described in the series is illustrated in Fig. 1. Hand-held SNM monitors are described in of Guide C1112, and performance criteria illustrating their capabilities can be found in Appendix X1.

1.2 The purpose of this guide to in-plant performance evaluation is to provide a comparatively rapid procedure to verify that a hand-held SNM monitor performs as expected for detecting SNM or alternative test sources or to disclose the need for repair. The procedure can be used as a routine operational evaluation or it can be used to verify performance after a monitor is calibrated.

1.3 In-plant performance evaluations are more comprehensive than daily functional tests. They take place less often, at intervals ranging from weekly to once every three months, and derive their result from multiple trials.

1.4 Note that the performance of both the hand-held monitor and its operator are important for effective monitoring. Operator training is discussed in Appendix X2.

1.5 The values stated in SI units are to be regarded as standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note—The procedures shown “above” the user provide the user with information before acquiring a monitor, and those “below” assist the user to obtain continuing acceptable performance from the monitor.

WITHDRAWN RATIONALE

This guide is one of a series on the application and evaluation of special nuclear material (SNM) monitors.

Formerly under the jurisdiction of Committee C26 on Nuclear Fuel Cycle, this practice was withdrawn in January 2014 in accordance with section 10.6.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1237 − 99 (Reapproved2005)

Standard Guide to

In-Plant Performance Evaluation of Hand-Held SNM

Monitors

This standard is issued under the fixed designation C1237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This guide is one of a series on the application and 2.1 The guide is based on ASTM standards that describe

evaluation of special nuclear material (SNM) monitors. Other application and evaluation of SNM monitors, as well as

guides in the series are listed in Section 2, and the relationship technical publications that describe aspects of SNM monitor-

of in-plant performance evaluation to other procedures de- ing.

scribed in the series is illustrated in Fig. 1. Hand-held SNM 2

2.2 ASTM Standards:

monitors are described in of Guide C1112, and performance

C859 Terminology Relating to Nuclear Materials

criteria illustrating their capabilities can be found in Appendix

C1112 Guide for Application of Radiation Monitors to the

X1.

Control and Physical Security of Special Nuclear Material

1.2 The purpose of this guide to in-plant performance C1189 Guide to Procedures for Calibrating Automatic Pe-

evaluation is to provide a comparatively rapid procedure to destrian SNM Monitors

verify that a hand-held SNM monitor performs as expected for

3. Terminology

detecting SNM or alternative test sources or to disclose the

need for repair. The procedure can be used as a routine

3.1 Definitions:

operational evaluation or it can be used to verify performance

3.1.1 alarm—the audible sound made by a hand-held SNM

after a monitor is calibrated.

monitor to indicate that it has detected radiation intensity at or

above the alarm threshold.

1.3 In-plant performance evaluations are more comprehen-

3.1.1.1 Discussion—One or more closely spaced alarms

sive than daily functional tests. They take place less often, at

may be chosen to signify detection of SNM.

intervals ranging from weekly to once every three months, and

derive their result from multiple trials.

3.1.2 alternative test source—Although no other radioactive

materials individually or collectively duplicate the radioactive

1.4 Notethattheperformanceofboththehand-heldmonitor

emissions of uranium or plutonium, some materials have

and its operator are important for effective monitoring. Opera-

similar attributes and are sometimes used as alternative test

tor training is discussed in Appendix X2.

sources.

1.5 The values stated in SI units are to be regarded as

3.1.2.1 alternative gamma-ray test sources—Examples of

standard.

alternative gamma-ray sources are highly enriched uranium

1.6 This standard does not purport to address all of the

(HEU) or Ba used in place of plutonium when a plutonium

safety problems, if any, associated with its use. It is the

source is not readily available or is prohibited.

responsibility of the user of this standard to establish appro-

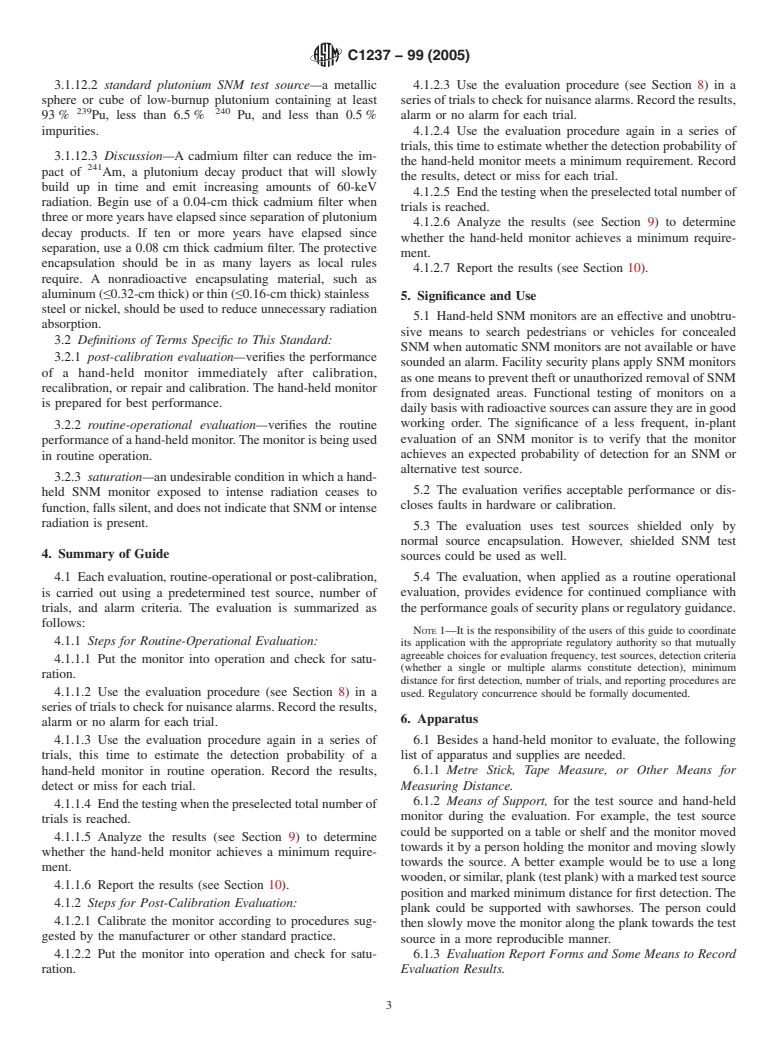

priate safety and health practices and determine the applica- 3.1.2.2 Discussion—Table 1 tabulates amounts of HEU

mass, plutonium mass, and Ba source activity that produce

bility of regulatory limitations prior to use.

equal response in two different types of monitor.

This guide is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel

Cycleand is the direct responsibility of Subcommittee C26.12 on Safeguard

Applications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2005. Published November 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 1999 as C1237 – 99. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1237-99R05. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1237 − 99 (2005)

3.1.5 detection—one or more alarm sounds from a hand-

held SNM monitor may constitute detection of SNM.

3.1.5.1 Discussion—Nuisance alarms are more likely to

occur in hand-held monitors than in other types of SNM

monitors for several reasons. Repeated alarms are most often

used to indicate detection of SNM.

3.1.6 detection probability—for hand-held monitors, ex-

pressed as the proportion of trials with a particular test source

for which the monitor is expected to detect the source.

3.1.6.1 Discussion—Although probabilities are properly ex-

pressedasproportions,performancerequirementsfordetection

probability in regulatory guidance have sometimes been ex-

pressed in percentage. In that case, the detection probability as

a proportion can be obtained by dividing the percentage by

100.

3.1.7 hand-held SNM monitor—ahand-heldradiationdetec-

tion system that measures ambient radiation intensity, deter-

mines an alarm threshold from the result, and then when it is

used for monitoring, sounds an alarm whenever its measured

radiation intensity exceeds the threshold.

3.1.8 nuisance alarm—a monitoring alarm not caused by

SNM but by other causes, that may be a statistical variation in

the measurement process, a background intensity variation, or

an equipment malfunction.

NOTE 1—The procedures shown “above” the user provide the user with

information before acquiring a monitor, and those “below” assist the user

3.1.9 operator—an individual who uses a hand-held SNM

to obtain continuing acceptable performance from the monitor.

monitor to search pedestrians, packages, or vehicles to detect

FIG. 1 The Relationship of In-plant Evaluation to Other Proce-

the presence of SNM.

dures Described in Guides for SNM Monitors

3.1.10 process-SNM test source—an SNM test source fab-

A

ricated by a facility from process material that differs in

TABLE 1 Alternative Test Source Equivalent Amounts

physical or isotopic form from the material recommended in

Monitor Ba (µCi) Required in:

NaI(Tl) Plastic

3.1.12 for standard test sources.

Plutonium, g Uranium, g

Category Description Scintillator Scintillator

3.1.10.1 Discussion—This type of source is used when it

Monitors Monitors

meetsplantoperatororregulatoryagencyperformancerequire-

I Plutonium 1 64 2.5 3.2

II Uranium 0.29 10 0.9 1.4

ments and a standard source is not appropriate or readily

A

This table combines information from Tables II and V of the report referenced in

available. Encapsulation and filtering should follow that rec-

Footnote 5. Note that the term “category” refers to an SNM monitor performance

ommended in 3.1.12.

category used in that report and not to an SNM accountability category. Also note

that the Ba source strengths depend on individual differences in how the

3.1.11 SNM (special nuclear material)—plutonium of any

scintillators respond to radiation from the barium isotope and plutonium.

isotopic composition, U, or enriched uranium as defined in

Terminology C859.

3.1.11.1 Discussion—Thistermisusedheretodescribeboth

3.1.2.3 alternative neutron test source—Acommon alterna-

SNM and strategic SNM, which is plutonium, U, and

tive neutron source used in place of plutonium is Cf, which

uranium enriched to 20 % or more in the U isotope.

emits neutrons from spontaneous fission as does plutonium.

3.1.12 standard SNM test source—a metallic sphere or cube

3.1.2.4 Discussion—Alternative test sources may have short of SNM having maximum self attenuation of its emitted

radiation and an isotopic composition listed below that mini-

decay half-lives in comparison to SNM isotopes, for example

133 252

the half-life of Ba is 10.7 years and Cf 2.64 years. Larger mizes the intensity of its radiation emission. Encapsulation and

filteringalsoaffectradiationintensity,andparticulardetailsare

source activities than initially needed are often purchased to

obtain a longer working lifetime for the source. listed for each source. This type of test source is used in

laboratory evaluation but, if suitable and readily available, also

3.1.3 confidence coeffıcient—the approximate percentage of

may be used for in-plant evaluation.

confidence intervals from a large number of repetitions of an

evaluation that would contain the true result.

3.1.12.1 standard uranium SNM test source—a metallic

3.1.3.1 Discussion—Forexample,aconfidencecoefficientis

sphere or cube of HEU containing at least 93 % U and less

being referred to by the words “with 95 % confidence.”

than0.25 %impurities.Protectiveencapsulationshouldbethin

3.1.4 confidence interval—a range that contains the (true) plastic or thin aluminum (≤0.32 cm thick) to reduce unneces-

detection probability for an evaluation situation with a stated sary radiation absorption in the encapsulation. No additional

confidence. filter is needed.

C1237 − 99 (2005)

3.1.12.2 standard plutonium SNM test source—a metallic 4.1.2.3 Use the evaluation procedure (see Section 8)ina

sphere or cube of low-burnup plutonium containing at least series of trials to check for nuisance alarms. Record the results,

239 240

93 % Pu, less than 6.5 % Pu, and less than 0.5 % alarm or no alarm for each trial.

impurities. 4.1.2.4 Use the evaluation procedure again in a series of

trials, this time to estimate whether the detection probability of

3.1.12.3 Discussion—A cadmium filter can reduce the im-

the hand-held monitor meets a minimum requirement. Record

pact of Am, a plutonium decay product that will slowly

the results, detect or miss for each trial.

build up in time and emit increasing amounts of 60-keV

4.1.2.5 End the testing when the preselected total number of

radiation. Begin use of a 0.04-cm thick cadmium filter when

trials is reached.

three or more years have elapsed since separation of plutonium

4.1.2.6 Analyze the results (see Section 9) to determine

decay products. If ten or more years have elapsed since

whether the hand-held monitor achieves a minimum require-

separation, use a 0.08 cm thick cadmium filter. The protective

ment.

encapsulation should be in as many layers as local rules

4.1.2.7 Report the results (see Section 10).

require. A nonradioactive encapsulating material, such as

aluminum (≤0.32-cm thick) or thin (≤0.16-cm thick) stainless

5. Significance and Use

steel or nickel, should be used to reduce unnecessary radiation

5.1 Hand-held SNM monitors are an effective and unobtru-

absorption.

sive means to search pedestrians or vehicles for concealed

3.2 Definitions of Terms Specific to This Standard:

SNM when automatic SNM monitors are not available or have

3.2.1 post-calibration evaluation—verifies the performance

sounded an alarm. Facility security plans apply SNM monitors

of a hand-held monitor immediately after calibration,

as one means to prevent theft or unauthorized removal of SNM

recalibration, or repair and calibration. The hand-held monitor

from designated areas. Functional testing of monitors on a

is prepared for best performance.

dailybasiswithradioactivesourcescanassuretheyareingood

working order. The significance of a less frequent, in-plant

3.2.2 routine-operational evaluation—verifies the routine

evaluation of an SNM monitor is to verify that the monitor

performanceofahand-heldmonitor.Themonitorisbeingused

achieves an expected probability of detection for an SNM or

in routine operation.

alternative test source.

3.2.3 saturation—an undesirable condition in which a hand-

5.2 The evaluation verifies acceptable performance or dis-

held SNM monitor exposed to intense radiation ceases to

closes faults in hardware or calibration.

function, falls silent, and does not indicate that SNM or intense

radiation is present.

5.3 The evaluation uses test sources shielded only by

normal source encapsulation. However, shielded SNM test

4. Summary of Guide

sources could be used as well.

4.1 Each evaluation, routine-operational or post-calibration, 5.4 The evaluation, when applied as a routine operational

is carried out using a predetermined test source, number of evaluation, provides evidence for continued compliance with

trials, and alarm criteria. The evaluation is summarized as theperformancegoalsofsecurityplansorregulatoryguidance.

follows:

NOTE 1—It is the responsibility of the users of this guide to coordinate

4.1.1 Steps for Routine-Operational Evaluation:

its application with the appropriate regulatory authority so that mutually

agreeable choices for evaluation frequency, test sources, detection criteria

4.1.1.1 Put the monitor into operation and check for satu-

(whether a single or multiple alarms constitute detection), minimum

ration.

distance for first detection, number of trials, and reporting procedures are

4.1.1.2 Use the evaluation procedure (see Section 8)ina

used. Regulatory concurrence should be formally documented.

series of trials to check for nuisance alarms. Record the results,

6. Apparatus

alarm or no alarm for each trial.

4.1.1.3 Use the evaluation procedure again in a series of 6.1 Besides a hand-held monitor to evaluate, the following

list of apparatus and supplies are needed.

trials, this time to estimate the detection probability of a

hand-held monitor in routine operation. Record the results, 6.1.1 Metre Stick, Tape Measure, or Other Means for

Measuring Distance.

detect or miss for each trial.

6.1.2 Means of Support, for the test source and hand-held

4.1.1.4 End the testing when the preselected total number of

monitor during the evaluation. For example, the test source

trials is reached.

could be supported on a table or shelf and the monitor moved

4.1.1.5 Analyze the results (see Section 9) to determine

towards it by a person holding the monitor and moving slowly

whether the hand-held monitor achieves a minimum require-

towards the source. A better example would be to use a long

ment.

wooden,orsimilar,plank(testplank)withamarkedtestsource

4.1.1.6 Report the results (see Section 10).

position and marked minimum distance for first detection. The

4.1.2 Steps for Post-Calibration Evaluation:

plank could be supported with sawhorses. The person could

4.1.2.1 Calibrate the monitor according to procedures sug-

then slowly move the monitor along the plank towards the test

gested by the manufacturer or other standard practice.

source in a more reproducible manner.

4.1.2.2 Put the monitor into operation and check for satu- 6.1.3 Evaluation Report Forms and Some Means to Record

ration. Evaluation Results.

C1237 − 99 (2005)

7. Test Materials serve to evaluate all monitors in all circumstances. Different

locations may require different test sources.

7.1 The materials ne

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.