ASTM D7219-05

(Specification)Standard Specification for Isotropic and Near-isotropic Nuclear Graphites

Standard Specification for Isotropic and Near-isotropic Nuclear Graphites

SCOPE

1.1 This specification covers the classification, processing, and properties of nuclear grade graphite billets with dimensions sufficient to meet the designers requirements for fuel elements, moderator or reflector blocks, in a high temperature gas cooled reactor. The graphite classes specified here would be suitable for reactor core applications where neutron irradiation induced dimensional changes are a significant design consideration.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 7219 – 05

Standard Specification for

Isotropic and Near-isotropic Nuclear Graphites

This standard is issued under the fixed designation D 7219; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope NQA-1 Quality Assurance Program Requirements for

Nuclear Facilities

1.1 This specification covers the classification, processing,

and properties of nuclear grade graphite billets with dimen-

3. Terminology

sions sufficient to meet the designer’s requirements for fuel

3.1 Definitions—Definitionsrelatingtothisspecificationare

elements, moderator or reflector blocks, in a high temperature

given in Terminology C 709.

gas cooled reactor. The graphite classes specified here would

3.2 Definitions of Terms Specific to This Standard:

be suitable for reactor core applications where neutron irradia-

3.2.1 apparent porosity—ratio of the volume of open pores

tion induced dimensional changes are a significant design

to the exterior volume expressed as a percentage.

consideration.

3.2.2 baking/re-baking charge—the number of billets in a

1.2 The values stated in SI units are to be regarded as

baking/re-baking furnace run.

standard. No other units of measurement are included in this

3.2.3 bulk density—the mass of a unit volume of material

standard.

including both permeable and impermeable voids.

1.3 This standard does not purport to address all of the

3.2.4 extrusion forming lot—the number of billets of the

safety concerns, if any, associated with its use. It is the

same size extruded in an uninterrupted sequence.

responsibility of the user of this standard to establish appro-

3.2.5 green batch—the mass of coke, recycle green mix,

priate safety and health practices and determine the applica-

recycle graphite, and pitch that is required to produce a

bility of regulatory limitations prior to use.

forming lot.

2. Referenced Documents 3.2.6 graphite billet—an extruded, molded, or iso-molded

graphite artifact with dimensions sufficient to meet the design-

2.1 ASTM Standards:

er’s requirements for reactor components.

C 709 Terminology Relating to Manufactured Carbon and

3.2.7 graphite grade—the designation given to a material

Graphite

byamanufacturersuchthatitisalwaysreproducedtothesame

C 781 PracticeforTestingGraphiteandBoronatedGraphite

specification and from the same raw materials and mix

for High-Temperature Gas-Cooled Nuclear Reactors

formulation.

C 838 Test Method for Bulk Density of As-Manufactured

3.2.8 graphitization charge—the number of billets in a

Carbon and Graphite Shapes

graphitizing furnace run.

C 1233 Practice for Determining Equivalent Boron Con-

3.2.9 high purity nuclear graphite—nuclear graphite whose

tents of Nuclear Materials

Boron Equivalent content is less that 2 ppm.

D 346 Practice for Collection and Preparation of Coke

3.2.10 impregnation charge—the number of billets in an

Samples for Laboratory Analysis

autoclave cycle.

D 2638 Test Method for Real Density of Calcined Petro-

3.2.11 isotropic nuclear graphite—a graphite in which the

leum Coke by Helium Pycnometer

isotropy ratio based on the coefficient of thermal expansion is

2.2 ASME Standard:

1.00 to 1.10.

3.2.12 low purity nuclear graphite—nuclear graphite whose

Boron Equivalent content is greater than 2 ppm but less that 10

This specification is under the jurisdiction of ASTM Committee D02 on

ppm.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3.2.13 mix formulation—the percentages of each specifi-

D02.F0 on Manufactured Carbon and Graphite Products.

Current edition approved Nov. 1, 2005. Published December 2005.

cally sized filler used to manufacture a graphite grade.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Society of Mechanical Engineers (ASME), ASME

the ASTM website. International Headquarters, Three Park Ave., New York, NY 10016-5990.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7219–05

TABLE 2 ASTM Graphite Grain Size Definitions from

3.2.14 molding forming lot—the number of billets molded

Terminology C 709

from a molding powder lot.

Definition of

3.2.15 molding powder lot—a sufficient quantity of re-

Graphite Designation

A

Grains in the Starting Mix that are:

milled and blended green batch produced from an uninter-

Medium Grained Generally<4mm

rupted flow of raw materials, or produced in a sequence of

Fine Grained Generally < 100 µm

identical materials batches, to produce a molding forming lot.

Superfine Grained Generally < 50 µm

3.2.16 near isotropic nuclear graphite—a graphite in which Ultrafine Grained Generally < 10 µm

Microfine Grained Generally<2µm

the isotropy ratio based on the coefficient of thermal expansion

A

Grain size as defined in Terminology C 709.

is 1.10 to 1.15.

3.2.17 nuclear graphite class—the designation of a nuclear

graphite based upon its forming method, isotropy, purity and

5.2.1.4 Graphite manufactured in compliance with this

density (see Table 1).

3.2.18 production lot—aspecifiednumberofbilletsmadein specification but failing to meet the property requirements of

Sections 6 and 7 may be used as recycle material in the mix

accordance with this specification as determined by the pur-

chaser. formulation.

3.2.19 purification charge—the number of billets in a puri-

5.2.1.5 Recyclegreenmixmanufacturedfromrawmaterials

fication run. in compliance with this specification may be used in the mix

3.2.20 recycle green mix—ground non-baked billets or non-

formulation.

formed formulation manufactured in compliance with the mix 5.2.1.6 The maximum filler particle size used in the mix

formulation specified here.

formulation shall be 1.68 mm.

5.3 Binder—The binder shall consist of coal tar pitch. The

4. Significance and Use

specific binder used shall be identified to the purchaser and be

4.1 The purpose of this specification is to document the traceable through the forming lot.

minimum acceptable properties and levels of quality assurance 5.4 Impregnant—The impregnant shall consist of a petro-

and traceability for isotropic and near-isotropic nuclear grade leum or coal tar pitch and be traceable through the impregna-

graphites. tion step.

5.5 Manufacturing or Processing Additives—Additives (for

5. Materials and Manufacture

example, extrusion aids) may be used to improve the process-

ing, quality and properties of the product, but only with the

5.1 Nuclear Graphite Classes—See Table 1.

consent and approval of the purchaser, and they must be

5.2 Raw Materials:

traceable through the forming lot.

5.2.1 Fillers:

5.2.1.1 The filler shall consist of a near-isotropic or isotro- 5.6 Manufacture:

5.6.1 Formulation—The mix formulation (as defined in

pic coke derived from a petroleum oil or coal tar.

5.2.1.2 The coke shall have a coefficient of linear thermal 3.2.13) and recycle green mix fraction (as defined in 3.2.20)in

the filler shall be recorded. This information shall be reported

expansion (CTE), determined in accordance with Practice

C 781 and measured over the temperature range 25 to 500°C, to the purchaser if requested.

-6 -6 -1

of between 3.5 3 10 and 5.5 3 10 °C . 5.6.2 Forming—The green carbon mix may be formed by

5.2.1.3 The coke shall be sampled and distributed as de- extrusion, molding (including vibrationally molding), or iso-

scribed in Table 3. molding.

TABLE 1 ASTM Standard Classes of Nuclear Graphite

Purity

B C

CTE Isotropy Ratio Bulk Density,

A

B D

Class Class Designation

Ash Content, Boron Equivalent,

(a /a ) g/cm (min)

AG WG

ppm (max) ppm (max)

Isomolded, isotropic—High Purity 1.0-1.1 300 2 1.7 IIHP

Isomolded, isotropic—Low Purity 1.0-1.1 1000 10 1.7 IILP

Isomolded, near-isotropic—High Purity 1.1-1.15 300 2 1.7 INHP

Isomolded, near-isotropic—Low Purity 1.1-1.15 1000 10 1.7 INLP

Extruded, isotropic—High Purity 1.0-1.1 300 2 1.7 EIHP

Extruded, isotropic—Low Purity 1.0-1.1 1000 10 1.7 EILP

Extruded, near-isotropic—High Purity 1.1-1.15 300 2 1.7 ENHP

Extruded, near-isotropic—Low Purity 1.1-1.15 1000 10 1.7 ENLP

Molded, isotropic—High Purity 1.0-1.1 300 2 1.7 MIHP

Molded, isotropic—Low Purity 1.0-1.1 1000 10 1.7 MILP

Molded, near-isotropic—High Purity 1.1-1.15 300 2 1.7 MNHP

Molded, near-isotropic—Low Purity 1.1-1.15 1000 10 1.7 MNLP

A

These classes may be further modified by the grain size as defined in Terminology C 709.

B

Determined in accordance with Practice C 781.

C

Determined in accordance with Test Method C 838.

D

Determined in accordance with Practice C 1233.

D7219–05

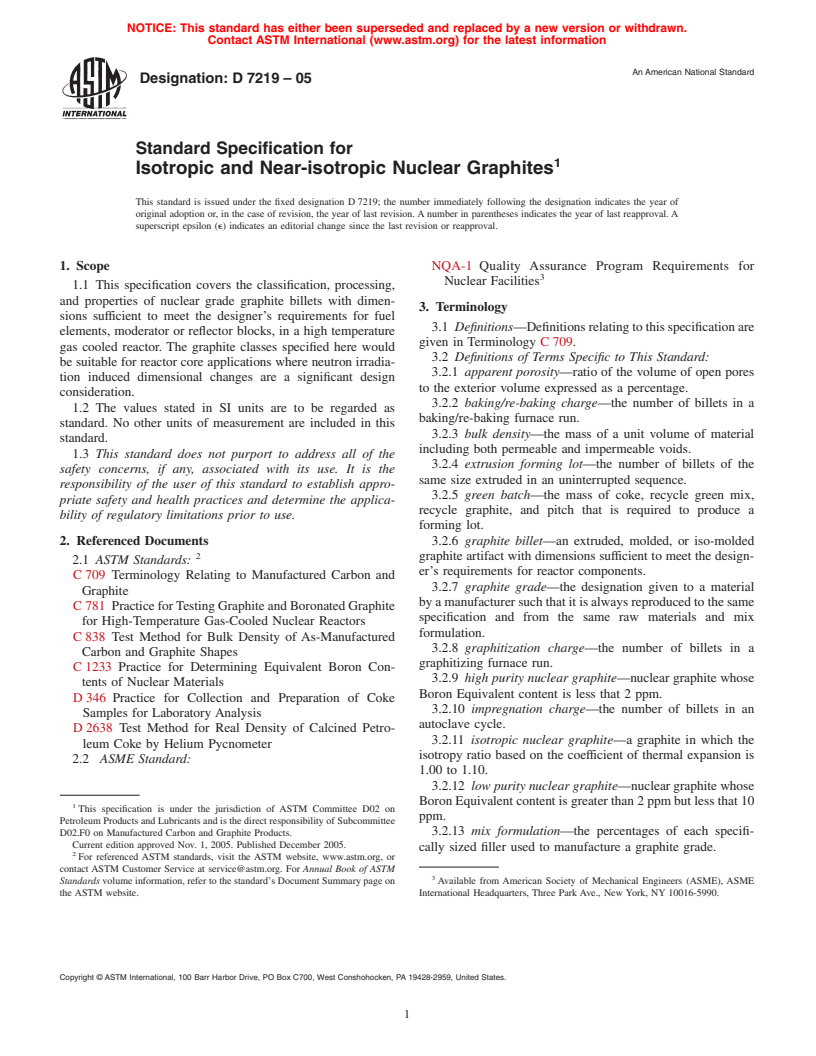

TABLE 3 Inspection Sampling and Testing of Filler Cokes

Raw Material Inspection Plan Sampling Procedure Tests and Test Methods

Filler coke A representative sample of the Sample in accordance with Practice D 346 The procedure in Practice C 781 shall be used to

coke shall be taken prior to the 1. A sufficient sample for preparation of CTE test prepare test specimens for the measurement of

mixing step of manufacture specimens coke CTE

2. A sufficient sample will be taken for additional Measure the coke real density in accordance with

testing. This sample shall be retained for a Test Method D 2638

period specified by the graphite purchaser

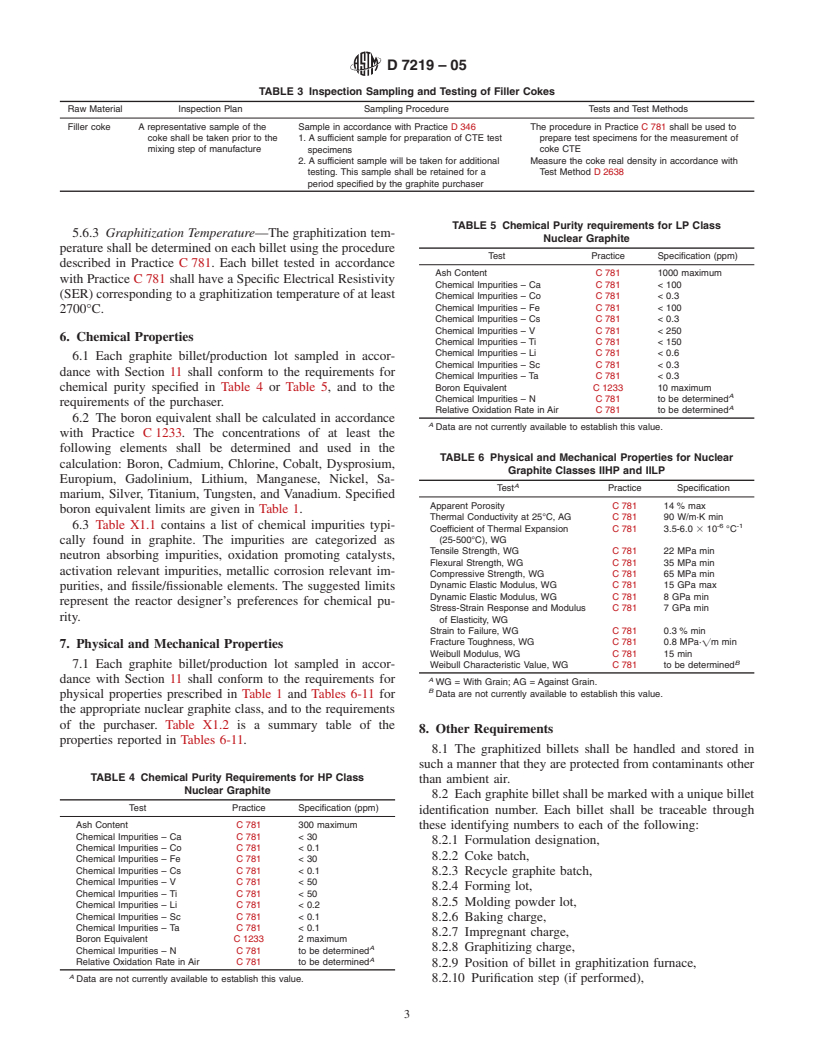

TABLE 5 Chemical Purity requirements for LP Class

5.6.3 Graphitization Temperature—The graphitization tem-

Nuclear Graphite

perature shall be determined on each billet using the procedure

Test Practice Specification (ppm)

described in Practice C 781. Each billet tested in accordance

Ash Content C 781 1000 maximum

with Practice C 781 shall have a Specific Electrical Resistivity

Chemical Impurities – Ca C 781 < 100

(SER) corresponding to a graphitization temperature of at least

Chemical Impurities – Co C 781 <0.3

Chemical Impurities – Fe C 781 < 100

2700°C.

Chemical Impurities – Cs C 781 <0.3

Chemical Impurities – V C 781 < 250

6. Chemical Properties

Chemical Impurities – Ti C 781 < 150

Chemical Impurities – Li C 781 <0.6

6.1 Each graphite billet/production lot sampled in accor-

Chemical Impurities – Sc C 781 <0.3

dance with Section 11 shall conform to the requirements for

Chemical Impurities – Ta C 781 <0.3

Boron Equivalent C 1233 10 maximum

chemical purity specified in Table 4 or Table 5, and to the

A

Chemical Impurities – N C 781 to be determined

requirements of the purchaser.

A

Relative Oxidation Rate in Air C 781 to be determined

6.2 The boron equivalent shall be calculated in accordance

A

Data are not currently available to establish this value.

with Practice C 1233. The concentrations of at least the

following elements shall be determined and used in the

TABLE 6 Physical and Mechanical Properties for Nuclear

calculation: Boron, Cadmium, Chlorine, Cobalt, Dysprosium,

Graphite Classes IIHP and IILP

Europium, Gadolinium, Lithium, Manganese, Nickel, Sa-

A

Test Practice Specification

marium, Silver, Titanium, Tungsten, and Vanadium. Specified

Apparent Porosity C 781 14 % max

boron equivalent limits are given in Table 1.

Thermal Conductivity at 25°C, AG C 781 90 W/m·K min

-6 -1

6.3 Table X1.1 contains a list of chemical impurities typi-

Coefficient of Thermal Expansion C 781 3.5-6.0 3 10 °C

(25-500°C), WG

cally found in graphite. The impurities are categorized as

Tensile Strength, WG C 781 22 MPa min

neutron absorbing impurities, oxidation promoting catalysts,

Flexural Strength, WG C 781 35 MPa min

activation relevant impurities, metallic corrosion relevant im-

Compressive Strength, WG C 781 65 MPa min

Dynamic Elastic Modulus, WG C 781 15 GPa max

purities, and fissile/fissionable elements. The suggested limits

Dynamic Elastic Modulus, WG C 781 8 GPa min

represent the reactor designer’s preferences for chemical pu-

Stress-Strain Response and Modulus C 781 7 GPa min

rity.

of Elasticity, WG

Strain to Failure, WG C 781 0.3 % min

Fracture Toughness, WG C 781 0.8 MPa·=mmin

7. Physical and Mechanical Properties

Weibull Modulus, WG C 781 15 min

B

7.1 Each graphite billet/production lot sampled in accor-

Weibull Characteristic Value, WG C 781 to be determined

A

dance with Section 11 shall conform to the requirements for

WG = With Grain; AG = Against Grain.

B

Data are not currently available to establish this value.

physical properties prescribed in Table 1 and Tables 6-11 for

the appropriate nuclear graphite class, and to the requirements

of the purchaser. Table X1.2 is a summary table of the

8. Other Requirements

properties reported in Tables 6-11.

8.1 The graphitized billets shall be handled and stored in

such a manner that they are protected from contaminants other

TABLE 4 Chemical Purity Requirements for HP Class

than ambient air.

Nuclear Graphite

8.2 Each graphite billet shall be marked with a unique billet

Test Practice Specification (ppm)

identification number. Each billet shall be traceable through

Ash Content C 781 300 maximum these identifying numbers to each of the following:

Chemical Impurities – Ca C 781 <30

8.2.1 Formulation designation,

Chemical Impurities – Co C 781 <0.1

8.2.2 Coke batch,

Chemical Impurities – Fe C 781 <30

Chemical Impurities – Cs C 781 <0.1

8.2.3 Recycle graphite batch,

Chemical Impurities – V C 781 <50

8.2.4 Forming lot,

Chemical Impurities – Ti C 781 <50

8.2.5 Molding powder lot,

Chemical Impurities – Li C 781 <0.2

Chemical Impurities – Sc C 781 <0.1

8.2.6 Baking charge,

Chemical Impurities – Ta C 781 <0.1

8.2.7 Impregnant charge,

Boron Equivalent C 1233 2 maximum

A

8.2.8 Graphitizing charge,

Chemical Impurities – N C 781 to be determined

A

Relative Oxidation Rate in Air C 781 to be determined

8.2.9 Position of billet in graphitization furnace,

A

Data are not currently available to establish this value. 8.2.10 Purification step (if performed),

D7219–05

TABLE 7 Physical and Mechanical Properties for Nuclear TABLE 10 Physical and Mechanical Properties for Nuclear

Graphite Classes INHP and INLP Graphite Classes MIHP and MILP

A A

Test Practice Specification Test Practice Specification

Apparent Porosity C 781 14 % max Apparent Porosity C 781 14 % max

Thermal Conductivity at 25°C, AG C 781 80 W/m·K min Thermal Conductivity at 25°C, AG C 781 100 W/m·K min

-6 -1 -6 -1

Coefficient of Thermal Expansion C 781 3.5-6.0 3 10 °C Coefficient of Thermal Expansion C 781 3.5-6.0 3 10 °C

(25-500°C), WG (25-500°C), WG

Tensile Strength, WG C 781 20 MPa min Tensile Strength, WG C 781 15 MPa min

Flexural Strength, WG C 781 30 MP

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.