ASTM D8377-21a

(Guide)Standard Guide for High Temperature Strength Measurements of Graphite Impregnated with Molten Salt

Standard Guide for High Temperature Strength Measurements of Graphite Impregnated with Molten Salt

SIGNIFICANCE AND USE

5.1 The Molten Salt Reactor is a nuclear reactor which uses graphite as reflector and structural material, and molten salt as coolant. The graphite components will be submerged in the molten salt during the lifetime of the reactor. The porous structure of graphite may lead to molten salt permeation, which can affect the thermal and mechanical properties of graphite. Consequently, it may be necessary to measure the various strengths of the manufactured graphite materials after impregnation with molten salt and before exposure to the reactor environment in a range of test configurations in order for designers or operators to assess their performance.

Note 1: Depending upon the salt selected for the reactor, there may be some chemical reaction between the salt and the graphite that could affect properties. The user should establish, prior to following this guide, that any interactions between the molten salt and graphite are understood and any implications for the validity of the strength tests have been assessed.

5.2 For gas-cooled reactors, the strength of a graphite specimen is usually measured at room temperature. However, for molten salt reactors, the operating temperature of the reactor must be higher than the melting temperature of the salt, and so the salt will be in solid state at room temperature. Consequently, room temperature measurements may not be representative of the performance of the material at its true operating conditions. It is therefore necessary to measure the strength at an elevated temperature where the salt is in liquid form.

Note 2: Users should be aware that a small increase in graphite strength is expected with increasing temperature. Testing at the plant operating temperature will eliminate this small uncertainty.

5.3 The purpose of this guide is to provide considerations, which should be included in testing graphite specimens impregnated with molten salt at elevated temperature.

5.4 For the test results to be meaningful, the...

SCOPE

1.1 This guide covers the best practice for strength measurements at elevated temperature of graphite impregnated with molten salt.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8377 − 21a

Standard Guide for

High Temperature Strength Measurements of Graphite

1

Impregnated with Molten Salt

This standard is issued under the fixed designation D8377; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

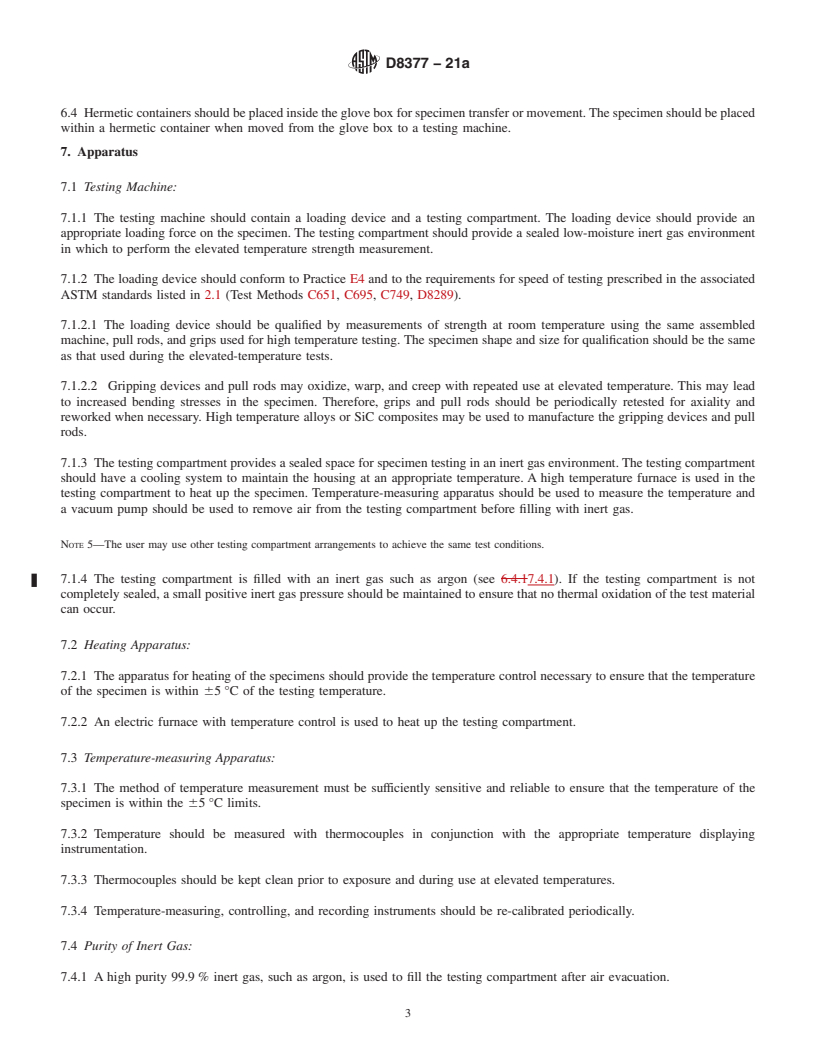

1. Scope* Compression of Manufactured Graphite

E4 Practices for Force Verification of Testing Machines

1.1 This guide covers the best practice for strength mea-

surements at elevated temperature of graphite impregnated

3. Terminology

with molten salt.

3.1 For definitions of terms used in this guide, refer to

1.2 The values stated in SI units are to be regarded as

Terminology D4175.

standard. No other units of measurement are included in this

standard.

4. Summary of Guide

1.3 This standard does not purport to address all of the

4.1 There is currently a set of ASTM standards as stated in

safety concerns, if any, associated with its use. It is the

2.1 that can be applied to graphite for different strength

responsibility of the user of this standard to establish appro-

measurements (Test Methods C651, C695, C749, D8289).

priate safety, health, and environmental practices and deter-

Each of these standards has been developed specifically to

mine the applicability of regulatory limitations prior to use.

provide a method of measurement for graphite as a single

1.4 This international standard was developed in accor-

material. However, in some applications such as in molten salt

dance with internationally recognized principles on standard-

reactors, graphite components are submerged in a molten salt.

ization established in the Decision on Principles for the

In order to assess the effect of molten salt on graphite

Development of International Standards, Guides and Recom-

components, a method may be necessary for the measurement

mendations issued by the World Trade Organization Technical

of strength for graphite specimens both impregnated with

Barriers to Trade (TBT) Committee.

molten salt and at elevated temperatures (see Section 6). The

objective of this guide is to provide advice on the application

2. Referenced Documents

of selected standards for graphite specimens impregnated with

2

2.1 ASTM Standards:

molten salt and tested at elevated temperatures. This includes

C651 Test Method for Flexural Strength of Manufactured

transportation of graphite specimens impregnated with molten

CarbonandGraphiteArticlesUsingFour-PointLoadingat

salt, temperature measurement, equipment for measuring

Room Temperature

compressive, tensile, or flexural strength at elevated

C695 Test Method for Compressive Strength of Carbon and

temperature, and safe handling of the molten salt.

Graphite

C749 Test Method for Tensile Stress-Strain of Carbon and

5. Significance and Use

Graphite

5.1 The Molten Salt Reactor is a nuclear reactor which uses

D4175 Terminology Relating to Petroleum Products, Liquid

graphite as reflector and structural material, and molten salt as

Fuels, and Lubricants

coolant. The graphite components will be submerged in the

D8091 Guide for Impregnation of Graphite with Molten Salt

molten salt during the lifetime of the reactor. The porous

D8289 Test Method for Tensile Strength Estimate by Disc

structureofgraphitemayleadtomoltensaltpermeation,which

can affect the thermal and mechanical properties of graphite.

1

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum Consequently, it may be necessary to measure the various

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

strengths of the manufactured graphite materials after impreg-

mittee D02.F0 on Manufactured Carbon and Graphite Products.

nation with molten salt and before exposure to the reactor

Current edition approved July 1, 2021. Published July 2021. Originally approved

environment in a range of test configurations in order for

in 2021. Last previous edition approved in 2021 as D8377 – 21. DOI: 10.1520/

D8377-21A.

designers or operators to assess their performance.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—Depending upon the salt selected for the reactor, there may be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on some chemical reaction between the salt and the graphite that could affect

the ASTM website. properties. The user should establish, prior to following this guide, that

*A Summary of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8377 − 21 D8377 − 21a

Standard Guide for

High Temperature Strength Measurements of Graphite

1

Impregnated with Molten Salt

This standard is issued under the fixed designation D8377; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This guide covers the best practice for strength measurements at elevated temperature of graphite impregnated with molten

salt.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C651 Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Four-Point Loading at Room

Temperature

C695 Test Method for Compressive Strength of Carbon and Graphite

C749 Test Method for Tensile Stress-Strain of Carbon and Graphite

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D8091 Guide for Impregnation of Graphite with Molten Salt

D8289 Test Method for Tensile Strength Estimate by Disc Compression of Manufactured Graphite

E4 Practices for Force Verification of Testing Machines

3. Terminology

3.1 For definitions of terms used in this guide, refer to Terminology D4175.

4. Summary of Guide

4.1 There is currently a set of ASTM standards as stated in 2.1 that can be applied to graphite for different strength measurements

1

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.F0 on Manufactured Carbon and Graphite Products.

Current edition approved Jan. 1, 2021July 1, 2021. Published January 2021July 2021. Originally approved in 2021. Last previous edition approved in 2021 as D8377 – 21.

DOI: 10.1520/D8377-21.10.1520/D8377-21A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8377 − 21a

(Test Methods C651, C695, C749, D8289). Each of these standards has been developed specifically to provide a method of

measurement for graphite as a single material. However, in some applications such as in molten salt reactors, graphite components

are submerged in a molten salt. In order to assess the effect of molten salt on graphite components, a method may be necessary

for the measurement of strength for graphite specimens both impregnated with molten salt and at elevated temperatures (see

Section 46). The objective of this guide is to provide advice on the application of selected standards for graphite specimens

impregnated with molten salt and tested at elevated temperatures. This includes transportation of graphite specimens impregnated

with molten salt, temperature measurement, equipment for measuring compressive, tensile, or flexural strength at elevated

temperature, and safe handling of the molten salt.

5. Significance and Use

5.1 The Molten Salt Reactor is a nuclear reactor which uses graphite as reflector and structural material, and molten salt as coolant.

The graphite components will be submerged in the molten salt during the lifetime of the reactor. The porous structure of graphite

may lead to molten salt permeation, which can affect the thermal and mechanical properties of graphite. Consequently, it may be

necessary to measure the various strengths of the manufactured

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.