ASTM F2140-11

(Test Method)Standard Test Method for Performance of Hot Food Holding Cabinets

Standard Test Method for Performance of Hot Food Holding Cabinets

SIGNIFICANCE AND USE

The energy input rate and thermostat calibration tests are used to confirm that the hot food holding cabinet is operating properly prior to further testing.

Preheat energy and time can be useful to food service operators to manage energy demands and to know how quickly the hot food holding cabinet can be ready for operation.

Energy consumption (idle energy rate) can be used by the food service operator to estimate energy consumption during operating periods.

Energy consumption (idle energy rate) with the water device can be used by the food service operator to estimate energy consumption during operating periods with the humidity device.

The relative humidity percentage can be used by operators to select a hot food holding cabinet that will meet their food-holding needs.

The temperature uniformity can be used by operators to choose a hot food cabinet that meets their food-holding needs.

SCOPE

1.1 This test method evaluates the preheat energy consumption and idle energy consumption of hot food holding cabinets. The food service operator can use this evaluation to select a hot food holding cabinet and understand its energy performance, temperature uniformity, and relative humidity (if applicable). A hot food holding cabinet is described as a commercial kitchen appliance that is used to hold hot food (usually no greater than 200°F) that has been cooked in a separate appliance at a specified temperature.

1.2 This test method is applicable to electric hot food holding cabinets.

1.3 The hot food holding cabinet can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate (10.2),

1.3.2 Temperature calibration (10.3),

1.3.3 Preheat energy consumption and time (10.4),

1.3.4 Energy consumption (idle energy rate) (10.5),

1.3.5 Energy consumption with water (humidity pan) device and relative humidity (if applicable) (10.5) and

1.3.6 Temperature uniformity (10.5).

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2140 − 11 An American National Standard

Standard Test Method for

1

Performance of Hot Food Holding Cabinets

This standard is issued under the fixed designation F2140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

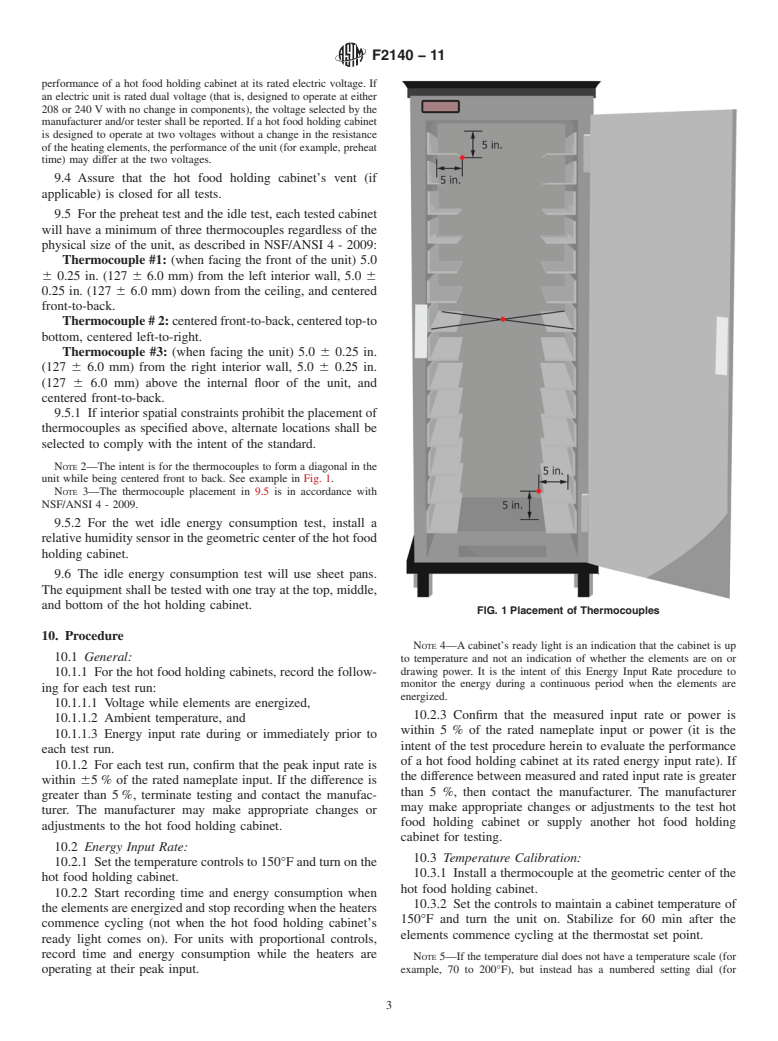

1. Scope 2.2 NSF Standard:

NSF/ANSI 4 - 2009 Commercial Cooking,

1.1 This test method evaluates the preheat energy consump-

Rethermalization, and Powered Hot Food Holding and

tion and idle energy consumption of hot food holding cabinets.

Transport Equipment

Thefoodserviceoperatorcanusethisevaluationtoselectahot

food holding cabinet and understand its energy performance,

3. Terminology

temperatureuniformity,andrelativehumidity(ifapplicable).A

3.1 Definitions:

hot food holding cabinet is described as a commercial kitchen

3.1.1 cook-and-hold appliance, n—a multiple-mode appli-

appliance that is used to hold hot food (usually no greater than

ance intended for cooking food that may be used to hold the

200°F) that has been cooked in a separate appliance at a

temperature of the food that has been cooked in the same

specified temperature.

appliance.

1.2 This test method is applicable to electric hot food

3.1.2 drawer warmer, n—an appliance that consists of one

holding cabinets.

or more heated drawers and that is designed to hold hot food

1.3 The hot food holding cabinet can be evaluated with

that has been cooked in a separate appliance at a specified

respect to the following (where applicable):

temperature.

1.3.1 Energy input rate (10.2),

3.1.3 energy input rate, n—peak rate at which a hot food

1.3.2 Temperature calibration (10.3),

holding cabinet consumes energy (kW), typically reflected

1.3.3 Preheat energy consumption and time (10.4),

during preheat.

1.3.4 Energy consumption (idle energy rate) (10.5),

3.1.4 heated glass merchandising cabinets, n—an appliance

1.3.5 Energyconsumptionwithwater(humiditypan)device

with a heated compartment that is designed to display and

and relative humidity (if applicable) (10.5) and

maintain the temperature of hot food that has been cooked in a

1.3.6 Temperature uniformity (10.5).

separate appliance.

1.4 The values stated in inch-pound units are to be regarded

3.1.5 heater cycle, n—a complete sequence of the heat

as standard.

source energizing, de-energizing, and energizing during the

1.5 This standard does not purport to address all of the

idle test. Heater cycle applies to snap-action style controls.

safety concerns, if any, associated with its use. It is the

Proportional style controls may not exhibit clear energized/de-

responsibility of the user of this standard to establish appro-

energized sequences.

priate safety and health practices and determine the applica-

3.1.6 holding cavity, n—that portion of the appliance in

bility of regulatory limitations prior to use.

which food products are held.

2. Referenced Documents

3.1.7 hot food holding cabinet, n—a heated, fully-enclosed

2 compartment, with one or more solid or transparent doors, that

2.1 ASHRAE Document:

is designed to maintain the temperature of hot food that has

ASHRAE Guideline 2—1986 (RA90) “Engineering Analy-

been cooked in a separate appliance. Does not refer to heated

sis of Experimental Data”

glass merchandising cabinets, drawer warmers or cook-and-

hold appliances.

1 3.1.8 idle energy rate—dry, n—the rate of energy consumed

This test method is under the jurisdiction of ASTM Committee F26 on Food

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

(kW) by the hot food holding cabinet while “idling” the

Productivity and Energy Protocol.

holding cavity at the control set point without using the

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved

humidity generating device, if applicable.

in 2001. Last previous edition approved in 2007 as F2140–01 (2007). DOI:

10.1520/F2140-11.

2

Available from American Society of Heating, Refrigerating, and Air-

3

Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

30329, http://www.ashrae.org. Arbor, MI 48113-0140, http://www.nsf.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2140 − 11

3.1.9 idle energy rate—wet, n—therateofenergyconsumed 5.4 Energy consumption (idle energy rate) with the water

(kW) by the hot food holding cabinet while “idling” the device can be used by the food service operator to estimate

holding cavity at the control set point while generating energy consumptio

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F2140–01 (Reapproved 2007) Designation:F2140–11

Standard Test Method for

1

Performance of Hot Food Holding Cabinets

This standard is issued under the fixed designation F2140; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method evaluates the preheat energy consumption and idle energy consumption of hot food holding cabinets. The

food service operator can use this evaluation to select a hot food holding cabinet and understand its energy performance,

temperature uniformity, and relative humidity (if applicable). A hot food holding cabinet is described as a commercial kitchen

appliance that is used to hold hot food (usually no greater than 200°F) that has been cooked in a separate appliance at a specified

temperature.

1.2 This test method is applicable to electric hot food holding cabinets.

1.3 The hot food holding cabinet can be evaluated with respect to the following (where applicable):

1.3.1 Energy input rate (10.2),

1.3.2 Temperature calibration (10.3),

1.3.3 Preheat energy consumption and time (10.4),

1.3.4 Energy consumption (idle energy rate) (10.5),

1.3.5 Energy consumption with water (humidity pan) device and relative humidity (if applicable) (10.5) and

1.3.6 Temperature uniformity (10.5).

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASHRAE Document:

ASHRAE Guideline 2—1986 (RA90) “Engineering Analysis of Experimental Data”

3

2.2 NSF Standard:

Standard Number 4—Commercial Cooking, Rethermalization, and Powered Hot Food Holding and Transport Equipment

NSF/ANSI 4 - 2009 Commercial Cooking, Rethermalization, and Powered Hot Food Holding and Transport Equipment

3. Terminology

3.1 Definitions:

3.1.1 cook-and-hold appliance, n—a multiple-mode appliance intended for cooking food that may be used to hold the

temperature of the food that has been cooked in the same appliance.

3.1.2 drawer warmer, n—an appliance that consists of one or more heated drawers and that is designed to hold hot food that

has been cooked in a separate appliance at a specified temperature.

3.1.3 energy input rate, n—peak rate at which a hot food holding cabinet consumes energy (kW), typically reflected during

preheat.

3.1.2

3.1.4 heated glass merchandising cabinets, n—an appliance with a heated compartment that is designed to display and maintain

the temperature of hot food that has been cooked in a separate appliance.

3.1.5 heater cycle, n—a complete sequence of the heat source energizing, de-energizing, and energizing during the idle test.

1

This test method is under the jurisdiction ofASTM Committee F26 on Food Service Equipment and is the direct responsibility of Subcommittee F26.06 on Productivity

and Energy Protocol.

Current edition approved AprilJune 1, 2007.2011. Published July 2007.2011. Originally approved in 2001. Last previous edition approved in 20012007 as F2140 – 01

(2007). DOI: 10.1520/F2140-01R07.10.1520/F2140-11.

2

Available from American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA 30329,

http://www.ashrae.org.

3

Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd., Ann Arbor, MI 48113-0140, http://www.nsf.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2140–11

Heater cycle applies to snap-action style controls. Proportional style controls may not exhibit clear energized/de-energized

sequences.

3.1.6 holding cavity, n—that portion of the appliance in which food products are held.

3.1.3

3.1.7 hot food holding cabinet, n—an appliance that is designed to hold hot food that has been cooked in a separate appliance

at a specified temperature.

3.1.4—a heated, fully-enclosed compartment, with one or more solid or transparent doors, that is designed to maintain the

temperature of hot food that has been cooked in a separate a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.