ASTM A618-99

(Specification)Standard Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing

Standard Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural Tubing

SCOPE

1.1 This specification covers grades of hot-formed welded and seamless high-strength low-alloy square, rectangular, round, or special shape structural tubing for welded, riveted, or bolted construction of bridges and buildings and for general structural purposes. When the steel is used in welded construction, the welding procedure shall be suitable for the steel and the intended service.

1.2 Grade II has atmospheric corrosion resistance equivalent to that of carbon steel with copper (0.20 minimum Cu) Grades Ia and Ib have atmospheric corrosion resistance substantially better than that of Grade II (Note 1). When properly exposed to the atmosphere, Grades Ia and Ib can be used bare (unpainted) for many applications. When enhanced corrosion resistance is desired, Grade III, copper limits may be specified. Note 1--For methods of estimating the atmospheric corrosion resistance of low alloy steels see Guide G101 or actual data.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 618 – 99 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Hot-Formed Welded and Seamless High-Strength Low-Alloy

1

Structural Tubing

This standard is issued under the fixed designation A 618; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 Quantity (feet or number of lengths),

3.1.2 Grade (Table 1 and Table 2),

1.1 This specification covers grades of hot-formed welded

3.1.3 Material (round, square, or rectangular tubing),

and seamless high-strength low-alloy square, rectangular,

3.1.4 Method of manufacture (seamless, buttwelded, or

round, or special shape structural tubing for welded, riveted, or

hot-stretch-reduced electric-resistance welded),

bolted construction of bridges and buildings and for general

3.1.5 Size (outside diameter and nominal wall thickness for

structural purposes. When the steel is used in welded construc-

round tubing and the outside dimensions and calculated nomi-

tion, the welding procedure shall be suitable for the steel and

nal wall thickness for square and rectangular tubing),

the intended service.

3.1.6 Length (specific or random, see 8.2),

1.2 Grade II has atmospheric corrosion resistance equiva-

3.1.7 End condition (see 9.2),

lent to that of carbon steel with copper (0.20 minimum Cu)

3.1.8 Burr removal (see 9.2),

Grades Ia and Ib have atmospheric corrosion resistance sub-

3.1.9 Certification (see 12.1),

stantially better than that of Grade II (Note 1). When properly

3.1.10 Specification designation,

exposed to the atmosphere, Grades Ia and Ib can be used bare

3.1.11 End use, and

(unpainted) for many applications. When enhanced corrosion

3.1.12 Special requirements.

resistance is desired, Grade III, copper limits may be specified.

NOTE 1—For methods of estimating the atmospheric corrosion resis- 4. Process

tance of low alloy steels see Guide G 101 or actual data.

4.1 The steel shall be made by one or more of the following

1.3 The values stated in inch-pound units are to be regarded

processes: open-hearth, basic-oxygen, or electric-furnace.

as the standard.

4.2 Steel may be cast in ingots or may be strand cast. When

steels of different grades are sequentially strand cast, identifi-

2. Referenced Documents

cation of the resultant transition material is required. The

2.1 ASTM Standards:

producer shall remove the transition material by any estab-

A 370 Test Methods and Definitions for Mechanical Testing

lished procedure that positively separates the grades.

2

of Steel Products

5. Manufacture

A 700 Practices for Packaging, Marking, and Loading

3

Methods for Steel Products for Domestic Shipment

5.1 The tubing shall be made by the seamless, furnace-

A 751 Test Methods, Practices, and Terminology for

buttwelded (continuous-welded), or hot-stretch-reduced

2

Chemical Analysis of Steel Products

electric-resistance-welded process.

G 101 Guide for Estimating the Atmospheric Corrosion

4

6. Chemical Composition

Resistance of Low-Alloy Steels

6.1 When subjected to the heat and product analysis, respec-

3. Ordering Information

tively, the steel shall conform to the requirements prescribed in

3.1 Orders for material under this specification should

Table 1.

include the following as required to describe the material

6.1.1 For Grades Ia and Ib, the choice and use of alloying

adequately:

elements, combined with carbon, manganese, and sulfur within

the limits prescribed in Table 1 to give the mechanical

1

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, properties prescribed in Table 2 and to provide the atmospheric

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

corrosion resistance of 1.2, should be made by the manufac-

A01.09 on Carbon Steel Tubular Products.

turer and included and reported in the heat analysis for

Current edition approved Mar. 10, 1999. Published May 1999. Originally

published as A 618 – 68. Last previous edition A 618 – 97. information purposes only to identify the type of steel applied.

2

Annual Book of ASTM Standards, Vol 01.03.

For Grades Ia and Ib material, the atmospheric corrosion-

3

Annual Book of ASTM Standards, Vol 01.05.

resistance index, calculated on the basis of the chemical

4

Annual Book of ASTM Standards, Vol 03.02.

1

---------------------- Page: 1 ----------------------

A 618

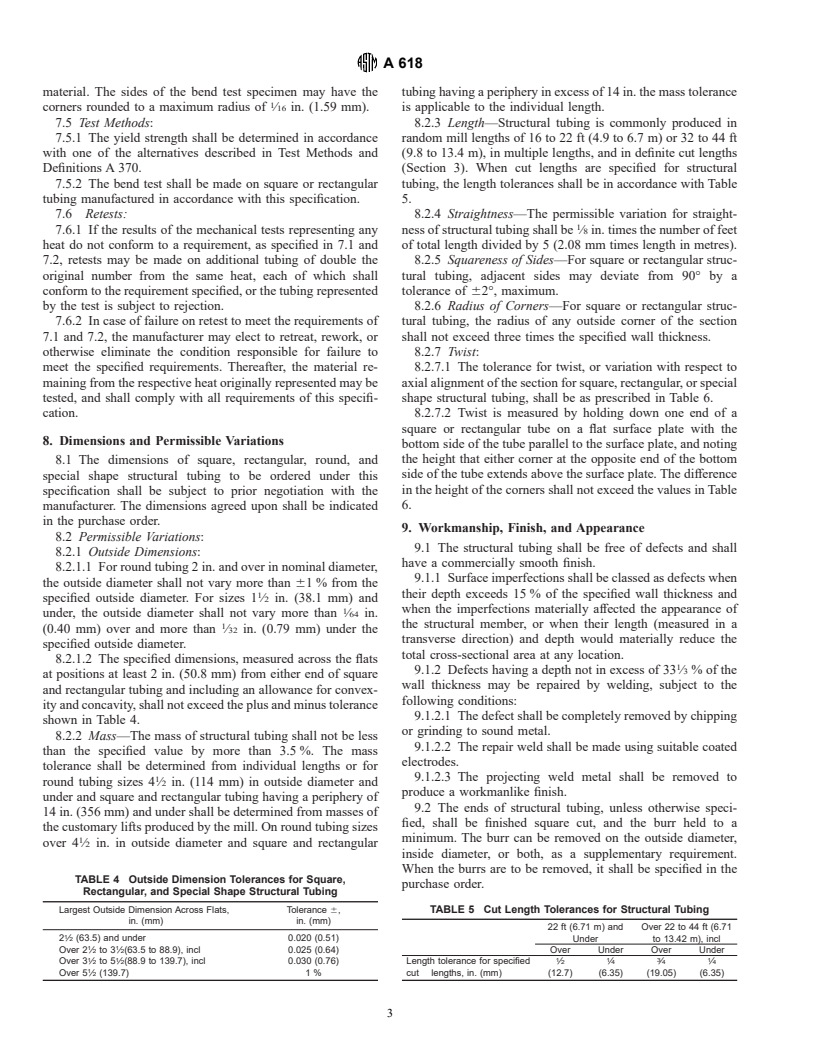

TABLE 1 Chemical Requirements

Element Compositi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.