ASTM A589/A589M-06(2018)

(Specification)Standard Specification for Seamless and Welded Carbon Steel Water-Well Pipe

Standard Specification for Seamless and Welded Carbon Steel Water-Well Pipe

ABSTRACT

This specification covers four specific types of plain end or threaded and coupled carbon steel pipe for use in water wells. Water well pipe are classified into four types according to grads: type I, drive pipe; type II, water-well reamed and drifted pipe; type III, driven well pipe; and type IV, water-well casing pipe. The steel for both seamless and welded pipe shall be made by one of the following processes: open-hearth, electric furnace, or basic-oxygen. Tensile test, tension test, and hydrostatic test shall be required to conform to the requirements specified.

SCOPE

1.1 This specification covers four specific types of plain end or threaded and coupled carbon steel pipe for use in water wells.

1.2 Each type of water well pipe shall conform to the following methods of manufacture and grade as specified on the purchase order:

1.2.1 Type I, Drive Pipe—Seamless or electric-resistance-welded, Grades A and B.

1.2.2 Type II, Water-Well Reamed and Drifted Pipe—Seamless or electric-resistance-welded, Grades A and B, or furnace-butt welded.

1.2.3 Type III, Driven Well Pipe—Seamless or electric-resistance-welded, Grades A and B, or furnace-butt welded.

1.2.4 Type IV, Water-Well Casing Pipe—Seamless or electric-resistance-welded, Grades A and B, or furnace-butt welded.

1.3 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values in each system are not exact equivalents; therefore, each system is to be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

Note 1: The dimensionless designator NPS (nominal pipe size) and DN (Nominal Diameter) have been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A589/A589M −06 (Reapproved 2018)

Standard Specification for

Seamless and Welded Carbon Steel Water-Well Pipe

This standard is issued under the fixed designationA589/A589M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thisspecificationcoversfourspecifictypesofplainend

A53/A53MSpecification for Pipe, Steel, Black and Hot-

or threaded and coupled carbon steel pipe for use in water

Dipped, Zinc-Coated, Welded and Seamless

wells.

A370Test Methods and Definitions for Mechanical Testing

1.2 Each type of water well pipe shall conform to the

of Steel Products

following methods of manufacture and grade as specified on

A751Test Methods, Practices, and Terminology for Chemi-

the purchase order:

cal Analysis of Steel Products

A865/A865MSpecification for Threaded Couplings, Steel,

1.2.1 Type I, Drive Pipe—Seamless or electric-resistance-

Black or Zinc-Coated (Galvanized) Welded or Seamless,

welded, Grades A and B.

for Use in Steel Pipe Joints

1.2.2 Type II, Water-Well Reamed and Drifted Pipe—

2.2 API Standard:

Seamless or electric-resistance-welded, Grades A and B, or

5LSpecification for Line Pipe

furnace-butt welded.

1.2.3 Type III, Driven Well Pipe—Seamless or electric-

3. Terminology

resistance-welded, Grades A and B, or furnace-butt welded.

3.1 Definitions of Terms Specific to This Standard:

1.2.4 Type IV, Water-Well Casing Pipe—Seamless or

3.1.1 defect—animperfectionofsufficientsizeormagnitude

electric-resistance-welded, Grades A and B, or furnace-butt

to be cause for rejection.

welded.

3.1.2 imperfection—any discontinuity or irregularity found

in the pipe.

1.3 The values stated in either inch-pound units or in SI

units are to be regarded separately as standard.Within the text,

4. Ordering Information

the SI units are shown in brackets. The values in each system

4.1 Orders for material to this specification should include

are not exact equivalents; therefore, each system is to be used

the following, as required to describe the desired material

independently of the other. Combining values from the two

adequately:

systems may result in nonconformance with the standard.

4.1.1 Quantity (feet or number of lengths),

NOTE 1—The dimensionless designator NPS (nominal pipe size) and

4.1.2 Name of material or type number (see 1.2),

DN (Nominal Diameter) have been substituted in this standard for such

4.1.3 Method of manufacture (furnace-butt welded,

traditional terms as “nominal diameter,” “size,” and “nominal size.”

seamless, or electric-resistance-welded),

1.4 This international standard was developed in accor-

4.1.4 Grade (A or B for seamless or electric-resistance

dance with internationally recognized principles on standard-

welded),

ization established in the Decision on Principles for the

4.1.5 Finish (black or galvanized),

Development of International Standards, Guides and Recom- 4.1.6 Dimensions (NPS or outside diameter and wall

mendations issued by the World Trade Organization Technical thickness,orboth,forTypesI,II,andIII.Outsidediameterand

Barriers to Trade (TBT) Committee. wall thickness for Type IV),

4.1.7 End finish (plain end or threaded and coupled),

1 2

This specification is under the jurisdiction ofASTM Committee A01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.09 on Carbon Steel Tubular Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2018. Published October 2018. Originally the ASTM website.

approved in 1968. Last previous edition approved in 2012 as A589/A589M–06 Available from American Petroleum Institute (API), 1220 L. St., NW,

(2012). DOI: 10.1520/A0589_A0589M-06R18. Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A589/A589M−06 (2018)

TABLE 1 Tensile Requirements

4.1.8 Coupling class for Type III (standard pipe, line pipe,

or reamed and drifted pipe coupling), Butt Welded Grade A Grade B

Tensile strength, min, 48 000 (330) 48 000 (330) 60 000 (415)

4.1.9 Coupling make-up (hand tight or power tight),

psi (MPa)

4.1.10 Length (required random range length or special

Yield strength, min, psi 30 000 (205) 30 000 (205) 35 000 (240)

lengths), (MPa)

AAA

Elongation in 2 in.

4.1.11 Specification designation, and

A

The minimum elongation in 2 in. (50.8 mm) shall be that determined by the

4.1.12 Special requirements.

following equation:

0.2 0.9

e5 625 000 A /U

5. Materials and Manufacture

where:

5.1 The steel for both seamless and welded pipe shall be

e = minimum elongation in 2 in. (50.8 mm) in percent rounded to the

nearest 0.5 %.

made by one of the following processes: open-hearth, electric-

A = cross-sectional area of the tension test specimen in square inches,

furnace, or basic-oxygen.

based on specified outside diameter or nominal specimen width and

specified wall thickness rounded to the nearest 0.01 in. If the area thus

5.2 Steel may be cast in ingots or may be strand cast.When

calculated is greater than 0.75 in. , then the value 0.75 shall be used.

steels of different grades are sequentially strand cast, identifi-

U = specified tensile strength, psi.

cation of the resultant transition material is required. The

producer shall remove the transition material by any estab-

lished procedure that positively separates the grades.

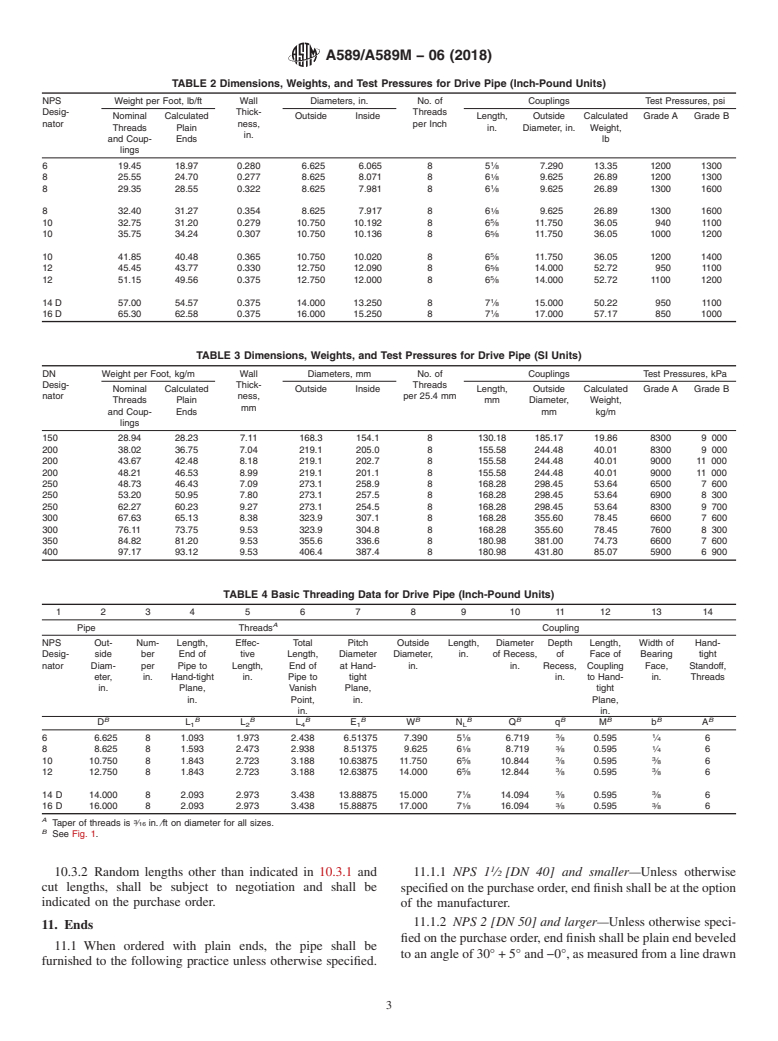

Type Tables

6. Chemical Composition

I, Drive Pipe Table 2, Table 3,

6.1 Thesteelshallconformtothefollowingrequirementsas

Table 4, Table 5

to chemical composition:

II, Reamed and Drifted Pipe Table 6, Table 7,

Phosphorus, max, % 0.050

Table 8, Table 9

Sulfur, max, % 0.060

III, Driven Well Pipe Table 10, Table 11,

7. Heat Analysis

Table 12, Table 13

7.1 An analysis of each heat of steel shall be made by the

IV, Water-Well Casing Pipe Table 14, Table 15,

manufacturer to determine the percentage of the elements Table 16, Table 17

specifiedin6.1.Whenrequestedbythepurchaser,thechemical

10.2 Permissible Variations in Weight and Dimensions:

compositionthusdeterminedshallbereportedtothepurchaser,

10.2.1 Weight—The weight of all types of pipe included in

and shall conform to the requirements specified in 6.1.

this specification shall vary not more than 65% from that

prescribed.The weight tolerance for pipe NPS 4 [DN 100] and

8. Product Analysis

under may be determined from the weight of the customary

lifts of pipe as produced for shipment, divided by the number

8.1 An analysis may be made by the purchaser on two

offeetofpipeinthelift.ForpipeoverNPS4[DN100],where

lengthsofpipefromeachlotof500lengths,orfractionthereof.

individual lengths may be weighed, the weight is applicable to

Samples for chemical analysis and the methods of analysis

the individual length.

shall conform to the requirements of Test Methods, Practices,

10.2.2 Outside Diameter—For pipe NPS 1 ⁄2[DN 40] and

and Terminology A751. The chemical composition thus deter-

under, the outside diameters shall vary not more than ⁄64in.

mined shall conform to the requirements specified in 6.1.

[0.4 mm] from the outside diameter specified. For pipe NPS 2

8.2 If the analysis of either pipe does not conform to the

[DN 50] and over, the outside diameter shall vary not more

requirements of 6.1, analysis shall be made on additional

than 61% from the size specified.

lengths of pipe of double the original number from the same

10.2.3 Inside Diameter—For Type II pipe, the inside diam-

lot, each of which shall conform to the requirements specified.

eter at any point, shall permit passage of a drift pin having a

length and diameter as indicated in Table 6, Table 7, and Table

9. Tensile Requirements

18.

10.2.4 Thickness—Theminimumwallthicknessshallbenot

9.1 The material shall conform to the requirements as to

more than 12.5% under the nominal wall thickness specified.

tensile properties specified in Table 1.

10.3 Lengths:

9.2 The test specimen taken across the weld shall show a

10.3.1 Unless otherwise specified on the purchase order,

tensile strength not less than the minimum tensile strength

pipe lengths shall be in accordance with the following regular

specifiedforthegradeofpipeordered.Thistestisnotrequired

practice:

for pipe under 8 in. [DN 200] in outside diameter.

10.3.1.1 Types I, II, and IV pipe may be furnished in single

random lengths of 16 to 22 ft [4.9 to 6.7 m].

10. Dimensions, Weights, and Permissible Variations

10.3.1.2 Type III pipe may be furnished in a random range

10.1 The dimensions and weights of all types of pipe from 3 to 6 ft [0.9 to 1.8 m] or 6 to 10 ft [1.8 to 3.0 m] as

included in this specification are listed in Tables 2-17: specified.

A589/A589M−06 (2018)

TABLE 2 Dimensions, Weights, and Test Pressures for Drive Pipe (Inch-Pound Units)

NPS Weight per Foot, lb/ft Wall Diameters, in. No. of Couplings Test Pressures, psi

Desig- Thick- Threads

Nominal Calculated Outside Inside Length, Outside Calculated Grade A Grade B

nator ness, per Inch

Threads Plain in. Diameter, in. Weight,

in.

and Coup- Ends lb

lings

6 19.45 18.97 0.280 6.625 6.065 8 5 ⁄8 7.290 13.35 1200 1300

8 25.55 24.70 0.277 8.625 8.071 8 6 ⁄8 9.625 26.89 1200 1300

8 29.35 28.55 0.322 8.625 7.981 8 6 ⁄8 9.625 26.89 1300 1600

8 32.40 31.27 0.354 8.625 7.917 8 6 ⁄8 9.625 26.89 1300 1600

10 32.75 31.20 0.279 10.750 10.192 8 6 ⁄8 11.750 36.05 940 1100

10 35.75 34.24 0.307 10.750 10.136 8 6 ⁄8 11.750 36.05 1000 1200

10 41.85 40.48 0.365 10.750 10.020 8 6 ⁄8 11.750 36.05 1200 1400

12 45.45 43.77 0.330 12.750 12.090 8 6 ⁄8 14.000 52.72 950 1100

12 51.15 49.56 0.375 12.750 12.000 8 6 ⁄8 14.000 52.72 1100 1200

14 D 57.00 54.57 0.375 14.000 13.250 8 7 ⁄8 15.000 50.22 950 1100

16 D 65.30 62.58 0.375 16.000 15.250 8 7 ⁄8 17.000 57.17 850 1000

TABLE 3 Dimensions, Weights, and Test Pressures for Drive Pipe (SI Units)

DN Weight per Foot, kg/m Wall Diameters, mm No. of Couplings Test Pressures, kPa

Desig- Thick- Threads

Nominal Calculated Outside Inside Length, Outside Calculated Grade A Grade B

nator ness, per 25.4 mm

Threads Plain mm Diameter, Weight,

mm

and Coup- Ends mm kg/m

lings

150 28.94 28.23 7.11 168.3 154.1 8 130.18 185.17 19.86 8300 9 000

200 38.02 36.75 7.04 219.1 205.0 8 155.58 244.48 40.01 8300 9 000

200 43.67 42.48 8.18 219.1 202.7 8 155.58 244.48 40.01 9000 11 000

200 48.21 46.53 8.99 219.1 201.1 8 155.58 244.48 40.01 9000 11 000

250 48.73 46.43 7.09 273.1 258.9 8 168.28 298.45 53.64 6500 7 600

250 53.20 50.95 7.80 273.1 257.5 8 168.28 298.45 53.64 6900 8 300

250 62.27 60.23 9.27 273.1 254.5 8 168.28 298.45 53.64 8300 9 700

300 67.63 65.13 8.38 323.9 307.1 8 168.28 355.60 78.45 6600 7 600

300 76.11 73.75 9.53 323.9 304.8 8 168.28 355.60 78.45 7600 8 300

350 84.82 81.20 9.53 355.6 336.6 8 180.98 381.00 74.73 6600 7 600

400 97.17 93.12 9.53 406.4 387.4 8 180.98 431.80 85.07 5900 6 900

TABLE 4 Basic Threading Data for Drive Pipe (Inch-Pound Units)

1 2 3 45678 9 10 11 12 13 14

A

Pipe Threads Coupling

NPS Out- Num- Length, Effec- Total Pitch Outside Length, Diameter Depth Length, Width of Hand-

Desig- side ber End of tive Length, Diameter Diameter, in. of Recess, of Face of Bearing tight

nator Diam- per Pipe to Length, End of at Hand- in. in. Recess, Coupling Face, Standoff,

eter, in. Hand-tight in. Pipe to tight in. to Hand- in. Threads

in. Plane, Vanish Plane, tight

in. Point, in. Plane,

in. in.

B B B B B B B B B B B B

D L L L E W N Q q M b A

1 2 4 1 L

1 3 1

6 6.625 8 1.093 1.973 2.438 6.51375 7.390 5 ⁄8 6.719 ⁄8 0.595 ⁄4 6

1 3 1

8 8.625 8 1.593 2.473 2.938 8.51375 9.625 6 ⁄8 8.719 ⁄8 0.595 ⁄4 6

5 3 3

10 10.750 8 1.843 2.723 3.188 10.63875 11.750 6 ⁄8 10.844 ⁄8 0.595 ⁄8 6

5 3 3

12 12.750 8 1.843 2.723 3.188 12.63875 14.000 6 ⁄8 12.844 ⁄8 0.595 ⁄8 6

1 3 3

14 D 14.000 8 2.093 2.973 3.438 13.88875 15.000 7 ⁄8 14.094 ⁄8 0.595 ⁄8 6

1 3 3

16 D 16.000 8 2.093 2.973 3.438 15.88875 17.000 7 ⁄8 16.094 ⁄8 0.595 ⁄8 6

A

Taper of threads is ⁄16 in. ⁄ft on diameter for all sizes.

B

See Fig. 1.

10.3.2 Random lengths other than indicated in 10.3.1 and 11.1.1 NPS 1 ⁄2 [DN 40] and smaller—Unless otherwise

cut lengths, shall be subject to negotiation and shall be

specifiedonthepurchaseorder,endfinishshallbeattheoption

indicated on the purchase order.

of the manufacturer.

11.1.2 NPS 2 [DN 50] and larger—Unless otherwise speci-

11. Ends

fiedonthepurchaseorder,endfinishshallbeplainendbeveled

11.1 When ordered with plain ends, the pipe shall be

toanangleof30°+5°and−0°,asmeasuredfromalinedrawn

furnished to the following practice unless otherwise specified.

A589/A589M−06 (2018)

TABLE 5 Basic Threading Data for Drive Pipe (SI Units)

1 2 3 45678 9 10 11 12 13 14

A

Pipe Threads Coupling

DN Out- Num- Length, Effec- Total Pitch Outside Length, Diameter Depth Length, Width of Hand-

Desig- side ber End of tive Length, Diameter Diameter, mm of Recess, of Face of Bearing tight

nator Diam- per Pipe to Length, End of at Hand- mm mm Recess, Coupling Face, Standoff,

eter, 25.4 Hand-tight mm Pipe to tight mm to Hand- mm Threads,

mm mm Plane, Vanish Plane, tight mm

mm Point, mm Plane,

mm mm

B B B B B B B B B B B B

D L L L E W N Q q M b A

1 2 4 1 L

150 168.28 8 27.76 50.11 61.93 165.45 187.71 130.18 170.66 9.53 15.11 6.35 6

200 219.08 8 40.46 62.81 74.63 216.25 244.48 155.58 221.46 9.53 15.11 6.35 6

250 273.05 8 46.81 69.16 80.98 270.22 298.45 168.28 275.44 9.53 15.11 9.53 6

300 323.85 8 46.81 69.16 80.98 321.02 355.60 168.28 326.24 9.53 15.11 9.53 6

350 355.60 8 53.16 75.51 87.33 352.77 381.00 180.98 357.99 9.53 15.11 9.53 6

400 406.40 8 53.16 75.51 87.33 403.57 431.80 180.98 408.79 9.53 15.11 9.53 6

A

Taper of threads is 4.8 mm/305 mm on diameter for all sizes.

B

See Fig. 1.

TABLE 6 Dimensions, Weights, and Test Pressures for Water-Well Reamed and Drifted Pipe (Inch-Pound Units)

NPS Weight per Foot, lb/ft Wall Diameters, in. No. of Couplings Test Pressures, psi

Designator Thickness, Threads

Nominal Calculat- Out- In- Length, Outside Calcu- Butt Grade Grade

in. A per Inch

Threads ed Plain side side in. Diam- lated Weld- A B

and Ends eter, Weight, ed

Coup- in. lb

lin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.