ASTM D4424-09

(Test Method)Standard Test Method for Butylene Analysis by Gas Chromatography

Standard Test Method for Butylene Analysis by Gas Chromatography

SIGNIFICANCE AND USE

This test method could be used to determine butylene stream composition for custody transfer payments. It is also capable of providing data necessary to evaluate processing requirements in an operating plant.

SCOPE

1.1 This test method covers the gas chromatographic analysis of commercial butylenes, butylene concentrates, and butane-butylene mixtures.

1.2 This test method does not cover high-purity butene-1 or high-purity isobutene streams, or both. However, it is possible that one or more columns listed in Appendix X3 may be capable of the separation necessary for high-purity analyses.

1.3 This test method is designed to cover the components listed below at about 0.05 % or greater. It is not intended for trace hydrocarbon analysis. Components to be determined are: propane, propylene, isobutane, n-butane, butene-1, isobutene, trans-butene-2, cis-butene-2, 1,3-butadiene, isopentane, n-pentane.

1.4 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units are for information only.

1.5 This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 5.3.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4424 − 09

StandardTest Method for

1

Butylene Analysis by Gas Chromatography

This standard is issued under the fixed designation D4424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope by a flame ionization detector. Calibration data are obtained by

using either relative response factors or by using a standard

1.1 This test method covers the gas chromatographic analy-

calibration blend.

sis of commercial butylenes, butylene concentrates, and

butane-butylene mixtures.

4. Significance and Use

1.2 This test method does not cover high-purity butene-1 or

4.1 This test method could be used to determine butylene

high-purity isobutene streams, or both. However, it is possible

stream composition for custody transfer payments. It is also

that one or more columns listed in Appendix X3 may be

capable of providing data necessary to evaluate processing

capable of the separation necessary for high-purity analyses.

requirements in an operating plant.

1.3 This test method is designed to cover the components

listed below at about 0.05 % or greater. It is not intended for

5. Apparatus

trace hydrocarbon analysis. Components to be determined are:

propane, propylene, isobutane, n-butane, butene-1, isobutene,

5.1 Chromatograph—Any chromatographic instrument

trans-butene-2, cis-butene-2, 1,3-butadiene, isopentane, having either a thermal conductivity or flame ionization

n-pentane.

detector with an overall sensitivity sufficient to detect at least

0.05 % of each of the components listed in 1.3.

1.4 The values stated in SI units are to be regarded as the

standard. The values stated in inch-pound units are for infor-

5.2 Detector—Either a thermal conductivity or flame ion-

mation only.

ization detector may be used.

1.5 This standard does not purport to address all of the

5.3 Sample Valve—Either a constant-volume gas sampling

safety concerns associated with its use. It is the responsibility

valveoraliquidsamplingvalvemaybeused.Ifagassampling

of the user of this standard to establish appropriate safety and

valve is used, greater care must be taken to ensure that the

health practices and determine the applicability of regulatory

vaporized butylenes that are injected into the chromatograph

limitations prior to use. For specific warning statements, see

are a true representation of the sample.

5.3.1.

5.3.1 If the liquid sample valve is used, the sample cylinder

must be pressured up to at least 1100 kPa (160 psig) with an

2. Referenced Documents

inert gas, such as nitrogen or helium. (Warning—Compressed

2

2.1 ASTM Standards:

gas under high pressure. Gas reduces oxygen available for

E260 Practice for Packed Column Gas Chromatography

breathing.) Also a valve must be installed in the purge line

downstream of the liquid sample valve to ensure the butylenes

3. Summary of Test Method

sample in the sampling valve is entirely in the liquid phase

3.1 The sample is separated in a gas chromatograph system

prior to injection into the column. (Warning—Extremely

using a packed chromatographic column with either helium or

flammable liquefied gas under pressure. Vapor reduces oxygen

hydrogen as the carrier gas. The separated components of the

available for breathing.)

samplearedetectedbyeitherathermalconductivitydetectoror

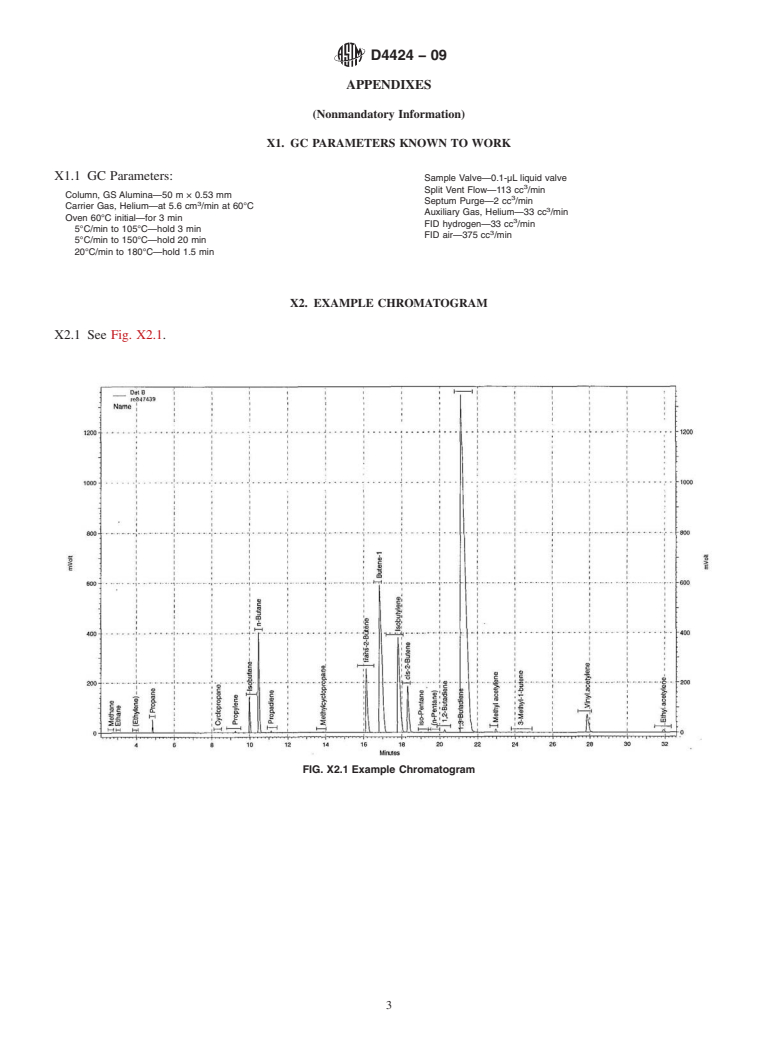

5.4 Column—Any chromatographic column may be used,

providing the components listed in the scope can be separated

1

This test method is under the jurisdiction of ASTM Committee D02 on

sufficiently for the accurate determination of component con-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.D0.04 on C4 Hydrocarbons. centration. Resolution between peaks must afford a resolution

Current edition approved July 15, 2009. Published November 2009. Originally

such that the depth of the valleys between peaks are no less

ϵ1

approved in 1984. Last previous edition approved in 2001 as D4424–90(2001) .

than 50 % of the peak height of the lesser component.Alist of

DOI: 10.1520/D4424-09.

2 satisfactory columns is given in Appendix X3.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.5 Recorder—A recorder with a full-scale response of 2 s

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. or less and a maximum rate of noise of 60.3 % of full scale.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4424 − 09

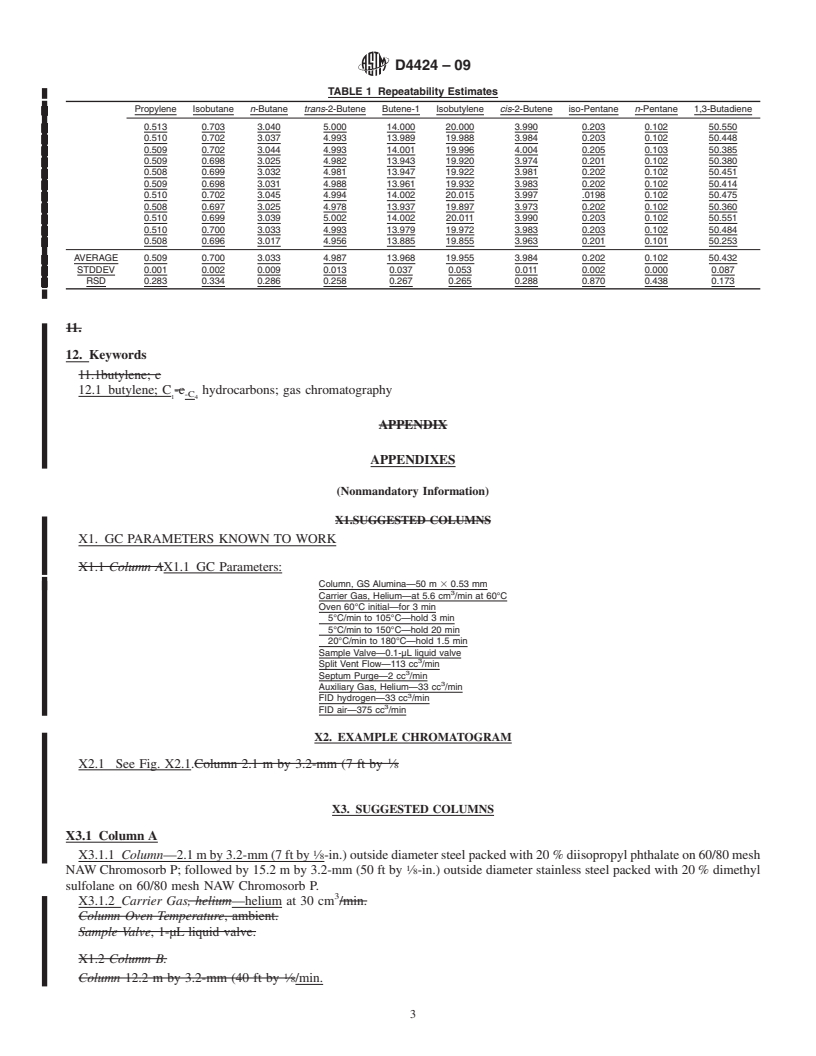

TABLE 1 Repeatabil

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D4424–90(Reapproved 2001) Designation:D4424–09

Standard Test Method for

1

Butylene Analysis by Gas Chromatography

This standard is issued under the fixed designation D4424; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Warning notes were placed in the text editorially in January 2001.

1. Scope

1.1 This test method covers the gas chromatographic analysis of commercial butylenes, butylene concentrates, and

butane-butylene mixtures.

1.2 This test method does not cover high-purity butene-1 or high-purity isobutene streams, or both. However, it is possible that

one or more columns listed in Appendix X1 Appendix X3 may be capable of the separation necessary for high-purity analyses.

1.3 This test method is designed to cover the components listed below at about 0.05 % or greater. It is not intended for trace

hydrocarbon analysis. Components to be determined are: propane, propylene, isobutane, n-butane, butene-1, isobutene,

trans-butene-2, cis-butene-2, 1,3-butadiene, isopentane, n-pentane.

1.4 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound units are for information

only.

1.5 This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use. For specific warning statements, see 5.3.1.

2. Referenced Documents

2

2.1 ASTM Standards:

E260 Practice for Packed Column Gas Chromatography

3. Summary of Test Method

3.1 The sample is separated in a gas chromatograph system using a packed chromatographic column with either helium or

hydrogen as the carrier gas. The separated components of the sample are detected by either a thermal conductivity detector or by

a flame ionization detector. Calibration data are obtained by using either relative response factors or by using a standard calibration

blend.

4. Significance and Use

4.1 This test method could be used to determine butylene stream composition for custody transfer payments. It is also capable

of providing data necessary to evaluate processing requirements in an operating plant.

5. Apparatus

5.1 Chromatograph—Any chromatographic instrument having either a thermal conductivity or flame ionization detector with

an overall sensitivity sufficient to detect at least 0.05 % of each of the components listed in the scope. 1.3.

5.2 Detector—Either a thermal conductivity or flame ionization detector may be used.

5.3 SampleValve—Eitheraconstant-volumegassamplingvalveoraliquidsamplingvalvemaybeused.Ifagassamplingvalve

is used, greater care must be taken to ensure that the vaporized butylenes that are injected into the chromatograph are a true

representation of the sample.

5.3.1 If the liquid sample valve is used, the sample cylinder must be pressured up to at least 1100 kPa (160 psig) with an inert

gas, such as nitrogen or helium. (Warning —Compressed gas under high pressure. Gas reduces oxygen available for breathing.).

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.D0.04

on C4 Hydrocarbons.

Current edition approved Jan. 10, 2001. Published November 1990. Originally published as D4424–84. Last previous edition D4424–84. DOI: 10.1520/D4424-90R01E01.

´1

Current edition approved July 15, 2009. Published November 2009. Originally approved in 1984. Last previous edition approved in 2001 as D4424–90(2001) . DOI:

10.1520/D4424-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 03.06.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4424–09

Also a valve must be installed in the purge line downstream of the liquid sample valve to ensure the butylenes sample in the

sampling valve is entirely in the liquid phase prior to injection into the column. (Warning—Extremely flammable liquefied gas

under pressure. Vapor reduces

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.