ASTM A473-01(2009)

(Specification)Standard Specification for Stainless Steel Forgings

Standard Specification for Stainless Steel Forgings

ABSTRACT

This specification covers austenitic, austenitic-ferritic, ferritic, and martensitic stainless steel forgings for general use, and for low- or high-temperature service. The different solution heat treatment and annealing treatment received by the steel material are presented in details. The steel shall conform to the specified chemical composition and room temperature mechanical requirements. The forgings shall be produced with prolongations for testing, unless otherwise specified. The number of and procedure for tension test for forgings depending on their weight are presented. The tension test specimens shall be taken from the test prolongations or from the forgings.

SCOPE

1.1 This specification covers austenitic, austenitic-ferritic, ferritic, and martensitic stainless steel forgings for general use, and for low- or high-temperature service.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A473 −01(Reapproved 2009)

Standard Specification for

Stainless Steel Forgings

This standard is issued under the fixed designation A473; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.6 ASTM designation and date of issue.

3.1.7 Test for magnetic permeability if specified by cus-

1.1 This specification covers austenitic, austenitic-ferritic,

tomer purchase order when ordering Types 207 and 205.

ferritic, and martensitic stainless steel forgings for general use,

3.1.8 Special requirements.

and for low- or high-temperature service.

3.2 If possible the intended end use of the item should be

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical givenonthepurchaseorderespeciallywhentheitemisordered

for a specific end use or uses.

conversions to SI units that are provided for information only

and are not considered standard.

NOTE 1—A typical ordering description is as follows: 5 stainless steel

forgings, Type 410, Designation A, ASTM Specification A473 dated

2. Referenced Documents

———. End use: pump blocks for oil well equipment.

2.1 ASTM Standards:

4. General Requirements

A314 Specification for Stainless Steel Billets and Bars for

Forging

4.1 In addition to the requirements of this specification, all

A370 Test Methods and Definitions for Mechanical Testing

requirements of the current edition of Specification A484/

of Steel Products

A484M shall apply. Failure to comply with the general

A484/A484M Specification for General Requirements for

requirements of Specification A484/A484M constitutes non-

Stainless Steel Bars, Billets, and Forgings

conformance with this specification.

A751 Test Methods, Practices, and Terminology for Chemi-

cal Analysis of Steel Products

5. Manufacture

E527 Practice for Numbering Metals and Alloys in the

5.1 Material for forgings shall consist of ingots or blooms,

Unified Numbering System (UNS)

billets, slabs, or bars, either forged or rolled from an ingot, and

cut to the required length by a suitable process. This material,

3. Ordering Information

except for ingots, may be specified to Specification A314.

3.1 It is the responsibility of the purchaser to specify all

requirements that are necessary for material ordered under this 5.2 The material shall be forged by hammering, pressing,

specification. Such requirements may include, but are not rolling, extruding, or upsetting. It shall be brought as nearly as

limited to, the following: possible to the finished shape and size by hot-working; and

3.1.1 Quantity (weight or number of pieces), shall be processed, if practicable, so as to cause metal-flow

3.1.2 Dimensions, including prints or sketches, during the hot-working operation in the direction most favor-

3.1.3 Name of material (stainless steel forgings), able for resisting the stresses encountered in service as may be

3.1.4 Type or UNS designation (Table 1), indicated to the manufacturer by the purchaser.

3.1.5 Condition (Table 2), and

5.3 When specified on the order, a sample forging may be

sectioned and etched to show flow lines and the condition as

regards internal imperfections. When so specified, the question

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

of acceptable and unacceptable metal-flow shall be subject to

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.17 on Flat-Rolled and Wrought Stainless Steel.

agreement between the manufacturer and the purchaser prior to

Current edition approved May 1, 2009. Published May 2009. Originally

order entry.

approved in 1962. Last previous edition approved in 2001 as A473 – 01. DOI:

10.1520/A0473-01R09.

5.4 When specified on the order, the manufacturer shall

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

submit for approval of the purchaser a sketch showing the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shape of the rough forging before machining, or before heat

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. treating for mechanical properties.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A473−01 (2009)

A

TABLE 1 Chemical Requirements

Phos-

UNS Type Manga- Other

Carbon, pho- Sulfur, Silicon, Chromium, Nickel, Molyb- Nitro-

Desig- Num- nese, Elements,

% rus, % % % % denum, % gen, %

B

nation ber % %

%

Austenitic Grades

S20100 201 0.15 5.5–7.5 0.060 0.030 1.00 16.0–18.0 3.5–5.5 . . . 0.25

S20200 202 0.15 7.5–10.0 0.060 0.030 1.00 17.0–19.0 4.0–6.0 . . . 0.25

S20500 205 0.12–0.25 14.0–15.5 0.060 0.030 1.00 16.5–18.0 1.00–1.75 . . . 0.32–0.40

S21900 XM-10 0.08 8.0–10.0 0.060 0.030 1.00 19.0–21.5 5.5–7.5 . . . 0.15–0.40

S21904 XM-11 0.04 8.0–10.0 0.060 0.030 1.00 19.0–21.5 5.5–7.5 . . . 0.15–0.40

S28200 . . . 0.15 17.0–19.0 0.045 0.030 1.00 17.0–19.0 . . . 0.75–1.25 0.40–0.60 Cu 0.75–1.25

S30200 302 0.15 2.00 0.045 0.030 1.00 17.0–19.0 8.0–10.0 . . . 0.10

S30215 302B 0.15 2.00 0.045 0.030 2.00–3.00 17.0–19.0 8.0–10.0 . . . . . .

C

S30300 303 0.15 2.00 0.20 0.15 min 1.00 17.0–19.0 8.0–10.0 0.60 .

S30323 303 Se 0.15 2.00 0.20 0.06 1.00 17.0–19.0 8.0–10.0 . . . . . . Se 0.15 min

S30400 304 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–10.5 . . . 0.10

S30403 304L 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–12.0 . . . 0.10

S30500 305 0.12 2.00 0.045 0.030 1.00 17.0–19.0 10.5–13.0 . . . . . .

S30800 308 0.08 2.00 0.045 0.030 1.00 19.0–21.0 10.0–12.0 . . . . . .

S30815 . . . 0.10 0.80 0.040 0.030 1.40–2.00 20.0–22.0 10.0–12.0 . . . 0.14–0.20 Ce 0.03–0.08

S30900 309 0.20 2.00 0.045 0.030 1.00 22.0–24.0 12.0–15.0 . . . . . .

S30908 309S 0.08 2.00 0.045 0.030 1.00 22.0–24.0 12.0–15.0 . . . . . .

S31000 310 0.25 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . .

S31008 310S 0.08 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . .

S31254 . . . 0.020 1.00 0.030 0.010 0.80 19.5–20.5 17.5–18.5 6.0–6.5 0.18–0.22 Cu 0.50–1.00

S31400 314 0.25 2.00 0.045 0.030 1.50–3.00 23.0–26.0 19.0–22.0 . . . . . .

S31600 316 0.08 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 0.10

S31603 316L 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 0.10

S31700 317 0.08 2.00 0.045 0.030 1.00 18.0–20.0 11.0–15.0 3.0–4.0 0.10

S32100 321 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . Ti 5×C min

S34700 347 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . Cb+Ta 10×C,

min

S34800 348 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . Cb+Ta 10×C,

min

Ta 0.10

Co 0.20

Austenitic-Ferritic Grades

D

S32550 . . . 0.04 1.50 0.040 0.030 1.00 24.0-27.0 4.5-6.5 2.9-3.9 0.10-0.25 Cu 1.50–2.50

D

S32760 . . . 0.030 1.00 0.030 0.010 1.00 24.0–26.0 6.0–8.0 3.0–4.0 0.20–0.30 Cu 0.50–1.00

W 0.50–1.00

S32950 . . . 0.03 2.00 0.035 0.010 0.60 26.0–29.0 3.5–5.2 1.00–2.50 0.15–0.35

Ferritic Grades

S40500 405 0.08 1.00 0.040 0.030 1.00 11.5–14.5 0.60 . . . . . . A1 0.10–0.30

S42900 429 0.12 1.00 0.040 0.030 1.00 14.0–16.0 0.75 . . . . . .

S43000 430 0.12 1.00 0.040 0.030 1.00 16.0–18.0 0.75 . . . . . .

C

S43020 430F 0.12 1.25 0.06 0.15 min 1.00 16.0–18.0 0.75 0.60 .

S43023 430F Se 0.12 1.25 0.06 0.06 1.00 16.0–18.0 0.75 . . Se 0.15 min

S44600 446 0.20 1.50 0.040 0.030 1.00 23.0–27.0 0.75 . 0.25

Martensitic Grades

S40300 403 0.15 1.00 0.040 0.030 0.50 11.5–13.0 . . . . . . . . . . . .

S41000 410 0.15 1.00 0.040 0.030 1.00 11.5–13.5 0.75 . . . . . . . . .

S41008 410S 0.08 1.00 0.040 0.030 1.00 11.5–13.5 0.75 . . . . . . . . .

S41400 414 0.15 1.00 0.040 0.030 1.00 11.5–13.5 1.25–2.50 . . . . . . . . .

S41425 . . . 0.05 0.50–1.00 0.020 0.005 0.50 12.0–15.0 4.0–7.0 1.50–2.00 0.06–0.12 Cu 0.30

E

S41500 0.05 0.5–1.0 0.030 0.030 0.60 11.5–14.0 3.5–5.5 0.40–0.80 . . .

C

S41600 416 0.15 1.25 0.06 0.15 min 1.00 12.0–14.0 . . . 0.60 .

S41623 416 Se 0.15 1.25 0.06 0.06 1.00 12.0–14.0 . . . . . . . . . Se 0.15 min

S42000 420 Over 0.15 1.00 0.040 0.030 1.00 12.0–14.0 . . . . . . . . . . . .

S43100 431 0.20 1.00 0.040 0.030 1.00 15.0–17.0 1.25–2.50 . . . . . . . . .

S44002 440A 0.60–0.75 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

S44003 440B 0.75–0.95 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

S44004 440C 0.95–1.20 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

A

Maximum, unless range or minimum is indicated.

B

New designation established in accordance with Practice E527 and SAE J 1086.

C

At manufacturer’s option; reported only when intentionally added.

D

%Cr + 3.3×% Mo + 16×%N$ 40.

E

Wrought version of CA6NM.

A473−01 (2009)

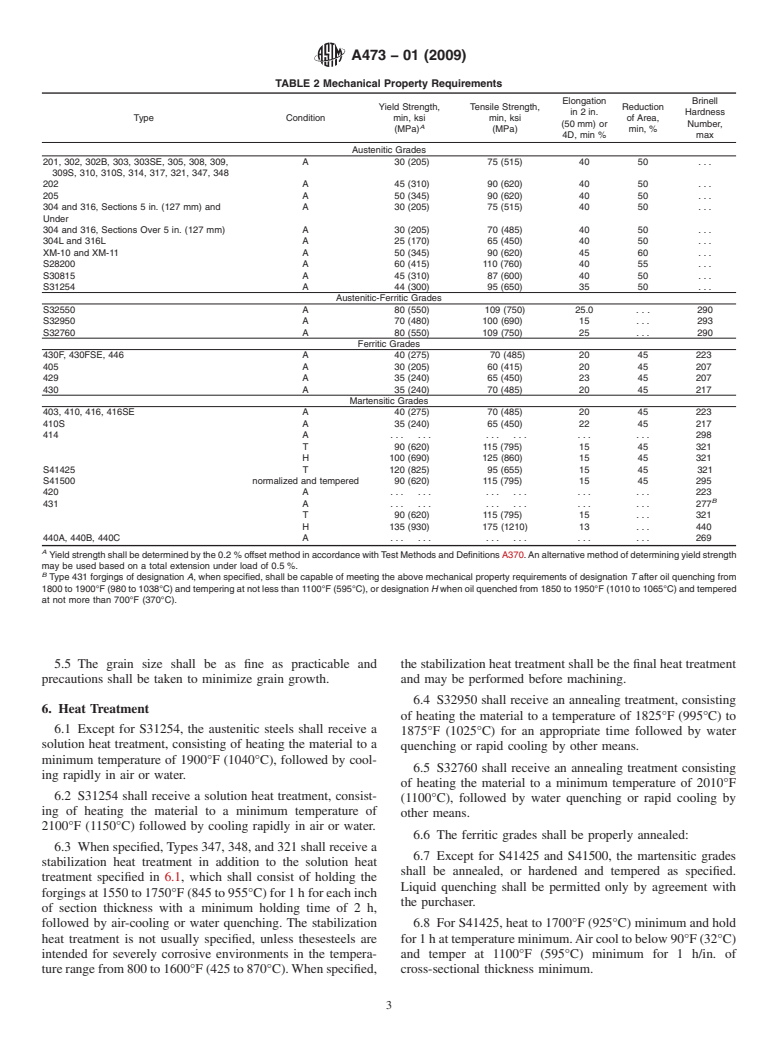

TABLE 2 Mechanical Property Requirements

Elongation Brinell

Yield Strength, Tensile Strength, Reduction

in 2 in. Hardness

Type Condition min, ksi min, ksi of Area,

(50 mm) or Number,

A

(MPa) (MPa) min, %

4D, min % max

Austenitic Grades

201, 302, 302B, 303, 303SE, 305, 308, 309, A 30 (205) 75 (515) 40 50 . . .

309S, 310, 310S, 314, 317, 321, 347, 348

202 A 45 (310) 90 (620) 40 50 . . .

205 A 50 (345) 90 (620) 40 50 . . .

304 and 316, Sections 5 in. (127 mm) and A 30 (205) 75 (515) 40 50 . . .

Under

304 and 316, Sections Over 5 in. (127 mm) A 30 (205) 70 (485) 40 50 . . .

304L and 316L A 25 (170) 65 (450) 40 50 . . .

XM-10 and XM-11 A 50 (345) 90 (620) 45 60 . . .

S28200 A 60 (415) 110 (760) 40 55 . . .

S30815 A 45 (310) 87 (600) 40 50 . . .

S31254 A 44 (300) 95 (650) 35 50 . . .

Austenitic-Ferritic Grades

S32550 A 80 (550) 109 (750) 25.0 . . . 290

S32950 A 70 (480) 100 (690) 15 . .

...

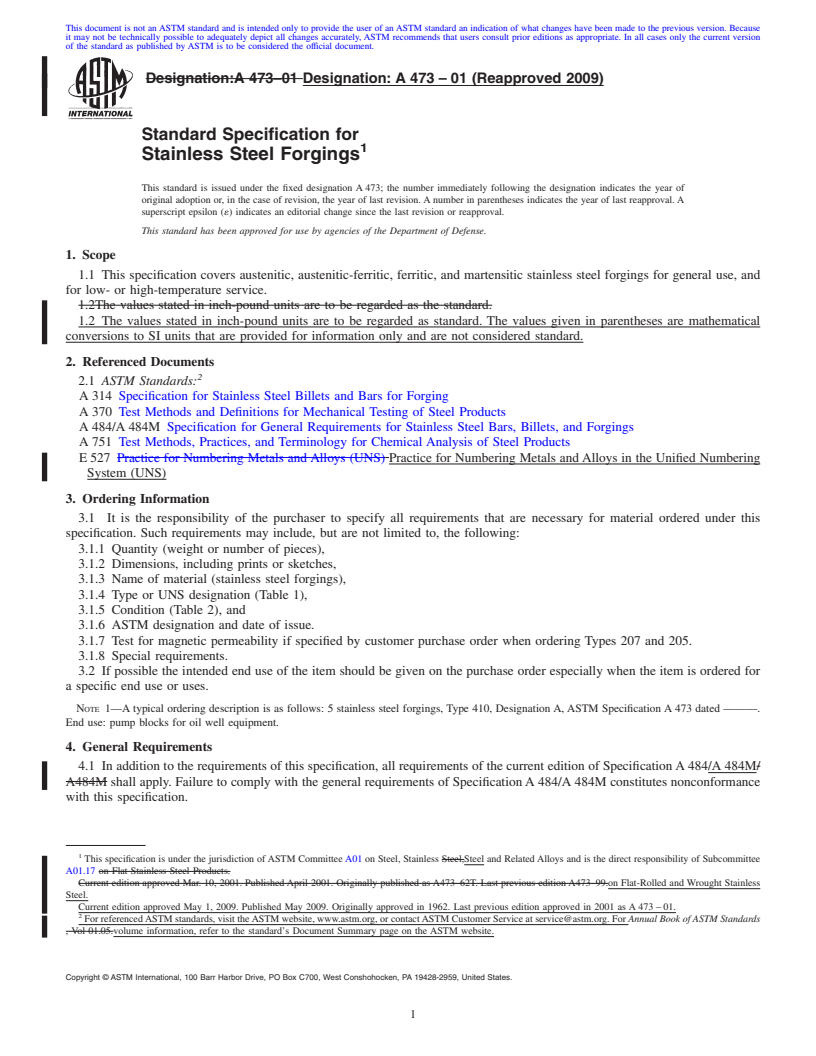

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 473–99 Designation: A 473 – 01 (Reapproved 2009)

Standard Specification for

Stainless Steel Forgings

This standard is issued under the fixed designation A 473; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers austenitic, austenitic-ferritic, ferritic, and martensitic stainless steel forgings for general use, and

for low- or high-temperature service.

1.2The values stated in inch-pound units are to be regarded as the standard.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

A 314 Specification for Stainless Steel Billets and Bars for Forging

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 484/A 484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A 751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E 527 Practice for Numbering Metals and Alloys (UNS) Practice for Numbering Metals and Alloys in the Unified Numbering

System (UNS)

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not limited to, the following:

3.1.1 Quantity (weight or number of pieces),

3.1.2 Dimensions, including prints or sketches,

3.1.3 Name of material (stainless steel forgings),

3.1.4 Type or UNS designation (Table 1),

3.1.5 Condition (Table 2), and

3.1.6 ASTM designation and date of issue.

3.1.7 Test for magnetic permeability if specified by customer purchase order when ordering Types 207 and 205.

3.1.8 Special requirements.

3.2 If possible the intended end use of the item should be given on the purchase order especially when the item is ordered for

a specific end use or uses.

NOTE 1—A typical ordering description is as follows: 5 stainless steel forgings, Type 410, Designation A, ASTM Specification A 473 dated ———.

End use: pump blocks for oil well equipment.

4. General Requirements

4.1 In addition to the requirements of this specification, all requirements of the current edition of SpecificationA 484/A 484M/

A484M shall apply. Failure to comply with the general requirements of SpecificationA 484/A 484M constitutes nonconformance

with this specification.

ThisspecificationisunderthejurisdictionofASTMCommitteeA-1A01onSteel,StainlessSteel,SteelandRelatedAlloysandisthedirectresponsibilityofSubcommittee

A01.17 on Flat Stainless Steel Products.

Current edition approved Sept. 10, 1999. Published November 1999. Originally published as A473–62T. Last previous edition A473–98.on Flat-Rolled and Wrought

Stainless Steel.

Current edition approved May 1, 2009. Published May 2009. Originally approved in 1962. Last previous edition approved in 2001 as A 473 – 01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 01.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 473 – 01 (2009)

A

TABLE 1 Chemical Requirements

Phos-

UNS Type Manga- Other

Carbon, pho- Sulfur, Silicon, Chromium, Nickel, Molyb- Nitro-

Desig- Num- nese, Elements,

% rus, % % % % denum, % gen, %

B

nation ber % %

%

Austenitic Grades

S20100 201 0.15 5.5–7.5 0.060 0.030 1.00 16.0–18.0 3.5–5.5 . . . 0.25

S20200 202 0.15 7.5–10.0 0.060 0.030 1.00 17.0–19.0 4.0–6.0 . . . 0.25

S20500 205 0.12–0.25 14.0–15.5 0.060 0.030 1.00 16.5–18.0 1.00–1.75 . . . 0.32–0.40

S21900 XM-10 0.08 8.0–10.0 0.060 0.030 1.00 19.0–21.5 5.5–7.5 . . . 0.15–0.40

S21904 XM-11 0.04 8.0–10.0 0.060 0.030 1.00 19.0–21.5 5.5–7.5 . . . 0.15–0.40

S28200 . . . 0.15 17.0–19.0 0.045 0.030 1.00 17.0–19.0 . . . 0.75–1.25 0.40–0.60 Cu 0.75–1.25

S30200 302 0.15 2.00 0.045 0.030 1.00 17.0–19.0 8.0–10.0 . . . 0.10

S30215 302B 0.15 2.00 0.045 0.030 2.00–3.00 17.0–19.0 8.0–10.0 . . . . . .

C

S30300 303 0.15 2.00 0.20 0.15 min 1.00 17.0–19.0 8.0–10.0 0.60 .

S30323 303 Se 0.15 2.00 0.20 0.06 1.00 17.0–19.0 8.0–10.0 . . . . . . Se 0.15 min

S30400 304 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–10.5 . . . 0.10

S30403 304L 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–12.0 . . . 0.10

S30500 305 0.12 2.00 0.045 0.030 1.00 17.0–19.0 10.5–13.0 . . . . . .

S30800 308 0.08 2.00 0.045 0.030 1.00 19.0–21.0 10.0–12.0 . . . . . .

S30815 . . . 0.10 0.80 0.040 0.030 1.40–2.00 20.0–22.0 10.0–12.0 . . . 0.14–0.20 Ce 0.03–0.08

S30900 309 0.20 2.00 0.045 0.030 1.00 22.0–24.0 12.0–15.0 . . . . . .

S30908 309S 0.08 2.00 0.045 0.030 1.00 22.0–24.0 12.0–15.0 . . . . . .

S31000 310 0.25 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . .

S31008 310S 0.08 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . .

S31254 . . . 0.020 1.00 0.030 0.010 0.80 19.5–20.5 17.5–18.5 6.0–6.5 0.18–0.22 Cu 0.50–1.00

S31400 314 0.25 2.00 0.045 0.030 1.50–3.00 23.0–26.0 19.0–22.0 . . . . . .

S31600 316 0.08 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 0.10

S31603 316L 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 0.10

S31700 317 0.08 2.00 0.045 0.030 1.00 18.0–20.0 11.0–15.0 3.0–4.0 0.10

S32100 321 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . Ti 53Cmin

S34700 347 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . Cb+Ta 103C,

min

S34800 348 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . Cb+Ta 103C,

min

Ta 0.10

Co 0.20

Austenitic-Ferritic Grades

D

S32550 . . . 0.04 1.50 0.040 0.030 1.00 24.0-27.0 4.5-6.5 2.9-3.9 0.10-0.25 Cu 1.50–2.50

D

S32760 . . . 0.030 1.00 0.030 0.010 1.00 24.0–26.0 6.0–8.0 3.0–4.0 0.20–0.30 Cu 0.50–1.00

W 0.50–1.00

S32950 . . . 0.03 2.00 0.035 0.010 0.60 26.0–29.0 3.5–5.2 1.00–2.50 0.15–0.35

Ferritic Grades

S40500 405 0.08 1.00 0.040 0.030 1.00 11.5–14.5 0.60 . . . . . . A1 0.10–0.30

S42900 429 0.12 1.00 0.040 0.030 1.00 14.0–16.0 0.75 . . . . . .

S43000 430 0.12 1.00 0.040 0.030 1.00 16.0–18.0 0.75 . . . . . .

C

S43020 430F 0.12 1.25 0.06 0.15 min 1.00 16.0–18.0 0.75 0.60 .

S43023 430F Se 0.12 1.25 0.06 0.06 1.00 16.0–18.0 0.75 . . Se 0.15 min

S44600 446 0.20 1.50 0.040 0.030 1.00 23.0–27.0 0.75 . 0.25

Martensitic Grades

S40300 403 0.15 1.00 0.040 0.030 0.50 11.5–13.0 . . . . . . . . . . . .

S41000 410 0.15 1.00 0.040 0.030 1.00 11.5–13.5 0.75 . . . . . . . . .

S41008 410S 0.08 1.00 0.040 0.030 1.00 11.5–13.5 0.75 . . . . . . . . .

S41400 414 0.15 1.00 0.040 0.030 1.00 11.5–13.5 1.25–2.50 . . . . . . . . .

S41425 . . . 0.05 0.50–1.00 0.020 0.005 0.50 12.0–15.0 4.0–7.0 1.50–2.00 0.06–0.12 Cu 0.30

E

S41500 0.05 0.5–1.0 0.030 0.030 0.60 11.5–14.0 3.5–5.5 0.40–0.80 . . .

C

S41600 416 0.15 1.25 0.06 0.15 min 1.00 12.0–14.0 . . . 0.60 .

S41623 416 Se 0.15 1.25 0.06 0.06 1.00 12.0–14.0 . . . . . . . . . Se 0.15 min

S42000 420 Over 0.15 1.00 0.040 0.030 1.00 12.0–14.0 . . . . . . . . . . . .

S43100 431 0.20 1.00 0.040 0.030 1.00 15.0–17.0 1.25–2.50 . . . . . . . . .

S44002 440A 0.60–0.75 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

S44003 440B 0.75–0.95 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

S44004 440C 0.95–1.20 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

S50100 501 Over 0.10 1.00 0.040 0.030 1.00 4.0–6.0 . 0.40–0.65 .

... 501A 0.15 0.30–0.60 0.030 0.030 0.50–1.00 6.0–8.0 ... 0.45–0.65 ...

... 501B 0.15 0.30–0.60 0.030 0.030 0.50–1.00 8.0–10.0 ... 0.90–1.10 ...

S50200 502 0.10 1.00 0.040 0.030 1.00 4.0–6.0 . 0.40–0.65 .

A

Maximum, unless range or minimum is indicated.

B

New designation established in accordance with Practice E 527 and SAE J 1086.

C

At manufacturer’s option; reported only when intentionally added.

D

%Cr + 3.3 3%Mo+16 3 %N$ 40.

E

Wrought version of CA6NM.

A 473 – 01 (2009)

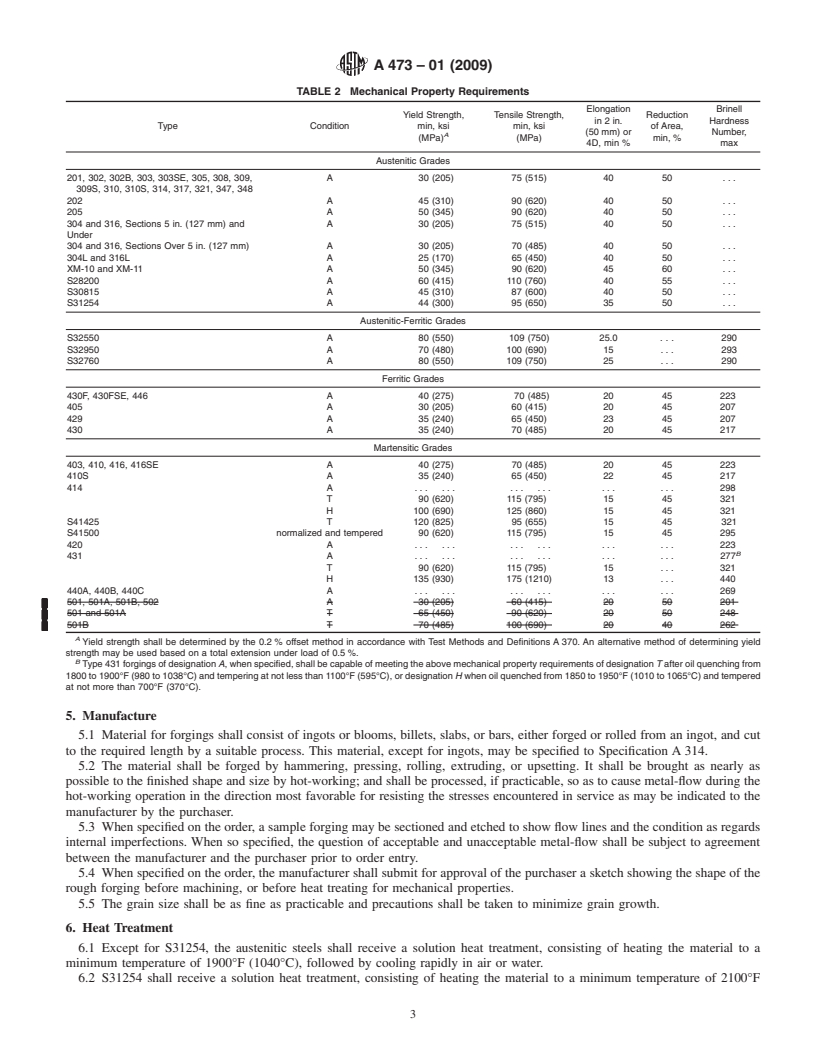

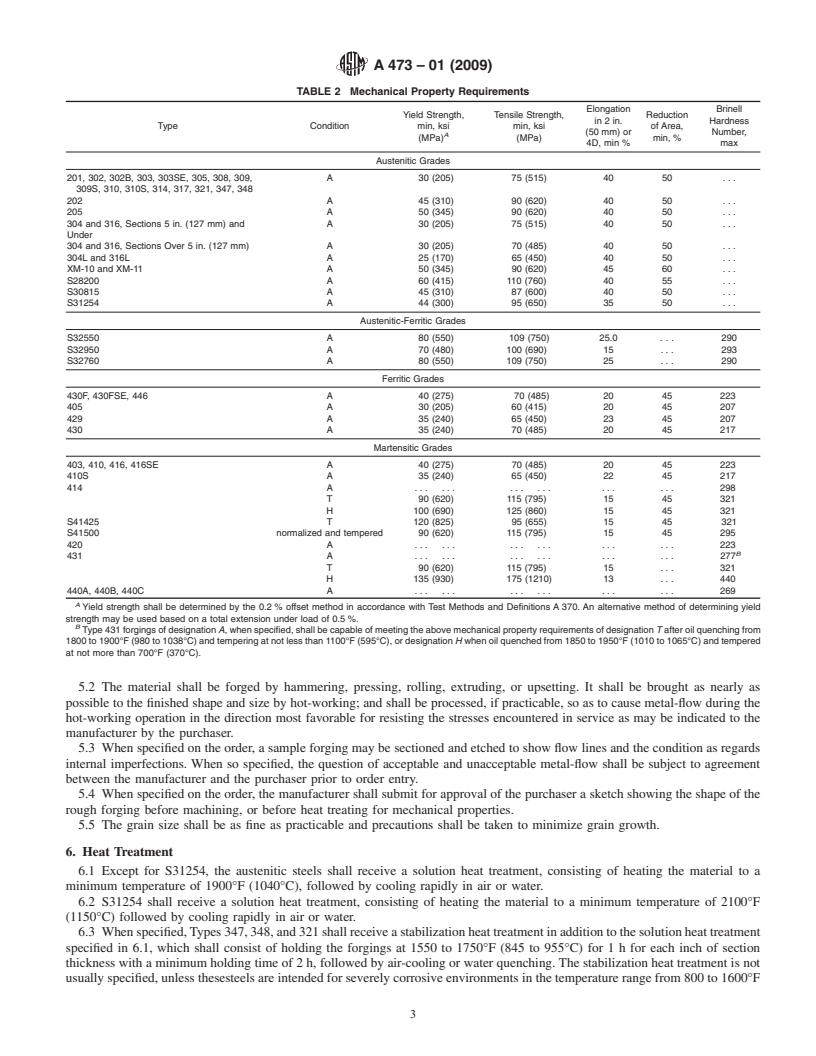

TABLE 2 Mechanical Property Requirements

Elongation Brinell

Yield Strength, Tensile Strength, Reduction

in 2 in. Hardness

Type Condition min, ksi min, ksi of Area,

(50 mm) or Number,

A

(MPa) (MPa) min, %

4D, min % max

Austenitic Grades

201, 302, 302B, 303, 303SE, 305, 308, 309, A 30 (205) 75 (515) 40 50 . . .

309S, 310, 310S, 314, 317, 321, 347, 348

202 A 45 (310) 90 (620) 40 50 . . .

205 A 50 (345) 90 (620) 40 50 . . .

304 and 316, Sections 5 in. (127 mm) and A 30 (205) 75 (515) 40 50 . . .

Under

304 and 316, Sections Over 5 in. (127 mm) A 30 (205) 70 (485) 40 50 . . .

304L and 316L A 25 (170) 65 (450) 40 50 . . .

XM-10 and XM-11 A 50 (345) 90 (620) 45 60 . . .

S28200 A 60 (415) 110 (760) 40 55 . . .

S30815 A 45 (310) 87 (600) 40 50 . . .

S31254 A 44 (300) 95 (650) 35 50 . . .

Austenitic-Ferritic Grades

S32550 A 80 (550) 109 (750) 25.0 . . . 290

S32950 A 70 (480) 100 (690) 15 . . . 293

S32760 A 80 (550) 109 (750) 25 . . . 290

Ferritic Grades

430F, 430FSE, 446 A 40 (275) 70 (485) 20 45 223

405 A 30 (205) 60 (415) 20 45 207

429 A 35 (240) 65 (450) 23 45 207

430 A 35 (240) 70 (485) 20 45 217

Martensitic Grades

403, 410, 416, 416SE A 40 (275) 70 (485) 20 45 223

410S A 35 (240) 65 (450) 22 45 217

414 A . . . . . . 298

T 90 (620) 115 (795) 15 45 321

H 100 (690) 125 (860) 15 45 321

S41425 T 120 (825) 95 (655) 15 45 321

S41500 normalized and tempered 90 (620) 115 (795) 15 45 295

420 A . . . . . . 223

B

431 A . . . . . . 277

T 90 (620) 115 (795) 15 . . . 321

H 135 (930) 175 (1210) 13 . . . 440

440A, 440B, 440C A . . . . . . . . . . . . . . . . . . 269

501, 501A, 501B, 502 A 30 (205) 60 (415) 20 50 201

501 and 501A T 65 (450)

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 473–01 Designation: A 473 – 01 (Reapproved 2009)

Standard Specification for

Stainless Steel Forgings

This standard is issued under the fixed designation A 473; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers austenitic, austenitic-ferritic, ferritic, and martensitic stainless steel forgings for general use, and

for low- or high-temperature service.

1.2The values stated in inch-pound units are to be regarded as the standard.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

A 314 Specification for Stainless Steel Billets and Bars for Forging

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 484/A 484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A 751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E 527 Practice for Numbering Metals and Alloys (UNS) Practice for Numbering Metals and Alloys in the Unified Numbering

System (UNS)

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include, but are not limited to, the following:

3.1.1 Quantity (weight or number of pieces),

3.1.2 Dimensions, including prints or sketches,

3.1.3 Name of material (stainless steel forgings),

3.1.4 Type or UNS designation (Table 1),

3.1.5 Condition (Table 2), and

3.1.6 ASTM designation and date of issue.

3.1.7 Test for magnetic permeability if specified by customer purchase order when ordering Types 207 and 205.

3.1.8 Special requirements.

3.2 If possible the intended end use of the item should be given on the purchase order especially when the item is ordered for

a specific end use or uses.

NOTE 1—A typical ordering description is as follows: 5 stainless steel forgings, Type 410, Designation A, ASTM Specification A 473 dated ———.

End use: pump blocks for oil well equipment.

4. General Requirements

4.1 In addition to the requirements of this specification, all requirements of the current edition of SpecificationA 484/A 484M/

A484M shall apply. Failure to comply with the general requirements of SpecificationA 484/A 484M constitutes nonconformance

with this specification.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel,Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.17 on Flat Stainless Steel Products.

Current edition approved Mar. 10, 2001. Published April 2001. Originally published as A473–62T. Last previous edition A473–99.on Flat-Rolled and Wrought Stainless

Steel.

Current edition approved May 1, 2009. Published May 2009. Originally approved in 1962. Last previous edition approved in 2001 as A 473 – 01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 01.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 473 – 01 (2009)

A

TABLE 1 Chemical Requirements

Phos-

UNS Type Manga- Other

Carbon, pho- Sulfur, Silicon, Chromium, Nickel, Molyb- Nitro-

Desig- Num- nese, Elements,

% rus, % % % % denum, % gen, %

B

nation ber % %

%

Austenitic Grades

S20100 201 0.15 5.5–7.5 0.060 0.030 1.00 16.0–18.0 3.5–5.5 . . . 0.25

S20200 202 0.15 7.5–10.0 0.060 0.030 1.00 17.0–19.0 4.0–6.0 . . . 0.25

S20500 205 0.12–0.25 14.0–15.5 0.060 0.030 1.00 16.5–18.0 1.00–1.75 . . . 0.32–0.40

S21900 XM-10 0.08 8.0–10.0 0.060 0.030 1.00 19.0–21.5 5.5–7.5 . . . 0.15–0.40

S21904 XM-11 0.04 8.0–10.0 0.060 0.030 1.00 19.0–21.5 5.5–7.5 . . . 0.15–0.40

S28200 . . . 0.15 17.0–19.0 0.045 0.030 1.00 17.0–19.0 . . . 0.75–1.25 0.40–0.60 Cu 0.75–1.25

S30200 302 0.15 2.00 0.045 0.030 1.00 17.0–19.0 8.0–10.0 . . . 0.10

S30215 302B 0.15 2.00 0.045 0.030 2.00–3.00 17.0–19.0 8.0–10.0 . . . . . .

C

S30300 303 0.15 2.00 0.20 0.15 min 1.00 17.0–19.0 8.0–10.0 0.60 .

S30323 303 Se 0.15 2.00 0.20 0.06 1.00 17.0–19.0 8.0–10.0 . . . . . . Se 0.15 min

S30400 304 0.08 2.00 0.045 0.030 1.00 18.0–20.0 8.0–10.5 . . . 0.10

S30403 304L 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–12.0 . . . 0.10

S30500 305 0.12 2.00 0.045 0.030 1.00 17.0–19.0 10.5–13.0 . . . . . .

S30800 308 0.08 2.00 0.045 0.030 1.00 19.0–21.0 10.0–12.0 . . . . . .

S30815 . . . 0.10 0.80 0.040 0.030 1.40–2.00 20.0–22.0 10.0–12.0 . . . 0.14–0.20 Ce 0.03–0.08

S30900 309 0.20 2.00 0.045 0.030 1.00 22.0–24.0 12.0–15.0 . . . . . .

S30908 309S 0.08 2.00 0.045 0.030 1.00 22.0–24.0 12.0–15.0 . . . . . .

S31000 310 0.25 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . .

S31008 310S 0.08 2.00 0.045 0.030 1.50 24.0–26.0 19.0–22.0 . . . . . .

S31254 . . . 0.020 1.00 0.030 0.010 0.80 19.5–20.5 17.5–18.5 6.0–6.5 0.18–0.22 Cu 0.50–1.00

S31400 314 0.25 2.00 0.045 0.030 1.50–3.00 23.0–26.0 19.0–22.0 . . . . . .

S31600 316 0.08 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 0.10

S31603 316L 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00–3.00 0.10

S31700 317 0.08 2.00 0.045 0.030 1.00 18.0–20.0 11.0–15.0 3.0–4.0 0.10

S32100 321 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . . . . . Ti 53Cmin

S34700 347 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . Cb+Ta 103C,

min

S34800 348 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–13.0 . . . . . . Cb+Ta 103C,

min

Ta 0.10

Co 0.20

Austenitic-Ferritic Grades

D

S32550 . . . 0.04 1.50 0.040 0.030 1.00 24.0-27.0 4.5-6.5 2.9-3.9 0.10-0.25 Cu 1.50–2.50

D

S32760 . . . 0.030 1.00 0.030 0.010 1.00 24.0–26.0 6.0–8.0 3.0–4.0 0.20–0.30 Cu 0.50–1.00

W 0.50–1.00

S32950 . . . 0.03 2.00 0.035 0.010 0.60 26.0–29.0 3.5–5.2 1.00–2.50 0.15–0.35

Ferritic Grades

S40500 405 0.08 1.00 0.040 0.030 1.00 11.5–14.5 0.60 . . . . . . A1 0.10–0.30

S42900 429 0.12 1.00 0.040 0.030 1.00 14.0–16.0 0.75 . . . . . .

S43000 430 0.12 1.00 0.040 0.030 1.00 16.0–18.0 0.75 . . . . . .

C

S43020 430F 0.12 1.25 0.06 0.15 min 1.00 16.0–18.0 0.75 0.60 .

S43023 430F Se 0.12 1.25 0.06 0.06 1.00 16.0–18.0 0.75 . . Se 0.15 min

S44600 446 0.20 1.50 0.040 0.030 1.00 23.0–27.0 0.75 . 0.25

Martensitic Grades

S40300 403 0.15 1.00 0.040 0.030 0.50 11.5–13.0 . . . . . . . . . . . .

S41000 410 0.15 1.00 0.040 0.030 1.00 11.5–13.5 0.75 . . . . . . . . .

S41008 410S 0.08 1.00 0.040 0.030 1.00 11.5–13.5 0.75 . . . . . . . . .

S41400 414 0.15 1.00 0.040 0.030 1.00 11.5–13.5 1.25–2.50 . . . . . . . . .

S41425 . . . 0.05 0.50–1.00 0.020 0.005 0.50 12.0–15.0 4.0–7.0 1.50–2.00 0.06–0.12 Cu 0.30

E

S41500 0.05 0.5–1.0 0.030 0.030 0.60 11.5–14.0 3.5–5.5 0.40–0.80 . . .

C

S41600 416 0.15 1.25 0.06 0.15 min 1.00 12.0–14.0 . . . 0.60 .

S41623 416 Se 0.15 1.25 0.06 0.06 1.00 12.0–14.0 . . . . . . . . . Se 0.15 min

S42000 420 Over 0.15 1.00 0.040 0.030 1.00 12.0–14.0 . . . . . . . . . . . .

S43100 431 0.20 1.00 0.040 0.030 1.00 15.0–17.0 1.25–2.50 . . . . . . . . .

S44002 440A 0.60–0.75 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

S44003 440B 0.75–0.95 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

S44004 440C 0.95–1.20 1.00 0.040 0.030 1.00 16.0–18.0 . . . 0.75 . . .

A

Maximum, unless range or minimum is indicated.

B

New designation established in accordance with Practice E 527 and SAE J 1086.

C

At manufacturer’s option; reported only when intentionally added.

D

%Cr + 3.3 3%Mo+16 3 %N$ 40.

E

Wrought version of CA6NM.

5. Manufacture

5.1 Material for forgings shall consist of ingots or blooms, billets, slabs, or bars, either forged or rolled from an ingot, and cut

to the required length by a suitable process. This material, except for ingots, may be specified to Specification A 314.

A 473 – 01 (2009)

TABLE 2 Mechanical Property Requirements

Elongation Brinell

Yield Strength, Tensile Strength, Reduction

in 2 in. Hardness

Type Condition min, ksi min, ksi of Area,

(50 mm) or Number,

A

(MPa) (MPa) min, %

4D, min % max

Austenitic Grades

201, 302, 302B, 303, 303SE, 305, 308, 309, A 30 (205) 75 (515) 40 50 . . .

309S, 310, 310S, 314, 317, 321, 347, 348

202 A 45 (310) 90 (620) 40 50 . . .

205 A 50 (345) 90 (620) 40 50 . . .

304 and 316, Sections 5 in. (127 mm) and A 30 (205) 75 (515) 40 50 . . .

Under

304 and 316, Sections Over 5 in. (127 mm) A 30 (205) 70 (485) 40 50 . . .

304L and 316L A 25 (170) 65 (450) 40 50 . . .

XM-10 and XM-11 A 50 (345) 90 (620) 45 60 . . .

S28200 A 60 (415) 110 (760) 40 55 . . .

S30815 A 45 (310) 87 (600) 40 50 . . .

S31254 A 44 (300) 95 (650) 35 50 . . .

Austenitic-Ferritic Grades

S32550 A 80 (550) 109 (750) 25.0 . . . 290

S32950 A 70 (480) 100 (690) 15 . . . 293

S32760 A 80 (550) 109 (750) 25 . . . 290

Ferritic Grades

430F, 430FSE, 446 A 40 (275) 70 (485) 20 45 223

405 A 30 (205) 60 (415) 20 45 207

429 A 35 (240) 65 (450) 23 45 207

430 A 35 (240) 70 (485) 20 45 217

Martensitic Grades

403, 410, 416, 416SE A 40 (275) 70 (485) 20 45 223

410S A 35 (240) 65 (450) 22 45 217

414 A . . . . . . 298

T 90 (620) 115 (795) 15 45 321

H 100 (690) 125 (860) 15 45 321

S41425 T 120 (825) 95 (655) 15 45 321

S41500 normalized and tempered 90 (620) 115 (795) 15 45 295

420 A . . . . . . 223

B

431 A . . . . . . 277

T 90

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.