ASTM D2440-13(2021)

(Test Method)Standard Test Method for Oxidation Stability of Mineral Insulating Oil

Standard Test Method for Oxidation Stability of Mineral Insulating Oil

SIGNIFICANCE AND USE

4.1 The oxidation stability test of mineral transformer oils is a method for assessing the amount of sludge and acid products formed in a transformer oil when the oil is tested under prescribed conditions. Good oxidation stability is necessary in order to maximize the service life of the oil by minimizing the formation of sludge and acid. Oils that meet the requirements specified for this test in Specification D3487 tend to minimize electrical conduction, ensure acceptable heat transfer, and preserve system life. There is no proven correlation between performance in this test and performance in service, since the test does not model the whole insulation system (oil, paper, enamel, wire). However, the test can be used as a control test for evaluating oxidation inhibitors and to check the consistency of oxidation stability of production oils.

SCOPE

1.1 This test method determines the resistance of mineral transformer oils to oxidation under prescribed accelerated aging conditions. Oxidation stability is measured by the propensity of oils to form sludge and acid products during oxidation. This test method is applicable to new oils, both uninhibited and inhibited, but is not well defined for used or reclaimed oils.

Note 1: A shorter duration oxidation test for evaluation of inhibited oils is available in Test Method D2112.

Note 2: For those interested in the measurement of volatile acidity, reference is made to IEC Method 61125. 2

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2440 − 13 (Reapproved 2021)

Standard Test Method for

1

Oxidation Stability of Mineral Insulating Oil

This standard is issued under the fixed designation D2440; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D664 Test Method for Acid Number of Petroleum Products

by Potentiometric Titration

1.1 This test method determines the resistance of mineral

D974 Test Method for Acid and Base Number by Color-

transformer oils to oxidation under prescribed accelerated

Indicator Titration

aging conditions. Oxidation stability is measured by the

D2112 Test Method for Oxidation Stability of Inhibited

propensity of oils to form sludge and acid products during

Mineral Insulating Oil by Pressure Vessel

oxidation. This test method is applicable to new oils, both

D2272 Test Method for Oxidation Stability of Steam Tur-

uninhibited and inhibited, but is not well defined for used or

bine Oils by Rotating Pressure Vessel

reclaimed oils.

D3487 Specification for Mineral Insulating Oil Used in

NOTE 1—A shorter duration oxidation test for evaluation of inhibited

Electrical Apparatus

oils is available in Test Method D2112.

2.2 IEC Publication:

NOTE 2—For those interested in the measurement of volatile acidity,

2

IEC 61125: 1992 Unused Hydrocarbon–Based Insulating

reference is made to IEC Method 61125.

Liquids—Test Methods for Evaluating the Oxidation Sta-

1.2 The values stated in SI units are to be regarded as

4

bility

standard. No other units of measurement are included in this

standard.

3. Summary of Test Method

1.3 This standard does not purport to address all of the

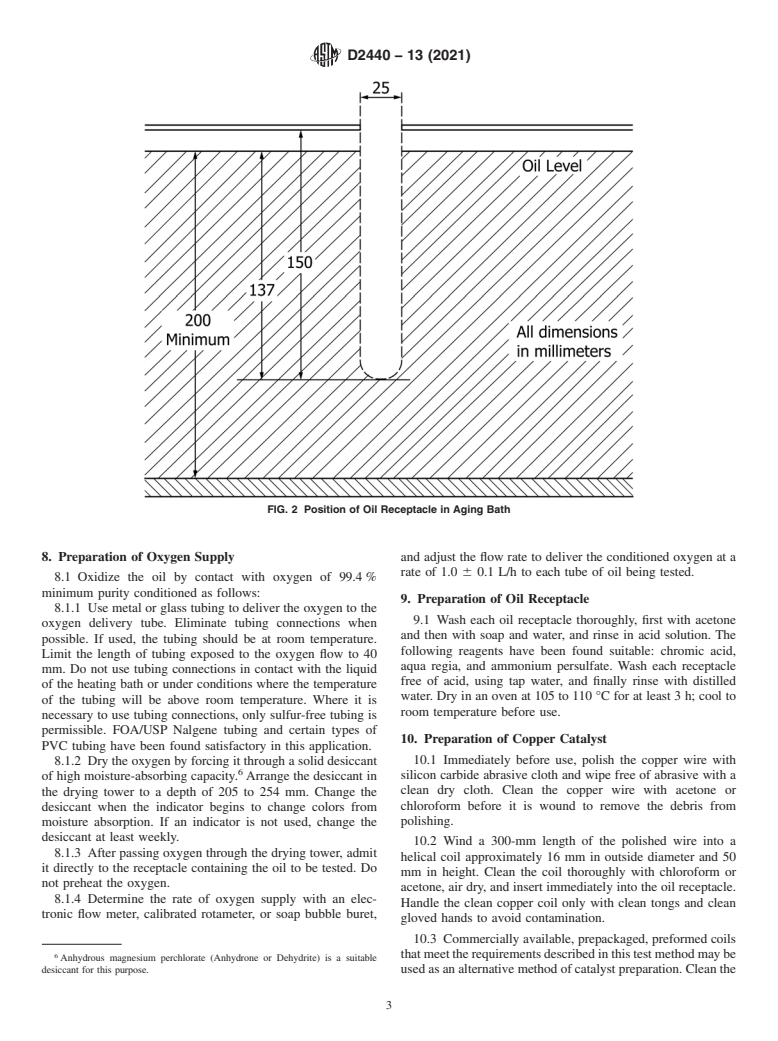

3.1 Atest specimen of mineral transformer oil is oxidized at

safety concerns, if any, associated with its use. It is the

a bath temperature of 110 °C, in the presence of a copper

responsibility of the user of this standard to establish appro-

catalyst coil, by bubbling oxygen through duplicate test speci-

priate safety, health, and environmental practices and deter-

mens for 72 and 164 h, respectively. The oil is evaluated at the

mine the applicability of regulatory limitations prior to use.

end of each aging period by measuring the amount of sludge

1.4 This international standard was developed in accor-

and acid formed. The test specimen is diluted with n-heptane

dance with internationally recognized principles on standard-

and the solution filtered to remove the sludge. The sludge is

ization established in the Decision on Principles for the

dried and weighed. The sludge-free solution is titrated at room

Development of International Standards, Guides and Recom-

temperature with standard alcoholic base to the end point

mendations issued by the World Trade Organization Technical

indicated by the color change (green-brown) of the added

Barriers to Trade (TBT) Committee.

p-naphthol-benzein solution.

2. Referenced Documents

4. Significance and Use

3

2.1 ASTM Standards:

4.1 Theoxidationstabilitytestofmineraltransformeroilsis

B1 Specification for Hard-Drawn Copper Wire

a method for assessing the amount of sludge and acid products

formed in a transformer oil when the oil is tested under

1

prescribed conditions. Good oxidation stability is necessary in

This test method is under the jurisdiction of ASTM Committee D27 on

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

order to maximize the service life of the oil by minimizing the

mittee D27.06 on Chemical Test.

formation of sludge and acid. Oils that meet the requirements

Current edition approved Nov. 1, 2021. Published November 2021. Originally

specified for this test in Specification D3487 tend to minimize

approved in 1965 as D2440 – 65 T. Last previous edition approved in 2013 as

D2440 – 13. DOI: 10.1520/D2440-13R21. electrical conduction, ensure acceptable heat transfer, and

2

Supporting data have been filed at ASTM International Headquarters and may

preserve system life. There is no proven correlation between

beobtainedbyrequestingResearchReportRR:D27-1001.ContactASTMCustomer

performance in this test and performance in service, since the

Service at service@astm.org.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on International Electrotechnical Comm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.