ASTM B552-98e1

(Specification)Standard Specification for Seamless and Welded Copper--Nickel Tubes For Water Desalting Plants

Standard Specification for Seamless and Welded Copper--Nickel Tubes For Water Desalting Plants

SCOPE

1.1 This specification establishes requirements for seamless and welded copper-nickel tubes from 0.625 to 1.25 in. (15.9 to 31.8 mm) in diameter for use in heat exchangers in water desalting plants. The following alloys are involved: Copper Alloy UNS Nos. C70600, C71500, C71640, and C72200.

1.2 The values stated in inch-pound units are the standard. Values given in parentheses are provided for information only.

The following safety hazard caveat pertains only to the test methods of Section described in this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: B 552 – 98

Standard Specification for

Seamless and Welded Copper–Nickel Tubes for Water

Desalting Plants

This standard is issued under the fixed designation B 552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Note 1 was editorially deleted in March 2000.

1. Scope * E 118 Test Methods for Chemical Analysis of Copper-

Chromium Alloys

1.1 This specification establishes requirements for seamless

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

and welded copper-nickel tubes from 0.625 to 1.25 in. (15.9 to

nation of Copper and Copper-Alloy Tubes

31.8 mm) in diameter for use in heat exchangers in water

E 255 Practice for Sampling Copper and Copper Alloys for

desalting plants. The following alloys are involved: Copper

Determination of Chemical Composition

Alloy UNS Nos. C70600, C71500, C71640, and C72200.

E 478 Test Methods for Chemical Analysis of Copper

1.2 The values stated in inch-pound units are the standard.

Alloys

Values given in parentheses are provided for information only.

1.3 The following safety hazard caveat pertains only to the

3. Terminology

test methods of Section 16 described in this specification: This

3.1 For definitions of terms related to copper and copper

standard does not purport to address all of the safety concerns,

alloys, refer to Terminology B 846.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

4. Classification

practices and determine the applicability of regulatory limita-

4.1 Tubes furnished to this specification are classified into

tions prior to its use.

two types, as follows:

2. Referenced Documents 4.1.1 Seamless tube and

4.1.2 Welded tube.

2.1 ASTM Standards:

B 111 Specification for Copper and Copper-Alloy Seamless

5. Ordering Information

Condenser Tubes and Ferrule Stock

5.1 Orders for products under this specification shall include

B 153 Test Method for Expansion (Pin Test) of Copper and

the following information:

Copper-Alloy Pipe and Tubing

5.1.1 ASTM designation and year of issue,

B 543 Specification for Welded Copper and Copper-Alloy

5.1.2 Copper Alloy UNS number designation,

Heat Exchanger Tube

5.1.3 Whether seamless or welded (Section 4),

B 601 Practice for Temper Designations for Copper and

5.1.4 Temper (Section 8),

Copper Alloys—Wrought and Cast

2 5.1.5 Dimensions: diameter and wall thickness (whether

B 846 Terminology for Copper and Copper Alloys

minimum or nominal), and length (Section 12),

E 8 Test Methods for Tension Testing of Metallic Materials

5.1.6 Total number of pieces of each size, and

E 62 Test Methods for Chemical Analysis of Copper and

4 5.1.7 How furnished, whether in straight lengths or coils.

Copper Alloys (Photometric Methods)

5.2 The following options are available and, when required,

E 76 Test Methods for Chemical Analysis of Nickel-Copper

4 are to be specified at the time of placing of the order:

Alloys

5.2.1 Whether further finish processing of welded tube is

needed (6.2.2.1),

This specification is under the jurisdiction of ASTM Committee B05 on Copper 5.2.2 Hydrostatic test (11.2),

and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe

5.2.3 Pneumatic test (11.3),

and Tube.

5.2.4 Certification (Section 20), and

Current edition approved Nov. 10, 1998. Published March 1999. Originally

published as B 552–71. Last previous edition B 552–92.

Annual Book of Standards, Vol 02.01.

3 5

Annual Book of Standards, Vol 03.01. Annual Book of Standards, Vol 03.03.

4 6

Annual Book of Standards, Vol 03.05. Annual Book of Standards, Vol 03.06.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 552

5.2.5 Mill test report (Section 21). 8. Temper

8.1 Tempers within this specification are as defined in

6. Materials and Manufacture

Practice B 601.

6.1 Material:

8.1.1 Seamless Tube—The product shall be furnished in

6.1.1 The material of manufacture shall be cast billets of

either the O61 (annealed), or the H55 (light drawn, light

Copper Alloys UNS Nos. C70600, C71500, C71640, and

cold-worked) temper, as specified in the ordering information.

C72200 as specified in the ordering information, and shall be

8.1.2 Welded Tube—The product shall be furnished in either

of such quality and soundness as to be suitable for processing

the WO61 (welded and annealed) or the WC55 (welded and

into finished lengths or coils of tube to meet the properties

light cold worked) temper as specified in the ordering infor-

prescribed herein.

mation.

6.2 Manufacture:

8.2 Tubes shall conform to the tensile requirements shown

6.2.1 Seamless Tube— The product shall be manufactured

in Table 2.

by such hot extrusion or piercing, and subsequent cold working

9. Mechanical Property Requirements

and annealing as to produce a uniform, seamless wrought

structure in the finished product.

9.1 Tensile Strength:

6.2.2 Welded Tube— The product shall be manufactured

9.1.1 The product shall conform with the tensile strength

from cold rolled strip which is subsequently formed and

requirements prescribed in Table 2 for the temper, alloy and

welded by an automatic welding process.

type specified in the ordering information when tested in

6.2.2.1 As-welded tubes are permitted to have further pro-

accordance with Test Methods E 8.

cessing when agreement is established between the manufac-

10. Performance Requirements

turer or supplier and purchaser.

6.2.3 The product shall be cold worked and annealed as

10.1 Expansion Test Requirements:

necessary to meet properties of the temper specified.

10.1.1 Tube specimens selected for test shall withstand the

expansion shown in Table 3 at one end when tested in

7. Chemical Composition

accordance with Test Method B 153. The expanded tube shall

show no cracking or rupture visible to the unaided eye.

7.1 The product shall conform to the chemical composition

requirements specified in Table 1 for the Copper Alloy UNS 10.2 Flattening Test Requirements:

10.2.1 Tube specimens approximately 4 ft (1.22 m) long

number designation specified in the ordering information.

7.2 These composition limits do not preclude the presence shall be tested in the annealed condition by flattening on

different elements throughout the length. Each element shall be

of other elements. When required, limits for unnamed elements

shall be established and analysis required by agreement be- flattened by one stroke of a press. The term “flattened” shall be

interpreted as follows: a micrometer set at three times the wall

tween the manufacture or supplier and purchaser.

7.2.1 For copper alloys in which copper is specified as the thickness shall pass over the tube freely throughout the

flattened part except as the points where the change in element

remainder, copper may be taken as the difference between the

sum of all the elements analyzed and 100 %. of flattening takes place.

10.2.1.1 For seamless tube the flattened elements shall not

7.2.1.1 When all the elements in Table 1 are analyzed, their

sum shall be as shown in the following table: show cracking or rupture visible to the unaided eye. Superficial

ruptures resulting from surface imperfections shall not be cause

Copper Alloy UNS No. Copper Plus Named Elements, % min

for rejection.

C70600 99.5

10.2.1.2 For seam-welded tube, the weld shall be placed in

C71500 99.5

a position of maximum bend for at least one fourth of the

C71640 99.5

C72200 99.8

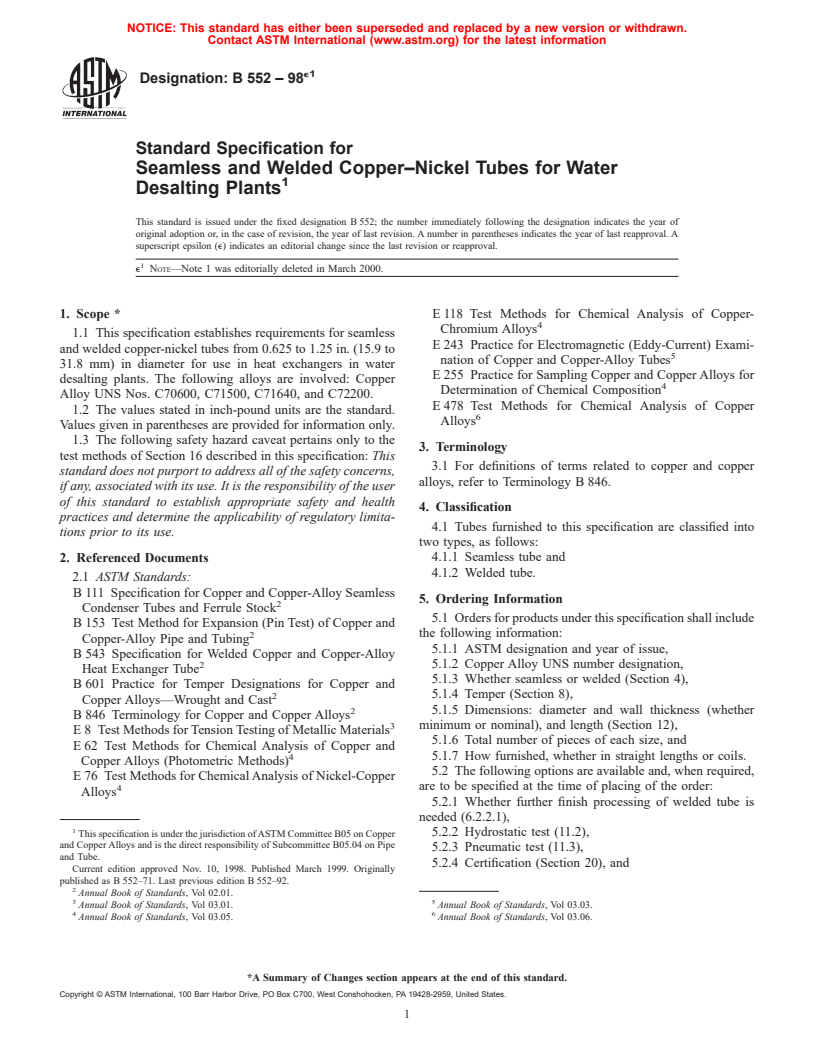

TABLE 2 Tensile Requirements

Temper

Copper Alloy Tensile Strength,

TABLE 1 Chemical Requirements

UNS No. min, ksi (MPa)

Standard Former

Composition, %

C70600 O61 annealed 40 (275)

Element Copper Alloy UNS No.

W061 welded and annealed 40 (275)

C70600 C71500 C71640 C72200 H55 light drawn, light cold worked 45 (310)

WC55 welded and light cold worked 45 (310)

Copper (incl silver) remainder remainder remainder remainder

C71500 O61 annealed 52 (360)

A A A A

Lead, max 0.05 0.05 0.05 0.05

WO61 welded and annealed 52 (360)

Iron 1.0–1.8 0.40–1.0 1.7–2.3 0.5–1.0

H55 light drawn, light cold worked 54 (370)

A A A A

Zinc, max 1.0 1.0 1.0 1.0

WC55 welded and light cold worked 54 (370)

Nickel (incl cobalt) 9.0–11.0 29.0–33.0 29.0–32.0 15.0–18.0

C71640 O61 annealed 63 (435)

Manganese 1.0 max 1.0 max 1.5–2.5 1.0

WO61 welded and annealed 63 (435)

Chromium . . . . . . . . . 0.30–0.70

H55 light drawn, light cold worked 75 (515)

AAAA

Other named elements

WC55 welded and light cold worked 75 (515)

Copper + elements with specific . . . . . . . . . 99.5 min

C72200 O61 annealed 45 (310)

limits

WO61 welded and annealed 45 (310)

A

When the product is for subsequent welding applications and so specified by H55 light drawn, light cold worked 50 (345)

WC55 welded and light cold worked 50 (345)

the purchaser, zinc shall be 0.50 % max, lead 0.02 % max, phosphorus 0.02 %

max, sulfur 0.02 max, and carbon 0.05 % max.

B 552

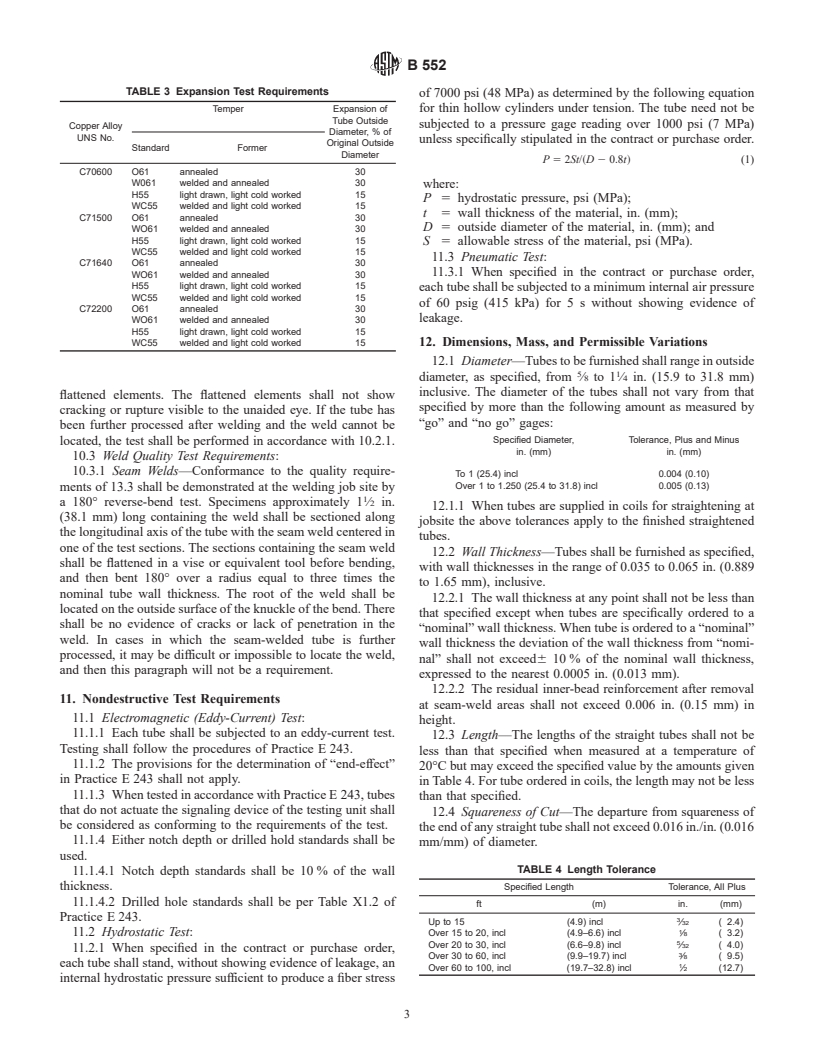

TABLE 3 Expansion Test Requirements

of 7000 psi (48 MPa) as determined by the following equation

Temper Expansion of for thin hollow cylinders under tension. The tube need not be

Tube Outside

subjected to a pressure gage reading over 1000 psi (7 MPa)

Copper Alloy

Diameter, % of

UNS No.

unless specifically stipulated in the contract or purchase order.

Original Outside

Standard Former

Diameter

P 5 2St/~D 2 0.8t! (1)

C70600 O61 annealed 30

W061 welded and annealed 30

where:

H55 light drawn, light cold worked 15

P 5 hydrostatic pressure, psi (MPa);

WC55 welded and light cold worked 15

t 5 wall thickness of the material, in. (mm);

C71500 O61 annealed 30

D 5 outside diameter of the material, in. (mm); and

WO61 welded and annealed 30

H55 light drawn, light cold worked 15

S 5 allowable stress of the material, psi (MPa).

WC55 welded and light cold worked 15

11.3 Pneumatic Test:

C71640 O61 annealed 30

11.3.1 When specified in the contract or purchase order,

WO61 welded and annealed 30

H55 light drawn, light cold worked 15

each tube shall be subjected to a minimum internal air pressure

WC55 welded and light cold worked 15

of 60 psig (415 kPa) for 5 s without showing evidence of

C72200 O61 annealed 30

leakage.

WO61 welded and annealed 30

H55 light drawn, light cold worked 15

WC55 welded and light cold worked 15 12. Dimensions, Mass, and Permissible Variations

12.1 Diameter—Tubes to be furnished shall range in outside

5 1

diameter, as specified, from ⁄8 to 1 ⁄4 in. (15.9 to 31.8 mm)

inclusive. The diameter of the tubes shall not vary from that

flattened elements. The flattened elements shall not show

specified by more than the following amount as measured by

cracking or rupture visible to the unaided eye. If the tube has

“go” and “no go” gages:

been further processed after welding and the weld cannot be

Specified Diameter, Tolerance, Plus and Minus

located, the test shall be performed in accordance with 10.2.1.

in. (mm) in. (mm)

10.3 Weld Quality Test Requirements:

10.3.1 Seam Welds—Conformance to the quality require-

To 1 (25.4) incl 0.004 (0.10)

Over 1 to 1.250 (25.4 to 31.8) incl 0.005 (0.13)

ments of 13.3 shall be demonstrated at the welding job site by

a 180° reverse-bend test. Specimens approximately 1 ⁄2 in.

12.1.1 When tubes are supplied in coils for straightening at

(38.1 mm) long containing the weld shall be sectioned along

jobsite the above tolerances apply to the finished straightened

the longitudinal axis of the tube with the seam weld centered in

tubes.

one of the test sections. The sections containing the seam weld

12.2 Wall Thickness—Tubes shall be furnished as specified,

shall be flattened in a vise or equivalent tool before bending,

with wall thicknesses in the range of 0.035 to 0.065 in. (0.889

and then bent 180° over a radius equal to three times the

to 1.65 mm), inclusive.

nominal tube wall thickness. The root of the weld shall be

12.2.1 The wall thickness at any point shall not be less than

located on the outside surface of the knuckle of the bend. There

that specified except when tubes are specifically ordered to a

shall be no evidence of cracks or lack of penetration in the

“nominal” wall thickness. When tube is ordered to a “nominal”

weld. In cases in which the seam-welded tube is further

wall thickness the deviation of the wall thickness from “nomi-

processed, it may be difficult or impossible to locate the weld,

nal” shall not exceed6 10 % of the nominal wall thickness,

and then this paragraph will not be a requirement.

expressed to the nearest 0.0005 in. (0.013 mm).

12.2.2 The residual inner-bead reinforcement after removal

11. Nondestructive Test Requirements

at seam-weld areas shall not exceed 0.006 in. (0.15 mm) in

11.1 Electromagnetic (Eddy-Current) Test:

height.

11.1.1 Each tube shall be subjected to an eddy-current test.

12.3 Length—The lengths of the straight tubes shall not be

Testing shall follow the procedures of Practice E 243.

less than that specified when measured at a temperature of

11.1.2 The provisions for the determination of “end-effect”

20°C but may exceed the specified value by the amounts given

in Practice E 243 shall not apply.

in Table 4. For tube ordered in coils, the length may not be less

11.1.3 When tested in accordance with Practice E 243, tubes

than that specified.

that do not actuate the signaling device of the testing unit shall

12.4 Squareness of Cut—The departure from squareness of

be considered as conforming to the requirements of the test.

the end of any straight tube shall not exceed 0.016 in./in. (0.016

11.1.4 Either notch depth or drilled hold standards shall be

mm/mm) of diameter.

used.

TABLE 4 Length Tolerance

11.1.4.1 Notch depth standards shall be 10 % of the wall

thickness. Specified Length Tolerance, All Plus

11.1.4.2 Drilled hole standards shall be per Table X1.2 of

ft (m) in. (mm)

Practice E 243.

Up to 15 (4.9) incl ⁄32 ( 2.4)

11.2 Hydrostatic Test: Over 15 to 20, incl (4.9–6.6) incl ⁄8 ( 3.2)

Over 20 to 30, incl (6.6–9.8) incl ⁄32 ( 4.0)

11.2.1 When specified in the contract or purchase order,

Over 30 to 60, incl (9.9–19.7) incl ⁄8 ( 9.5)

each tube shall stand, without showing evidence of leakage, an

Over 60 to 100, incl (19.7–32.8) incl ⁄2 (12.7)

internal hydrostatic pressure sufficient to produce a fiber stress

B 552

12.5 Tubes furnished in straight lengths shall be reasonably 14.2.1.3 Because of the discontinuous nature of the process-

straight when inspected at the mill. The maximum curvature ing of castings into wrought products, it is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.