ASTM D409-02(2007)e1

(Test Method)Standard Test Method for Grindability of Coal by the Hardgrove-Machine Method

Standard Test Method for Grindability of Coal by the Hardgrove-Machine Method

SIGNIFICANCE AND USE

This test method develops a measurement of grinding or pulverizing characteristics that can be used to evaluate the yield, or energy input, or both, required in a grinding or pulverizing process.

SCOPE

1.1 This test method covers the determination of the relative grindability or ease of pulverization of coals in comparison with coals chosen as standards. A prepared and sized sample receives a definite amount of grinding energy in a miniature pulverizer, and the size consist of the pulverized product is determined by sieving. The resultant size consist is used to produce an index relative to the ease of grinding (Hardgrove Grindability Index (HGI)).

1.1.1 Some coals, such as some high-volatile bituminous, subbituminous, and lignite coals, can undergo physical change as the natural or seam moisture is released during handling and preparation. This change is often sufficient to alter the grindability characteristics that will be reported when tested in the laboratory and could produce different indices dependent on the conditions of drying and the moisture level of the 1.18-mm by 600-m (No. 16 No. 30) (see Test Method D 4749) materials used for the test. Therefore, the repeatability and reproducibility cited in this test method may not apply for these high-volatile bituminous, subbituminous, and lignite coals.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses may be approximate.

1.3 It is recognized that the term weight is considered equivalent to mass as used in this test method.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D409–02 (Reapproved 2007)

Standard Test Method for

Grindability of Coal by the Hardgrove-Machine Method

This standard is issued under the fixed designation D409; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Section 10.2 was editorially corrected in October 2007.

1. Scope 2. Referenced Documents

2 3

1.1 This test method covers the determination of the 2.1 ASTM Standards:

relative grindability or ease of pulverization of coals in D2013 Practice for Preparing Coal Samples for Analysis

comparison with coals chosen as standards. A prepared and D2234/D2234M PracticeforCollectionofaGrossSample

sized sample receives a definite amount of grinding energy in of Coal

a miniature pulverizer, and the size consist of the pulverized D4749 Test Method for Performing the Sieve Analysis of

product is determined by sieving. The resultant size consist is Coal and Designating Coal Size

used to produce an index relative to the ease of grinding E11 Specification for Wire Cloth and Sieves for Testing

(Hardgrove Grindability Index (HGI)). Purposes

1.1.1 Some coals, such as some high-volatile bituminous,

3. Significance and Use

subbituminous, and lignite coals, can undergo physical change

asthenaturalorseammoistureisreleasedduringhandlingand 3.1 Thistestmethoddevelopsameasurementofgrindingor

pulverizing characteristics that can be used to evaluate the

preparation. This change is often sufficient to alter the grind-

ability characteristics that will be reported when tested in the yield, or energy input, or both, required in a grinding or

pulverizing process.

laboratory and could produce different indices dependent on

theconditionsofdryingandthemoisturelevelofthe1.18-mm

4. Apparatus

by 600-µm (No. 16 3No. 30) (see Test Method D4749)

4.1 Air-Drying Oven—A device for passing slightly heated

materials used for the test. Therefore, the repeatability and

air over the sample. The oven shall be capable of maintaining

reproducibilitycitedinthistestmethodmaynotapplyforthese

a temperature of 10 to 15°C (18 to 27°F) above room

high-volatile bituminous, subbituminous, and lignite coals.

temperature with a maximum oven temperature of 40°C

1.2 The values stated in SI units are to be regarded as the

(104°F) unless ambient temperature is above 40°C, in which

standard.Thevaluesgiveninparenthesesmaybeapproximate.

case ambient temperature shall be used. In the case of easily

1.3 It is recognized that the term weight is considered

oxidized coals, the temperature shall not be over 10°C (18°F)

equivalent to mass as used in this test method.

above room temperature unless ambient temperature is above

1.4 This standard does not purport to address all of the

37°C(100°F)inwhichcaseambienttemperatureshallbeused.

safety concerns, if any, associated with its use. It is the

Air changes shall be at the rate of 1 to 4 air volumes of oven

responsibility of the user of this standard to establish appro-

capacity per minute.

priate safety and health practices and determine the applica-

4.2 Drying Pans—Drying pans of sufficient size so that the

bility of regulatory limitations prior to use.

sample may be spread to a depth of not more than 25 mm (1.0

in.) with sides not more than 38 mm (1.5 in.) high. The pans

This test method is under the jurisdiction of ASTM Committee D05 on Coal

shall be nonreactive with coal and unaffected by the method of

and Coke and is the direct responsibility of D05.07 on Physical Characteristics of

air drying selected.

Coal.

4.3 Balances—Two balances may be required: one with a

CurrenteditionapprovedOct.1,2007.PublishedJuly2002.Originallyapproved

e1

in 1951. Last previous edition approved in 2002 as D409– .

sensitivity of 10 mg and a minimum capacity of 800 g and one

Forinformationconcerningtheexperimentalworkonwhichthistestmethodis

with a sensitivity of 0.5 g in 1000 g and sufficient capacity to

based, see paper by Hardgrove, R. M., “Grindability of Coal,” Transactions,

American Society of Mechanical Engineers, Vol 54, F.S.P., p. 37, 1932.

D05.07.02 on Grindability is conducting ongoing investigations in regard to

quality control during preparation, distribution, and use of standard reference

materials and during preparation and testing of actual samples. Annual Book of ASTM Standards, Vol 05.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D409–02 (2007)

NOTE 4—The most frequently used plate mill can be equipped with

weigh a$1000-g sample along with the drying pan. A single

“fine” or “coarse” plates. One independent study has found evidence of

balance meeting these specifications is permitted.

differences in percent recovery resulting from use of different types of

4.3.1 Calibration Weights—These calibration weights shall

plate. Only the coarse plate should be used in preparation of both HGI

beusedtomonitortheresponseofeachbalanceovertherange

calibration standards and unknown samples.

of normal use each time HGIs are determined.

4.7 Mechanical Sieving Machine—The mechanical sieving

4.4 SampleDivider—Anenclosedriffledividerasdescribed

machine shall accept an assembly of vertically nested circular

in Method D2013 is required and shall be used.

sieves of 203 mm (8 in.) in diameter, together with cover and

4.5 Standard Sieves—A working set of circular, standard

receiver. The machine shall simulate the motions given testing

testing sieves which are 203 mm (8 in.) in diameter and

sieves during hand sieving by imparting a horizontal oscilla-

conform to Specification E11, are required in the following

tory motion of approximately 28-mm (1.1-in.) amplitude at a

sizes, together with cover and catch pan (receiver):

rate of approximately 300 oscillations or cycles per minute

Sieve Designation

(cpm). Simultaneously, the top of the oscillating assembly is

Standard Alternate

(ISO Designation) (U.S.A. Designation)

struck at a rate of approximately 150 blows per minute by a

weight of 1.9 kg (4.2 lb) moving through a vertical distance of

16.0 mm ⁄8 in.

approximately 28 mm (1.1 in.) under the influence of gravity.

4.75 mm No. 4

2.36 mm No. 8

4.8 Grindability Machine—The Hardgrove Grindability

1.18 mm No. 16

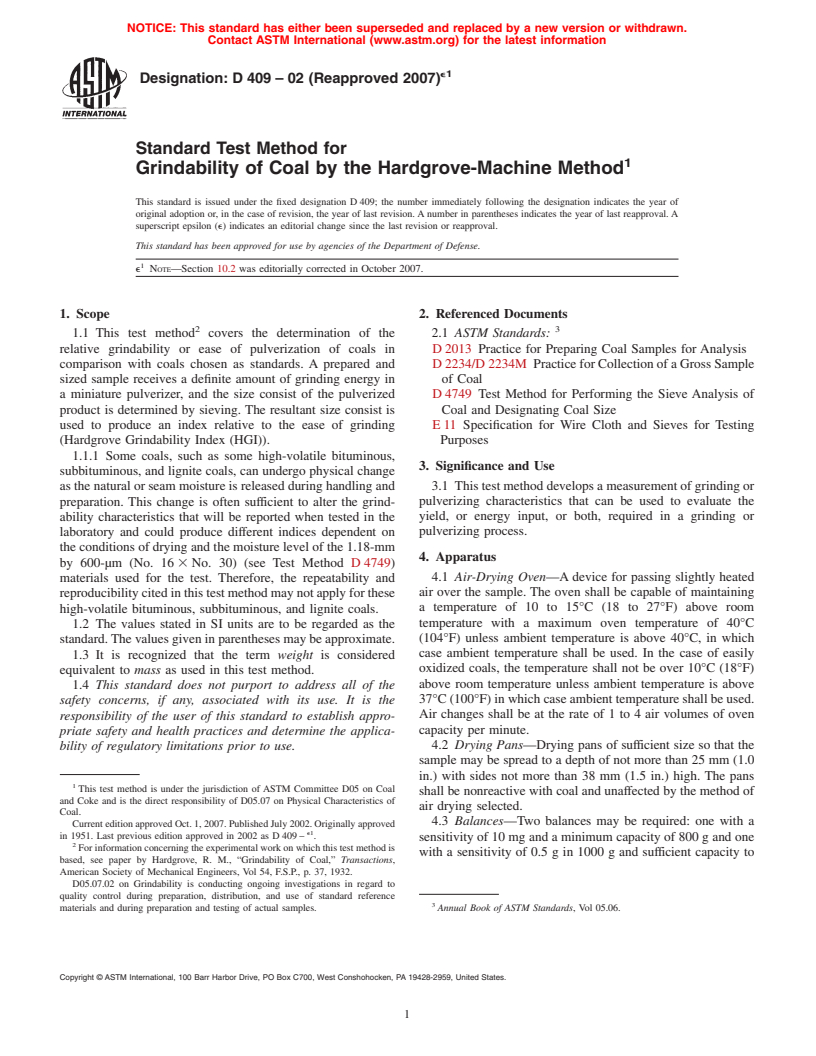

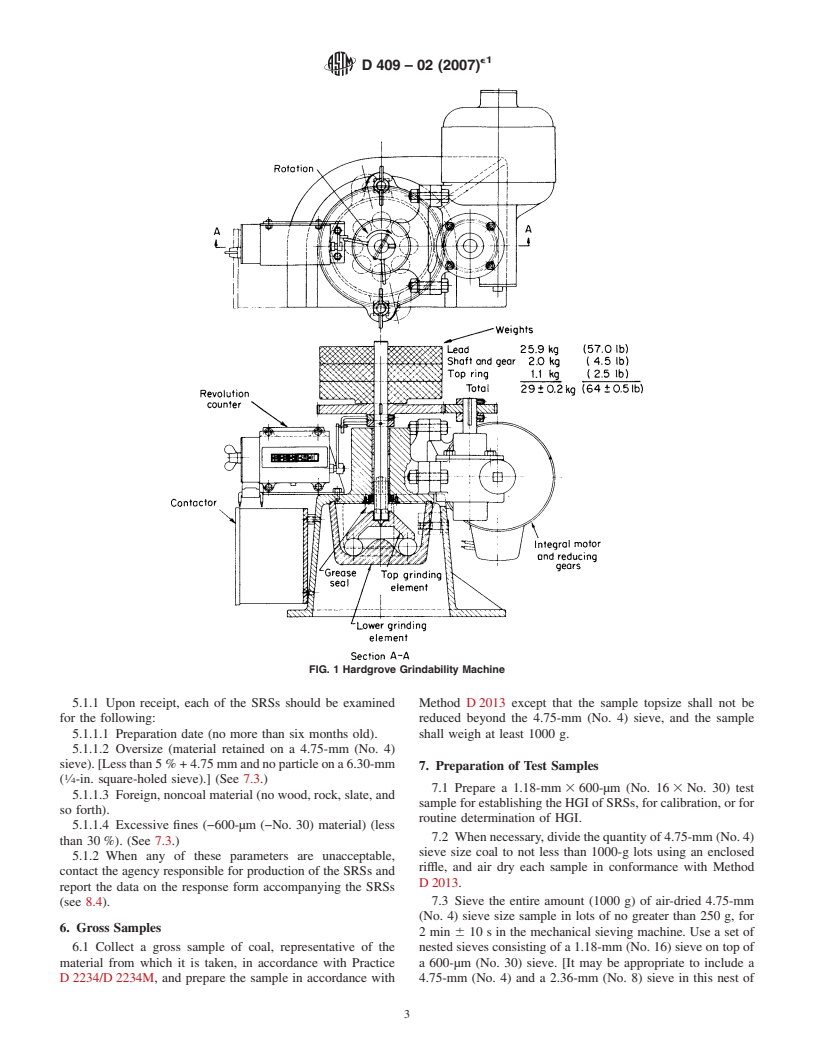

Machine such as is shown in Fig. 1 is required for this test.

600 µm No. 30

EssentialtolerancesandspecificationsareshowninFig.2.The

75 µm No. 200

grindability machine includes a stationary grinding bowl of

4.5.1 These working sieves must be periodically inspected

polished cast iron, with a circular horizontal track that holds

for wear or damage.Any excessively worn or damaged sieves

eight polished steel balls, each 25.40 6 0.13 mm (1.000 6

(sieveswithholes,tearscracks,andsoforth,seeNote1).must

0.005 in.) in diameter. The balls are driven by an upper

be replaced immediately, and the HGI calibration procedure

grinding ring which is rotated at 20 6 1 r/min by means of the

must be repeated after the damaged sieves are replaced (see

upperspindleandwhich,inturn,isdrivenbyanelectricmotor

Section 8). Since the HGI depends upon the sieve analysis and

through reduction gears and, in newer models, belts. Weights

since the 75-µm (No. 200) sieve is fragile, it is recommended

are added to the driving spindle so that the total vertical force

that at least one set of working sieves be obtained, identified,

on the balls as a result of the weights, shaft, top grinding ring,

andusedexclusivelyforHGIdeterminationsandthatonlythis

and gear is equal to 29.0 6 0.2 kg (64 6 0.5 lb). The machine

exclusive set of sieves be used.

is equipped with a counter and automatic device which can be

NOTE 1—Excessive wear may be indicated by poor repeatability or by

properly adjusted for stopping the machine after 60 6 0.25

failureofqualitycontrolchecks(8.1.1)toagreereasonablywiththeinitial

revolutions.

calibration data.

4.8.1 Thepositionofthecountertripmechanismbeforeand

4.5.2 Normal wear on sieves is compensated by the use of

after the test must be used to determine the number of

proper standard reference samples (SRSs) and proper calibra- revolutions completed. Sometimes, it may be necessary to

tion of equipment; excessive wear such as holes or tears in the position strategically the counter trip mechanism at the begin-

sieve cloth, and so forth is not compensated by SRSs. Because ning of the test to accomplish the desired number of revolu-

excessive wear is unacceptable, inspect sieves carefully before tions(thatis,watchwherethetripmechanismisinitially,count

each test to ensure the absence of excessive wear. For the 75- the number of revolutions from the point of origin, determine

and 600-µm (No. 200 and 30) sieves, use only a soft-bristled where the trip mechanism is at the end of the test, and

brush (such as short-bristled camel hair) for brushing and determine if the specified 60 6 0.25 revolutions are obtained.

cleaning. If not, adjust the position of the trip mechanism at the

beginning of the test until the specified number of revolutions

NOTE 2—Itisgoodpracticetokeepaseparateprimary75-µm(No.200)

are obtained).

check sieve to be used only to check the 75-µm working sieve described

in 4.5.1 when the working sieve becomes suspect. This check is done by

runningacomparativeHGItestbetweenthetwo75-µmsieves.Useofthe 5. Standard Reference Samples (SRSs) for Calibration

workingsieveforHGIsshouldbediscontinuedifHGIdifferencebetween

5.1 Four SRSs prepared especially for this purpose (in

the sieves is greater than 1 HGI unit.

accordance with Annex A1) and representing grindability

4.6 Crusher—A laboratory plate mill capable of reducing

indices of approximately 40, 60, 80, and 100 shall be used for

4.75-mm (No. 4) sieve size coal particles with the production

calibration. (See Section 8.)

of a minimum of minus 600-µm (minus No. 30) sieve size

material (Note 3). The crusher plates shall be serrated and

about 100 mm (4 in.) in diameter (Note 4). The distance

D05.07 Minutes, J. Gardner, Georgia Power and G. Linton, October 1990.

betweentheplatesshallbeadjustable,andtherelativespeedof

Primary standard reference samples are available from The Pennsylvania State

rotation of the plates shall not exceed 200 r/min.

University,RonaldS.WascoTheEnergyInstitute,C-211CUL,UniversityPark,PA

16802, Telephone: 814-863-5384, Fax: 814-863-7432, email: rxw19@psu.edu,

NOTE 3—Evidence from HGI standard reference sample user-response

www.energy.psu.edu/HGI. ASTM Subcommittee D05.07 and the ASTM/DOE

forms (8.4) indicates that the median value of percent recovery of the

Liaison Task Group maintain oversight for production of only the primary standard

4.75-mm (No. 4) material as 1.18-mm by 600-µm (Nos. 16 by 30)

reference samples. Secondary standard reference samples are available from other

material, regardless of the HGI level, is about 55%. sources.

e1

D409–02 (2007)

FIG. 1 Hardgrove Grindability Machine

5.1.1 Upon receipt, each of the SRSs should be examined Method D2013 except that the sample topsize shall not be

for the following: reduced beyond the 4.75-mm (No. 4) sieve, and the sample

5.1.1.1 Preparation date (no more than six months old). shall weigh at least 1000 g.

5.1.1.2 Oversize (material retained on a 4.75-mm (No. 4)

sieve).[Lessthan5%+4.75mmandnoparticleona6.30-mm

7. Preparation of Test Samples

( ⁄4-in. square-holed sieve).] (See 7.3.)

7.1 Prepare a 1.18-mm 3600-µm (No. 16 3No. 30) test

5.1.1.3 Foreign, noncoal material (no wood, rock, slate, and

sampleforestablishingtheHGIofSRSs,forcalibration,orfor

so forth).

routine determination of HGI.

5.1.1.4 Excessive fines (−600-µm (−No. 30) material) (less

7.2 Whennecessary,dividethequantityof4.75-mm(No.4)

than 30%). (See 7.3.)

sieve size coal to not less than 1000-g lots using an enclosed

5.1.2 When any of these parameters are unacceptable,

riffle, and air dry each sample in conformance with Method

contact the agency responsible for production of the SRSs and

D2013.

report the data on the response form accompanying the SRSs

7.3 Sieve the entire amount (1000 g) of air-dried 4.75-mm

(see 8.4).

(No. 4) sieve size sample in lots of no greater than 250 g, for

6. Gross Samples

2 min 6 10 s in the mechanical sieving machine. Use a set of

6.1 Collect a gross sample of coal, representative of the nested sieves consisting of a 1.18-mm (No. 16) sieve on top of

a 600-µm (No. 30) sieve. [It may be appropriate to include a

material from which it is taken, in accordance with Practice

D2234/D2234M, and prepare the sample in accordance with 4.75-mm (No. 4) and a 2.36-mm (No. 8) sieve in this nest of

e1

D409–02 (2007)

8.2 For each calibration, process four standard reference

samples with indices of approximately 40, 60, 80, and 100

separately as described above. Process the samples as outlined

below(Section9),andusetheresultstodeterminetheequation

ofthelinebyuseofthesumofleastsquaresmethod(8.3)and,

if desired, to prepare a calibration chart (8.3.1).

8.3 Bythemethodofthesumofleastsquares,determinethe

equation of the line that best fits the analytical results obtained

from the four HGI SRSs. An example HGI calculation from

SRS data, shown in Table 1, illustrates this method.

8.3.1 Example—SumofLeastSquaresFit—Theequationof

the line for the sum of least squares takes the form of:

Y 5 a 1 bX (1)

where:

Y = HGI,

a = y axis intercept,

b = slope of the regression line, and

X = calculated−75-µm (−No. 200) material.

a and b can be determined by use of the following table and

equations:

YX X XY

40 4.35 18.92 174.00

FIG. 2 Grinding Elements of Hardgrove Machine

58 7.14 50.98 414.12

83 10.44 108.99 866.52

100 13.38 179.02 1338.00

(Y = 281 (X = 35.31 ((X ) = 357.91 ((XY ) = 2792.64

sieves to record the particle size distribution and the topsize of

the sample.] Weigh and record the mass of each sieve size. (Y(X 2 (X(XY

a 5 (2)

2 2

7.4 Stage crush the material retained on the 1.18-mm (No. n(X 2 ~(X!

16) sieve with the crusher adjusted so that only the largest

particles are crushed. Take the crushed material in lots no

n(XY 2 ( X(Y

b 5 (3)

2 2

greaterthan250gandsievefor2min 610sinthemechanical

n(X 2 ~(X!

sieving machine. Return the oversize to the crusher, after

settingthecrushersothatonlythelargestparticlesarecrushed.

where:

Continue the stage crushing and sieving procedure until all the

(Y = 281,

material passes the 1.18-mm sieve. Retain the 1.18-

(X = 35.31,

mm 3600-µm (No. 16 3No. 30) material.

((X ) = 357.91,

7.5 Mix well all

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.