ASTM C1685-15

(Specification)Standard Specification for Pneumatically Applied High-Temperature Fiber Thermal Insulation for Industrial Applications

Standard Specification for Pneumatically Applied High-Temperature Fiber Thermal Insulation for Industrial Applications

SCOPE

1.1 This specification covers the composition, thermal performance, sound absorption performance, and physical properties of high-temperature fiber thermal insulation for use at temperatures from ambient to 3000°F (1649°C).

1.2 The dry, loose high-temperature fibers shall be pneumatically conveyed to a chamber where they are mixed with a water-based chemical binder and then conveyed to a nozzle.

1.3 The pneumatically applied, high-temperature fiber insulation is intended for use in industrial applications on flat, or nearly flat, surfaces. It is not intended for use on pipes.

1.4 This specification addresses the use performance of this material in both thermal and acoustical applications.

1.5 This specification does not address the requirements for fire-resistive insulation, but it does not preclude this material’s use in that capacity.

1.6 This is a material specification only and is not intended to cover methods of application that are provided by the manufacturer.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1685 −15

Standard Specification for

Pneumatically Applied High-Temperature Fiber Thermal

1

Insulation for Industrial Applications

This standard is issued under the fixed designation C1685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C133 Test Methods for Cold Crushing Strength and Modu-

lus of Rupture of Refractories

1.1 This specification covers the composition, thermal

C165 Test Method for Measuring Compressive Properties of

performance, sound absorption performance, and physical

Thermal Insulations

properties of high-temperature fiber thermal insulation for use

C168 Terminology Relating to Thermal Insulation

at temperatures from ambient to 3000°F (1649°C).

C177 Test Method for Steady-State Heat Flux Measure-

1.2 The dry, loose high-temperature fibers shall be pneu-

ments and Thermal Transmission Properties by Means of

matically conveyed to a chamber where they are mixed with a

the Guarded-Hot-Plate Apparatus

water-based chemical binder and then conveyed to a nozzle.

C201 Test Method for Thermal Conductivity of Refractories

1.3 The pneumatically applied, high-temperature fiber insu-

C356 Test Method for Linear Shrinkage of Preformed High-

lation is intended for use in industrial applications on flat, or

Temperature Thermal Insulation Subjected to Soaking

nearly flat, surfaces. It is not intended for use on pipes.

Heat

C390 Practice for Sampling and Acceptance of Thermal

1.4 This specification addresses the use performance of this

Insulation Lots

material in both thermal and acoustical applications.

C411 Test Method for Hot-Surface Performance of High-

1.5 This specification does not address the requirements for

Temperature Thermal Insulation

fire-resistive insulation, but it does not preclude this material’s

C423 Test Method for SoundAbsorption and SoundAbsorp-

use in that capacity.

tion Coefficients by the Reverberation Room Method

1.6 This is a material specification only and is not intended

C447 Practice for Estimating the Maximum Use Tempera-

to cover methods of application that are provided by the

ture of Thermal Insulations

manufacturer.

C665 Specification for Mineral-Fiber Blanket Thermal Insu-

1.7 The values stated in inch-pound units are to be regarded

lation for Light Frame Construction and Manufactured

as standard. The values given in parentheses are mathematical

Housing

conversions to SI units that are provided for information only

C795 Specification for Thermal Insulation for Use in Con-

and are not considered standard.

tact with Austenitic Stainless Steel

C1045 Practice for Calculating Thermal Transmission Prop-

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the erties Under Steady-State Conditions

responsibility of the user of this standard to establish appro- C1104/C1104M Test Method for Determining the Water

priate safety and health practices and determine the applica- Vapor Sorption of Unfaced Mineral Fiber Insulation

bility of regulatory limitations prior to use. C1113 Test Method for Thermal Conductivity of Refracto-

ries by Hot Wire (Platinum Resistance Thermometer

2. Referenced Documents

Technique)

2

2.1 ASTM Standards:

E84 Test Method for Surface Burning Characteristics of

C71 Terminology Relating to Refractories

Building Materials

E136 Test Method for Behavior of Materials in a Vertical

1

This specification is under the jurisdiction of ASTM Committee C16 on

Tube Furnace at 750°C

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on

E605 Test Methods for Thickness and Density of Sprayed

Blanket and Loose Fill Insulation.

Fire-Resistive Material (SFRM) Applied to Structural

Current edition approved June 1, 2015. Published July 2015. Last previous

edition was approved in 2008 as C1685 –08. DOI: 10.1520/C1685-15.

Members

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

E2231 Practice for Specimen Preparation and Mounting of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Pipe and Duct Insulation Materials to Assess Surface

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Burning Characteristics

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

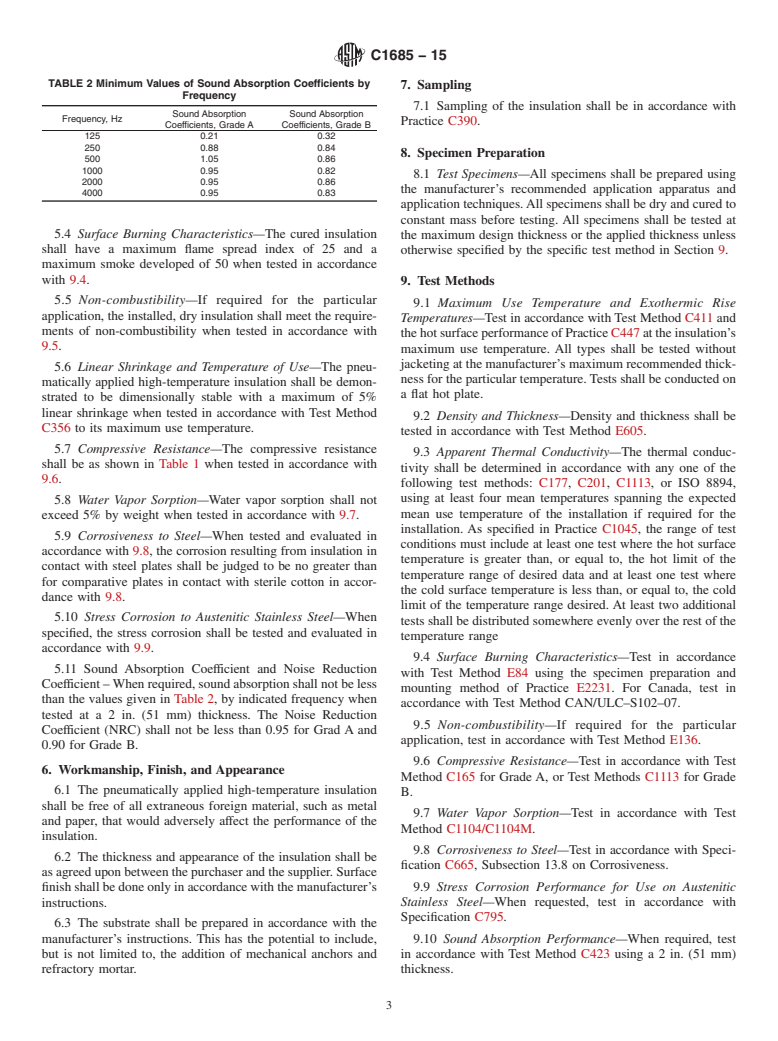

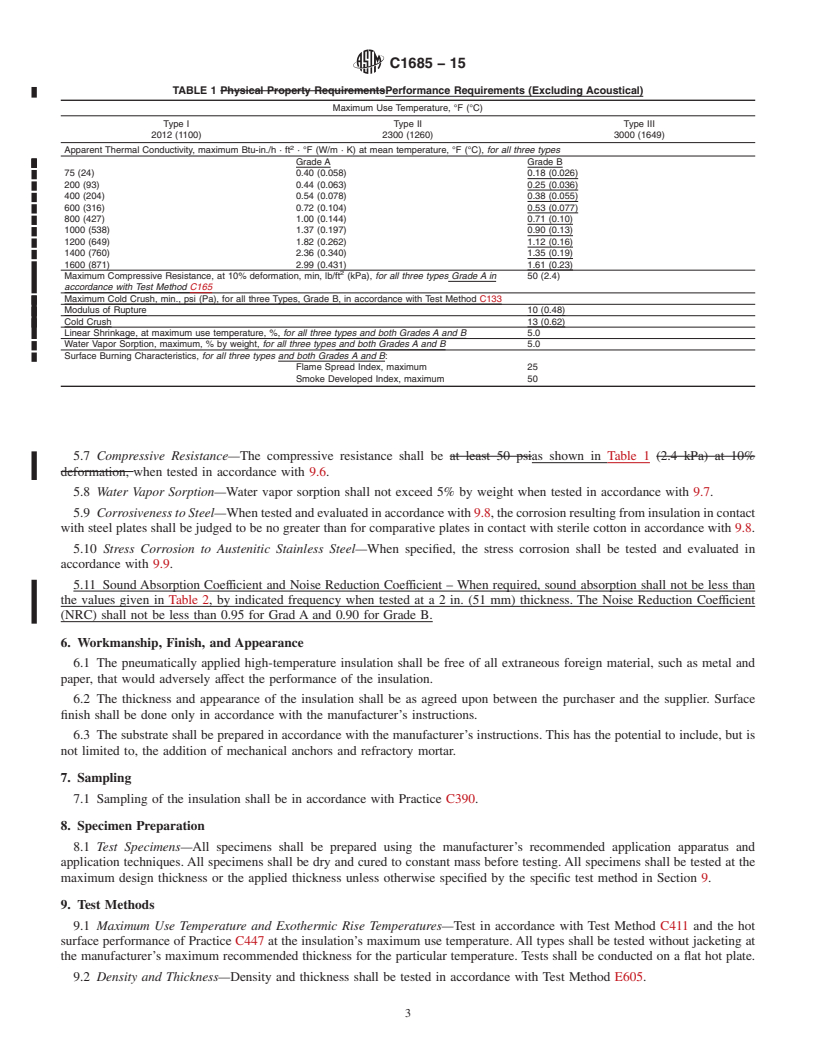

C1685−15

TABLE 1 Performance Requirements (Excluding Acoustical)

Maximum Use Temperature, °F (°C)

Type I Type II Type III

2012 (1100) 2300 (1260) 3000 (1649)

2

Apparent Thermal Conductivity, maximum Btu-in./h · ft ·

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1685 − 08 C1685 − 15

Standard Specification for

Pneumatically Applied High-Temperature Fiber Thermal

1

Insulation for Industrial Applications

This standard is issued under the fixed designation C1685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the composition, thermal performance, sound absorption performance, and physical properties of

high-temperature fiber thermal insulation for use at temperatures from ambient to 3000°F (1649°C).

1.2 The dry, loose high-temperature fibers shall be pneumatically conveyed to a nozzlechamber where they are mixed with a

water-based chemical binder.binder and then conveyed to a nozzle.

1.3 The pneumatically applied, high-temperature fiber insulation is intended for use in industrial applications on flat, or nearly

flat, surfaces. It is not intended for use on pipes.

1.4 This specification addresses the use performance of this material in both thermal and acoustical applications.

1.5 This specification does not address the requirements for fire-resistive insulation, but it does not preclude this material’s use

in that capacity.

1.6 This is a material specification only and is not intended to cover methods of application that are provided by the

manufacturer.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C71 Terminology Relating to Refractories

C133 Test Methods for Cold Crushing Strength and Modulus of Rupture of Refractories

C165 Test Method for Measuring Compressive Properties of Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C201 Test Method for Thermal Conductivity of Refractories

C356 Test Method for Linear Shrinkage of Preformed High-Temperature Thermal Insulation Subjected to Soaking Heat

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C411 Test Method for Hot-Surface Performance of High-Temperature Thermal Insulation

C423 Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method

C447 Practice for Estimating the Maximum Use Temperature of Thermal Insulations

C665 Specification for Mineral-Fiber Blanket Thermal Insulation for Light Frame Construction and Manufactured Housing

C795 Specification for Thermal Insulation for Use in Contact with Austenitic Stainless Steel

1

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on Blanket and Loose

Fill Insulation.

Current edition approved Oct. 1, 2008June 1, 2015. Published October 2008July 2015. Last previous edition was approved in 2008 as C1685 –08. DOI: 10.1520/C1685-08.

10.1520/C1685-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1685 − 15

C1045 Practice for Calculating Thermal Transmission Properties Under Steady-State Conditions

C1104/C1104M Test Method for Determining the Water Vapor Sorption of Unfaced Mineral Fiber Insulation

C1113 Test Method for Thermal Conductivity of Refractories by Hot Wire (Platinum Resistance Thermometer Technique)

E84 Test Method for Surface Burning Characteristics of Building Materials

E136 Test Method for Behavior of Materials in a Vertical Tube Furnace at 750°C

E605 Test Methods for Thickness and Density of Sprayed Fire-Resistive Material (SFRM) Applied to Structural Members

E2231 Practice

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.