ASTM C1350M-96(2013)

(Test Method)Standard Test Method for Measurement of Viscosity of Glass Between Softening Point and Annealing Range (Approximately 108 Pa·s to Approximately 1013 Pa·s) by Beam Bending (Metric)

Standard Test Method for Measurement of Viscosity of Glass Between Softening Point and Annealing Range (Approximately 10<sup>8</sup> Pa·s to Approximately 10<sup>13</sup> Pa·s) by Beam Bending (Metric)

SIGNIFICANCE AND USE

4.1 This test method is well suited for measuring the viscosity of glasses in ranges higher than those covered by parallel plate (see Test Method C1351M) and rotational viscometry (see Practice C965) methods. This test method is useful for providing information related to the behavior of glass after it has been formed into an object of commerce and in research and development.

SCOPE

1.1 This test method covers the determination of glass viscosity from approximately 108 Pa·s to approximately 10 13 Pa·s by measuring the rate of viscous bending of a simply loaded glass beam.2 Due to the thermal history of the glass, the viscosity may not represent conditions of thermal equilibrium at the high end of the measured viscosity range. Measurements carried out over extended periods of time at any temperature or thermal preconditioning will minimize these effects by allowing the glass to approach equilibrium structural conditions. Conversely, the method also may be used in experimental programs that focus on nonequilibrium conditions.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1350M − 96 (Reapproved 2013)

Standard Test Method for

Measurement of Viscosity of Glass Between Softening Point

and Annealing Range (Approximately 10 Pa·s to

13 1

Approximately 10 Pa·s) by Beam Bending (Metric)

This standard is issued under the fixed designation C1350M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C965 Practice for Measuring Viscosity of Glass Above the

Softening Point

1.1 This test method covers the determination of glass

8 13 C1351M Test Method for Measurement of Viscosity of

viscosity from approximately 10 Pa·s to approximately 10

4 8

Glass Between 10 Pa·s and 10 Pa·s by Viscous Com-

Pa·s by measuring the rate of viscous bending of a simply

2 pression of a Solid Right Cylinder [Metric]

loaded glass beam. Due to the thermal history of the glass, the

viscosity may not represent conditions of thermal equilibrium

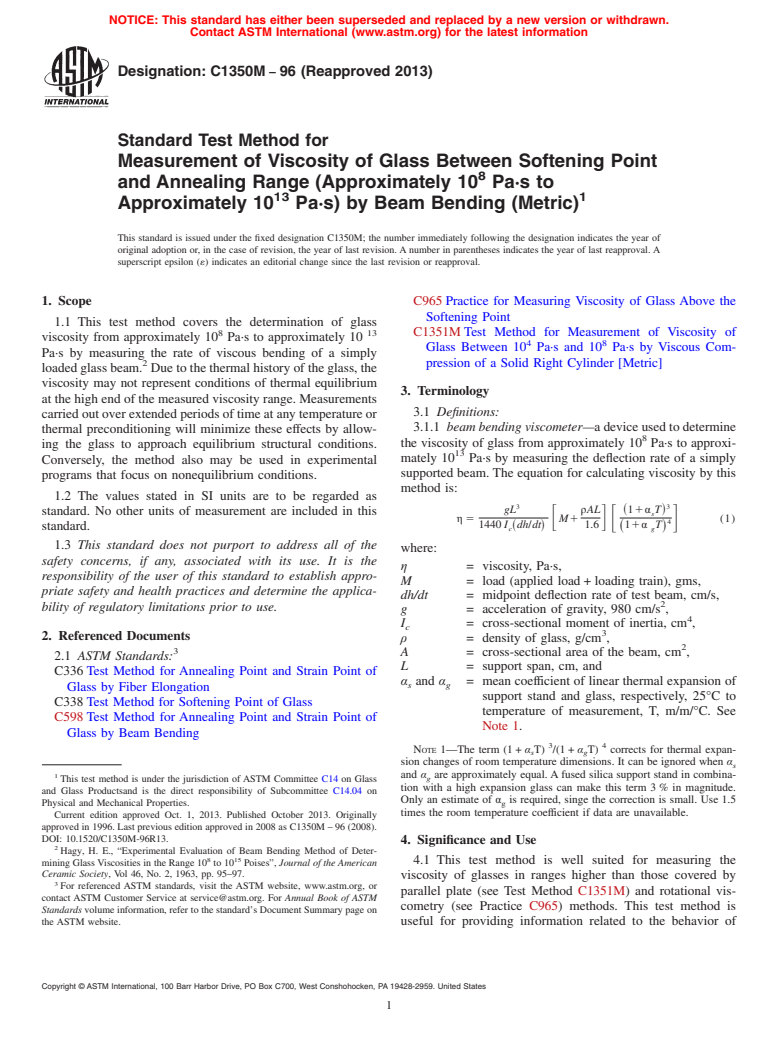

3. Terminology

at the high end of the measured viscosity range. Measurements

3.1 Definitions:

carried out over extended periods of time at any temperature or

3.1.1 beam bending viscometer—a device used to determine

thermal preconditioning will minimize these effects by allow-

the viscosity of glass from approximately 10 Pa·s to approxi-

ing the glass to approach equilibrium structural conditions.

mately 10 Pa·s by measuring the deflection rate of a simply

Conversely, the method also may be used in experimental

supported beam. The equation for calculating viscosity by this

programs that focus on nonequilibrium conditions.

method is:

1.2 The values stated in SI units are to be regarded as

3 3

gL ρAL ~11α T!

standard. No other units of measurement are included in this

s

η 5 M1 (1)

F G

F 4G

1440 I dh/dt 1.6 11α T

~ !

standard. c ~ g !

1.3 This standard does not purport to address all of the

where:

safety concerns, if any, associated with its use. It is the

η = viscosity, Pa·s,

responsibility of the user of this standard to establish appro-

M = load (applied load + loading train), gms,

priate safety and health practices and determine the applica-

dh/dt = midpoint deflection rate of test beam, cm/s,

bility of regulatory limitations prior to use.

g = acceleration of gravity, 980 cm/s ,

I = cross-sectional moment of inertia, cm ,

c

2. Referenced Documents

ρ = density of glass, g/cm ,

A = cross-sectional area of the beam, cm ,

2.1 ASTM Standards:

L = support span, cm, and

C336 Test Method for Annealing Point and Strain Point of

α and α = mean coefficient of linear thermal expansion of

s g

Glass by Fiber Elongation

support stand and glass, respectively, 25°C to

C338 Test Method for Softening Point of Glass

temperature of measurement, T, m/m/°C. See

C598 Test Method for Annealing Point and Strain Point of

Note 1.

Glass by Beam Bending

3 4

NOTE 1—The term (1 + α T) /(1 +α T) corrects for thermal expan-

s g

sion changes of room temperature dimensions. It can be ignored when α

s

1 and α are approximately equal. A fused silica support stand in combina-

This test method is under the jurisdiction of ASTM Committee C14 on Glass g

tion with a high expansion glass can make this term 3 % in magnitude.

and Glass Productsand is the direct responsibility of Subcommittee C14.04 on

Only an estimate of α is required, singe the correction is small. Use 1.5

Physical and Mechanical Properties.

g

times the room temperature coefficient if data are unavailable.

Current edition approved Oct. 1, 2013. Published October 2013. Originally

approved in 1996. Last previous edition approved in 2008 as C1350M – 96 (2008).

DOI: 10.1520/C1350M-96R13.

4. Significance and Use

Hagy, H. E., “Experimental Evaluation of Beam Bending Method of Deter-

8 15

4.1 This test method is well suited for measuring the

mining Glass Viscosities in the Range 10 to 10 Poises”, Journal of the American

Ceramic Society, Vol 46, No. 2, 1963, pp. 95–97.

viscosity of glasses in ranges higher than those covered by

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

parallel plate (see Test Method C1351M) and rotational vis-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cometry (see Practice C965) methods. This test method is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. useful for providing information related to the behavior of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1350M − 96 (2013)

glass after it has been formed into an object of commerce and a shepherd’s crook. This crook will contribute to the load on

in research and development. the specimen, so its weight should be kept to a minimum.

NOTE2—Vitreoussilicaisasuitablematerialforbothsupportstandand

5. Apparatus

loading rod. It is not recommended for temperatures above 900°C.

5.6 Extensometer for Measuring Midpoint Deflection:

5.1 The apparatus shall consist of a furnace, a means of

5.6.1 The means for observing the rate of deflection of the

controlling its temperature and heating rate, specimen holders

specimen shall allow reliable reading of total deflection of at

and loading rod, and a means of observing the rate of viscous

least 10 mm. The extensometer shall permit direct reading of

deflection of the glass specimen.

0.010 mm and estimates of 0.0010 mm. Its accuracy shall be

5.2 Furnace:

such that the error of indication will not exceed 62 % for any

5.2.1 The furnace shall be electrically heated by resistance

measured deflection. This will limit the minimum deflection

elements. The dimensions and the details of the furnace

that may be used in calculation.Alinearly variable differential

construction are not critical; its cross-section can be circular of

transformer (LVDT) is suitable for this purpose, as is any other

75 mm (;3 in.) diameter or square with sides of 75 mm. The

device (for example, optical or capacitive), provided that

furnace should have a constant temperature zone that covers

deflection is reliably measured as specified.

the specimen geometry, including the deflection range. Differ-

5.7 Weights:

ences in temperature greater than 2°C within that constant

5.7.1 A set of weights spanning the range from 1 to 500 g

temperature zone are unacceptable.

and accurate to 0.1 % relative is required.

5.3 Temperature Measuring and Indicating Instruments:

5.8 Micrometre Calipers:

5.3.1 For the measurement of temperature, there shall be

5.8.1 Micrometre calipers which can be read to an accuracy

provided a calibrated Type K, R, or S thermocouple. The

of at least 0.01 mm are required for measuring specimen

thermocouple shall be housed in a double-bore alumina tube

dimensions.

with its junction placed within 5 mm of the specimen near the

5.9 Analytical Balance:

axis of the furnace. The thermocouple shall be referenced to

5.9.1 An analytical balance capable of weighing the shep-

0°C by means of an ice bath, and its emf measured with a

herd’s crook and loading train to an accuracy of 0.1 % relative.

calibrated potentiometer that can be read with a sensitivity of

0.1°Candanaccuracyof 60.5°C.Precautionsshallbetakento

6. Preparation of Test Specimen

ensure that the ice bath is maintained at 0°C throughout the

6.1 Specimens may either be flame drawn or centerless

test. Alternately, the output of the thermocouple can be

ground into cylindrical form or diamond-saw cut and mill

measured on a calibrated, direct reading meter (electronic

groundintorectangularform.Nonuniformityofanydimension

thermometer) that can be read with a sensitivity of 0.1°C and

along the length of the specimen shall not exceed 2 %. When

an accuracy of 60.5°C. See Note 3 for temperature lag-lead

nonuniformity of any dimension exists, an average value shall

corrections.

be used.

5.4 Furnace Control:

6.2 The numerical ratio of beam span to moment of inertia

shall not be less than 60. The thickness or diameter to span

5.4.1 Suitable means shall be provided for maintaining the

furnace temperature at a fixed control point and for controlling ratio shall be less than 0.1.

the heating and cooling rates. Commercially available pro-

7. Calibration

gramming equipment provides excellent control. A variable

7.1 Direct calibration of the apparatus is accomplished by

transformer with manual control is an inexpensive, but less

adequate means of accomplishing the required control. using standard glasses, such as those supplied and certified by

the National Institute of Standards and Technology (NIST),

5.5 Specimen Holder and Loading Rod :

having known temperature values over the viscosity range

5.5.1 A diagram of the apparatus can be found in Test

covered by this practice. Bias should be corrected by overall

Method C598.

instrument calibration:

5.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.