ASTM D3591-97(2003)

(Test Method)Standard Test Method for Determining Logarithmic Viscosity Number of Poly(Vinyl Chloride) (PVC) in Formulated Compounds

Standard Test Method for Determining Logarithmic Viscosity Number of Poly(Vinyl Chloride) (PVC) in Formulated Compounds

SIGNIFICANCE AND USE

The logarithmic viscosity number provides information on the effect of compounding or processing of PVC.

Exposure of PVC compositions to shear or to high temperatures can result in a change in the logarithmic viscosity number of the resin.

SCOPE

1.1 This test method covers the determination of the logarithmic viscosity number of poly(vinyl chloride) (PVC) homopolymers after compounding or processing.

1.2 It is the basic assumption of this technique that the formulation of the compounded resin is known and that any additives present can be separated from the resin by extraction with diethyl ether. This is necessary to permit adjustment of the amount of sample used in the test to give a resin concentration in cyclohexanone of 0.2 ± 0.002 g/100 mL.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.3 and 8.4.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3591–97 (Reapproved 2003)

Standard Test Method for

Determining Logarithmic Viscosity Number of Poly(Vinyl

Chloride) (PVC) in Formulated Compounds

This standard is issued under the fixed designation D3591; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* System of Units (SI)

2.2 ISO Standard:

1.1 This test method covers the determination of the loga-

1628-2 Plastics—Determination of Viscosity Number and

rithmic viscosity number of poly(vinyl chloride) (PVC) ho-

Limiting Viscosity Number—Part 2: Poly (Vinyl Chlo-

mopolymers after compounding or processing.

ride) Resins

1.2 It is the basic assumption of this technique that the

formulation of the compounded resin is known and that any

3. Terminology

additives present can be separated from the resin by extraction

3.1 Units and symbols used in this test method are those

withdiethylether.Thisisnecessarytopermitadjustmentofthe

recommended in IEEE/ASTM SI-10.

amount of sample used in the test to give a resin concentration

3.2 Definitions of Terms Specific to This Standard:

in cyclohexanone of 0.2 6 0.002 g/100 mL.

3.2.1 The term logarithmic viscosity number is defined by

1.3 This standard does not purport to address all of the

the equation is 9.1.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 The sample is pressed into a thin film and extracted to

bility of regulatory limitations prior to use. Specific precau-

remove the plasticizer.

tionary statements are given in 7.3 and 8.4.1.

4.2 The plasticizer-free film is dissolved in cyclohexanone

NOTE 1—This test method and ISO 1628-2 are not equivalent.

and centrifuged to remove insoluble matter.

4.3 Theviscosityofthecyclohexanonesolutionismeasured

2. Referenced Documents

in accordance with Test Method D1243.

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent 5. Significance and Use

and Opaque Liquids (and Calculation of Dynamic Viscos-

5.1 The logarithmic viscosity number provides information

ity)

on the effect of compounding or processing of PVC.

D446 Specifications and Operating Instructions for Glass

5.2 Exposure of PVC compositions to shear or to high

Capillary Kinematic Viscometers

temperatures can result in a change in the logarithmic viscosity

D1243 Test Method for Dilute Solution Viscosity of Vinyl

number of the resin.

Chloride Polymers

6. Apparatus

D2124 Test Method for Analysis of Components in Poly-

(Vinyl Chloride) Compounds Using an Infrared Spectro-

6.1 Centrifuge, capable of 2500 rpm with 100-mL sample

photometric Technique

container.

E1 Specification for ASTM Liquid-in-Glass Thermometers

6.2 Heated Hydraulic Press, capable of 620-kN ram force

E691 Practice for Conducting an Interlaboratory Study to

and a temperature of 165°C.

Determine the Precision of a Test Method

6.3 Soxhlet Extraction Apparatus with a 150-mL flask and

IEEE/ASTM SI-10 Standard for the Use of International

a 27 by 100-mm thimble.

6.4 Volumetric Flasks, 100-mL.

6.5 Viscometers.

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

6.6 Infrared Spectrophotometer, see 5.4 of Method D2124.

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved March 10, 2003. Published April 2003. Originally

approved in 1977. Last previous edition approved in 1997 as D3591 – 97. DOI:

10.1520/D3591-97R03.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Cannon Fenske No. 75 or Ubbelohde No. 1 have been found satisfactory for

the ASTM website. this purpose.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3591–97 (2003)

7. Reagents

7.1 Cyclohexanone, high-purity (see Annex A1).

7.2 Diethyl Ether, anhydrous, reagent grade.

7.3 (Warning—Safety precautions should be taken to avoid

personal contact, to eliminate toxic vapors, and to guard

against explosive hazards in accordance with the hazardous

nature of the particular reagent being used.)

8. Procedure

8.1 Prepare the PVC sample for extraction by pressing a

film. The film should be 0.02 to 0.5 mm (1 to 2 mil) thick.

Prepare two films in order to make duplicate runs.

8.1.1 Heat the hydraulic press to 165°C (330°F).

8.1.2 Place2gof sample between two sheets of aluminum

foil and insert into the press.

8.1.3 Allow the sample to come to temperature for 2.5 min.

During the next 0.5 min, increase the force on the sample to

620 kN. Maintain the force for 3 min, then cool while

maintaining the force.

FIG. 1 Calibration Curve, 1% Plasticizer in PVC Resin at 5.8 µm

8.2 Weigh, to 60.2 mg, approximately1gof pressed film

into a 27 by 100-mm extraction thimble.

8.3 PlacethethimbleinaSoxhletextractionapparatusfitted

with a tared 150-mL flask, and extract with 120 mL of diethyl

ether for 20 h.

8.4 Remove the tared 150-mL flask containing the diethyl

ether and extracted plasticizer from the extraction apparatus,

and gently heat to boil off the ether.

8.4.1 (Warning—When evaporating a quantity of ether to

near dryness, precautions should be taken to guard against an

explosive hazard, due to peroxides which may be in the ether

or which may have been formed during use.)

8.5 Place the flask in an evacuated desiccator for a mini-

mumof1hto remove the last traces of ether.

8.6 Weigh, to 60.2 mg, the flask containing the extracted

plasticizer.

8.7 Calculate the percentage plasticizer as follows:

Plasticizer, % 5 ~A 3 100!/B (1)

where:

A = weight of extracted plasticizer (7.6), and

B = sample weight (7.2).

FIG. 2 Acceptable Residual Plasticizer,

Less than 0.05% at 5.8 µm

8.8 Dry the film to remove all solvent.

8.8.1 Theextractedfilmmustbefreeofplasticizer.Errorsin

excess of 10 % will result from small residual amounts of

where:

plasticizer. Examine the extracted film by infrared spectros-

F = weight of extracted film, g,

copy to ascertain that the plasticizer level is less than 0.05 % in

P = plasticizer, %, and

order to obtain satisfactory results. An example for a carbonyl

R = PVC, %.

containing plasticizer is shown in Fig. 1 and Fig. 2.

8.10 Weigh a sample of extracted film as determined in 8.9

8.9 Determine the sample size of the extracted film that will

and transfer to a 100-mL glass-stopped volumetric flask. Take

yield 0.02 6 0.002 g of PVC resin as follows:

care to transfer all of the weighed sample.

8.11 Add 50 to 70 mL of cyclohexanone to the flask. Make

100 2 P

F 5 3 0.2 (2)

sure that all the sample is in the solvent and not attached to the

R

neck of the flask.

D3591–97 (2003)

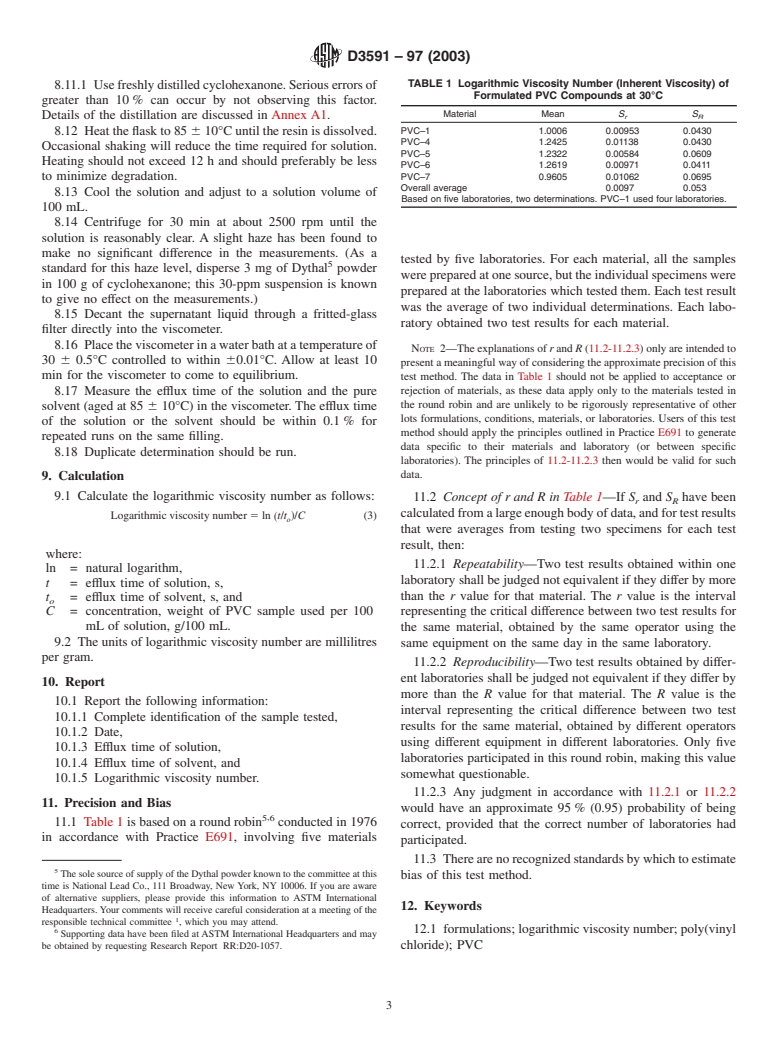

TABLE 1 Logarithmic Viscosity Number (Inherent Viscosity) of

8.11.1 Usefreshlydistilledcyclohexanone.Seriouserrorsof

Formulated PVC Compou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.