ASTM F2454-05(2022)

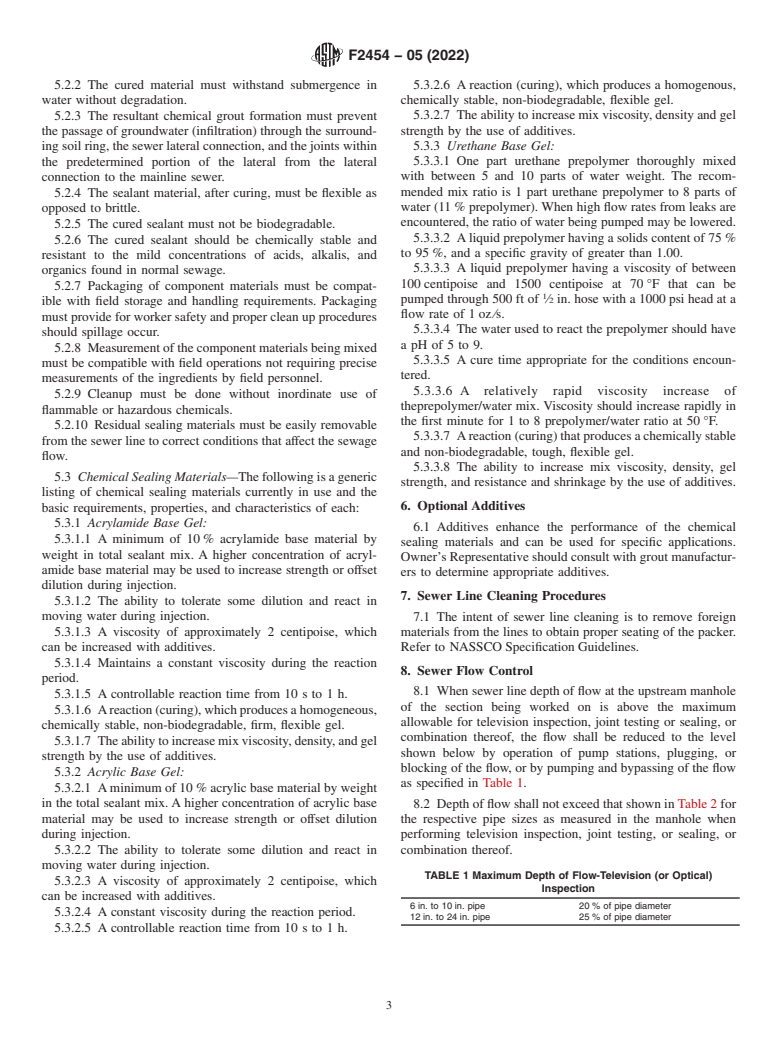

(Practice)Standard Practice for Sealing Lateral Connections and lines from the mainline Sewer Systems by the Lateral Packer Method, Using Chemical Grouting

Standard Practice for Sealing Lateral Connections and lines from the mainline Sewer Systems by the Lateral Packer Method, Using Chemical Grouting

SIGNIFICANCE AND USE

3.1 The inspection, testing, and repair of lateral connections for sanitary sewers are regular practice necessary for the maintenance and optimal performance of the system. It is important to identify methods that use the most current compounds and technology to ensure the reduction of infiltration and exfiltration. It is important to minimize disruption to traffic and lessen the environmental impacts for both the municipal and private owners.

3.2 This practice serves as a means to inspect, test, and seal sewer lateral connections and a predetermined portion of the lateral lines from the mainline sewer, having selected the appropriate chemical grouts using the lateral packer method. Television (or optical) inspection and sewer lateral connection testing are used to assess the condition and document any repairs.

3.3 This practice should not be used where mainline and lateral connections are found with longitudinally cracked pipe, structurally unsound pipe, or flattened or out of round pipe.

SCOPE

1.1 This practice covers the procedures for testing and sealing sewer lateral connections and lateral lines from the mainline sewer with appropriate chemical grouts using the lateral packer method. Chemical grouting is used to stop infiltration of ground water and exfiltration of sewage in gravity flow sewer systems that are structurally sound.

1.2 This practice applies to mainline sewer diameters of 6 in. to 24 in. with 4 in., 5 in., or 6 in. diameter laterals. Larger diameter pipes with lateral connections and lines can be grouted with special packers or man-entry methods. The mainline and lateral pipes must be structurally adequate to create an effective seal.

1.3 Worker safety training should include reviewing the biohazards and gases from sewage, confined spaces, pumping equipment, and related apparatus. Additional safety considerations including proper handling, mixing, and transporting of chemical grouts should be provided by the chemical grout manufacturer or supplier, or both. Their safe operating practices and procedures should describe in detail appropriate personal protective equipment (PPE) for the various grouting operations. Operations covered should include the proper storage, transportation, mixing, and disposal of chemical grouts, additives, and their associated containers.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and to determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2454 − 05 (Reapproved 2022)

Standard Practice for

Sealing Lateral Connections and lines from the mainline

Sewer Systems by the Lateral Packer Method, Using

1

Chemical Grouting

This standard is issued under the fixed designation F2454; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The infiltration of water in sanitary sewer systems through the lateral service connection and the

first few joints of the lateral below the groundwater table is a major problem for collection system

owners. The combined length of the lateral services often exceeds the length of the mainline sewers.

Often, the lateral services have been built with little or no supervision and little or no above-ground

access for monitoring and inspection.

1. Scope 1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

1.1 This practice covers the procedures for testing and

conversions to SI units that are provided for information only

sealing sewer lateral connections and lateral lines from the

and are not considered standard.

mainline sewer with appropriate chemical grouts using the

1.5 This standard does not purport to address all of the

lateral packer method. Chemical grouting is used to stop

safety concerns, if any, associated with its use. It is the

infiltration of ground water and exfiltration of sewage in

responsibility of the user of this standard to establish appro-

gravity flow sewer systems that are structurally sound.

priate safety, health, and environmental practices and to

1.2 This practice applies to mainline sewer diameters of

determine the applicability of regulatory limitations prior to

6 in. to 24 in. with 4 in., 5 in., or 6 in. diameter laterals. Larger

use.

diameter pipes with lateral connections and lines can be

1.6 This international standard was developed in accor-

grouted with special packers or man-entry methods. The

dance with internationally recognized principles on standard-

mainline and lateral pipes must be structurally adequate to

ization established in the Decision on Principles for the

create an effective seal.

Development of International Standards, Guides and Recom-

1.3 Worker safety training should include reviewing the

mendations issued by the World Trade Organization Technical

biohazards and gases from sewage, confined spaces, pumping

Barriers to Trade (TBT) Committee.

equipment, and related apparatus. Additional safety consider-

2. Referenced Documents

ations including proper handling, mixing, and transporting of

2

chemical grouts should be provided by the chemical grout

2.1 ASTM Standards:

manufacturer or supplier, or both. Their safe operating prac-

F2304 Practice for Sealing of Sewers Using Chemical

tices and procedures should describe in detail appropriate

Grouting

3

personal protective equipment (PPE) for the various grouting

2.2 NASSCO Standard:

operations. Operations covered should include the proper

NASSCO Specification Guidelines Wastewater Collection

storage, transportation, mixing, and disposal of chemical

System Maintenance and Rehabilitation, 2003

grouts, additives, and their associated containers.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This practice is under the jurisdiction ofASTM Committee F36 on Technology contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Underground Utilities and is the direct responsibility of Subcommittee F36.20 Standards volume information, refer to the standard’s Document Summary page on

on Inspection and Renewal of Water and Wastewater Infrastructure. the ASTM website.

3

Current edition approved June 1, 2022. Published June 2022. Originally Available from NationalAssociation of Sewer Service Companies (NASSCO),

ɛ1

approved 2005. Last previous edition approved in 2016 as F2454 – 05(2016) . Inc., 5285 Westview Drive, Suite 202, Frederick, MD 21703, http://

DOI: 10.1520/F2454-05R22. www.nassco.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2454 − 05 (2022)

3. Significance and Use 4.1.9 Disposal Area, for all materials removed from the

sewers during the performance of the work and the unencum-

3.1 The inspection, testing, and repair of lateral connections

bered right of the contractor to transport and expeditiously

for sanitar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.