ASTM F3220-17(2023)

(Practice)Standard Practice for Prioritizing Sewer Pipe Cleaning Operations by Using Transmissive Acoustic Inspection

Standard Practice for Prioritizing Sewer Pipe Cleaning Operations by Using Transmissive Acoustic Inspection

SIGNIFICANCE AND USE

4.1 Significance:

4.1.1 Collection system maintenance requires allocating cleaning resources to the right place prior to system failure (sanitary sewer overflows, mainline blockages, and building backups). Transmissive acoustic inspection provides a tool to assist in allocating cleaning resources by prioritizing pipe segments based on their blockage assessment and thereby facilitating efficient cleaning resource allocation.

4.1.2 This standard practice provides minimum requirements and suggested practices regarding the transmissive acoustic inspection of gravity-fed sewer line blockage assessment to meet the needs of maintenance personnel, engineers, contractors, authorities, regulatory agencies, and financing institutions.

4.2 Limitations and Appropriate Uses:

4.2.1 The blockage assessment provided by the transmissive acoustic inspection may not resolve the type of blockage(s) within the pipe segment nor resolve the location(s) of the blockage(s) within the pipe segment.

4.2.2 Due to the physics associated with transmissive acoustic inspection, the blockage assessment may be confounded due to:

(1) Structural designs resulting in poor acoustic coupling,

(2) Pipe segments completely filled with water, for example, full pipe sag or inverted siphon, and

(3) Transient conditions within the pipe, for example, active lateral discharge or temporary flow surcharges.

These issues are addressed as part of the performance criteria specified in X1.5.

4.2.3 Due to physics associated with acoustics and trade-offs in equipment design for conducting transmissive acoustic inspection, there are limitations based on the following pipe segment attributes:

(1) Pipe diameter,

(2) Pipe segment length,

(3) MH depth, and

(4) Flow levels.

Inspections conducted outside the manufacturer’s recommended ranges for these pipe segment attributes may result in the transmissive acoustic blockage assessment deviating from the performance criteria specified in X1.5...

SCOPE

1.1 This practice covers procedures for assessing the blockage within gravity-fed sewer pipes using transmissive acoustics for the purpose of prioritizing sewer pipe cleaning operations.2 The assessment is based on an acoustic receiver measuring the acoustic plane wave transmitted through the pipe segment under test in order to evaluate the blockage condition of an entire segment and to provide an onsite assessment of the blockage within the pipe segment. (1, 2, 3, 4, 5)3

1.2 The scope of this practice covers the use of the transmissive acoustic inspection as a screening tool. The blockage assessment provided by the acoustic inspection should be used to identify and prioritize pipe segments requiring further maintenance action such as cleaning or visual inspection, or both. Thereby, also identifying the pipe segments which are sufficiently clean and do not require additional maintenance action.

1.3 This standard practice does not address structural issues with the pipe wall.

1.4 The inspection process requires access to the manhole (MH) from ground level. It does not require physical access to the sewer line by either the equipment or the operator.

1.5 This standard practice applies to all types of pipe material.

1.6 The inspection process requires access to sewers and operations along roadways or other locations that are safety hazards. This standard does not describe the hazards likely to be encountered or the safety procedures that must be carried out when operating in these hazardous environments.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate s...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3220 − 17 (Reapproved 2023)

Standard Practice for

Prioritizing Sewer Pipe Cleaning Operations by Using

Transmissive Acoustic Inspection

This standard is issued under the fixed designation F3220; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

1.1 This practice covers procedures for assessing the block-

conversions to SI units that are provided for information only

age within gravity-fed sewer pipes using transmissive acoustics

2 and are not considered standard.

for the purpose of prioritizing sewer pipe cleaning operations.

1.8 This standard does not purport to address all of the

The assessment is based on an acoustic receiver measuring the

safety concerns, if any, associated with its use. It is the

acoustic plane wave transmitted through the pipe segment

responsibility of the user of this standard to establish appro-

under test in order to evaluate the blockage condition of an

priate safety, health, and environmental practices and deter-

entire segment and to provide an onsite assessment of the

mine the applicability of regulatory limitations prior to use.

blockage within the pipe segment. (1, 2, 3, 4, 5)

1.9 This international standard was developed in accor-

1.2 The scope of this practice covers the use of the trans-

dance with internationally recognized principles on standard-

missive acoustic inspection as a screening tool. The blockage

ization established in the Decision on Principles for the

assessment provided by the acoustic inspection should be used

Development of International Standards, Guides and Recom-

to identify and prioritize pipe segments requiring further

mendations issued by the World Trade Organization Technical

maintenance action such as cleaning or visual inspection, or

Barriers to Trade (TBT) Committee.

both. Thereby, also identifying the pipe segments which are

sufficiently clean and do not require additional maintenance

2. Terminology

action.

2.1 Definitions:

1.3 This standard practice does not address structural issues

2.1.1 authority, n—party responsible for the generation and

with the pipe wall.

verification of performance to job specification(s) and contract

requirements.

1.4 The inspection process requires access to the manhole

(MH) from ground level. It does not require physical access to 2.1.2 blockage assessment, n—the aggregate blockage

the sewer line by either the equipment or the operator. within a pipe segment between two adjacent MHs.

2.1.3 closed circuit television (CCTV), n—a closed circuit

1.5 This standard practice applies to all types of pipe

pipeline inspection television system including a camera,

material.

camera transporter, integrated lighting, central control system,

1.6 The inspection process requires access to sewers and

video monitor, and recording device.

operations along roadways or other locations that are safety

2.1.4 coordinated universal time (UTC), n—the primary

hazards. This standard does not describe the hazards likely to

international time standard for regulating clocks and time.

be encountered or the safety procedures that must be carried

out when operating in these hazardous environments.

2.1.5 geographic information system (GIS), n—system de-

signed to capture, store, manipulate, analyze, manage, and

present all types of spatial or geographical data.

This practice is under the jurisdiction of ASTM Committee F36 on Technology

and Underground Utilities and is the direct responsibility of Subcommittee F36.20

2.1.6 global position system (GPS), n—space-based naviga-

on Inspection and Renewal of Water and Wastewater Infrastructure.

tion system that provides location and time information any-

Current edition approved Sept. 1, 2023. Published September 2023. Originally

where on or near the earth where there is an unobstructed line

approved in 2017. Last previous edition approved in 2017 as F3220 – 17. DOI:

10.1520/F3220-17R23. of sight to four or more GPS satellites.

The transmissive acoustic inspection is covered by Patent US8220484B2.

2.1.7 manhole (MH), n—vertical shafts intersecting a sewer

Interested parties are invited to submit information regarding the identification of an

that allow entry to the sewer for cleaning, inspection, and

alternative(s) to this patented item to the ASTM International Headquarters. Your

comments will receive careful consideration at a meeting of the responsible

maintenance.

technical committee, which you may attend.

2.1.8 pipe segment, n—the section of a sewer line between

The boldface numbers in parentheses refer to a list of references at the end of

this standard. two adjacent MHs.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3220 − 17 (2023)

2.1.9 segment’s acoustic fingerprint (SAF), n—acoustic fea- segments based on their blockage assessment and thereby

ture set which characterizes a pipe segment. The acoustic facilitating efficient cleaning resource allocation.

feature set is used in classifying the blockage assessment. (2, 6)

4.1.2 This standard practice provides minimum require-

ments and suggested practices regarding the transmissive

2.2 Abbreviation:

acoustic inspection of gravity-fed sewer line blockage assess-

2.2.1 ID—identification

ment to meet the needs of maintenance personnel, engineers,

3. Summary of Practice contractors, authorities, regulatory agencies, and financing

institutions.

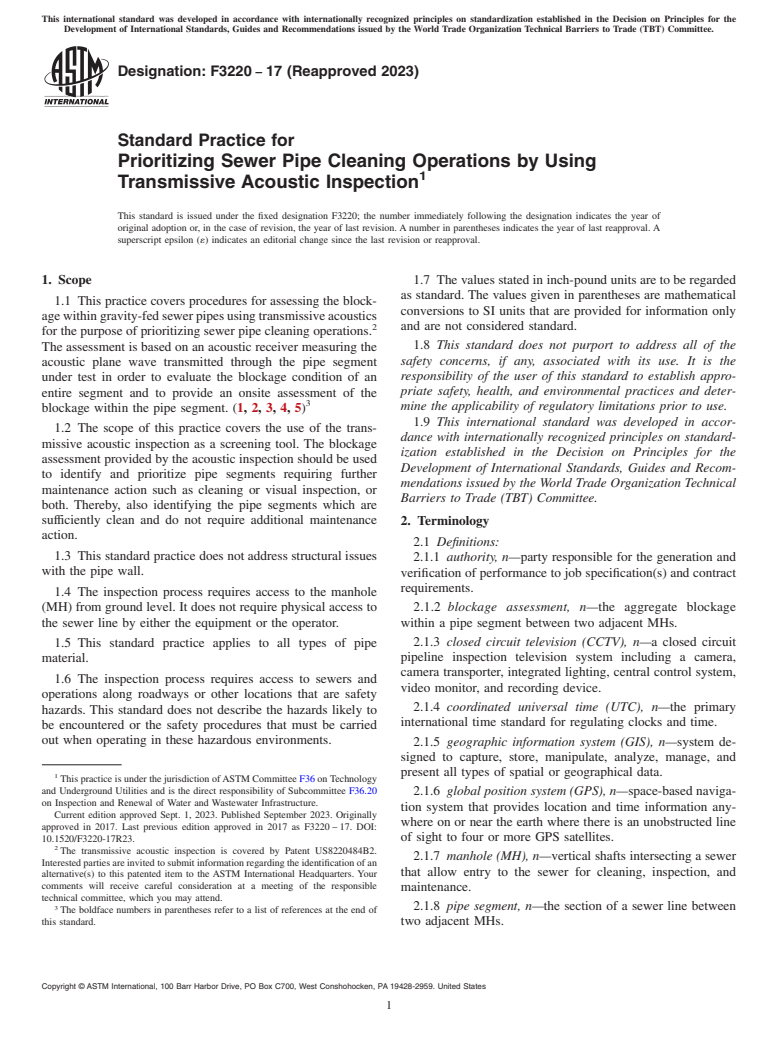

3.1 Transmissive acoustic inspection operational procedure

is based on measuring the signal received from an active

4.2 Limitations and Appropriate Uses:

acoustic transmission through a pipe segment. Fig. 1 depicts

4.2.1 The blockage assessment provided by the transmissive

the general configuration of a transmissive acoustic inspection.

acoustic inspection may not resolve the type of blockage(s)

The acoustic transmitter generates sound waves just below the

within the pipe segment nor resolve the location(s) of the

entrance to the MH which couple into the connecting sewer

blockage(s) within the pipe segment.

line segments. The sound wave propagates in the air gap above

4.2.2 Due to the physics associated with transmissive acous-

the wastewater flow from the speaker to the receiving micro-

tic inspection, the blockage assessment may be confounded

phone attached to the acoustic receiver located at the adjacent

due to:

MH. The acoustic receiver measures the acoustic plane wave

(1) Structural designs resulting in poor acoustic coupling,

from the transmitted signal in order to evaluate the blockage

(2) Pipe segments completely filled with water, for

condition of an entire segment and provides an onsite blockage

example, full pipe sag or inverted siphon, and

assessment. Both the speaker and the microphone are placed

(3) Transient conditions within the pipe, for example,

just within the opening of the MH and should never come in

active lateral discharge or temporary flow surcharges.

contact with the wastewater flow. The operators have no

These issues are addressed as part of the performance criteria

requirement for confined space entry.

specified in X1.5.

3.2 Transmissive acoustic inspection principle of operation

4.2.3 Due to physics associated with acoustics and trade-

is based on the observation that a pipe segment is a natural

offs in equipment design for conducting transmissive acoustic

acoustic waveguide. Commonly encountered sanitary sewer

inspection, there are limitations based on the following pipe

defects, such as roots, grease, pipe sags, and pipe breakages

segment attributes:

naturally absorb or reflect acoustic energy. These defects

(1) Pipe diameter,

change a segment’s acoustic properties and produce a measur-

(2) Pipe segment length,

able impact on the received signal at the microphone, that is,

(3) MH depth, and

the segment’s acoustic fingerprint (SAF). Each segment has an

(4) Flow levels.

individual SAF representative of its current state. Transmissive

Inspections conducted outside the manufacturer’s recom-

acoustic inspection measures and assesses the SAF to deter-

mended ranges for these pipe segment attributes may result in

mine the Blockage Assessment, that is, an estimate of the

the transmissive acoustic blockage assessment deviating from

aggregate blockage within the pipe segment between the

the performance criteria specified in X1.5.

acoustic transmitter and acoustic receiver.

4.2.4 Inspections conducted between non-adjacent MHs, for

example, skipping an intermediate MH, may result in the

4. Significance and Use

transmissive acoustic blockage assessment deviating from the

4.1 Significance:

performance criteria specified in X1.5.

4.1.1 Collection system maintenance requires allocating

cleaning resources to the right place prior to system failure

5. Procedure

(sanitary sewer overflows, mainline blockages, and building

backups). Transmissive acoustic inspection provides a tool to 5.1 If the work is to be conducted by an outside contractor,

assist in allocating cleaning resources by prioritizing pipe apart from the provisions generally included in an inspection

FIG. 1 Transmissive Acoustic Inspection System Operation

F3220 − 17 (2023)

services contract, the transmissive acoustic inspection contract 5.8 On a daily basis, the data recorded electronically by the

should define and assign responsibilities for the following transmissive acoustic equipment shall be uploaded for report

items: generation and data registration quality control.

(1) Access to the site of work is to be provided to the extent

6. Report

that the authority is legally able to so provide or, if not so able,

6.1 A report shall be produced as described in 6.2 through

a written release from responsibility for the performance of

6.4. The objective of the report is to provide clear and concise

work at sites where access cannot be made available;

information to assist in prioritizing cleaning operations on the

(2) MH numbering system for all areas of the project;

pipe segments inspected.

(3) Location, exposure, and accessibility of all MH should

6.2 Daily Verification Report—A table listing the operation

be provided; and

(4) Geographic Information System (GIS) maps should be verification results. The table is based on data recorded

electronically by the transmissive acoustic inspection equip-

provided, when available.

ment. Each table entry will include: the date, the time, and the

5.2 The transmissive acoustic inspection procedure detailed

results of the equipment operation verification. If an operation

in this practice is based on the transmissive acoustic inspection

verification fails, then the table entry will indicate the correc-

equipment meeting the minimum requirements detailed in

tive measures taken as well as an additional operation verifi-

Appendix X1.

cation entry to show that the corrective measures were suc-

cessful.

5.3 The transmissive acoustic inspection should only be

conducted for pipe segments which meet the manufacturer’s

6.3 Summary of Pipe Sections Tested—A table of pipe

recommended specifications for: pipe diameter, pipe segment

sections tested shall be produced that shows the name/number

length, MH depth, and flow levels.

of the upstream and downstream MHs, the distance between

MHs as specified by the authority’s GIS data (when available),

5.4 The transmissive acoustic inspection shall be conducted

the distance between MHs as measured by using the inspection

using the following procedure for each pipe segment under

equipment global position system (GPS) location estimates, the

test. The acoustic transmitter and the acoustic receiver shall be

pipe length specified by the operator in the field as recorded by

placed on adjacent MHs by their respective field operators. The

the equipment, the acoustic receiver device ID, measurement

transducers (microphone and speaker) shall be placed within

timing verification, the blockage assessment ID, the blockage

the MH, as illustrated in Fig. 1.

assessment based on the operator specified pipe length in the

5.5 The inspection shall follow the manufacturer’s recom-

field, and the blockage assessment based on the corrected pipe

mendation for the equipment with the procedure outlined as

length. In addition, the table shall indicate whether the:

follows:

(1) Pipe segment location was verified, that is, location was

5.5.1 Based on the authority’s policy for providing a pipe verified by correlating the field operator recorded information

with the transmissive acoustic inspection equipment GPS

segment’s length, the acoustic receiver operator enters the

length of the pipe segment under test. This parameter is used in location estimates and the authority’s GIS data;

(2) Pipe segment was tested based on skipping an interme-

assessing the blockage assessment. The pipe segment’s length

diate MH due to the intermediate MH not being located or not

should be based on the authority’s GIS data, when available,

and when deemed to be sufficiently accurate as specified by the being accessible; and

(3) Pipe segment was not tested based on not being able to

manufacturer’s requirements, for example, pipe segment’s

length is entered to within 650 ft. locate or access two adjacent MHs.

5.5.2 The field operators initiate the automated test. The test 6.4 Field Recorded Electronic Data—The following reports

shall be started on both the acoustic transmitter and acoustic

will be provided based on the data recorded by the transmissive

receiver within the time interval specified by the equipment acoustic inspection equipment:

manufacturer.

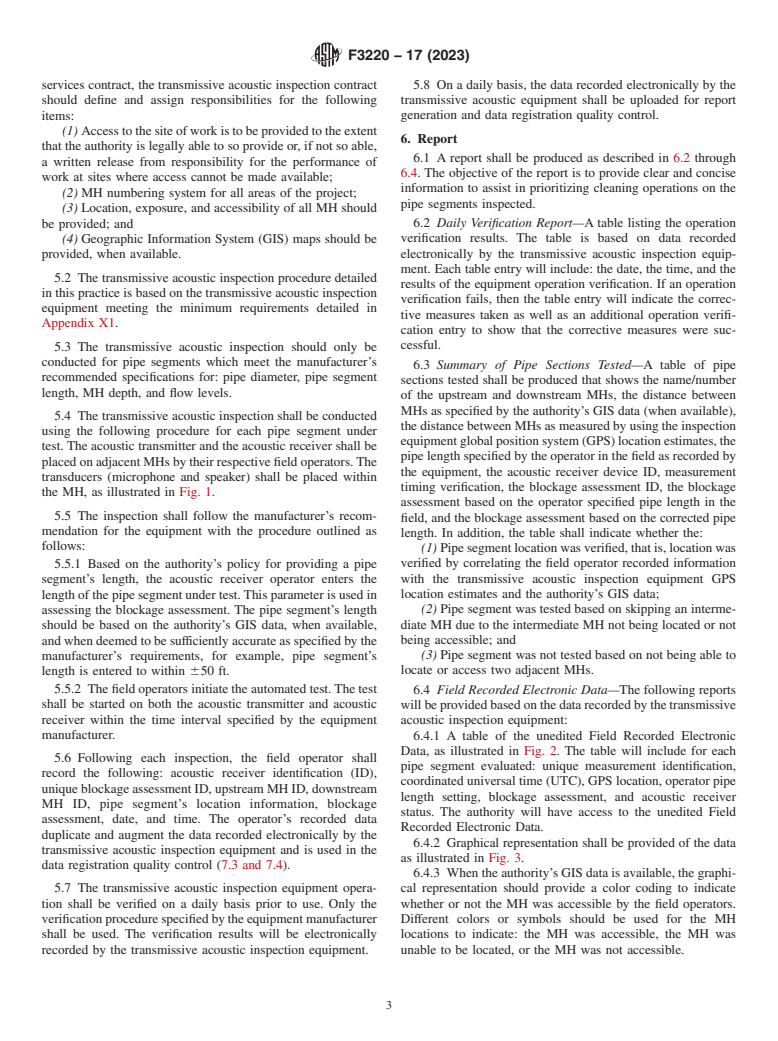

6.4.1 A table of the unedited Field Recorded Electronic

Data, as illustrated in Fig. 2. The table will include for each

5.6 Following each inspection, the field operator shall

pipe segment evaluated: unique measurement identification,

record the following: acoustic receiver identification (ID),

coordinated universal time (UTC), GPS location, operator pipe

unique blockage assessment ID, upstream MH ID, downstream

length setting, blockage assessment, and acoustic receiver

MH ID, pipe segment’s location information, blockage

status. The authority will have access to the unedited Field

assessment, date, and time. The operator’s recorded data

Recorded Electronic Data.

duplicate and augment the data recorded electronically by the

6.4.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.