ASTM D4811/D4811M-16(2023)

(Specification)Standard Specification for Nonvulcanized (Uncured) Rubber Sheet Used as Roof Flashing

Standard Specification for Nonvulcanized (Uncured) Rubber Sheet Used as Roof Flashing

ABSTRACT

This specification covers nonvulcanized (uncured) rubber sheet made of ethylene-propylene-diene terpolymer (EPDM) or polychloroprene (CR) intended for use as watertight roof flashing exposed to the weather. In-place roof system design criteria such as fire resistance, field seaming strength, material compatibility, and uplift resistance, among others, are beyond the scope of this specification. The flashing material shall be formulated from the appropriate polymer type and other compounding ingredients, and shall be capable of being bonded to itself, to the roofing membrane, and to substrate for making watertight field splices and repairs. Property requirements for flashing before vulcanization include thickness, Green strength modulus, ultimate elongation, shelf stability, vulcanizability, tensile strength and set, dimensional stability, and weatherability. Consequently, the property requirements for flashing after vulcanization includes tensile strength and set, elongation, tear resistance, brittle point, ozone resistance, air oven heat aging, water absorption and weight change, linear dimension change, and weatherability.

SCOPE

1.1 This specification covers nonvulcanized (uncured) rubber sheet made of EPDM (ethylene-propylene-diene terpolymer) or CR (polychloroprene) intended for use as watertight roof flashing exposed to the weather.

1.2 The tests and property limits used to characterize these flashing materials are specific for each classification and are minimum values to make the product fit for its intended purpose.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 In-place roof system design criteria, such as fire resistance, field seaming strength, material compatibility, and uplift resistance, among others, are beyond the scope of this specification.

1.5 The following precautionary caveat pertains to the test methods portion only, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D4811/D4811M −16 (Reapproved 2023)

Standard Specification for

Nonvulcanized (Uncured) Rubber Sheet Used as Roof

Flashing

This standard is issued under the fixed designation D4811/D4811M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers nonvulcanized (uncured) rub-

D412TestMethodsforVulcanizedRubberandThermoplas-

ber sheet made of EPDM (ethylene-propylene-diene terpoly-

tic Elastomers—Tension

mer) or CR (polychloroprene) intended for use as watertight

D471Test Method for Rubber Property—Effect of Liquids

roof flashing exposed to the weather.

D518 Test Method for Rubber Deterioration—Surface

1.2 The tests and property limits used to characterize these

Cracking (Withdrawn 2007)

flashing materials are specific for each classification and are

D573Test Method for Rubber—Deterioration in an Air

minimum values to make the product fit for its intended

Oven

purpose. D624Test Method for Tear Strength of Conventional Vul-

canized Rubber and Thermoplastic Elastomers

1.3 The values stated in either SI units or inch-pound units

D1079Terminology Relating to Roofing and Waterproofing

are to be regarded separately as standard. The values stated in

D1149TestMethodsforRubberDeterioration—Crackingin

each system may not be exact equivalents; therefore, each

an Ozone Controlled Environment

system shall be used independently of the other. Combining

D1204Test Method for Linear Dimensional Changes of

values from the two systems may result in nonconformance

Nonrigid Thermoplastic Sheeting or Film at Elevated

with the standard.

Temperature

D1418 Practice for Rubber and Rubber Latices—

1.4 In-place roof system design criteria, such as fire

Nomenclature

resistance, field seaming strength, material compatibility, and

D2137TestMethodsforRubberProperty—BrittlenessPoint

uplift resistance, among others, are beyond the scope of this

of Flexible Polymers and Coated Fabrics

specification.

D3182PracticeforRubber—Materials,Equipment,andPro-

1.5 The following precautionary caveat pertains to the test

cedures for Mixing Standard Compounds and Preparing

methods portion only, Section 8, of this specification: This

Standard Vulcanized Sheets

standarddoesnotpurporttoaddressallofthesafetyconcerns,

G151PracticeforExposingNonmetallicMaterialsinAccel-

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

erated Test Devices that Use Laboratory Light Sources

of this standard to establish appropriate safety, health, and

G154Practice for Operating Fluorescent Ultraviolet (UV)

environmental practices and determine the applicability of

Lamp Apparatus for Exposure of Nonmetallic Materials

regulatory limitations prior to use. G155PracticeforOperatingXenonArcLampApparatusfor

Exposure of Materials

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Classification

ization established in the Decision on Principles for the

3.1 The following types are used to identify the principal

Development of International Standards, Guides and Recom-

polymer components of the flashing material (see Note 1):

mendations issued by the World Trade Organization Technical

3.1.1 Type I—Ethylene-Propylene-Diene Terpolymer

Barriers to Trade (TBT) Committee.

(EPDM).

1 2

This specification is under the jurisdiction of ASTM Committee D08 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

RoofingandWaterproofingandisthedirectresponsibilityofSubcommitteeD08.18 contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

on Nonbituminous Organic Roof Coverings. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2023. Published January 2023. Originally the ASTM website.

approved in 1990. Last previous edition approved in 2016 as D4811/D4811M–16. The last approved version of this historical standard is referenced on

DOI: 10.1520/D4811_D4811M-16R23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4811/D4811M−16 (2023)

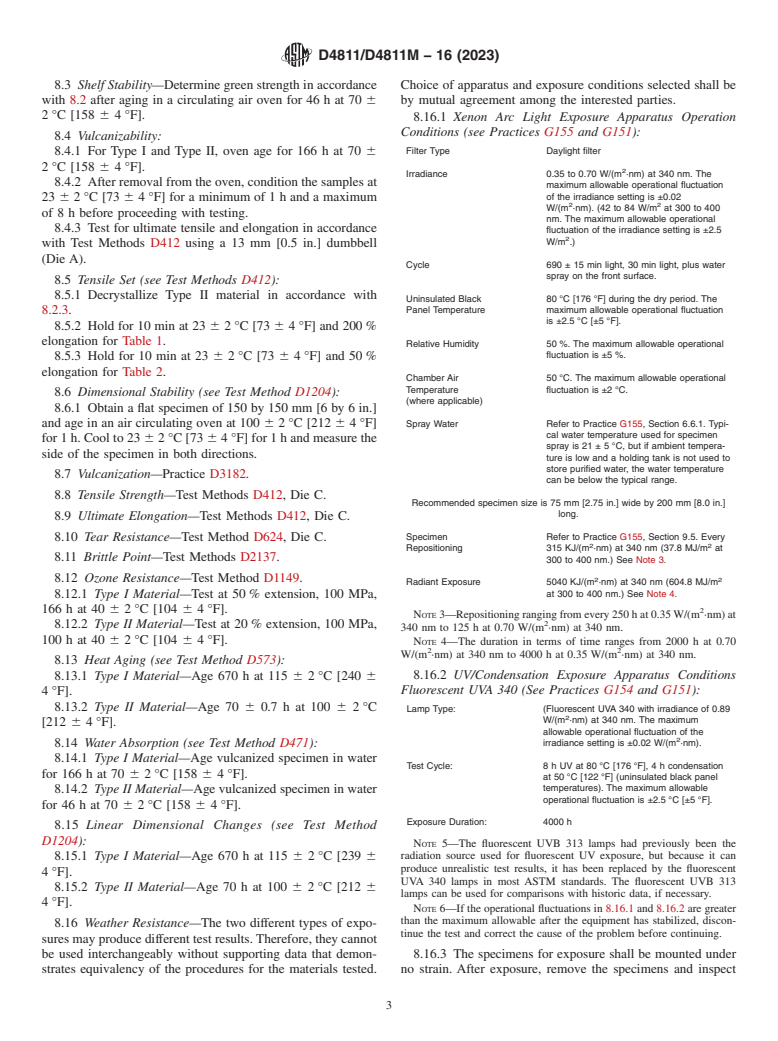

TABLE 2 Property Requirements for Flashing After Vulcanization

3.1.2 Type II—Chloroprene Polymer (CR).

Type I, Type II,

NOTE 1—For definitions of polymer types, see Practice D1418. For

Class V Class V

definitions of terms related to roofing, see Terminology D1079.

Vulcanization, at 160 °C [320 °F], min 20 ± 2 20 ± 2

Tensile Strength, min, MPa [psi] 9.0 [1305] 8.3 [1205]

3.2 The following classes describe the ability to vulcanize

Elongation, min, % 300 250

on the roof:

Tear Resistance, min, kN/m [lb/in.] 22 [125] 22 [125]

3.2.1 Class V—Vulcanizing.

Brittle Point, max, °C [°F] −45 [−49] pass −35 [−31] pass

3.2.2 Class NV—Nonvulcanizing. Tensile Set, max, % 10 10

Ozone Resistance, (7×) no cracks no cracks

NOTE 2—Class V compounds continue to vulcanize (that is, cure) after Heat Aging, Air Oven

Tensile Strength, min, MPa [psi] 8.3 [1205] 8.3 [1205]

emplacement on the roof. Class NV indicates non-vulcanizable com-

Elongation, min, % 200 200

pounds.

Tear Resistance (Die C), kN/m [lbf/in.], 22 [125] 22 [125]

min

4. Materials and Manufacture

Water Absorption, weight change, range, % +8, −2 +8, −2

Linear Dimension Change, max, % ±2 ±2

4.1 The flashing material shall be formulated from the

Weatherability, no cracks or crazing pass pass

appropriate polymer type and other compounding ingredients.

The principal polymer in the flashing material shall be one of

those listed in 3.1 and greater than 95% of the total polymer.

4.2 The flashing material shall be capable of being bonded

6.2 Sheet thicknesses greater than minimum shall be agreed

to itself, to the roofing membrane, and to substrate for making

upon between the purchaser and the supplier as part of the

watertight field splices and repairs. The manufacturer or

purchase contract.

fabricator shall recommend suitable bonding methods and

6.2.1 The thickness tolerance shall be+15% and−10% of

materials.

the specified thickness, but in no case shall the thickness be

less than the minimum listed in Table 1.

5. Physical Property Requirements

7. Workmanship, Finish, and Appearance

5.1 Class V flashing material shall conform to the physical

property requirements prescribed in Tables 1 and 2. Class NV

7.1 The flashing material shall be visually free of pinholes,

flashing material shall conform to the physical property re-

particles of foreign matter, undispersed raw materials, or other

quirements prescribed in Table 1.

manufacturing defects that might affect serviceability.

5.2 Other requirements shall be agreed upon between the

7.2 If the number of irregularities appear excessive on a

purchaser and the supplier as part of the purchase contract.

sheet (or portion thereof), then its rejection should be negoti-

ated between involved parties.

6. Dimensions and Permissible Variations

7.3 Edges of the sheet shall be capable of being seamed to

6.1 The width and length shall be agreed upon between the

one another and to other roofing components without fish-

purchaser and the supplier as part of the purchase contract.

mouthing.

6.1.1 The width and length tolerance shall be +3 %

and−0%.

8. Test Methods

8.1 Thickness—Test Methods D412.

TABLE 1 Property Requirements for Flashing Before

8.2 Green Strength:

Vulcanization

8.2.1 Test a fresh sample manufactured within one week.

Type I, Type I, Type II,

8.2.2 ConditionTypeImaterialat23 62°C[73 64°F]for

Class V Class NV Class V

a minimum of 1 h and a maximum of 8 h before proceeding

Thickness, min, mm [in.] 1.4 [0.055] 1.4 [0.055] 1.4 [0.055]

with the testing.

Green Strength Modulus

172–1725 172–1725 172–517

100 % at 23 °C [73 °F] kPa

8.2.3 Decrystallize Type II material by placing in a circu-

[25–250] [25–250] [25–75]

[psi]

lating air oven at 70 6 2°C [158 6 4°F] for 15 min. After

Elongation (Ultimate), min, % 400 400 400

removalfromtheoven,conditionat23 62°C[73 64°F]for

Modulus 100 % at 50 °C 83 [12] 83 [12] 83 [12]

[122 °F] kPa [psi]

a minimum of 1 h and a maximum of 8 h before proceeding

Elongation (Ultimate), min, % 200 200 200

with the testing.

Shelf Stability:

8.2.4 Afterconditioning,dieouta13mm[0.5in.]dumbbell

Modulus 100 %

at 23 °C [73 °F], max, kPa 1725 [250] n/a 1725 [250]

(DieA)anddeterminethemodulusat100%extensionandthe

[psi]

ultimate elongation at 23 6 2°C [73 6 4°F] in accordance

Elongation, min, % 400 n/a 400

with T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.