ASTM C794-18(2022)

(Test Method)Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

Standard Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

SIGNIFICANCE AND USE

5.1 There are differences in opinion among those concerned with sealant technology whether or not this adhesion-in-peel test simulates the type of strain and e-tensile stresses encountered by a sealant in normal use. Nevertheless, this test provides a valuable measurement of the ability of the cured sealant to maintain a bond to the substrate under severe peel conditions.

5.2 Many sealant manufacturers utilize the adhesion-in-peel test for determining the adhesive characteristics of sealant/primer combinations with unusual or proprietary substrates. This test is especially useful for quality measurements comparing batches of the same sealant relative to adhesion or for studying adhesion of a given sealant to a variety of substrates.

5.3 This test method alone is not appropriate for comparing the overall performance of different sealants in a given application. The adhesive force that determines if a given sealant is useful in a given application also depends on the modulus of elasticity and the degree to which the sealant will be strained. This test, as it exists, does not consider the modulus of elasticity, nor amount of stress that will be produced by a given strain in an actual sealant in a moving joint. No known correlations are given to relate and apply modulus values to the peel values.

5.4 This test requires that the results indicate whether the failure mode is primarily adhesive or cohesive. It is important to note that a cohesive failure is not necessarily better than an adhesive failure, if the adhesive value is sufficient for the application. Having adhesive failure allows one to study the change of adhesion with time and with the various stress conditions.

SCOPE

1.1 This test method covers a laboratory procedure for determining the strength and characteristics of the peel properties of a cured-in-place elastomeric joint sealant, single- or multicomponent, for use in building construction.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C794 − 18 (Reapproved 2022)

Standard Test Method for

Adhesion-in-Peel of Elastomeric Joint Sealants

This standard is issued under the fixed designation C794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Terminology

1.1 This test method covers a laboratory procedure for 3.1 For the definitions used in this test method, see Termi-

determining the strength and characteristics of the peel prop- nology C717, standard conditions.

erties of a cured-in-place elastomeric joint sealant, single- or

4. Summary of Test Method

multicomponent, for use in building construction.

1.2 The values stated in SI units are to be regarded as 4.1 This test method consists of preparing test specimens by

embedding a wire mesh screen between two thin layers of the

standard. The values given in parentheses after SI units are

provided for information only and are not considered standard. sealant being tested, on test substrates, curing these specimens

under specified time and conditions, then placing the specimen

1.3 Thecommitteewithjurisdictionoverthisstandardisnot

in a tension-testing machine in such a way that the embedded

aware of any comparable standards published by other orga-

wire mesh screen is peeled back from the substrate at 180°,

nizations.

while measuring the force exerted as well as the mode of

1.4 This standard does not purport to address all of the

failure of the sealant from the substrate.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety, health, and environmental practices and deter-

5.1 There are differences in opinion among those concerned

mine the applicability of regulatory limitations prior to use.

with sealant technology whether or not this adhesion-in-peel

1.5 This international standard was developed in accor-

test simulates the type of strain and e-tensile stresses encoun-

dance with internationally recognized principles on standard-

tered by a sealant in normal use. Nevertheless, this test

ization established in the Decision on Principles for the

provides a valuable measurement of the ability of the cured

Development of International Standards, Guides and Recom-

sealant to maintain a bond to the substrate under severe peel

mendations issued by the World Trade Organization Technical

conditions.

Barriers to Trade (TBT) Committee.

5.2 Many sealant manufacturers utilize the adhesion-in-peel

2. Referenced Documents

test for determining the adhesive characteristics of sealant/

primer combinations with unusual or proprietary substrates.

2.1 ASTM Standards:

This test is especially useful for quality measurements com-

C717 Terminology of Building Seals and Sealants

paring batches of the same sealant relative to adhesion or for

C1375 Guide for Substrates Used in Testing Building Seals

studying adhesion of a given sealant to a variety of substrates.

and Sealants

E177 Practice for Use of the Terms Precision and Bias in

5.3 This test method alone is not appropriate for comparing

ASTM Test Methods

the overall performance of different sealants in a given appli-

E691 Practice for Conducting an Interlaboratory Study to

cation. The adhesive force that determines if a given sealant is

Determine the Precision of a Test Method

useful in a given application also depends on the modulus of

elasticity and the degree to which the sealant will be strained.

This test, as it exists, does not consider the modulus of

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

elasticity, nor amount of stress that will be produced by a given

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on

Adhesion.

strain in an actual sealant in a moving joint. No known

CurrenteditionapprovedJune1,2022.PublishedJuly2022.Originallyapproved

correlations are given to relate and apply modulus values to the

in 1975. Last previous edition approved in 2018 as C794 – 18. DOI: 10.1520/

peel values.

C0794-18R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.4 This test requires that the results indicate whether the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

failure mode is primarily adhesive or cohesive. It is important

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to note that a cohesive failure is not necessarily better than an

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C794 − 18 (2022)

adhesive failure, if the adhesive value is sufficient for the

application. Having adhesive failure allows one to study the

change of adhesion with time and with the various stress

conditions.

6. Apparatus and Materials

6.1 Tensile Testing Machine with tension grips capable of

pulling at the rate of separation of approximately 50 mm (2

in.)/min, and having a chart indicator calibrated in 0.45 N

(0.1-lbf) units.

6.2 Standard Substrates—This test method may be per-

formed on a wide variety of substrates. See Guide C1375 for a

description of standard substrates and recommended surface

preparation. Since adhesive properties of a joint sealant are

related to the nature of the substrate, it is strongly recom-

mendedthatwheneverpossiblethatadhesion-in-peeltestingbe

performed on substrate samples that are representative of the

building materials. Examples of such substrates include brick,

marble, limestone, granite, aluminum, stainless steel, plastic,

ceramic tile, and others.

6.3 Masking Tape, paper, roll, 25 mm (1 in.) wide.

NOTE 1—A – 25 mm by 2 mm (1 in. by 0.08 in.) indentation

6.4 Wire Mesh Screen, stainless steel or aluminum, 20-

B – 25 mm by 4 mm (1 in. by 0.16 in.) indentation

mesh, 0.4 mm (0.016 in.) wire thickness, cut to a width of 25

FIG. 1 Special Tooling Device

mm + 0 mm, -2 mm (1.0 in. + 0 in., -0.08 in.) by a minimum

length of 250 mm (10 in.).The wire mesh screen selected must

7.1.1 Condition a minimum of 250 g of sealant for 24 h at

be flexible yet strong enough to not tear during adhesion-in-

standard conditions. Multi-component sealants will require

peel testing. The wire mesh screen must be flat and free of

mixing for 5 min or as recommended by the sealant manufac-

kinks.To ensure adhesion of the joint sealant to the wire mesh,

turer. Specific mixing equipment and mixing procedures may

thoroughly clean the screen prior to use. Sealant primer on the

be recommended by the sealant manufacturer.

wire mesh screen is generally recommended by the sealant

7.1.2 Clean and prepare the substrate samples as described

manufacturer to enhance adhesion of the joint sealant to the

in Guide C1375. Substrate materials not described in C1375

screen. Sealant may also be pre-applied to the screen to

should be prepared in accordance with the sealant manufactur-

enhance adhesion.

er’s recommendations.

6.4.1 Discussion—Adhesion of the joint sealant to the mesh

7.1.3 Applyprimer(s)tothesubstrate(s)ifrecommendedby

screen is essential to evaluate adhesion-in-peel properties of

the sealant manufacturer.

the sealant to the substrate. Due to the unique characteristics of

7.1.4 Masking tape can be applied to the substrate surfaces

each sealant, the sealant manufacturer must determine for each

adjacent to the test area to allow easy removal of excess joint

sealant the appropriate screen composition, mesh dimension,

sealant.

wire diameter and screen cleaning and priming procedure.

7.1.5 Wire mesh screens must be thoroughly cleaned and

Polyester mesh, fiberglass mesh, airplane cloth, fabric, plastic

primed, if required, as recommended by the sealant manufac-

film or similar material can be used in lieu of a wire mesh

turer.

provided that the material is pliable, of a thickness no greater

7.1.6 For each substrate preparation/cleaning condition to

than 0.5 mm (0.02 in.), does not adversely affect sealant cure

be tested, apply a bead of sealant at least 100 mm (4 in.) in

and does not rupture during adhesion-in-peel testing.

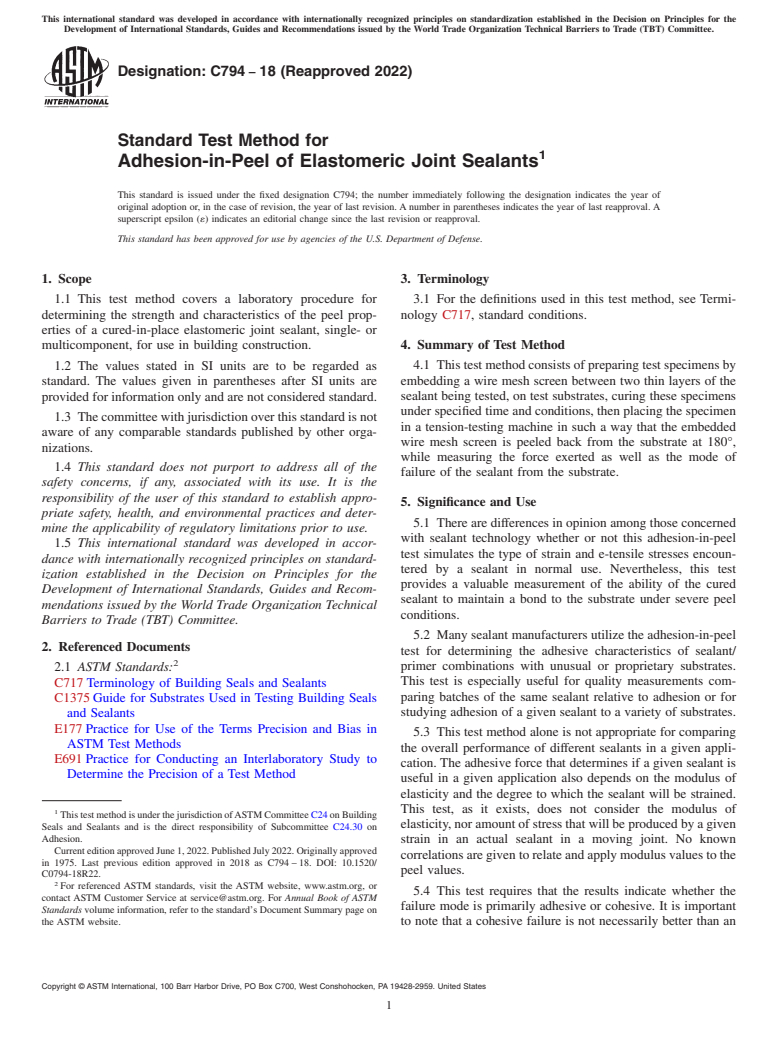

length to the substrate surface (Fig. 2).

6.5 Tooling Device—aluminum or similar rigid material,

7.1.7 Immediately place the wire mesh screen on the sealant

created to producea2mm (0.08 in.) by 25 mm (1 in.) sealant

bead and lightly tap it into the joint sealant (Fig. 3).

bead and 4 mm (0.16 in.) by 25 mm (1 in.) sealant bead after

7.1.8 Holding the screen with a finger to prevent slippage,

tooling (Fig. 1). The width of the tooling device may be up to

gentlydrawdownthesealantimbeddingthewiremeshintothe

27 mm (1.06 in.) to allow easy tooling of the sealant without

wet sealant, using the special tooling device – side A (Fig. 1)

snagging the edges of the screen.

at an 90° angle to the substrate (Fig. 4). The wire mesh screen

6.6 Putty Knife, rigid, approximately 40 mm (1.6 in.) wide.

shouldbeimbeddedtoauniformdepthof2mm(0.08in.)from

the substrate surface (Fig. 5).

6.7 Knife, with sharp razor-type blade.

7.1.9 Immediately apply a second bead of joint sealant over

7. Test Specimens and Cure Procedures

the first bead of sealant and wire mesh screen (Fig. 6).

7.1 Four test specimens (adhesion-in-peel samples) shall be 7.1.10 Again holding down the screen with a finger to

prepared on each of the substrates using the following proce- prevent slippage, use the special tooling device – side B (Fig.

dures: 1) and draw down the sealant at a 90° angle to the substrate.

C794 − 18 (2022)

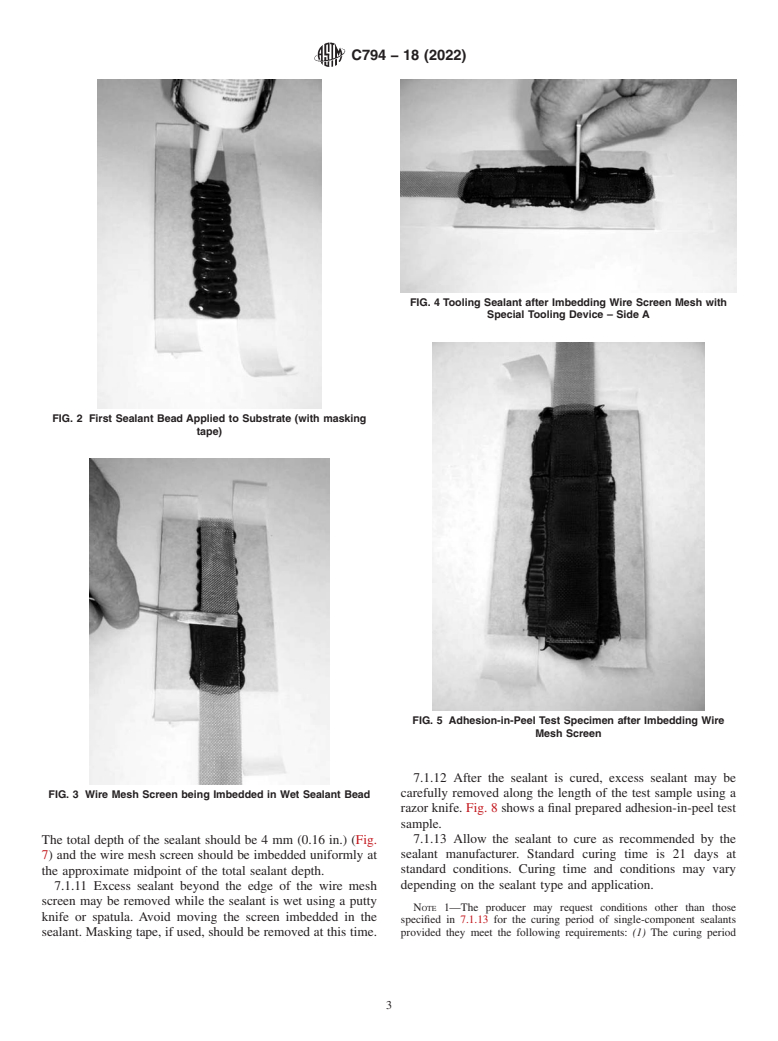

FIG. 4 Tooling Sealant after Imbedding Wire Screen Mesh with

Special Tooling Device – Side A

FIG. 2 First Sealant Bead Applied to Substrate (with masking

tape)

FIG. 5 Adhesion-in-Peel Test Specimen after Imbedding Wire

Mesh Screen

7.1.12 After the sealant is cured, excess sealant may be

carefully removed along the length of the test sample using a

FIG. 3 Wire Mesh Screen being Imbedded in Wet Sealant Bead

razor knife. Fig. 8 shows a final prepared adhesion-in-peel test

sample.

7.1.13 Allow the sealant to cure as recommended by the

The total depth of the sealant should be 4 mm (0.16 in.) (Fig.

sealant manufacturer. Standard curing time is 21 days at

7) and the wire mesh screen should be imbedded uniformly at

standard conditions. Curing time and conditions may vary

the approximate midpoint of the total sealant depth.

depending on the sealant type and application.

7.1.11 Excess sealant beyond the edge of the wire mesh

screen may be removed while the sealant is wet using a putty

NOTE 1—The producer may request conditions other than those

knife or spatula. Avoid moving the screen imbedded in the

specified in 7.1.13 for the curing period of single-component sealants

sealant. Masking tape, if used, should be removed at this time. provided they meet the following requirements: (1) The curing period

C794 − 18 (2022)

8. Test Procedure

8.1 Once the sealant is fully cured, gently wrap the loose

end of the wire mesh screen and bend back. Using a razor

knife, provide a fresh cut along the sealant to the substrate

interface (Fig. 9).

8.1.1 Place the test specimen in the tensile testing machine

with the substrate secured to the fixed member and the loose

end of the wire mesh screen secured to the movable member at

an angle of 180° (Fig. 10).

8.1.2 Pullthescreenatarateof50mm(2in.)/minforatotal

of 1 min (Fig. 11).

8.1.2.1 If the screen breaks during the testing, disregard the

value. If possible, undercut the sealant with a razor knife and

repeat the test. If the screen continues to break, prepare new

test samples using a higher strength wire mesh screen.

FIG. 6 Applying Second Bead of Sealant

8.1.2.2 If the sealant peels away cleanly from the screen,

disregard the value. Undercut the sealant with the razor knife

and repeat the test. If adhesive failure to the screen continues,

prepare new test samples using a more thoroughly cleaned or

primed, or both, wire mesh screen. If necessary, use a material

other than a wire mesh screen.

8.1.2.3 If the adhesion-in-peel test sample shows adhesive

failure to the screen in two repeated attempts but peel force

values are above the specified requirements, further sample

testing may not be required. In such cases, report failure mode

as screen delamination, since adhesive or cohesive failure of

the sealant to the substrate is not fully established. The screen

should be pulled for a total of 1 min as described in 8.1.2.

NOTE 2—Discussion—Some sealants may have a non-homogeneous

mode of failure during the initial adhesion-in-peel testing. During the first

30 to 60 s of testing, the sealant may achieve a steady state and longer test

duration may be needed to accurately assess the failure mode of the

FIG. 7 Tooling Second Bead of Sealant with Special Tooling De-

sealant.

vice–SideB

FIG. 8 Finished Adhesion-in-Peel Test Samples

shall extend for 21 days; and(2)The temperature during the curing period

shall not exceed 122 °F (50 °C). FIG. 9 Cut Along Sealant/Substrate Interface with Razor Knife

C794 − 18 (2022)

8.1.4 Record the peak force in Newton (pound force).

8.1.5 Observe and record the approximate percentages of

sealant failure modes over the total test area. Sealant failure is

described as either adhesive or cohesive failure. SeeFig. 12 for

an example of each failure mode. Failure observed within the

substrate (that is, paint removal, etc.) should be reported as

substrate failure.

8.2 Water Immersion Test—Using either four separate test

specimens or the same test specimen used for dry adhesion

testing and following completion of standard cure as described

in 7.1.12, immerse the test samples for 7 days in distilled water

conditioned to 23 °C 6 2 °C (73 °F 6 4 °F). Mortar and

concrete specimen should be placed in a separate container

from glass and aluminum specimen because the high alkali

condition generated could have an adverse effect on the glass

and aluminum.

8.2.1 Following water immersion, remove the test samples,

lightly dry with a cloth or paper towel and test within 10 min

as described in 8.1 through 8.1.5.

8.3 Additional conditions may be used including different

cure conditions, different water temperature or duration of

immersion, exposure of sealant to chemicals or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.