ASTM E672-87(2019)e1

(Specification)Standard Specification for Disposable Glass Micropipets

Standard Specification for Disposable Glass Micropipets

ABSTRACT

This specification covers two different types of disposable glass micropipets, calibrated “to contain,” used in measuring microlitre volumes of liquids. The pipets made to these specifications shall be fabricated from borosilicate glass (Type I, Class A or B) or soda lime glass (Type II). Pipets shall be of one piece construction and shall meet the specified requirements for shape, dimensions, and capacity. The calibration line and identification markings such as color code marking are illustrated. The methods of reading and setting a liquid meniscus and a mercury meniscus are detailed. Capacity test shall be performed and calculation of micropipet volume shall be taken using the given formula.

SCOPE

1.1 This specification covers two different types of disposable micropipets, calibrated “to contain,” used in measuring microlitre volumes of liquids.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 The following precautionary caveat pertains only to paragraph 9.1.1 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ϵ1

Designation:E672 −87 (Reapproved 2019)

Standard Specification for

Disposable Glass Micropipets

This standard is issued under the fixed designation E672; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Text in 6.2.2, 9.1.2,and 9.2 was corrected editorially in February 2019.

1. Scope test procedure specified in 9.4.1. It is quantified by the

inaccuracy of the mean (bias).

1.1 This specification covers two different types of dispos-

able micropipets, calibrated “to contain,” used in measuring 3.1.2 disposable micropipet—such micropipets will only be

microlitre volumes of liquids.

expected to provide their specified performance during their

original use or operation.

1.2 The values stated in SI units are to be regarded as the

standard.

NOTE 1—The descriptions of “accuracy” and “repeatability” apply only

in cases where the distributions are Gaussian.

1.3 The following precautionary caveat pertains only to

paragraph 9.1.1 of this specification. This standard does not

3.1.3 repeatability—the closeness of agreement between the

purport to address all of the safety concerns, if any, associated

individual volumes obtained by applying the test procedure

with its use. It is the responsibility of the user of this standard

specified in 9.4.2. It is quantified by the imprecision.

to establish appropriate safety, health, and environmental

practices and determine the applicability of regulatory limita-

4. Classification

tions prior to use.

4.1 This specification covers two different pipet designs as

1.4 This international standard was developed in accor-

follows:

dance with internationally recognized principles on standard-

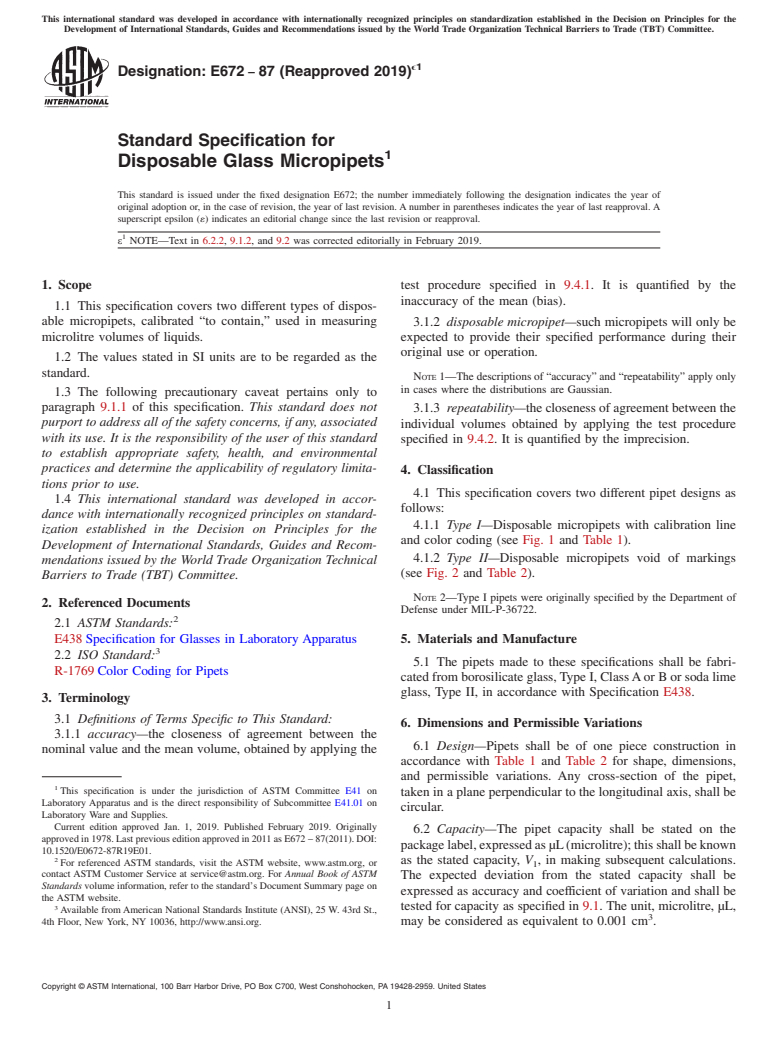

4.1.1 Type I—Disposable micropipets with calibration line

ization established in the Decision on Principles for the

and color coding (see Fig. 1 and Table 1).

Development of International Standards, Guides and Recom-

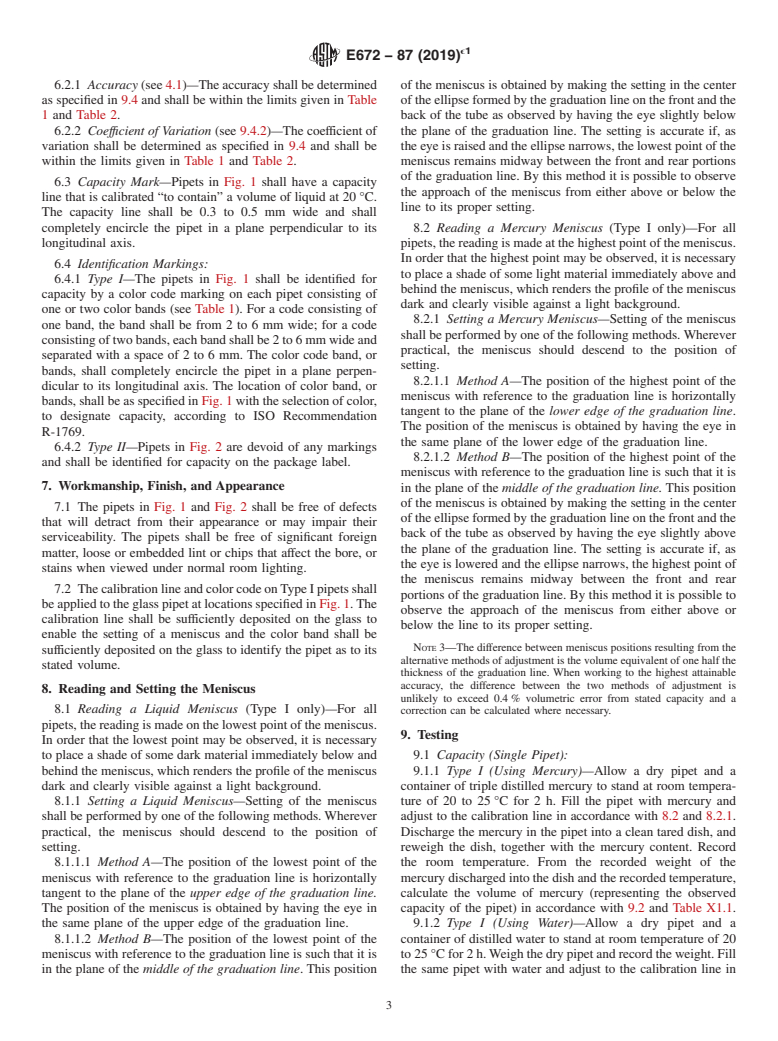

4.1.2 Type II—Disposable micropipets void of markings

mendations issued by the World Trade Organization Technical

(see Fig. 2 and Table 2).

Barriers to Trade (TBT) Committee.

NOTE 2—Type I pipets were originally specified by the Department of

2. Referenced Documents

Defense under MIL-P-36722.

2.1 ASTM Standards:

E438 Specification for Glasses in Laboratory Apparatus 5. Materials and Manufacture

2.2 ISO Standard:

5.1 The pipets made to these specifications shall be fabri-

R-1769 Color Coding for Pipets

cated from borosilicate glass,Type I, ClassAor B or soda lime

glass, Type II, in accordance with Specification E438.

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

6. Dimensions and Permissible Variations

3.1.1 accuracy—the closeness of agreement between the

6.1 Design—Pipets shall be of one piece construction in

nominal value and the mean volume, obtained by applying the

accordance with Table 1 and Table 2 for shape, dimensions,

and permissible variations. Any cross-section of the pipet,

This specification is under the jurisdiction of ASTM Committee E41 on

taken in a plane perpendicular to the longitudinal axis, shall be

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

circular.

Laboratory Ware and Supplies.

Current edition approved Jan. 1, 2019. Published February 2019. Originally

6.2 Capacity—The pipet capacity shall be stated on the

approvedin1978.Lastpreviouseditionapprovedin2011asE672 – 87(2011).DOI:

packagelabel,expressedasµL(microlitre);thisshallbeknown

10.1520/E0672-87R19E01.

as the stated capacity, V , in making subsequent calculations.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The expected deviation from the stated capacity shall be

Standards volume information, refer to the standard’s Document Summary page on

expressed as accuracy and coefficient of variation and shall be

the ASTM website.

tested for capacity as specified in 9.1. The unit, microlitre, µL,

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. may be considered as equivalent to 0.001 cm .

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

ϵ1

E672−87 (2019)

FIG. 1 Type I Pipet

TABLE 1 Dimensions for Type I Pipet

Maximum Volumetric Deviation

Stated Capacity, Minimum Di- Minimum Wall

Color Code Coefficient of

µL ameter A, mm B, mm Accuracy, %

Variation, %

5 white 1.0 0.35 ±1.0 <1.5

10 orange 1.0 0.25 ±0.5 <1.0

20 black 1.1 0.25 ±0.5 <1.0

25 2 white 1.1 0.25 ±0.5 <1.0

50 green 1.3 0.20 ±0.5 <1.0

100 blue 1.6 0.20 ±0.5 <1.0

200 red 2.2 0.20 ±0.5 <1.0

FIG. 2 Type II Pipet

TABLE 2 Dimensions for Type II Pipet

Maximum Volumetric Deviation

Stated Capacity, Minimum Minimum Di- Minimum Wall

Coefficient of

µL Length A, mm ameter B, mm C, mm Accuracy, %

Variation, %

1 20 0.5 0.20 ±1.5 <2.0

2 20 0.5 0.20 ±1.2 <1.5

3 20 0.6 0.20 ±1.2 <1.5

4 20 0.6 0.20 ±1.2 <1.5

5 20 0.6 0.20 ±1.2 <1.5

10 20 0.6 0.10 ±1.0 <1.2

20 20 0.6 0.10 ±1.0 <1.2

25 30 0.6 0.10 ±1.0 <1.2

50 30 1.0 0.10 ±1.0 <1.2

100 50 1.3 0.10 ±1.0 <1.2

ϵ1

E672−87 (2019)

6.2.1 Accuracy (see 4.1)—The accuracy shall be determined of the meniscus is obtained by making the setting in the center

as specified in 9.4 and shall be within the limits given in Table oftheellipseformedbythegraduationlineonthefrontandthe

1 and Table 2. back of the tube as observed by having the eye slightly below

6.2.2 Coeffıcient of Variation (see 9.4.2)—The coefficient of the plane of the graduation line. The setting is accurate if, as

variation shall be determined as specified in 9.4 and shall be the eye is raised and the ellipse narrows, the lowest point of the

within the limits given in Table 1 and Table 2. meniscus remains midway between the front and rear portions

of the graduation line. By this method it is possible to observe

6.3 Capacity Mark—Pipets in Fig. 1 shall have a capacity

the approach of the meniscus from either above or below the

line that is calibrated “to contain” a volume of liquid at 20 °C.

line to its proper setting.

The capacity line shall be 0.3 to 0.5 mm wide and shall

completely encircle the pipet in a plane perpendicular to its 8.2 Reading a Mercury Meniscus (Type I only)—For all

longitudinal axis. pipets,thereadingismadeatthehighestpointofthemeniscus.

In order that the highest point may be observed, it is necessary

6.4 Identification Markings:

to place a shade of some light material immediately above and

6.4.1 Type I—The pipets in Fig. 1 shall be identified for

behind the meniscus, which renders the profile of the meniscus

capacity by a color code marking on each pipet consisting of

dark and clearly visible against a light background.

one or two color bands (see Table 1). For a code consisting of

8.2.1 Setting a Mercury Meniscus—Setting of the meniscus

one band, the band shall be from 2 to 6 mm wide; for a code

shall be performed by one of the following methods.Wherever

consistingoftwobands,eachbandshallbe2to6mmwideand

practical, the meniscus should descend to the position of

separated with a space of 2 to 6 mm. The color code band, or

setting.

bands, shall completely encircle the pipet in a plane perpen-

8.2.1.1 Method A—The position of the highest point of the

dicular to its longitudinal axis. The location of color band, or

meniscus with reference to the graduation line is horizontally

bands, shall be as specified in Fig. 1 with the selection of color,

tangent to the plane of the lower edge of the graduation line.

to designate capacity, according to ISO Recommendation

The position of the meniscus is obtained by having the eye in

R-1769.

the same plane of the lower edge of the graduation line.

6.4.2 Type II—Pipets in Fig. 2 are devoid of any markings

8.2.1.2 Method B—The position of the highest point of the

and shall be identified for capacity on the package label.

meniscus with reference to the graduation line is such that it is

7. Workmanship, Finish, and Appearance

in the plane of the middle of the graduation line. This position

of the meniscus is obtained by making the setting in the center

7.1 The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.