ASTM E438-92(1996)

(Specification)Standard Specification for Glasses in Laboratory Apparatus

Standard Specification for Glasses in Laboratory Apparatus

SCOPE

1.1 This specification covers the glasses commonly used to manufacture laboratory glass apparatus.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 438 – 92 (Reapproved 1996)

Standard Specification for

Glasses in Laboratory Apparatus

This standard is issued under the fixed designation E 438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

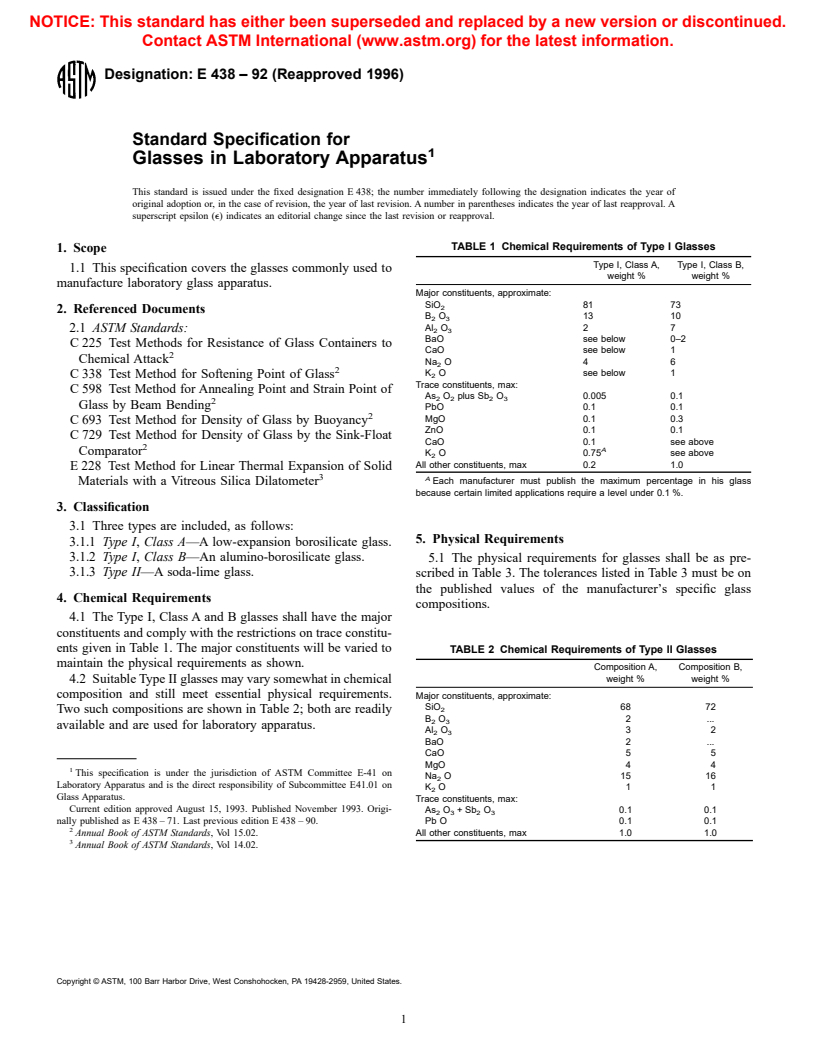

TABLE 1 Chemical Requirements of Type I Glasses

1. Scope

Type I, Class A, Type I, Class B,

1.1 This specification covers the glasses commonly used to

weight % weight %

manufacture laboratory glass apparatus.

Major constituents, approximate:

SiO 81 73

2. Referenced Documents

B O 13 10

2 3

Al O 27

2.1 ASTM Standards: 2 3

BaO see below 0–2

C 225 Test Methods for Resistance of Glass Containers to

CaO see below 1

Chemical Attack

NaO4 6

K O see below 1

C 338 Test Method for Softening Point of Glass 2

Trace constituents, max:

C 598 Test Method for Annealing Point and Strain Point of

As O plus Sb O 0.005 0.1

2 2 2 3

Glass by Beam Bending

PbO 0.1 0.1

MgO 0.1 0.3

C 693 Test Method for Density of Glass by Buoyancy

ZnO 0.1 0.1

C 729 Test Method for Density of Glass by the Sink-Float

CaO 0.1 see above

A

Comparator

K O 0.75 see above

All other constituents, max 0.2 1.0

E 228 Test Method for Linear Thermal Expansion of Solid

3 A

Materials with a Vitreous Silica Dilatometer Each manufacturer must publish the maximum percentage in his glass

because certain limited applications require a level under 0.1 %.

3. Classification

3.1 Three types are included, as follows:

5. Physical Requirements

3.1.1 Type I, Class A—A low-expansion borosilicate glass.

3.1.2 Type I, Class B—An alumino-borosilicate glass.

5.1 The physical requirements for glasses shall be as pre-

3.1.3 Type II—A soda-lime glass. scribed in Table 3. The tolerances listed in Table 3 must be on

the published values of the manufacturer’s specific glass

4. Chemical Requirements

compositions.

4.1 The Type I, Class A and B glasses shall have the major

constituents and comply with the restrictions on trace constitu-

ents given in Table 1. The major constituents will be varied to TABLE 2 Chemical Requirements of Type II Glasses

maintain the physical requirements as shown.

Composition A, Composition B,

weight % weight %

4.2 Suitable Type II glasses may vary somewhat in chemical

composition and still meet essential physical requirements.

Major constituents, approximate:

SiO 68 72

Two such compositions are shown in Table 2; both are readily 2

B O 2 .

2 3

available and are used for laboratory apparatus.

Al O 32

2 3

BaO 2 .

CaO 5 5

MgO 4 4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.