ASTM D5713-00

(Test Method)Standard Test Method for Analysis of High Purity Benzene for Cyclohexane Feedstock by Capillary Gas Chromatography

Standard Test Method for Analysis of High Purity Benzene for Cyclohexane Feedstock by Capillary Gas Chromatography

SCOPE

1.1 This test method covers the determination of specific impurities in, and the purity of benzene for cyclohexane feedstock by gas chromatography. It is applicable to benzene in the range from 99 to 100% purity and to impurities at concentrations of 2 to 10000 mg/kg.

1.2 The following applies to all specified limits in this test method: for purposes of determining conformance with this test method, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E29.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 7 and Note 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5713–00

Standard Test Method for

Analysis of High Purity Benzene for Cyclohexane Feedstock

by Capillary Gas Chromatography

This standard is issued under the fixed designation D5713; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope OSHA Regulations, 29 CFR, paragraphs 1910.1000 and

1910.1200

1.1 This test method covers the determination of specific

impurities in, and the purity of benzene for cyclohexane

3. Terminology

feedstockbygaschromatography.Itisapplicabletobenzenein

3.1 Definitions:

the range from 99 to 100% purity and to impurities at

3.1.1 For definition of terms used in this test method see

concentrations of 2 to 10000 mg/kg.

Terminology D4790.

1.2 The following applies to all specified limits in this test

method: for purposes of determining conformance with this

4. Summary of Test Method

test method, an observed value or a calculated value shall be

4.1 Inthistestmethod,thechromatogrampeakareaforeach

rounded off “to the nearest unit” in the last right-hand digit

impurity is compared to the peak area of the internal standard

used in expressing the specification limit, in accordance with

(n-octane or other suitable known) added to the sample. From

the rounding-off method of PracticeE29.

the response factor of toluene relative to that of the internal

1.3 This standard does not purport to address all of the

standard, and using a response factor of 1.00 for nonaromatic

safety concerns, if any, associated with its use. It is the

impurities and the amount of internal standard added, the

responsibility of the user of this standard to establish appro-

concentrations of the impurities are calculated. The benzene

priate safety and health practices and determine the applica-

content is obtained by subtracting the total amount of all

bility of regulatory limitations prior to use. For a specific

impurities from 100.00.

hazard statement, see Section 8 and Note 1.

5. Significance and Use

2. Referenced Documents

5.1 Thistestmethodisdesignedtoobtainbenzenepurityon

2.1 ASTM Standards:

thebasisofimpuritiesnormallypresentinbenzeneandmaybe

D3437 Practice for Sampling and Handling Cyclic Prod-

2 used for final product inspections and process control.

ucts

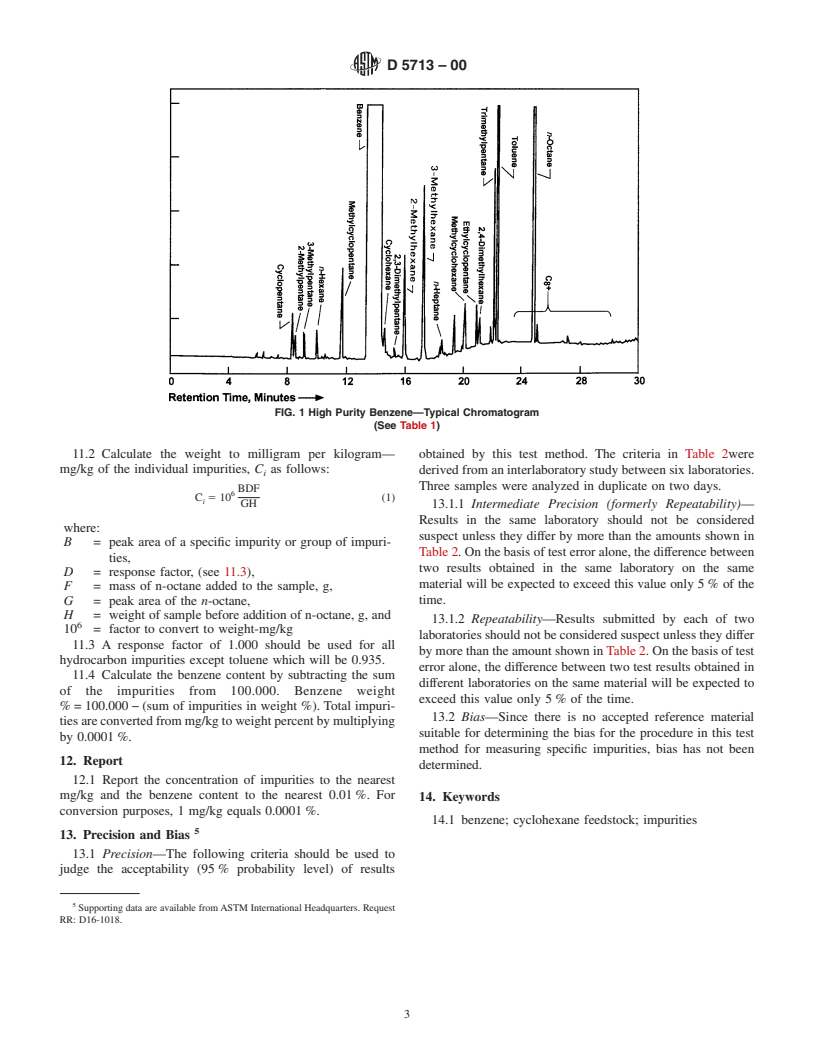

5.2 This test method will detect the following impurities:

D4790 Terminology of Aromatic Hydrocarbons and Re-

2 toluene, methylcyclopentane, n-hexane, 2-methylhexane, cy-

lated Chemicals

clohexane, cyclopentane, 2-methylpentane, 2,3-

E29 Practice for Using Significant Digits in Test Data to

3 dimethylpentane,3-methylhexane, n-heptane,methylcyclohex-

Determine Conformance with Specifications

ane, ethylcyclopentane, 2,4-dimethylhexane, trimethylpentane,

E260 Practice for Packed Column Gas Chromatography

and others where specific impurity standards are available.

E355 Practices for Gas Chromatography Terms and Rela-

Absolute purity cannot be accurately determined if unknown

tionships

impurities are present.

E1510 Practice for Installing Fused Silica Open Tubular

Capillary Columns in Gas Chromatographs

6. Apparatus

2.2 Other Document:

6.1 Gas Chromatograph—Anygaschromatographhavinga

temperatureprogrammableoven,flameionizationdetectorand

a splitter injector suitable for use with a fused silica capillary

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbon and Related Chemicals and is the direct responsibility of

column may be used, provided the system has sufficient

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane, and Their

sensitivity that will give a minimum peak height of 3 times the

Derivatives.

Current edition approved June 10, 2000. Published August 2000. Originally

published as D5713–95. Last previous edition D5713–96.

2 4

Annual Book of ASTM Standards, Vol 06.04. Available from the Superintendent of Documents, U.S. Government Printing

Annual Book of ASTM Standards, Vol 14.02. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5713–00

TABLE 2 Intermediate Precision and Reproducibility

background noise for 2 mg/kg of an impurity when operated at

recommended conditions. Average

Intermediate

Component Concentration ppm Reproducibility

6.2 Column—Fused silica capillary columns have been

Precision

Weight %

foundtobesatisfactory.Anexampleis50mof0.20-mminside

Benzene 99.96 0.006 0.022

diameter fused silica capillary internally coated to a film

99.97 0.007 0.020

thickness of 0.50 µm with cross-linked methyl silicone (see

99.96 0.008 0.025

Table1forparameters).Othercolumnsmaybeusedafterithas

Methylcyclopentane 104 8.3 27.9

beenestablishedthatsuchacolumniscapableofseparatingall

43 12.2 19.4

major impurities (for example, compounds listed in 5.2) and

54 2.5 15.1

the internal standard from the benzene under operating condi-

Toluene 64 5.1 22.0

tions appropriate for the column. The column must give

63 3.0 16.6

satisfactory resolution (distance from the valley between the 28 1.8 9.1

peaks is not greater than 50% of the peak heights of the

Methylcyclohexane 132 7.4 34.8

impurity) of cyclohexane from benzene as well as other

43 1.4 5.4

impurity peaks. A poorly resolved peak, such as cyclohexane, 79 3.2 17.0

will often require a tangent skim from the neighboring peak.

Methylcyclohexane + 196 7.9 54.9

6.3 Electronic Integration, with tangent skim capabilities is

Toluene 106 12.9 33.6

recommended. 106 4.4 20.4

6.4 Vial.

n-Hexane 4 2.2 3.7

6.5 Microsyringes, assorted volumes.

3 1.5 2.2

2 1.8 2.5

7. Reagents and Materials

n-Heptane 6 2.7 11.1

7.1 Carrier Gas—acarriergas(minimumpurityof99.95%

16 1.5 5.6

mol) appropriate to the type of detector used should be

15 4.0 23.4

employed.

Ethylcyclopentane 7 1.8 3.7

6 1.9 11.0

NOTE 1—Precaution: If hydrogen is used as the carrier gas, take

11 1.5 6.1

specialsafetyprecautions

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.