ASTM B165-05(2014)

(Specification)Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

Standard Specification for Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

ABSTRACT

This specification covers nickel-copper alloy UNS N04400 in the form of cold-worked seamless pipe and tube. The material shall conform to the composition limits specified. Tension test, hydrostatic test, nondestructive electric test, and rounding method shall be done in accordance to the specified requirements.

SCOPE

1.1 This specification2 covers nickel-copper alloy UNS N044003 in the form of cold-worked seamless pipe and tube in the conditions shown in Table 1 and Table X1.1.

1.1.1 Hot worked material is available. Properties and permissible tolerances are to be agreed upon between the manufacturer and purchaser.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B165 −05 (Reapproved 2014)

Standard Specification for

Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

This standard is issued under the fixed designation B165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Alloys (Withdrawn 2003)

1.1 This specification covers nickel-copper alloy UNS

3. Terminology

N04400 in the form of cold-worked seamless pipe and tube in

3.1 Definitions of Terms Specific to This Standard:

the conditions shown in Table 1 and Table X1.1.

3.1.1 average diameter, n—average of the maximum and

1.1.1 Hot worked material is available. Properties and

minimum outside diameters, as determined at any one cross-

permissible tolerances are to be agreed upon between the

section of the pipe or tube.

manufacturer and purchaser.

3.1.2 pipe, n—tube conforming to the particular dimensions

1.2 The values stated in inch-pound units are to be regarded

commercially known as pipe sizes, see Table X2.1.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3.1.3 seamless pipe or tube, n—pipe or tube produced with

and are not considered standard.

a continuous periphery in all stages of the operations.

1.3 This standard does not purport to address all of the 3.1.4 tube, n—hollow product of round or any other cross-

section having a continuous periphery.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to become familiar

4. Ordering Information

with all hazards including those identified in the appropriate

Material Safety Data Sheet (MSDS) for this product/material

4.1 Orders for material to this specification shall include

as provided by the manufacturer, to establish appropriate

information with respect to the following:

safety and health practices, and determine the applicability of

4.1.1 Alloy name or UNS number.

regulatory limitations prior to use.

4.1.2 ASTM designation and year of issue.

4.1.3 Condition (see Appendix X3).

2. Referenced Documents

4.1.4 Finish (see Appendix X3).

4.1.5 Dimensions:

2.1 ASTM Standards:

4.1.5.1 Tube—Specify outside diameter and nominal or

B829 Specification for General Requirements for Nickel and

minimum wall.

Nickel Alloys Seamless Pipe and Tube

4.1.5.2 Pipe—Specify standard pipe size and schedule.

E8 Test Methods for Tension Testing of Metallic Materials

4.1.5.3 Length—Cut to length or random.

E29 Practice for Using Significant Digits in Test Data to

4.1.6 Quantity—Feet or number of pieces.

Determine Conformance with Specifications

4.1.7 Hydrostatic Test or Nondestructive Electric Test—

E76 Test Methods for Chemical Analysis of Nickel-Copper

Specify type of test (see 6.2).

4.1.8 Hydrostatic Pressure Requirements—Specify test

pressure if other than required by 12.3.1.

This specification is under the jurisdiction of ASTM Committee B02 on

4.1.9 Certification—State if certification or a report of test

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

results is required (Section 15).

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Current edition approved Oct. 1, 2014. Published October 2014. Originally

4.1.10 Samples for Product (Check) Analysis—State

approved in 1941. Last previous edition approved in 2009 as B165 – 05 (2009).

whether samples for product (check) analysis should be fur-

DOI: 10.1520/B0165–05R14.

nished (see 5.2).

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SB-165 in Section II of that code. 4.1.11 Purchaser Inspection—If purchaser wishes to wit-

New designation established in accordance withASTM Practice E527 and SAE

ness tests or inspection of material at place of manufacture, the

J1086, Recommended Practice for Numbering Metals and Alloys (UNS).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B165−05 (2014)

TABLE 1 Mechanical Properties of Pipe and Tube

7.3 Straightness—Material shall be reasonably straight and

Yield Strength, Elongation in free of bends and kinks.

Tensile Strength, min. (0.2 % 2 in. or 50

Condition and Size

7.4 Ends—Ends shall be plain cut and deburred.

min, psi (MPa) offset), min, mm (or 4 D),

psi (MPa) min, %

7.5 Permissible variations for material specified as small-

Annealed:

diameter and light-wall tube (converter size) shall conform to

5 in. (127 mm) outside

diameter and under 70 000 (480) 28 000 (195) 35 the permissible variations prescribed in Table X1.2.

Over 5 in. (127 mm) outside

diameter 70 000 (480) 25 000 (170) 35

8. Workmanship, Finish, and Appearance

Stress-Relieved:

All sizes 85 000 (585) 55 000 (380) 15

8.1 The material shall be uniform in quality and temper,

smooth, commercially straight, and free of injurious imperfec-

tions.

purchase order must so state indicating which tests or inspec-

9. Sampling

tions are to be witnessed (Section 13).

4.1.12 Small-Diameter and Light-Wall Tube (Converter

9.1 Lot Definition:

Sizes)—See Appendix X1.

9.1.1 A lot for chemical analysis shall consist of one heat.

9.1.2 A lot for all other testing shall consist of all material

5. Chemical Composition

from the same heat, nominal size (excepting length), and

condition.

5.1 The material shall conform to the composition limits

specified in Table 2. 9.1.2.1 Where material cannot be identified by heat, a lot

shall consist of not more than 500 lb (227 kg) of material in the

5.2 If a product (check) analysis is performed by the

same condition and nominal size (excepting length).

purchaser, the material shall conform to the product (check)

analysis variations in Table 2. 9.2 Test Material Selection:

9.2.1 Chemical Analysis—Representative samples from

6. Mechanical and Other Requirements

each lot shall be taken during pouring or subsequent process-

ing.

6.1 Tension Test—The material shall conform to the tensile

9.2.1.1 Product (Check) Analysis shall be wholly the re-

properties specified in Table 1.

sponsibility of the purchaser.

6.1.1 Tensile properties for material specified as small-

9.2.2 Mechanical and other Properties—Samples of the

diameter and light-wall tube (converter sizes) shall be in

material to provide test specimens for mechanical and other

accordance with Table X1.1.

properties shall be taken from such locations in each lot as to

6.2 Hydrostatic or Nondestructive Electric Test—Each pipe

berepresentativeofthatlot.Testspecimensshallbetakenfrom

or tube shall be subjected to either the hydrostatic test or the

material in the final condition.

nondestructive electric test. The type of test to be used shall be

at the option of the manufacturer, unless otherwise specified in

10. Number of Tests

the purchase order.

10.1 Chemical Analysis—One test per lot.

7. Dimensions and Permissible Variations

10.2 Tension—One test per lot.

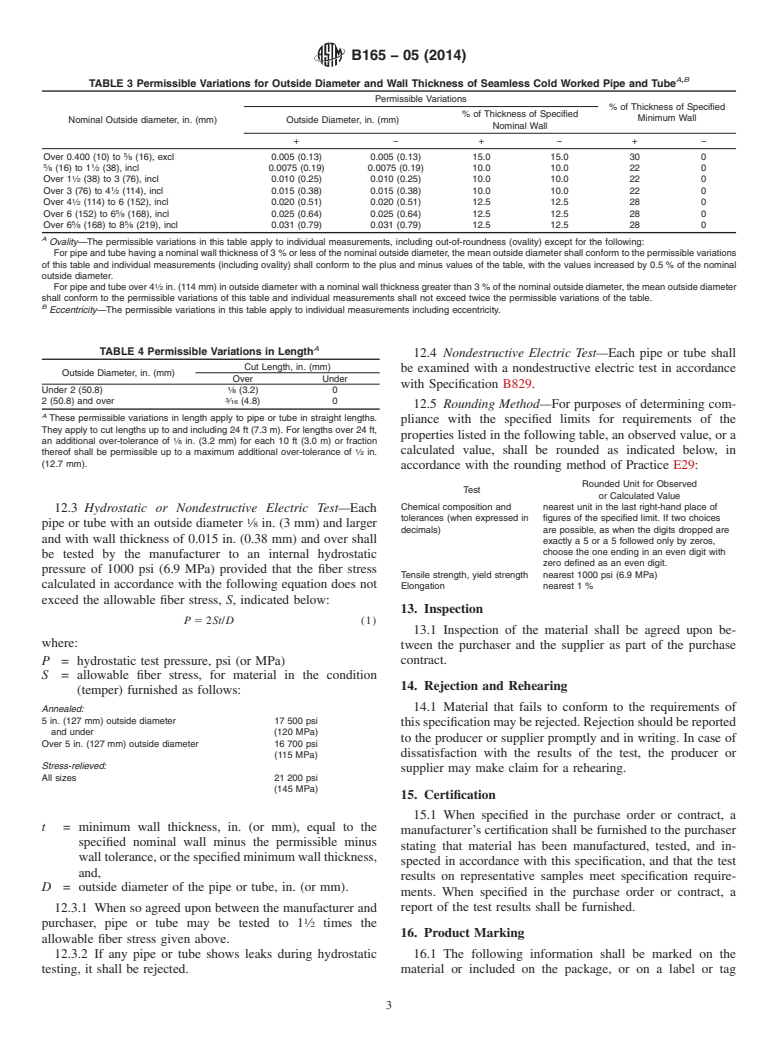

7.1 Diameter and Wall Thickness—The permissible varia-

10.3 Hydrostatic or Nondestructive Electric Test—Each

tions in the outside diameter and wall thickness shall conform

piece in each lot.

to the permissible variations prescribed in Table 3.

7.2 Length—When material is ordered cut-to-length, the

11. Specimen Preparation

length shall conform to the permissible variations prescribed in

11.1 Room Temperature Tensile Specimen—Material shall

Table 4.

be tested in the direction of fabrication. Whenever possible, all

pipe and tube shall be tested in full tubular size. When testing

in full tubular size is not possible, longitudinal strip specimens,

TABLE 2 Chemical Requirements

or the largest possible round specimen, shall be used. In the

Product (Check) Analysis

event of disagreement when full tubular testing is not possible,

Variations, under min or

Element Composition Limits, %

over max, of the Specified

a longitudinal strip specimen with reduced gauge length as

Limit of Element

contained in Test Methods E8 shall be used.

A

Ni 63.0 min 0.45

Cu 28.0 min 0.15

12. Test Methods

34.0 max 0.20

Fe 2.5 max 0.05

12.1 Chemical Composition—In case of disagreement, the

Mn 2.0 max 0.04

C 0.3 max 0.02 chemical composition shall be determined in accordance with

Si 0.5 max 0.03

Test Methods E76.

S 0.024 max 0.005

A 12.2 Tension Test—Tension testing shall be conducted in

Element shall be determined arithmetically by difference.

accordance with Test Methods E8.

B165−05 (2014)

A,B

TABLE 3 Permissible Variations for Outside Diameter and Wall Thickness of Seamless Cold Worked Pipe and Tube

Permissible Variations

% of Thickness of Specified

% of Thickness of Specified

Minimum Wall

Nominal Outside diameter, in. (mm) Outside Diameter, in. (mm)

Nominal Wall

+− + − + −

Over 0.400 (10) to ⁄8 (16), excl 0.005 (0.13) 0.005 (0.13) 15.0 15.0 30 0

5 1

⁄8 (16) to 1 ⁄2 (38), incl 0.0075 (0.19) 0.0075 (0.19) 10.0 10.0 22 0

Over 1 ⁄2 (38) to 3 (76), incl 0.010 (0.25) 0.010 (0.25) 10.0 10.0 22 0

Over 3 (76) to 4 ⁄2 (114), incl 0.015 (0.38) 0.015 (0.38) 10.0 10.0 22 0

Over 4 ⁄2 (114) to 6 (152), incl 0.020 (0.51) 0.020 (0.51) 12.5 12.5 28 0

Over 6 (152) to 6 ⁄8 (168), incl 0.025 (0.64) 0.025 (0.64) 12.5 12.5 28 0

5 5

Over 6 ⁄8 (168) to 8 ⁄8 (219), incl 0.031 (0.79) 0.031 (0.79) 12.5 12.5 28 0

A

Ovality—The permissible variations in this table apply to individual measurements, including out-of-roundness (ovality) except for the following:

Forpipeandtubehavinganominalwallthicknessof3 %orlessofthenominaloutsidediameter,themeanoutsidediametershallconformtothepermissiblevariations

of this table and individual measurements (including ovality) shall conform to the plus and minus values of the table, with the values increased by 0.5 % of the nominal

outside diameter.

Forpipeandtubeover4 ⁄2in.(114mm)inoutsidediameterwithanominalwallthicknessgreaterthan3 %ofthenominaloutsidediameter,themeanoutsidediameter

shall conform to the permissible variations of this table and individual measurements shall not exceed twice the permissible variations of the table.

B

Eccentricity—The permissible variations in this table apply to individual measurements including eccentricity.

A

TABLE 4 Permissible Variations in Length

12.4 Nondestructive Electric Test—Each pipe or tube shall

Cut Length, in. (mm)

be examined with a nondestructive electric test in accordance

Outside Diameter, in. (mm)

Over Under

with Specification B829.

Under 2 (50.8) ⁄8 (3.2) 0

2 (50.8) and over ⁄16 (4.8) 0

12.5 Rounding Method—For purposes of determining com-

A

These permissible variations in length apply to pipe or tube in straight lengths.

pliance with the specified limits for requirements of the

They apply to cut lengths up to and including 24 ft (7.3 m). For lengths over 24 ft,

properties listed in the following table, an observed value, or a

an additional over-tolerance of ⁄8 in. (3.2 mm) for each 10 ft (3.0 m) or fraction

1 calculated value, shall be rounded as indicated below, in

thereof shall be permissible up to a maximum additional over-tolerance of ⁄2 in.

(12.7 mm).

accordance with the rounding method of Practice E29:

Rounded Unit for Observed

Test

or Calculated Value

Chemical composition and nearest unit in the last right-hand place of

12.3 Hydrostatic or Nondestructive Electric Test—Each

tolerances (when expressed in figures of the specified limit. If two choices

pipe or tube with an outside diameter ⁄8 in. (3 mm) and larger

decimals) are possible, as when the digits dropped are

and with wall thickness of 0.015 in. (0.38 mm) and over shall

exactlya5ora5followed only by zeros,

choose the one ending in an even digit with

be tested by the manufacturer to an internal hydrostatic

zero defined as an even digit.

pressure of 1000 psi (6.9 MPa) provided that the fiber stress

Tensile strength, yield strength nearest 1000 psi (6.9 MPa)

calculated in accordance with the following equation does not

Elongation nearest 1 %

exceed the allowable fiber stress, S, indicated below:

13. Inspection

P 5 2St/D (1)

13.1 Inspection of the material shall be agreed upon be-

where:

tween the purchaser and the supplier as part of the purchase

contract.

P = hydrostatic test pressure, psi (or MPa)

S = allowable fiber stress, for material in the condition

14. Rejection and Rehearing

(temper) furnished as follows:

14.1 Material that fails to conform to the requirements of

Annealed:

5 in. (127 mm) outside diameter 17 500 psi

thisspecificationmayberejected.Rejectionshouldbereported

and under (120 MPa)

to the producer or supplier promptly and in writing. In case of

Over 5 in. (127 mm) outside diameter 16 700 psi

dissatisfaction with the results of the test, the producer or

(115 MPa)

Stress-relieved:

supplier may make claim for a rehearing.

All sizes 21 200 psi

(145 MPa)

15. Certification

15.1 When specified in the purchase order or contract, a

t = minimum wall thickness, in. (or mm), equal to the

manufacturer’s certification shall be furnished to the purchaser

specified nominal wall minus the permissible minus

stating that material has been manufactured, tested, and in-

walltolerance,orthespecifiedminimumwallthickness,

spected in accordance with this specification, and that the test

and,

results on representative samples meet specification require-

D = outside diameter of the pipe or tube, in. (or mm).

ments. When specified in the purchase order or contract, a

report of the test results shall be furnished.

12.3.1 When so agreed upon between the manufacturer and

purchaser, pipe or tube may be tested to 1 ⁄2 times the

16. Product Marking

allowable fiber stress given above.

12.3.2 If any pipe or tube shows leaks during hydrostatic 16.1 The following information shall be marked on the

testing, it shall be rejected. material or included on the package, or on a label or tag

B165−05 (2014)

attached thereto: The name of the material or UNS number, 17. Keywords

heat number, condition (temper), this specification number, the

17.1 seamless pipe; seamless tube; N04400

size, gross, tare and net weight, consignor and consignee

address, contract or order number, or such other information as

may be defined in the contract

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B165 − 05 (Reapproved 2009) B165 − 05 (Reapproved 2014)

Standard Specification for

Nickel-Copper Alloy (UNS N04400) Seamless Pipe and Tube

This standard is issued under the fixed designation B165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*Scope

2 3

1.1 This specification covers nickel-copper alloy UNS N04400*N04400 in the form of cold-worked seamless pipe and tube

in the conditions shown in Table 1 and Table X1.1.

1.1.1 Hot worked material is available. Properties and permissible tolerances are to be agreed upon between the manufacturer

and purchaser.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B829 Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E76 Test Methods for Chemical Analysis of Nickel-Copper Alloys (Withdrawn 2003)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 average diameter, n—average of the maximum and minimum outside diameters, as determined at any one cross-section

of the pipe or tube.

3.1.2 pipe, n—tube conforming to the particular dimensions commercially known as pipe sizes, see Table X2.1.

3.1.3 seamless pipe or tube, n—pipe or tube produced with a continuous periphery in all stages of the operations.

3.1.4 tube, n—hollow product of round or any other cross-section having a continuous periphery.

4. Ordering Information

4.1 Orders for material to this specification shall include information with respect to the following:

4.1.1 Alloy name or UNS number.

4.1.2 ASTM designation and year of issue.

4.1.3 Condition (see Appendix X3).

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved Oct. 1, 2009Oct. 1, 2014. Published October 2009October 2014. Originally approved in 1941. Last previous edition approved in 20052009 as

B165 – 05.B165 – 05 (2009). DOI: 10.1520/B0165–05R09.10.1520/B0165–05R14.

* New designation established in accordance with ASTM Practice E527 and SAE J1086, Recommended Practice for Numbering Metals and Alloys (UNS).

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-165 in Section II of that code.

New designation established in accordance with ASTM Practice E527 and SAE J1086, Recommended Practice for Numbering Metals and Alloys (UNS).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B165 − 05 (2014)

TABLE 1 Mechanical Properties of Pipe and Tube

Yield Strength,

Elongation in

min.

Tensile Strength, 2 in. or 50

Condition and Size (0.2%(0.2 %

min, psi (MPa) mm (or 4 D),

offset), min,

min, %

psi (MPa)

Annealed:

5 in. (127 mm) outside

diameter and under 70 000 (480) 28 000 (195) 35

Over 5 in. (127 mm) outside

diameter 70 000 (480) 25 000 (170) 35

Stress-Relieved:

All sizes 85 000 (585) 55 000 (380) 15

4.1.4 Finish (see Appendix X3).

4.1.5 Dimensions:

4.1.5.1 Tube—Specify outside diameter and nominal or minimum wall.

4.1.5.2 Pipe—Specify standard pipe size and schedule.

4.1.5.3 Length—Cut to length or random.

4.1.6 Quantity—Feet or number of pieces.

4.1.7 Hydrostatic Test or Nondestructive Electric Test—Specify type of test (see 6.2).

4.1.8 Hydrostatic Pressure Requirements—Specify test pressure if other than required by 12.3.1.

4.1.9 Certification—State if certification or a report of test results is required (Section 15).

4.1.10 Samples for Product (Check) Analysis—State whether samples for product (check) analysis should be furnished (see 5.2).

4.1.11 Purchaser Inspection—If purchaser wishes to witness tests or inspection of material at place of manufacture, the purchase

order must so state indicating which tests or inspections are to be witnessed (Section 13).

4.1.12 Small-Diameter and Light-Wall Tube (Converter Sizes)—See Appendix X1.

5. Chemical Composition

5.1 The material shall conform to the composition limits specified in Table 2.

5.2 If a product (check) analysis is performed by the purchaser, the material shall conform to the product (check) analysis

variations in Table 2.

6. Mechanical and Other Requirements

6.1 Tension Test—The material shall conform to the tensile properties specified in Table 1.

6.1.1 Tensile properties for material specified as small-diameter and light-wall tube (converter sizes) shall be in accordance with

Table X1.1.

6.2 Hydrostatic or Nondestructive Electric Test—Each pipe or tube shall be subjected to either the hydrostatic test or the

nondestructive electric test. The type of test to be used shall be at the option of the manufacturer, unless otherwise specified in the

purchase order.

7. Dimensions and Permissible Variations

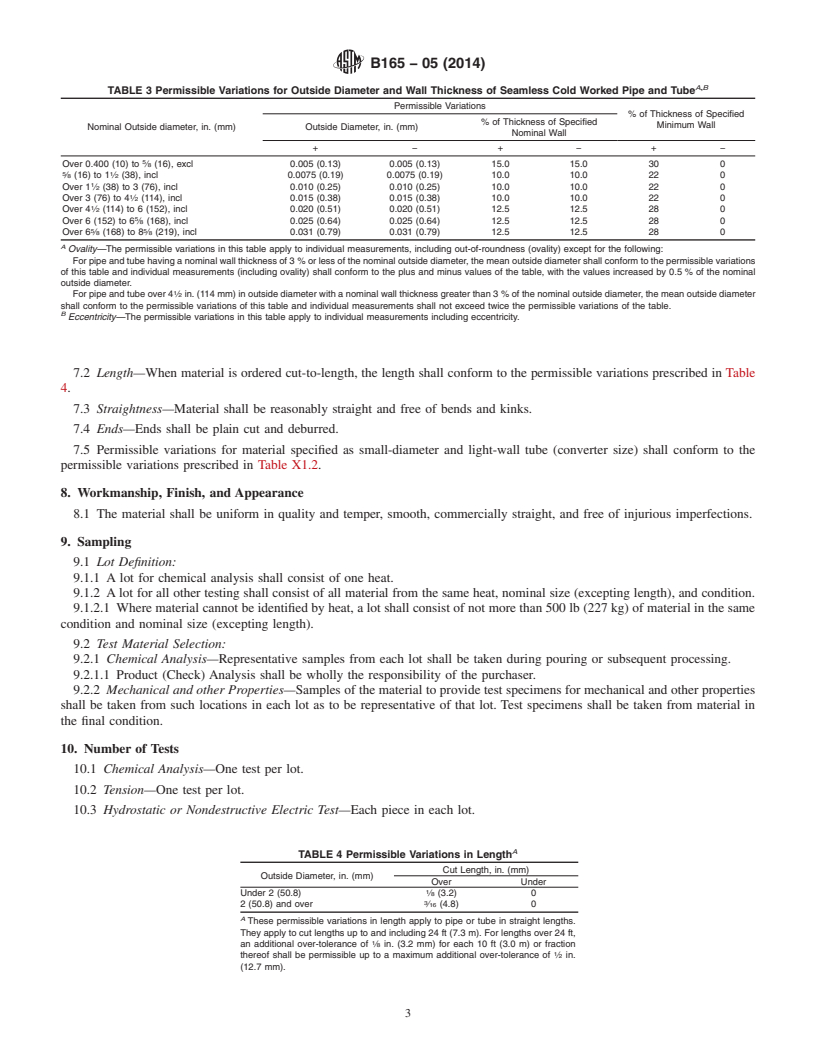

7.1 Diameter and Wall Thickness—The permissible variations in the outside diameter and wall thickness shall conform to the

permissible variations prescribed in Table 3.

TABLE 2 Chemical Requirements

Product (Check) Analysis

Variations, under min or

Element Composition Limits, %

over max, of the Specified

Limit of Element

A

Ni 63.0 min 0.45

Cu 28.0 min 0.15

34.0 max 0.20

Fe 2.5 max 0.05

Mn 2.0 max 0.04

C 0.3 max 0.02

Si 0.5 max 0.03

S 0.024 max 0.005

A

Element shall be determined arithmetically by difference.

B165 − 05 (2014)

A,B

TABLE 3 Permissible Variations for Outside Diameter and Wall Thickness of Seamless Cold Worked Pipe and Tube

Permissible Variations

% of Thickness of Specified

% of Thickness of Specified

Minimum Wall

Nominal Outside diameter, in. (mm) Outside Diameter, in. (mm)

Nominal Wall

+ − + − + −

Over 0.400 (10) to ⁄8 (16), excl 0.005 (0.13) 0.005 (0.13) 15.0 15.0 30 0

5 1

⁄8 (16) to 1 ⁄2 (38), incl 0.0075 (0.19) 0.0075 (0.19) 10.0 10.0 22 0

Over 1 ⁄2 (38) to 3 (76), incl 0.010 (0.25) 0.010 (0.25) 10.0 10.0 22 0

Over 3 (76) to 4 ⁄2 (114), incl 0.015 (0.38) 0.015 (0.38) 10.0 10.0 22 0

Over 4 ⁄2 (114) to 6 (152), incl 0.020 (0.51) 0.020 (0.51) 12.5 12.5 28 0

Over 6 (152) to 6 ⁄8 (168), incl 0.025 (0.64) 0.025 (0.64) 12.5 12.5 28 0

5 5

Over 6 ⁄8 (168) to 8 ⁄8 (219), incl 0.031 (0.79) 0.031 (0.79) 12.5 12.5 28 0

A

Ovality—The permissible variations in this table apply to individual measurements, including out-of-roundness (ovality) except for the following:

For pipe and tube having a nominal wall thickness of 3 % or less of the nominal outside diameter, the mean outside diameter shall conform to the permissible variations

of this table and individual measurements (including ovality) shall conform to the plus and minus values of the table, with the values increased by 0.5 % of the nominal

outside diameter.

For pipe and tube over 4 ⁄2 in. (114 mm) in outside diameter with a nominal wall thickness greater than 3 % of the nominal outside diameter, the mean outside diameter

shall conform to the permissible variations of this table and individual measurements shall not exceed twice the permissible variations of the table.

B

Eccentricity—The permissible variations in this table apply to individual measurements including eccentricity.

7.2 Length—When material is ordered cut-to-length, the length shall conform to the permissible variations prescribed in Table

4.

7.3 Straightness—Material shall be reasonably straight and free of bends and kinks.

7.4 Ends—Ends shall be plain cut and deburred.

7.5 Permissible variations for material specified as small-diameter and light-wall tube (converter size) shall conform to the

permissible variations prescribed in Table X1.2.

8. Workmanship, Finish, and Appearance

8.1 The material shall be uniform in quality and temper, smooth, commercially straight, and free of injurious imperfections.

9. Sampling

9.1 Lot Definition:

9.1.1 A lot for chemical analysis shall consist of one heat.

9.1.2 A lot for all other testing shall consist of all material from the same heat, nominal size (excepting length), and condition.

9.1.2.1 Where material cannot be identified by heat, a lot shall consist of not more than 500 lb (227 kg) of material in the same

condition and nominal size (excepting length).

9.2 Test Material Selection:

9.2.1 Chemical Analysis—Representative samples from each lot shall be taken during pouring or subsequent processing.

9.2.1.1 Product (Check) Analysis shall be wholly the responsibility of the purchaser.

9.2.2 Mechanical and other Properties—Samples of the material to provide test specimens for mechanical and other properties

shall be taken from such locations in each lot as to be representative of that lot. Test specimens shall be taken from material in

the final condition.

10. Number of Tests

10.1 Chemical Analysis—One test per lot.

10.2 Tension—One test per lot.

10.3 Hydrostatic or Nondestructive Electric Test—Each piece in each lot.

A

TABLE 4 Permissible Variations in Length

Cut Length, in. (mm)

Outside Diameter, in. (mm)

Over Under

Under 2 (50.8) ⁄8 (3.2) 0

2 (50.8) and over ⁄16 (4.8) 0

A

These permissible variations in length apply to pipe or tube in straight lengths.

They apply to cut lengths up to and including 24 ft (7.3 m). For lengths over 24 ft,

an additional over-tolerance of ⁄8 in. (3.2 mm) for each 10 ft (3.0 m) or fraction

thereof shall be permissible up to a maximum additional over-tolerance of ⁄2 in.

(12.7 mm).

B165 − 05 (2014)

11. Specimen Preparation

11.1 Room Temperature Tensile Specimen—Material shall be tested in the direction of fabrication. Whenever possible, all pipe

and tube shall be tested in full tubular size. When testing in full tubular size is not possible, longitudinal strip specimens, or the

largest possible round specimen, shall be used. In the event of disagreement when full tubular testing is not possible, a longitudinal

strip specimen with reduced gauge length as contained in Test Methods E8 shall be used.

12. Test Methods

12.1 Chemical Composition—In case of disagreement, the chemical composition shall be determined in accordance with Test

Methods E76.

12.2 Tension Test—Tension testing shall be conducted in accordance with Test Methods E8.

12.3 Hydrostatic or Nondestructive Electric Test—Each pipe or tube with an outside diameter ⁄8 in. (3 mm) and larger and with

wall thickness of 0.015 in. (0.38 mm) and over shall be tested by the manufacturer to an internal hydrostatic pressure of 1000 psi

(6.9 MPa) provided that the fiber stress calculated in accordance with the following equation does not exceed the allowable fiber

stress, S, indicated below:

P 5 2St/D (1)

where:

P = hydrostatic test pressure, psi (or MPa)

S = allowable fiber stress, for material in the condition (temper) furnished as follows:

where:

P = hydrostatic test pressure, psi (or MPa)

S = allowable fiber stress, for material in the condition (temper) furnished as follows:

Annealed:

5 in. (127 mm) outside diameter 17 500 psi

and under (120 MPa)

Over 5 in. (127 mm) outside diameter 16 700 psi

(115 MPa)

Stress-relieved:

All sizes 21 200 psi

(145 MPa)

t = minimum wall thickness, in. (or mm), equal to the specified nominal wall minus the permissible minus wall tolerance, or

the specified minimum wall thickness, and,

D = outside diameter of the pipe or tube, in. (or mm).

12.3.1 When so agreed upon between the manufacturer and purchaser, pipe or tube may be tested to 1 ⁄2 times the allowable

fiber stress given above.

12.3.2 If any pipe or tube shows leaks during hydrostatic testing, it shall be rejected.

12.4 Nondestructive Electric Test—Each pipe or tube shall be examined with a nondestructive electric test in accordance with

Specification B829.

12.5 Rounding Method—For purposes of determining compliance with the specified limits for requirements of the properties

listed in the following table, an observed value, or a calculated value, shall be rounded as indicated below, in accordance with the

rounding method of Practice E29:

Rounded Unit for Observed

Test

or Calculated Value

Chemical composition and nearest unit in the last right-hand place of

tolerances (when expressed in figures of the specified limit. If two choices

decimals) are possible, as when the digits dropped are

exactly a 5 or a 5 followed only by zeros,

choose the one ending in an even digit with

zero defined as an even digit.

Tensile strength, yield strength nearest 1000 psi (6.9 MPa)

Elongation nearest 1 %

13. Inspection

13.1 Inspection of the material shall be agreed upon between the purchaser and the supplier as part of the purchase contract.

14. Rejection and Rehearing

14.1 Material that fails to conform to the requirements of this specification may be rejected. Rejection should be reported to the

producer or supplier promptly and in writing. In case of dissatisfaction with the results of the test, the producer or supplier may

make claim for a rehearing.

B165 − 05 (2014)

15. Certification

15.1 When specified in the purchase order or con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.