ASTM C1499-09(2013)

(Test Method)Standard Test Method for Monotonic Equibiaxial Flexural Strength of Advanced Ceramics at Ambient Temperature

Standard Test Method for Monotonic Equibiaxial Flexural Strength of Advanced Ceramics at Ambient Temperature

SIGNIFICANCE AND USE

4.1 This test method may be used for material development, material comparison, quality assurance, characterization and design code or model verification.

4.2 Engineering applications of ceramics frequently involve biaxial tensile stresses. Generally, the resistance to equibiaxial flexure is the measure of the least flexural strength of a monolithic advanced ceramic. The equibiaxial flexural strength distributions of ceramics are probabilistic and can be described by a weakest link failure theory, (1, 2)4. Therefore, a sufficient number of test specimens at each testing condition is required for statistical estimation or' the equibiaxial strength.

4.3 Equibiaxial strength tests provide information on the strength and deformation of materials under multiple tensile stresses. Multiaxial stress states are required to effectively evaluate failure theories applicable to component design, and to efficiently sample surfaces that may exhibit anisotropic flaw distributions. Equibiaxial tests also minimize the effects of test specimen edge preparation as compared to uniaxial tests because the generated stresses are lowest at the test specimen edges.

4.4 The test results of equibiaxial test specimens fabricated to standardized dimensions from a particular material and/or selected portions of a component may not totally represent the strength properties in the entire, full-size component or its in-service behavior in different environments.

4.5 For quality control purposes, results derived from standardized equibiaxial test specimens may be considered indicative of the response of the bulk material from which they were taken for any given primary processing conditions and post-processing heat treatments or exposures.

SCOPE

1.1 This test method covers the determination of the equibiaxial strength of advanced ceramics at ambient temperature via concentric ring configurations under monotonic uniaxial loading. In addition, test specimen fabrication methods, testing modes, testing rates, allowable deflection, and data collection and reporting procedures are addressed. Two types of test specimens are considered: machined test specimens and as-fired test specimens exhibiting a limited degree of warpage. Strength as used in this test method refers to the maximum strength obtained under monotonic application of load. Monotonic loading refers to a test conducted at a constant rate in a continuous fashion, with no reversals from test initiation to final fracture.

1.2 This test method is intended primarily for use with advanced ceramics that macroscopically exhibit isotropic, homogeneous, continuous behavior. While this test method is intended for use on monolithic advanced ceramics, certain whisker- or particle-reinforced composite ceramics as well as certain discontinuous fiber-reinforced composite ceramics may also meet these macroscopic behavior assumptions. Generally, continuous fiber ceramic composites do not macroscopically exhibit isotropic, homogeneous, continuous behavior, and the application of this test method to these materials is not recommended.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1499 − 09(Reapproved 2013)

Standard Test Method for

Monotonic Equibiaxial Flexural Strength of Advanced

Ceramics at Ambient Temperature

This standard is issued under the fixed designation C1499; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thistestmethodcoversthedeterminationoftheequibi-

C1145Terminology of Advanced Ceramics

axialstrengthofadvancedceramicsatambienttemperaturevia

C1239Practice for Reporting Uniaxial Strength Data and

concentric ring configurations under monotonic uniaxial load-

Estimating Weibull Distribution Parameters forAdvanced

ing. In addition, test specimen fabrication methods, testing

Ceramics

modes, testing rates, allowable deflection, and data collection

C1259Test Method for Dynamic Young’s Modulus, Shear

and reporting procedures are addressed. Two types of test

Modulus, and Poisson’s Ratio forAdvanced Ceramics by

specimens are considered: machined test specimens and as-

Impulse Excitation of Vibration

fired test specimens exhibiting a limited degree of warpage.

C1322Practice for Fractography and Characterization of

Strength as used in this test method refers to the maximum

Fracture Origins in Advanced Ceramics

strength obtained under monotonic application of load. Mono-

E4Practices for Force Verification of Testing Machines

tonic loading refers to a test conducted at a constant rate in a

E6Terminology Relating to Methods of MechanicalTesting

continuous fashion, with no reversals from test initiation to

E83Practice for Verification and Classification of Exten-

final fracture.

someter Systems

1.2 This test method is intended primarily for use with E337Test Method for Measuring Humidity with a Psy-

advanced ceramics that macroscopically exhibit isotropic, chrometer (the Measurement of Wet- and Dry-Bulb Tem-

peratures)

homogeneous, continuous behavior. While this test method is

intended for use on monolithic advanced ceramics, certain F394Test Method for Biaxial Flexure Strength (Modulus of

Rupture) of Ceramic Substrates (Discontinued 2001)

whisker- or particle-reinforced composite ceramics as well as

(Withdrawn 2001)

certaindiscontinuousfiber-reinforcedcompositeceramicsmay

IEEE/ASTM SI 10Standard for Use of the International

also meet these macroscopic behavior assumptions. Generally,

System of Units (SI): The Modern Metric System

continuous fiber ceramic composites do not macroscopically

exhibit isotropic, homogeneous, continuous behavior, and the

3. Terminology

application of this test method to these materials is not

recommended.

3.1 Definitions:

3.1.1 The definitions of terms relating to biaxial testing

1.3 The values stated in SI units are to be regarded as

appearing in Terminology E6 and Terminology C1145 may

standard. No other units of measurement are included in this

applytothetermsusedinthistestmethod.Pertinentdefinitions

standard.

are listed below with the appropriate source given in parenthe-

1.4 This standard does not purport to address all of the

ses.Additionaltermsusedinconjunctionwiththistestmethod

safety concerns, if any, associated with its use. It is the

are defined in the following section.

responsibility of the user of this standard to establish appro-

3.1.2 advanced ceramic, n—highly engineered, high perfor-

priate safety and health practices and determine the applica-

mance predominately non- metallic, inorganic, ceramic mate-

bility of regulatory limitations prior to use.

rial having specific functional attributes. C1145

1 2

This test method is under the jurisdiction of ASTM Committee C28 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Mechanical Properties and Performance. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Aug. 1, 2013. Published September 2013. Originally the ASTM website.

approved in 2001. Last previous edition approved in 2009 as C1499–09. DOI: The last approved version of this historical standard is referenced on

10.1520/C1499-09R13. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1499 − 09 (2013)

3.1.3 breaking load, [F], n—load at which fracture occurs. taken for any given primary processing conditions and post-

E6 processing heat treatments or exposures.

3.1.4 equibiaxial flexural strength, [F/L ], n—maximum

5. Interferences

stressthatamaterialiscapableofsustainingwhensubjectedto

flexure between two concentric rings. This mode of flexure is

5.1 Test environment (vacuum, inert gas, ambient air, etc.)

a cupping of the circular plate caused by loading at the inner

including moisture content (for example, relative humidity)

load ring and outer support ring. The equibiaxial flexural

may have an influence on the measured equibiaxial strength.

strength is calculated from the maximum-load of a biaxial test

Testing to evaluate the maximum strength potential of a

carriedtorupture,theoriginaldimensionsofthetestspecimen,

material can be conducted in inert environments and/or at

and Poisson’s ratio.

sufficiently rapid testing rates so as to minimize any environ-

mental effects. Conversely, testing can be conducted in

3.1.5 homogeneous, n—condition of a material in which the

environments, test modes and test rates representative of

relevant properties (composition, structure, density, etc.) are

service conditions to evaluate material performance under use

uniform, so that any smaller sample taken from an original

conditions.

body is representative of the whole. Practically, as long as the

geometrical dimensions of a sample are large with respect to

5.2 Fabricationoftestspecimenscanintroducedimensional

thesizeoftheindividualgrains,crystals,components,pores,or

variations that may have pronounced effects on the measured

microcracks, the sample can be considered homogeneous.

equibiaxial mechanical properties and behavior (for example,

3.1.6 modulus of elasticity, [F/L ], n—ratio of stress to shape and level of the resulting stress-strain curve, equibiaxial

corresponding strain below the proportional limit. E6 strength, failure location, etc.). Surface preparation can also

leadtotheintroductionofresidualstressesandfinalmachining

3.1.7 Poisson’s ratio, n—negative value of the ratio of

steps might or might not negate machining damage introduced

transverse strain to the corresponding axial strain resulting

during the initial machining. Therefore, as universal or stan-

from uniformly distributed axial stress below the proportional

dardized methods of surface preparation do not exist, the test

limit of the material.

specimen fabrication history should be reported. In addition,

the nature of fabrication used for certain advanced ceramic

4. Significance and Use

components may require testing of specimens with surfaces in

4.1 Thistestmethodmaybeusedformaterialdevelopment,

the as-fabricated condition (that is, it may not be possible,

material comparison, quality assurance, characterization and

desired or required to machine some of the test specimen

design code or model verification.

surfaces directly in contact with the test fixture). For very

4.2 Engineeringapplicationsofceramicsfrequentlyinvolve

rough or wavy as-fabricated surfaces, perturbations in the

biaxial tensile stresses. Generally, the resistance to equibiaxial

stress state due to non-symmetric cross-sections as well as

flexure is the measure of the least flexural strength of a

variations in the cross-sectional dimensions may also interfere

monolithicadvancedceramic.Theequibiaxialflexuralstrength

with the equibiaxial strength measurement. Finally, close

distributionsofceramicsareprobabilisticandcanbedescribed

geometric tolerances, particularly in regard to flatness of test

by a weakest link failure theory, (1, 2) . Therefore, a sufficient

specimen surfaces in contact with the test fixture components

number of test specimens at each testing condition is required

are critical requirements for successful equibiaxial tests. In

for statistical estimation or’ the equibiaxial strength.

somecasesitmaybeappropriatetouseothertestmethods(for

4.3 Equibiaxial strength tests provide information on the example, Test Method F394).

strength and deformation of materials under multiple tensile

5.3 Contact and frictional stresses in equibiaxial tests can

stresses. Multiaxial stress states are required to effectively

introducelocalizedfailurenotrepresentativeoftheequibiaxial

evaluate failure theories applicable to component design, and

strength under ideal loading conditions. These effects may

to efficiently sample surfaces that may exhibit anisotropic flaw

resultineitheroverorunderestimatesoftheactualstrength (1,

distributions. Equibiaxial tests also minimize the effects of test

3).

specimen edge preparation as compared to uniaxial tests

5.4 Fractures that consistently initiate near or just outside

because the generated stresses are lowest at the test specimen

the load-ring may be due to factors such as friction or contact

edges.

stressesintroducedbytheloadfixtures,orviamisalignmentof

4.4 The test results of equibiaxial test specimens fabricated

thetestspecimenrings.Suchfractureswillnormallyconstitute

to standardized dimensions from a particular material and/or

invalid tests (see Note 14). Splitting of the test specimen along

selected portions of a component may not totally represent the

a diameter that expresses the characteristic size may result

strength properties in the entire, full-size component or its

from poor test specimen preparation (for example, severe

in-service behavior in different environments.

grinding or very poor edge preparation), excessive tangential

stresses at the test specimen edges, or a very weak material.

4.5 For quality control purposes, results derived from stan-

Such fractures will constitute invalid tests if failure occurred

dardized equibiaxial test specimens may be considered indica-

from the edge.

tive of the response of the bulk material from which they were

5.5 Deflectionsgreaterthanone-quarterofthetestspecimen

thickness can result in nonlinear behavior and stresses not

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this standard. accounted for by simple plate theory.

C1499 − 09 (2013)

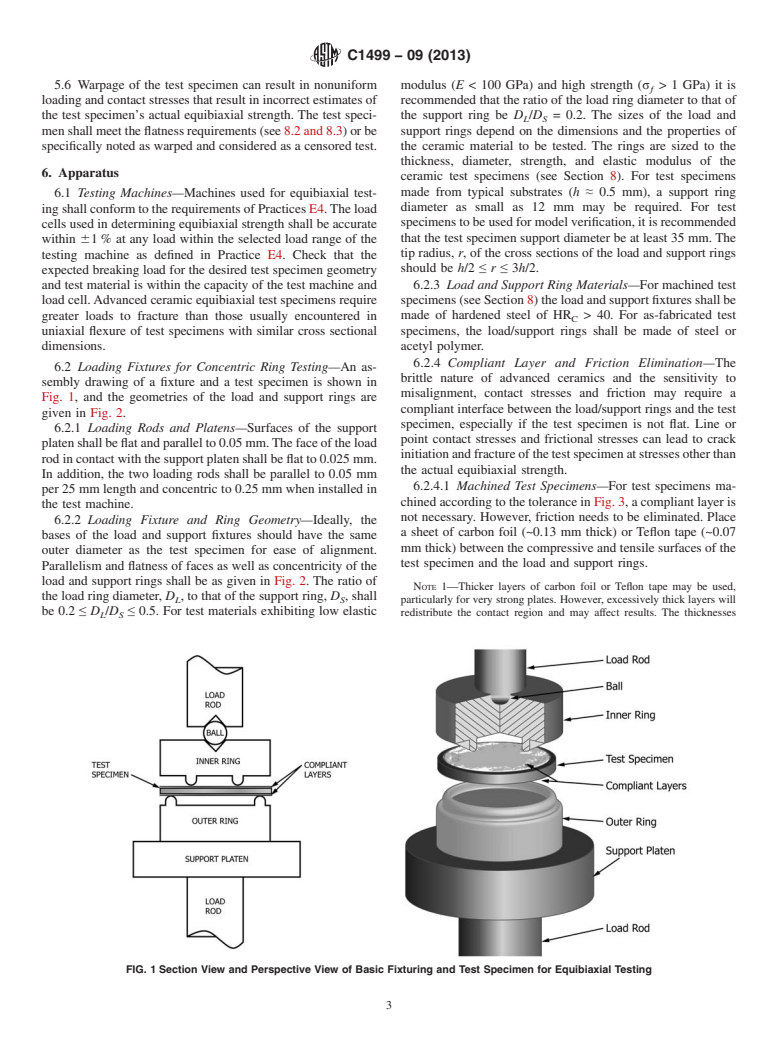

5.6 Warpage of the test specimen can result in nonuniform modulus (E < 100 GPa) and high strength (σ > 1 GPa) it is

ƒ

loadingandcontactstressesthatresultinincorrectestimatesof recommended that the ratio of the load ring diameter to that of

the test specimen’s actual equibiaxial strength. The test speci- the support ring be D /D = 0.2. The sizes of the load and

L S

menshallmeettheflatnessrequirements(see8.2and8.3)orbe support rings depend on the dimensions and the properties of

specifically noted as warped and considered as a censored test. the ceramic material to be tested. The rings are sized to the

thickness, diameter, strength, and elastic modulus of the

6. Apparatus

ceramic test specimens (see Section 8). For test specimens

made from typical substrates (h ≈ 0.5 mm), a support ring

6.1 Testing Machines—Machines used for equibiaxial test-

diameter as small as 12 mm may be required. For test

ingshallconformtotherequirementsofPracticesE4.Theload

specimenstobeusedformodelverification,itisrecommended

cells used in determining equibiaxial strength shall be accurate

that the test specimen support diameter be at least 35 mm.The

within 61% at any load within the selected load range of the

tip radius, r, of the cross sections of the load and support rings

testing machine as defined in Practice E4. Check that the

should be h/2 ≤ r ≤ 3h/2.

expected breaking load for the desired test specimen geometry

and test material is within the capacity of the test machine and 6.2.3 Load and Support Ring Materials—For machined test

loadcell.Advancedceramicequibiaxialtestspecimensrequire specimens(seeSection8)theloadandsupportfixturesshallbe

made of hardened steel of HR > 40. For as-fabricated test

greater loads to fracture than those usually encountered in

C

uniaxial flexure of test specimens with similar cross sectional specimens, the load/support rings shall be made of steel or

acetyl polymer.

dimensions.

6.2.4 Compliant Layer and Friction Elimination—The

6.2 Loading Fixtures for Concentric Ring Testing—An as-

brittle nature of advanced ceramics and the sensitivity to

sembly drawing of a fixture and a test specimen is shown in

misalignment, contact stresses and friction may require a

Fig. 1, and the geometries of the load and support rings are

compliant interface between the load/support rings and the test

given in Fig. 2.

specimen, especially if the test specimen is not flat. Line or

6.2.1 Loading Rods and Platens—Surfaces of the support

point contact stresses and frictional stresses can lead to crack

platenshallbeflatandparallelto0.05mm.Thefaceoftheload

initiationandfractureofthetestspecimenatstressesotherthan

rodincontactwiththesupportplatenshallbeflatto0.025mm.

the actual equibiaxial strength.

In addition, the two loading rods shall be parallel to 0.05 mm

6.2.4.1 Machined Test Specimens—For test specimens ma-

per25mmlengthandconcentricto0.25mmwheninstalledin

chinedaccordingtothetoleranceinFig.3,acompliantlayeris

the test machine.

not necessary. However, friction needs to be eliminated. Place

6.2.2 Loading Fixture and Ring Geometry—Ideally, the

a sheet of carbon foil (~0.13 mm thick) or Teflon tape (~0.07

bases of the load and support fixtures should have the same

mm thick) between the compressive and tensile surfaces of the

outer diameter as the test specimen for ease of alignment.

test specimen and the load and support rings.

Parallelism and flatness of faces as well as concentricity of the

load and support rings shall be as given in Fig. 2. The ratio of

NOTE 1—Thicker layers of carbon foil or Teflon tape may be used,

theloadringdiameter, D ,tothatofthesupportring, D ,shall

L S particularly for very strong plates. However, excessively thick layers will

be 0.2 ≤ D /D ≤ 0.5. For test materials exhibiting low elastic redistribute the contact region and may affect results. The thicknesses

L S

FIG. 1 Section View and Perspective View of Basic Fixturing and Test Specimen for Equibiaxial Testing

C1499 − 09 (2013)

NOTE 1—0.4 to 0.8 µm surface finish. Harden to 40 Rc or greater.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.