ASTM D3517-11

(Specification)Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe

Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe

ABSTRACT

This specification covers machine-made fiberglass (glass-fiber-reinforced thermosetting-resin or glass-fiber-reinforced polymer mortar) pressure pipe intended for use in water conveyance systems. It is suited primarily for pipes to be installed in buried applications, although it may be used to the extent applicable for other installations such as, but not limited to, jacking, tunnel lining, and slip lining rehabilitation of existing pipelines. The materials shall include the following: structural wall composition which shall consist of thermosetting resin, glass fiber reinforcement, and, if used, aggregate filler; a thermosetting polyester or epoxy resin with or without filler; E-type glass reinforcement; siliceous sand aggregates; liner and surface layers; unrestrained or restrained joints; and elastomeric gaskets. Pipe shall be supplied in the nominal diameters, lengths, wall thickness, squareness of pipe ends, and soundness. Test specimen shall be subjected to longitudinal loads or circumferential bending to test for its long-term hydrostatic design pressure. The pipe shall conform to the stiffness, hoop-tensile strength, joint tightness, beam strength, longitudinal compressive strength, and longitudinal tensile strength requirements.

SCOPE

1.1 This specification covers machine-made fiberglass pipe, 8 in. (200 mm) through 156 in. (4000 mm), intended for use in water conveyance systems which operate at internal gage pressures of 450 psi (3103 kPa) or less. Both glass-fiber-reinforced thermosetting-resin pipe (RTRP) and glass-fiber-reinforced polymer mortar pipe (RPMP) are fiberglass pipes. The standard is suited primarily for pipes to be installed in buried applications, although it may be used to the extent applicable for other installations such as, but not limited to, jacking, tunnel lining and slip-lining rehabilitation of existing pipelines.

Note 1—For the purposes of this standard, polymer does not include natural polymers.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

Note 2—There is no known ISO equivalent to this standard.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3517 −11 AnAmerican National Standard

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

1

Pressure Pipe

This standard is issued under the fixed designation D3517; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D790 Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materi-

1.1 This specification covers machine-made fiberglass pipe,

als

8 in. (200 mm) through 156 in. (4000 mm), intended for use in

D883 Terminology Relating to Plastics

water conveyance systems which operate at internal gage

D1600 Terminology forAbbreviatedTerms Relating to Plas-

pressures of 450 psi (3103 kPa) or less. Both glass-fiber-

tics

reinforced thermosetting-resin pipe (RTRP) and glass-fiber-

D2290 Test Method for Apparent Hoop Tensile Strength of

reinforced polymer mortar pipe (RPMP) are fiberglass pipes.

Plastic or Reinforced Plastic Pipe by Split Disk Method

The standard is suited primarily for pipes to be installed in

D2412 Test Method for Determination of External Loading

buried applications, although it may be used to the extent

Characteristics of Plastic Pipe by Parallel-Plate Loading

applicable for other installations such as, but not limited to,

D2584 Test Method for Ignition Loss of Cured Reinforced

jacking, tunnel lining and slip-lining rehabilitation of existing

Resins

pipelines.

D2992 Practice for Obtaining Hydrostatic or Pressure De-

NOTE 1—For the purposes of this standard, polymer does not include

sign Basis for “Fiberglass” (Glass-Fiber-Reinforced

natural polymers.

Thermosetting-Resin) Pipe and Fittings

1.2 The values stated in inch-pound units are to be regarded

D3567 Practice for Determining Dimensions of “Fiberglass”

as the standard. The values given in parentheses are provided

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

for information purposes only.

Fittings

NOTE 2—There is no known ISO equivalent to this standard.

D3892 Practice for Packaging/Packing of Plastics

1.3 The following safety hazards caveat pertains only to the

D4161 Specification for “Fiberglass” (Glass-Fiber-

test methods portion, Section 8, of this specification: This

Reinforced Thermosetting-Resin) Pipe Joints Using Flex-

standard does not purport to address all of the safety concerns,

ible Elastomeric Seals

if any, associated with its use. It is the responsibility of the user

F412 Terminology Relating to Plastic Piping Systems

of this standard to establish appropriate safety and health

F477 Specification for Elastomeric Seals (Gaskets) for Join-

practices and determine the applicability of regulatory limita-

ing Plastic Pipe

tions prior to use.

2.2 ISO Standard:

ISO 1172 TextileGlassReinforcedPlastics—Determination

2. Referenced Documents

3

of Loss on Ignition

2

2.1 ASTM Standards:

2.3 NSF Standard:

C33 Specification for Concrete Aggregates

4

Standard No. 61 Drinking Water System Components

D638 Test Method for Tensile Properties of Plastics

D695 Test Method for Compressive Properties of Rigid

3. Terminology

Plastics

3.1 Definitions:

3.1.1 General—Definitions are in accordance with Termi-

1

This specification is under the jurisdiction of ASTM Committee D20 on

nology D883 and Terminology F412 and abbreviations are in

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

accordance with Terminology D1600, unless otherwise indi-

Plastic Piping Systems and Chemical Equipment.

Current edition approved Sept. 1, 2011. Published September 2011. Originally

cated.

approved in 1976. Last previous edition approved 2006 as D3517 – 06. DOI:

10.1520/D3517-11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

the ASTM website. Arbor, MI 48113-0140, http://www.nsf.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3517−11

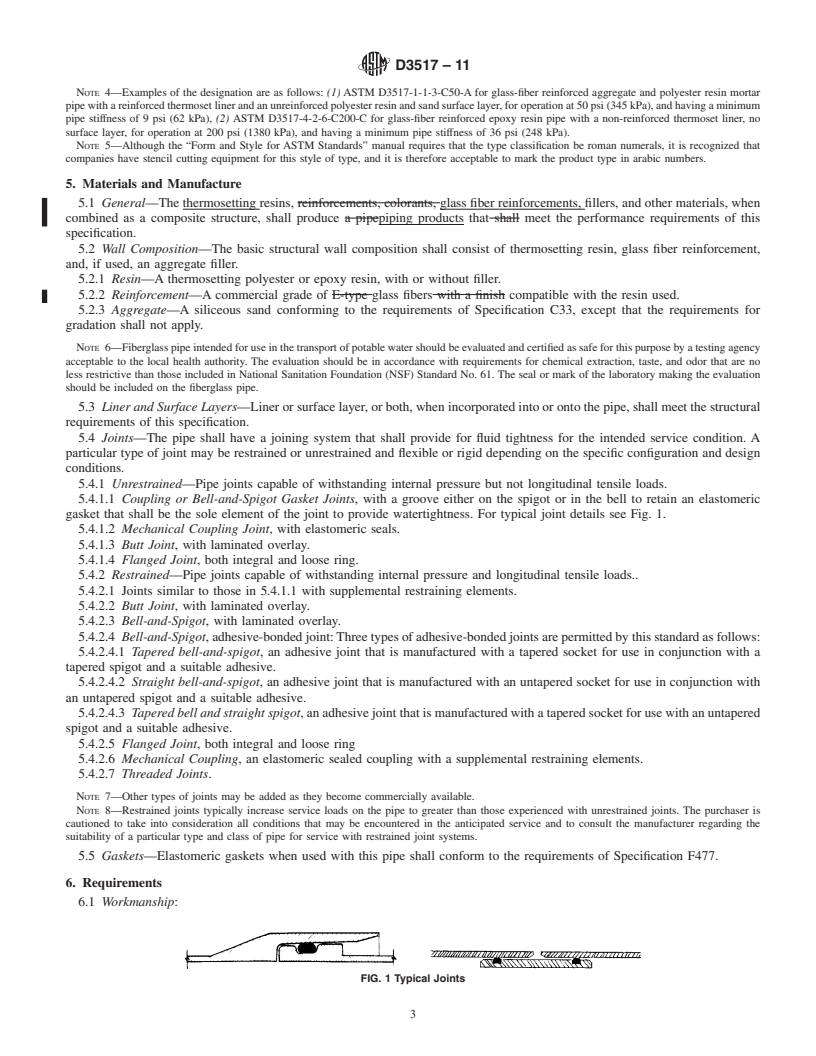

3.2 Definitions of Terms Specific to This Standard: a composite structure, shall produce piping products that meet

3.2.1 fiberglass pipe—a tubular product co

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D3517–06 Designation: D3517 – 11

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

1

Pressure Pipe

This standard is issued under the fixed designation D3517; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers machine-made fiberglass pipe, 8 in. (200 mm) through 156 in. (4000 mm), intended for use in

water conveyance systems which operate at internal gage pressures of 450 psi (3103 kPa) or less. Both glass-fiber-reinforced

thermosetting-resin pipe (RTRP) and glass-fiber-reinforced polymer mortar pipe (RPMP) are fiberglass pipes. The standard is

suited primarily for pipes to be installed in buried applications, although it may be used to the extent applicable for other

installations such as, but not limited to, jacking, tunnel lining and slip-lining rehabilitation of existing pipelines.

NOTE 1—For the purposes of this standard, polymer does not include natural polymers.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information purposes only.

NOTE2—There is no similar or equivalent ISO standard. 2—There is no known ISO equivalent to this standard.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C33 Specification for Concrete Aggregates

D638 Test Method for Tensile Properties of Plastics

D695 Test Method for Compressive Properties of Rigid Plastics

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2290 Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe by Split Disk Method

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2584 Test Method for Ignition Loss of Cured Reinforced Resins

D2992 Practice for Obtaining Hydrostatic or Pressure Design Basis for Fiberglass (Glass-Fiber-Reinforced Thermosetting-

Resin) Pipe and Fittings

D3567 Practice for Determining Dimensions of Fiberglass (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and Fittings

D3892 Practice for Packaging/Packing of Plastics

D4161 SpecificationforFiberglass(Glass-Fiber-ReinforcedThermosetting-Resin)PipeJointsUsingFlexibleElastomericSeals

F412 Terminology Relating to Plastic Piping Systems

F477 Specification for Elastomeric Seals (Gaskets) for Joining Plastic Pipe

2.2 ISO Standard:

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Piping

Systems and Chemical Equipment.

Current edition approved Nov. 1, 2006. Published November 2006. Originally approved in 1976. Last previous edition approved 2004 as D3517–04. DOI:

10.1520/D3517-06.

Current edition approved Sept. 1, 2011. Published September 2011. Originally approved in 1976. Last previous edition approved 2006 as D3517 – 06. DOI:

10.1520/D3517-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3517 – 11

3

ISO 1172 Textile Glass Reinforced Plastics—Determination of Loss on Ignition

2.3 NSF Standard:

4

Standard No. 61 Drinking Water System Components

3. Terminology

3.1 Definitions:

3.1.1 General—Definitions are in accordance with Terminology D883 and Terminology F412 and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.