ASTM B369/B369M-20

(Specification)Standard Specification for Copper-Nickel Alloy Castings

Standard Specification for Copper-Nickel Alloy Castings

ABSTRACT

This specification establishes the requirements for threadless, seamless, and deoxidized copper pipes in straight lengths, in all nominal or standard pipe sizes, for piping systems that are assembled with brazed-joint pipe fittings. The pipe shall be produced from coppers with either UNS No. C10300 or C12200. The materials for manufacture shall be cast billets, bars, or tubes of such purity and soundness as to be suitable for processing by hot extrusion or piercing, and subsequent cold working to produce a uniform wrought structure in the finished product. Products shall be produced in the H58 (drawn general purpose) temper. Products shall be sampled and prepared, then tested accordingly to examine their conformance to dimensional (outer and inner diameters, wall thickness, cross-sectional area, theoretical weight, mass, length, and roundness or squareness), mechanical (tensile strength and Rockwell hardness), and chemical composition requirements. Products shall also meet performance requirements under microscopical examination, electromagnetic (eddy-current) test, hydrostatic test, and pneumatic test.

SCOPE

1.1 This specification establishes the requirements for copper-nickel alloy castings with nominal compositions shown in Table 1.

1.2 Castings of these alloys are used primarily for corrosion-resistance applications such as construction or pressure vessels, particularly for marine pumps, valves, and fittings.

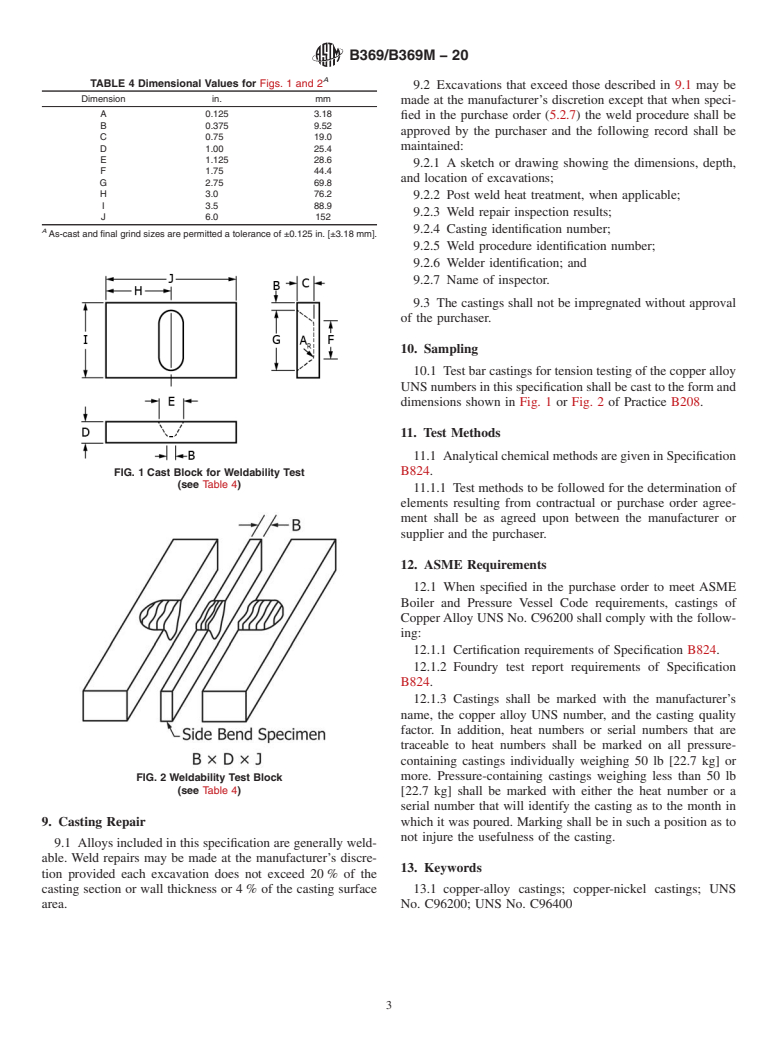

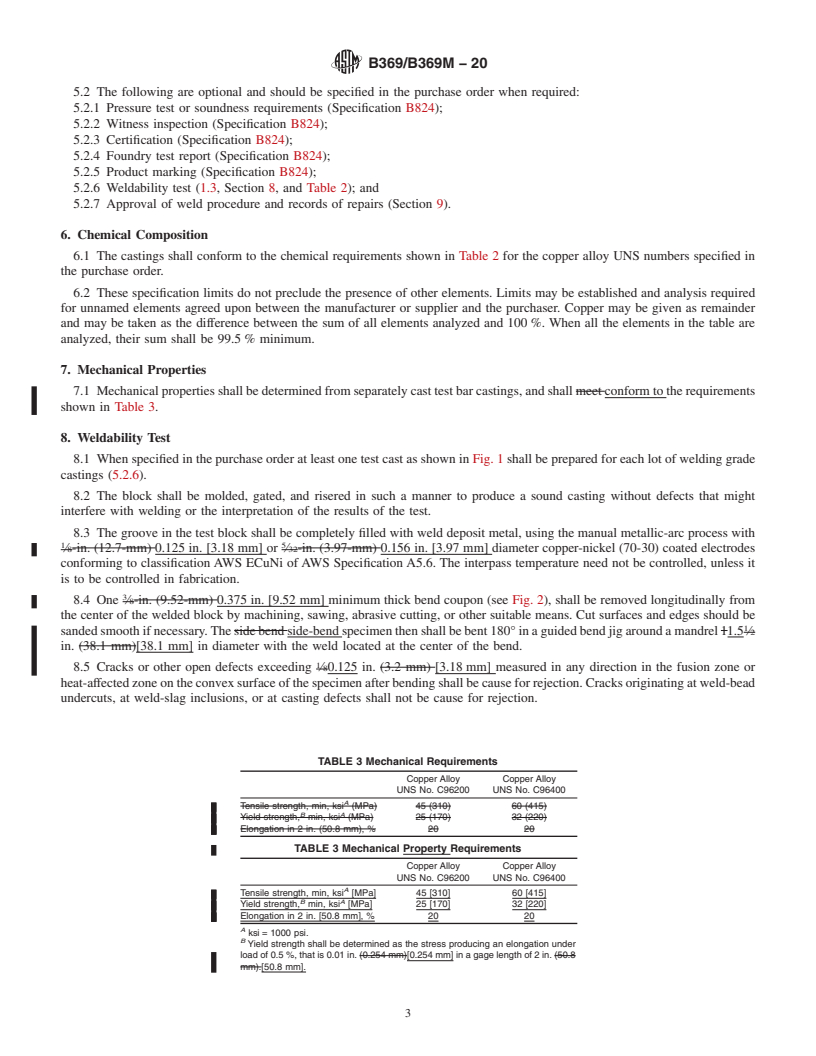

1.3 These alloys are considered weldable, but they may be ordered with a weld test to ensure weldability. When extensive welding is to be performed on the casting, weldability tests should be specified in the ordering information (5.2.6) to ensure proper welding characteristics.

1.4 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, SI units are shown in brackets. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 The following hazard statement applies only to Section 8, Weldability Test, of this specification.This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B369/B369M −20

Standard Specification for

1

Copper-Nickel Alloy Castings

This standard is issued under the fixed designation B369/B369M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification establishes the requirements for

B208 Practice for Preparing Tension Test Specimens for

copper-nickel alloy castings with nominal compositions shown

Copper Alloy Sand, Permanent Mold, Centrifugal, and

in Table 1.

Continuous Castings

1.2 Castings of these alloys are used primarily for

B824 Specification for General Requirements for Copper

corrosion-resistance applications such as construction or pres-

Alloy Castings

sure vessels, particularly for marine pumps, valves, and fit-

B846 Terminology for Copper and Copper Alloys

3

tings.

2.2 ASME Code:

ASME Boiler and Pressure Vessel Code

1.3 These alloys are considered weldable, but they may be

4

2.3 AWS Standard:

ordered with a weld test to ensure weldability. When extensive

AWS A5.6 Specification for Copper and Copper-Alloy Arc-

welding is to be performed on the casting, weldability tests

Welding Electrodes

should be specified in the ordering information (5.2.6)to

ensure proper welding characteristics.

3. General Requirements

1.4 Units—The values stated in either inch-pound units or

3.1 The following sections of Specification B824 form a

SI units are to be regarded separately as standard. Within the

part of this specification. In the event of a conflict between this

text, SI units are shown in brackets. The values stated in each

specification and Specification B824, the requirements of this

system are not necessarily exact equivalents; therefore, to

specification shall take precedence.

ensure conformance with the standard, each system shall be

3.1.1 Terminology

used independently of the other, and values from the two

3.1.2 Other Requirements

systems shall not be combined.

3.1.3 Dimensions, Mass, and Permissible Variations

3.1.4 Workmanship, Finish, and Appearance

1.5 The following hazard statement applies only to Section

3.1.5 Sampling

8,WeldabilityTest, of this specification.Thisstandarddoesnot

3.1.6 Number of Tests and Retests

purport to address all of the safety concerns, if any, associated

3.1.7 Specimen Preparation

with its use. It is the responsibility of the user of this standard

3.1.8 Test Methods

to establish appropriate safety, health, and environmental

3.1.9 Significance of Numerical Limits

practices and determine the applicability of regulatory limita-

3.1.10 Inspection

tions prior to use.

3.1.11 Rejection and Rehearing

1.6 This international standard was developed in accor-

3.1.12 Certification

dance with internationally recognized principles on standard-

3.1.13 Test Report

ization established in the Decision on Principles for the

3.1.14 Product Marking

Development of International Standards, Guides and Recom-

3.1.15 Packaging and Package Marking

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper the ASTM website.

3

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on Available from American Society of Mechanical Engineers (ASME), ASME

Castings and Ingots for Remelting. International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

Current edition approved April 1, 2020. Published April 2020. Originally www.asme.org.

4

approved in 1961. Last previous edition approved in 2016 as B369 – 09 (2016). Available from American Welding Society (AWS), 8669 NW 36 St., #130,

DOI: 10.1520/B0369_B0369M–20. Miami, FL 33166-6672, http://www.aws.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B369/B369M−20

TABLE 1 Nominal Compositions

Composition, %

Copper Alloy UNS No.

Copper Nickel Iron Silicon Manganese Niobium

C96200 87.5 10.0 1.5 0.1 0.9 .

C96400 67.0 30.0 0.7 0.5 0.8 1.0

4. Terminology manu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B369 − 09 (Reapproved 2016) B369/B369M − 20

Standard Specification for

1

Copper-Nickel Alloy Castings

This standard is issued under the fixed designation B369;B369/B369M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification establishes the requirements for copper-nickel alloy castings with nominal compositions shown in Table

1. These are as follows:

2

Copper Alloy UNS No. Previous Designation

C96200 Alloy A

C96400 Alloy B

1.2 Castings of these alloys are used primarily for corrosion-resistance applications such as in construction and for or pressure

vessels, particularly infor marine pumps, valves, and fittings.

1.3 These alloys are considered weldable, but they may be ordered with a weld test to ensure weldability. When extensive

welding is to be performed on the casting, weldability tests should be specified in the ordering information (5.2.6) to ensure proper

welding characteristics.

1.4 Units—The values stated in either inch-pound units or SI units are to be regarded as standard. The values given in

parentheses are mathematical conversions to SI units that are provided for information only and are not considered

standard.separately as standard. Within the text, SI units are shown in brackets. The values stated in each system are not necessarily

exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and

values from the two systems shall not be combined.

1.5 The following hazard statement applies only to Section 8, Weldability Test, of this specification.This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B208 Practice for Preparing Tension Test Specimens for Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous

Castings

B824 Specification for General Requirements for Copper Alloy Castings

B846 Terminology for Copper and Copper Alloys

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3

2.2 ASME Code:

ASME Boiler and Pressure Vessel Code

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on Castings

and Ingots for Remelting.

Current edition approved April 1, 2016April 1, 2020. Published May 2016April 2020. Originally approved in 1961. Last previous edition approved in 20092016 as

B369 – 09.B369 – 09 (2016). DOI: 10.1520/B0369-09R16.10.1520/B0369_B0369M–20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B369/B369M − 20

TABLE 1 Nominal Compositions

Composition, %

Copper Alloy UNS No.

Copper Nickel Iron Silicon Manganese Niobium

C96200 87.5 10.0 1.5 0.1 0.9 .

C96400 67.0 30.0 0.7 0.5 0.8 1.0

4

2.3 AWS Standard:

AWS A5.6 Specification for Copper and Copper-Alloy Arc-Welding Electrodes

3. General Requirements

3.1 The following sections of Specification B824 form a part of this specification. In the event of a conflict between this

specification and Specification B824, the requirements of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.