ASTM D1107-96(2007)

(Test Method)Standard Test Method for Ethanol-Toluene Solubility of Wood

Standard Test Method for Ethanol-Toluene Solubility of Wood

SIGNIFICANCE AND USE

The ethanol-toluene extract of wood consists of the soluble materials not generally considered part of the wood polymeric structure. They are primarily the waxes, fats, resins, and some gums, as well as some water-soluble substances. The amounts are influenced by seasoning and drying.

SCOPE

1.1 This test method covers the determination of the ethanol-toluene soluble content of wood, which is a measure of the waxes, fats, resins, and oils, plus tannins and certain other ether-insoluble components.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 4.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

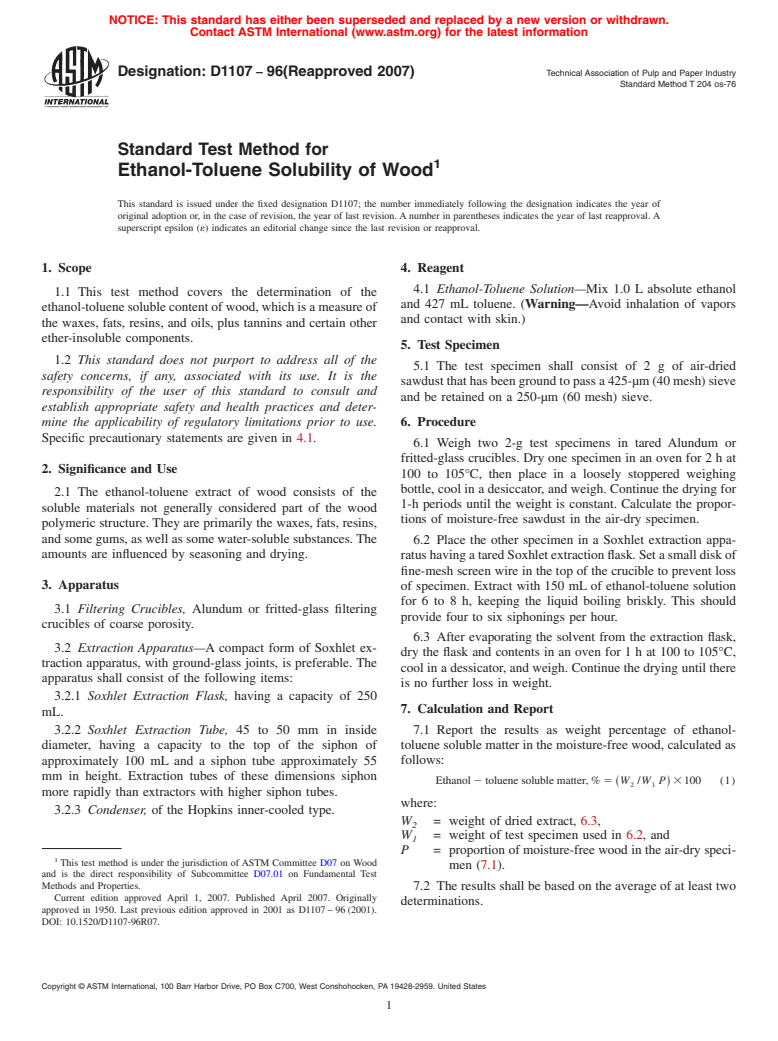

Designation: D1107 − 96(Reapproved 2007) Technical Association of Pulp and Paper Industry

Standard Method T 204 os-76

Standard Test Method for

Ethanol-Toluene Solubility of Wood

This standard is issued under the fixed designation D1107; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Reagent

4.1 Ethanol-Toluene Solution—Mix 1.0 L absolute ethanol

1.1 This test method covers the determination of the

and 427 mL toluene. (Warning—Avoid inhalation of vapors

ethanol-toluene soluble content of wood, which is a measure of

and contact with skin.)

the waxes, fats, resins, and oils, plus tannins and certain other

ether-insoluble components.

5. Test Specimen

1.2 This standard does not purport to address all of the

5.1 The test specimen shall consist of2gofair-dried

safety concerns, if any, associated with its use. It is the

sawdust that has been ground to pass a 425-µm (40 mesh) sieve

responsibility of the user of this standard to consult and

and be retained on a 250-µm (60 mesh) sieve.

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use. 6. Procedure

Specific precautionary statements are given in 4.1.

6.1 Weigh two 2-g test specimens in tared Alundum or

fritted-glass crucibles. Dry one specimen in an oven for2hat

2. Significance and Use

100 to 105°C, then place in a loosely stoppered weighing

bottle, cool in a desiccator, and weigh. Continue the drying for

2.1 The ethanol-toluene extract of wood consists of the

1-h periods until the weight is constant. Calculate the propor-

soluble materials not generally considered part of the wood

tions of moisture-free sawdust in the air-dry specimen.

polymeric structure. They are primarily the waxes, fats, resins,

and some gums, as well as some water-soluble substances. The

6.2 Place the other specimen in a Soxhlet extraction appa-

amounts are influenced by seasoning and drying.

ratushavingataredSoxhletextractionflask.Setasmalldiskof

fine-mesh screen wire in the top of the crucible to prevent loss

3. Apparatus

of specimen. Extract with 150 mL of ethanol-toluene solution

for 6 to 8 h, keeping the liquid boiling briskly. This should

3.1 Filtering Crucibles, Alundum or fritted-glass filtering

provide four to six siphonings per hour.

crucibles of coarse porosity.

6.3 After evaporating the solvent from the extraction flask,

3.2 Extraction Apparatus—A compact form of Soxhlet ex-

dry the flask and contents in an oven for 1 h at 100 to 105°C,

traction apparatus, with ground-glass joints, is preferable. The

cool in a dessicator, and weigh. Continue the drying until there

apparatus shall consist of the following items:

is no further loss in weight.

3.2.1 Soxhlet Extraction Flask, having a capacity of 250

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.