ASTM E2737-23

(Practice)Standard Practice for Digital Detector Array Performance Evaluation and Long-Term Stability

Standard Practice for Digital Detector Array Performance Evaluation and Long-Term Stability

SIGNIFICANCE AND USE

4.1 This practice is intended to be used by the DDA user to measure and record the baseline performance of an acquired DDA in order to monitor its performance throughout its service as an imaging system. This practice is not intended to be used as an “acceptance test” of a DDA.

4.2 This practice defines the tests to be performed and their required intervals. Also defined are the methods of tabulating results that DDA users will complete following initial baselining of the DDA system. These tests will also be performed periodically at the stated required intervals to evaluate the DDA system to determine if the system remains within acceptable operational limits as established in this practice and defined between the user and CEO.

4.3 There are several factors that affect the quality of a DDA image including the basic spatial resolution, geometric unsharpness, scatter, signal to noise ratio, contrast sensitivity, contrast/noise ratio, image lag, and for some types of DDAs, burn-in. There are several additional factors and settings which can affect these results (for example, integration time, detector parameters, imaging software, and even X-ray radiation quality). Additionally, detector correction techniques may have an impact on the quality of the image. This practice delineates tests for each of the properties listed herein and establishes standard techniques for assuring repeatability throughout the lifecycle testing of the DDA.

SCOPE

1.1 This practice covers the baseline and periodic performance evaluation of Digital Detector Array (DDA) systems used for industrial radiography. It is intended to ensure that the evaluation of image quality, as far as this is influenced by the DDA system, meets the needs of users, and their customers, and enables process control to monitor long-term stability of the DDA system.

1.2 This practice specifies the fundamental parameters of DDA systems to be measured to determine baseline performance, and to track the long-term stability of the DDA system.

1.3 The DDA system tests specified in this practice shall be completed upon acceptance of the system from the manufacturer to baseline the performance of the DDA. Periodic performance testing shall then be used to monitor long-term stability of the system in order to identify when an action needs to be taken due to system degradation beyond a certain defined level.

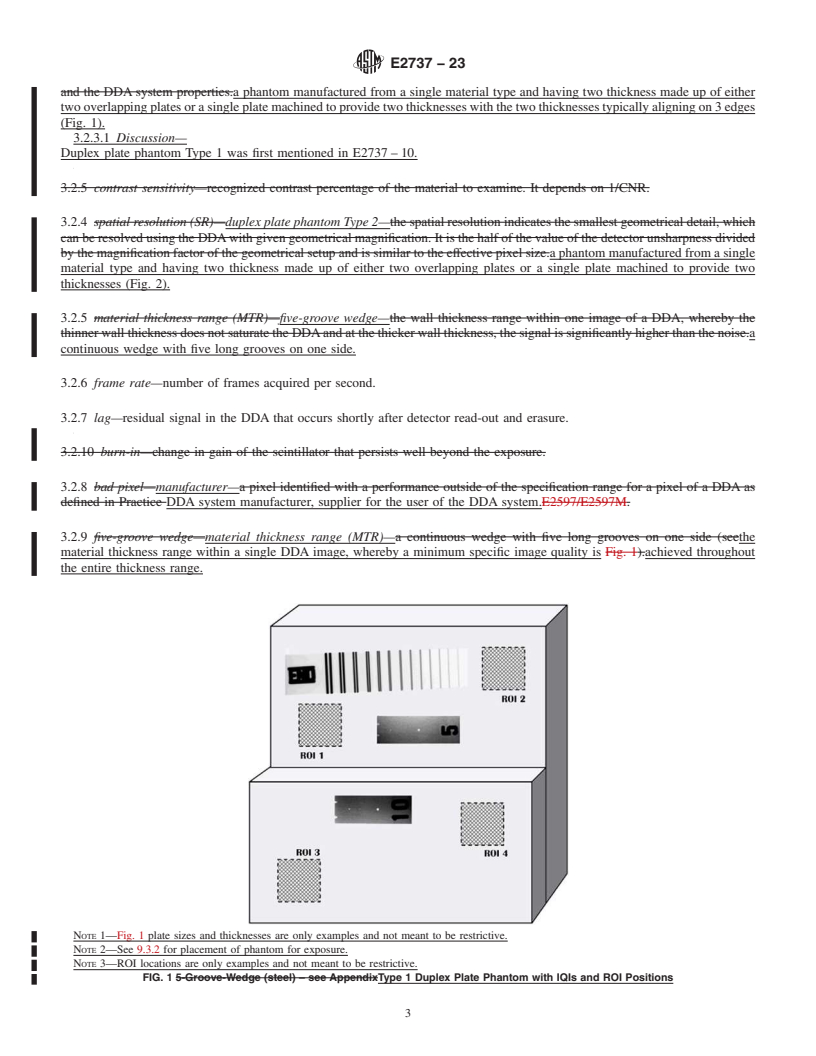

1.4 Two types of phantoms, the duplex plate and the five-groove wedge, are used for testing as specified herein. The use of these two types of phantoms is not intended to exclude the use of other phantom configurations. In the event the tests or phantoms specified herein are not sufficient or appropriate, the user, in coordination with the cognizant engineering organization (CEO) may develop additional or modified tests, test objects, phantoms, or image quality indicators to evaluate the DDA system performance. Acceptance levels for these ALTERNATE test methods shall be determined by agreement between the user and CEO.

1.5 The user of this practice shall consider that higher energies than 450 keV may require different test methods or modifications to the test methods described here. This practice is not intended for usage with isotopes.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2737 − 23

Standard Practice for

Digital Detector Array Performance Evaluation and Long-

1

Term Stability

This standard is issued under the fixed designation E2737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope modifications to the test methods described here. This practice

is not intended for usage with isotopes.

1.1 This practice covers the baseline and periodic perfor-

1.6 This standard does not purport to address all of the

mance evaluation of Digital Detector Array (DDA) systems

safety concerns, if any, associated with its use. It is the

used for industrial radiography. It is intended to ensure that the

responsibility of the user of this standard to establish appro-

evaluation of image quality, as far as this is influenced by the

priate safety, health, and environmental practices and deter-

DDA system, meets the needs of users, and their customers,

mine the applicability of regulatory limitations prior to use.

and enables process control to monitor long-term stability of

1.7 This international standard was developed in accor-

the DDA system.

dance with internationally recognized principles on standard-

1.2 This practice specifies the fundamental parameters of

ization established in the Decision on Principles for the

DDA systems to be measured to determine baseline

Development of International Standards, Guides and Recom-

performance, and to track the long-term stability of the DDA

mendations issued by the World Trade Organization Technical

system.

Barriers to Trade (TBT) Committee.

1.3 The DDA system tests specified in this practice shall be

completed upon acceptance of the system from the manufac-

2. Referenced Documents

turer to baseline the performance of the DDA. Periodic

2

2.1 ASTM Standards:

performance testing shall then be used to monitor long-term

E543 Specification for Agencies Performing Nondestructive

stability of the system in order to identify when an action needs

Testing

to be taken due to system degradation beyond a certain defined

E1025 Practice for Design, Manufacture, and Material

level.

Grouping Classification of Hole-Type Image Quality In-

1.4 Two types of phantoms, the duplex plate and the

dicators (IQI) Used for Radiography

five-groove wedge, are used for testing as specified herein. The

E1165 Test Method for Measurement of Focal Spots of

use of these two types of phantoms is not intended to exclude

Industrial X-Ray Tubes by Pinhole Imaging

the use of other phantom configurations. In the event the tests

E1316 Terminology for Nondestructive Examinations

or phantoms specified herein are not sufficient or appropriate,

E1742/E1742M Practice for Radiographic Examination

the user, in coordination with the cognizant engineering orga-

E2002 Practice for Determining Image Unsharpness and

nization (CEO) may develop additional or modified tests, test

Basic Spatial Resolution in Radiography and Radioscopy

objects, phantoms, or image quality indicators to evaluate the

E2446 Practice for Manufacturing Characterization of Com-

DDA system performance. Acceptance levels for these AL-

puted Radiography Systems

TERNATE test methods shall be determined by agreement

E2597/E2597M Practice for Manufacturing Characterization

between the user and CEO.

of Digital Detector Arrays

E2698 Practice for Radiographic Examination Using Digital

1.5 The user of this practice shall consider that higher

Detector Arrays

energies than 450 keV may require different test methods or

E2736 Guide for Digital Detector Array Radiography

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.01 on

2

Radiology (X and Gamma) Method. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2023. Published August 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2010. Last previous edition approved in 2018 as E2737 – 10 (2018). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E2737-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2737 − 23

E2903 Test Method for Measurement of the Effective Focal 3.2.10 phantom—a part or item being used to quantify DDA

Spot Size of Mini and Micro

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2737 − 10 (Reapproved 2018) E2737 − 23

Standard Practice for

Digital Detector Array Performance Evaluation and Long-

1

Term Stability

This standard is issued under the fixed designation E2737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the evaluation of DDA systems for industrial radiology.covers the baseline and periodic performance

evaluation of Digital Detector Array (DDA) systems used for industrial radiography. It is intended to ensure that the evaluation

of image quality, as far as this is influenced by the DDA system, meets the needs of users, and their customers, and enables process

control and long termto monitor long-term stability of the DDA system.

1.2 This practice specifies the fundamental parameters of Digital Detector Array (DDA) DDA systems to be measured to

determine baseline performance, and to track the long term long-term stability of the DDA system.

1.3 The DDA system performance tests specified in this practice shall be completed upon acceptance of the system from the

manufacturer and at intervals specified in this practice to monitor long term stability of the system. The intent of these tests is to

monitor the system performance for degradation and to baseline the performance of the DDA. Periodic performance testing shall

then be used to monitor long-term stability of the system in order to identify when an action needs to be taken when the system

degrades by a certain due to system degradation beyond a certain defined level.

1.4 Two types of phantoms, the duplex plate and the five-groove wedge, are used for testing as specified herein. The use of the

gages provided in this standard is mandatory for each test. these two types of phantoms is not intended to exclude the use of other

phantom configurations. In the event thesethe tests or gages are not sufficient, phantoms specified herein are not sufficient or

appropriate, the user, in coordination with the cognizant engineering organization (CEO) may develop additional or modified tests,

test objects, gages,phantoms, or image quality indicators to evaluate the DDA system. system performance. Acceptance levels for

these ALTERNATE tests test methods shall be determined by agreement between the user, CEO and manufacturer.user and CEO.

1.5 The user of this practice shall consider that higher energies than 450 keV may require different test methods or modifications

to the test methods described here. This practice is not intended for usage with isotopes.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology (X and

Gamma) Method.

Current edition approved Feb. 1, 2018July 1, 2023. Published February 2018August 2023. Originally approved in 2010. Last previous edition approved in 20102018 as

E2737 – 10.E2737 – 10 (2018). DOI: 10.1520/E2737-10R18.10.1520/E2737-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2737 − 23

2. Referenced Documents

2

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E1025 Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI)

Used for Radiography

E1165 Test Method for Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole Imaging

E1316 Terminology for Nondestructive Examinations

E1742/E1742M Practice for Radiographic Examination

E2002 Practice for Determining Image Unsharpness and Basic Spatial Resolution in Radiography and Radioscopy

E2445/E244

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.