ASTM D5492-10

(Test Method)Standard Test Method for Determination of Xylene Solubles in Propylene Plastics

Standard Test Method for Determination of Xylene Solubles in Propylene Plastics

SIGNIFICANCE AND USE

The results of this test provide a relative measure of the total soluble fraction of polypropylene homopolymers and copolymers. The soluble fraction approximately correlates to the amorphous fraction in the polypropylene. Xylene is widely used for determining the soluble fraction in polypropylene as it is more specific to the atactic fraction than other solvents. The concentration of a soluble fraction obtained with a specific solvent has been found to relate closely to the performance characteristics of a product in certain applications, for example film and fiber. Data obtained by one solvent and at one precipitation time cannot be compared with data obtained by another solvent or precipitation time, respectively.

SCOPE

1.1 This test method is to be used for determining the 25°C xylene-soluble fraction of polypropylene homopolymers and copolymers.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method is technically equivalent to ISO 16152.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5492 − 10

Standard Test Method for

1

Determination of Xylene Solubles in Propylene Plastics

This standard is issued under the fixed designation D5492; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

1.1 This test method is to be used for determining the 25°C 4.1 A weighed amount of sample is dissolved in xylene

xylene-soluble fraction of polypropylene homopolymers and under reflux conditions. The solution is cooled under con-

copolymers.

trolled conditions and maintained at a +25°C equilibrium

temperature so that the crystallization of the insoluble fraction

1.2 This standard does not purport to address all of the

takes place. When the solution is cooled the insoluble portion

safety concerns, if any, associated with its use. It is the

precipitates and is isolated by filtration. The xylene is evapo-

responsibility of the user of this standard to establish appro-

rated from the filtrate, leaving the soluble fraction in the

priate safety and health practices and determine the applica-

residue. The percentage of this fraction in the plastic is

bility of regulatory limitations prior to use.

determined gravimetrically.

NOTE 1—This test method is technically equivalent to ISO 16152.

5. Significance and Use

2. Referenced Documents

5.1 The results of this test provide a relative measure of the

2

2.1 ASTM Standards:

total soluble fraction of polypropylene homopolymers and

D883 Terminology Relating to Plastics

copolymers. The soluble fraction approximately correlates to

D1600 TerminologyforAbbreviatedTermsRelatingtoPlas-

the amorphous fraction in the polypropylene. Xylene is widely

tics

used for determining the soluble fraction in polypropylene as it

E691 Practice for Conducting an Interlaboratory Study to

is more specific to the atactic fraction than other solvents. The

Determine the Precision of a Test Method

concentration of a soluble fraction obtained with a specific

2.2 ISO Standard:

solvent has been found to relate closely to the performance

ISO 16152 Plastics—Determination of Xylene Solubles of

characteristics of a product in certain applications, for example

3

Polypropylene

film and fiber. Data obtained by one solvent and at one

precipitation time cannot be compared with data obtained by

3. Terminology

another solvent or precipitation time, respectively.

3.1 Definitions:

3.1.1 For definitions of plastic terms see Terminology D883

6. Interferences

and for abbreviations see Terminology D1600.

6.1 It is possible that materials with solubilities similar to

3.2 Definitions of Terms Specific to This Standard:

the soluble fraction, such as additives, can interfere with the

3.2.1 soluble-fraction (S )—the percentage of the polymer

S

measurement of solubles. When present in concentrations that

mass that does not precipitate out when the polymer solution is

are judged to impart a significant error to the soluble-fraction

cooledfromrefluxtemperatureto+25 60.5°Candheldatthat

data, the level of interference must be determined and correc-

temperature for a specified period of time.

tions made.

6.2 It is possible that small-particle fillers and pigments and

1 insolublegelspresentinthepolymercanpassthroughthefilter

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materi-

and cause errors in the measurement.

als.

6.3 The polymer flakes and spheres must be dried before

Current edition approved Aug. 1, 2010. Published September 2010. Originally

approved in 1994. Last previous edition approved in 2006 as D5492 - 06. DOI:

testing to eliminate moisture that can influence the initial

10.1520/D5492-10.

weight of sample added to the flask.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 7. Apparatus

the ASTM website.

3

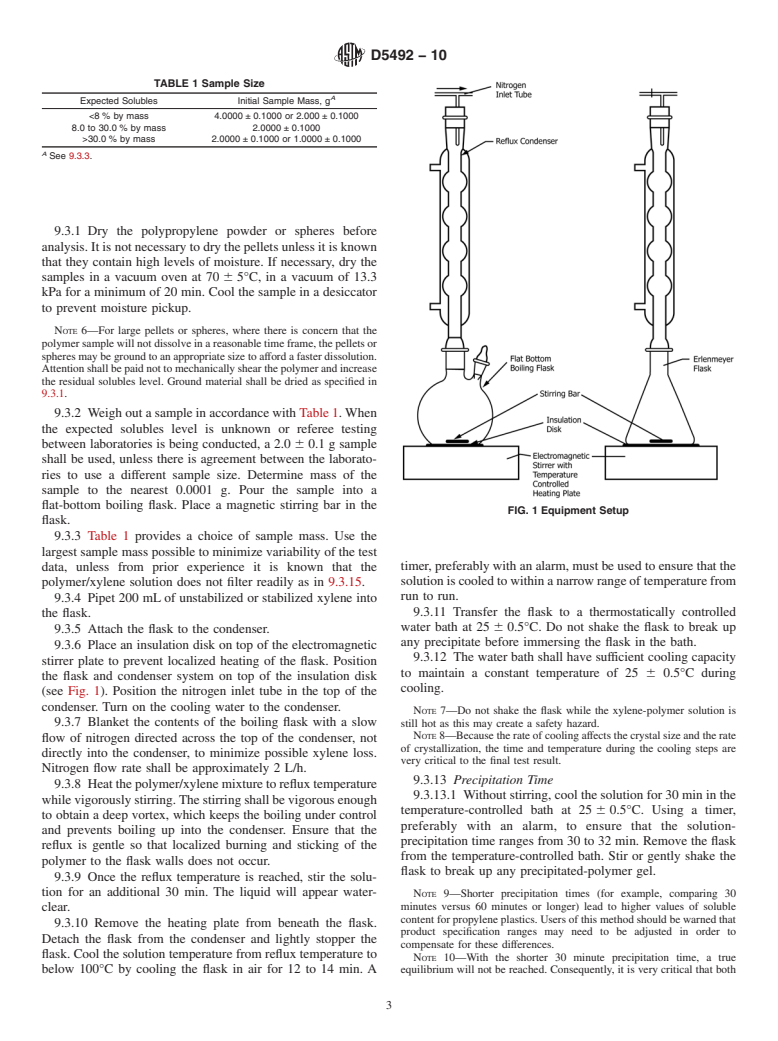

7.1 Reflux-Condenser Apparatus, 400 mm, with 24/40 glass

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. joint.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5492 − 10

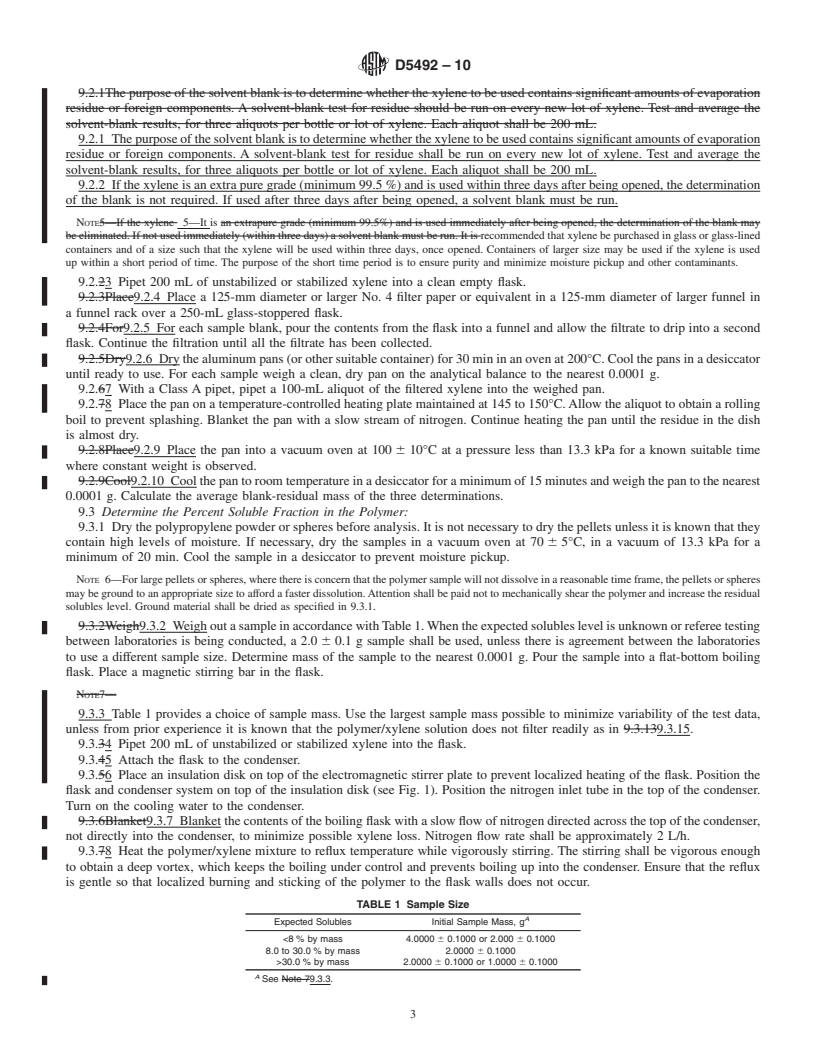

NOTE 3—When testing non-stabilized polypropylene powders or

7.2 Flat-Bottom Boiling Flask, with one or two necks, 400

spheres, antioxidants may be added to prevent degradation. This addition

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5492–06 Designation:D5492–10

Standard Test Method for

1

Determination of Xylene Solubles in Propylene Plastics

This standard is issued under the fixed designation D5492; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1This1.1 Thistestmethodistobeusedfordeterminingthe25°Cxylene-solublefractionofpolypropylenehomopolymersand

copolymers.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—This test method is technically equivalent to ISO 16152.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standard:

3

ISO 16152 Plastics—Determination of Xylene Solubles of Polypropylene

3. Terminology

3.1 Definitions:

3.1.1 For definitions of plastic terms see Terminology D883 and for abbreviations see Terminology D1600.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 soluble-fraction (S )—the percentage of the polymer mass that does not precipitate out when the polymer solution is

S

cooled from reflux temperature to +25 6 0.5°C and held at that temperature for a specified period of time.

4. Summary of Test Method

4.1A4.1 A weighed amount of sample is dissolved in xylene under reflux conditions. The solution is cooled under controlled

conditionsandmaintainedata+25°Cequilibriumtemperaturesothatthecrystallizationoftheinsolublefractiontakesplace.When

the solution is cooled the insoluble portion precipitates and is isolated by filtration.The ortho-xylenexylene is evaporated from the

filtrate, leaving the soluble fraction in the residue. The percentage of this fraction in the plastic is determined gravimetrically.

5. Significance and Use

5.1The5.1 The results of this test provide a relative measure of the total soluble fraction of polypropylene homopolymers and

copolymers. The soluble fraction can be approximately correlateds to the amorphous fraction in the polypropylene. Xylene is

widelyusedfordeterminingthesolublefractioninpolypropylene.Xylenepolypropyleneasitismorespecifictotheatacticfraction

than other solvents. The concentration of a soluble fraction obtained with a specific solvent has been found to relate closely to the

performance characteristics of a product in certain applications, for example film and fiber. Data obtained by one solvent and at

one precipitation time cannot be compared with data obtained by another solvent or precipitation time, respectively.

6. Interferences

6.1Materials 6.1 It is possible that materials with solubilities similar to the soluble fraction, such as additives, maycan interfere

with the measurement of solubles. When present in concentrations that are judged to impart a significant error to the

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved MayAug. 1, 2006.2010. Published June 2006.September 2010. Originally approved in 1994. Last previous edition approved in 20032006 as

D5492-98(2003).D5492 - 06. DOI: 10.1520/D5492-106.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5492–10

soluble-fraction data, the level of interference must be determined and corrections made.

6.2Small-particle fillers and pigments 6.2 It is possible that may pass through the filter small-particle fillers and pigments and

insoluble gels present in the polymer maycan pass through the filter and cause errors in the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.