ASTM D6761-07(2012)

(Test Method)Standard Test Method for Determination of the Total Pore Volume of Catalysts and Catalyst Carriers

Standard Test Method for Determination of the Total Pore Volume of Catalysts and Catalyst Carriers

SIGNIFICANCE AND USE

This test method provides for the measurement of volume of pores that are in the range of catalytic importance and possibly for adsorption processes. This test method requires the use of mercury in order to perform the measurements.

SCOPE

1.1 This test method covers the determination of the total pore volume of catalysts and catalyst carriers, that is, the volume of pores having pore diameter between approximately 14 µm and 0.4 nm (4 Å).

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 WARNINGMercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s websitehttp://www.epa.gov/mercury/faq.htmfor additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8. Warning statements are given in 9.1.4, 9.1.7, and 9.1.11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6761 − 07 (Reapproved 2012)

Standard Test Method for

Determination of the Total Pore Volume of Catalysts and

Catalyst Carriers

This standard is issued under the fixed designation D6761; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method covers the determination of the total

Determine the Precision of a Test Method

pore volume of catalysts and catalyst carriers, that is, the

volume of pores having pore diameter between approximately

3. Terminology

14 µm and 0.4 nm (4 Å).

3.1 Definitions:

1.2 The values stated in SI units are to be regarded as

3.1.1 particle volume—the volume of a particle including

standard. No other units of measurement are included in this

pores into which mercury cannot penetrate at ambient pressure

standard.

(smaller than approximately 14 µm diameter pore mouth).

1.3 WARNING—Mercury has been designated by many

3.1.2 true volume—the volume of a particle, including

regulatory agencies as a hazardous material that can cause

pores, into which helium cannot penetrate (smaller than about

central nervous system, kidney and liver damage. Mercury, or

approximately 0.4 nm (4 Å) diameter pore mouth).

its vapor, may be hazardous to health and corrosive to

3.1.3 Other definitions and terms used in this test method

materials. Caution should be taken when handling mercury and

are defined in Terminology D3766.

mercury containing products. See the applicable product Ma-

3.2 Symbols for Mercury Intrusion:

terial Safety Data Sheet (MSDS) for details and EPA’s

website—http://www.epa.gov/mercury/faq.htm—for addi-

tional information. Users should be aware that selling mercury

W = mass of sample

and/or mercury containing products into your state or country

W = mass of sealed empty sample cell

c

may be prohibited by law.

W' = mass of sealed sample cell filled with mercury

C

1.4 This standard does not purport to address all of the W = mass of sealed sample cell with sample

s

safety concerns, if any, associated with its use. It is the W' = mass of sealed sample cell with sample filled with

S

responsibility of the user of this standard to establish appro- mercury

C

V = volume of mercury in empty sample cell (volume of

priate safety and health practices and determine the applica-

Hg

sample cell)

bility of regulatory limitations prior to use. Specific hazard

S

V = volume of mercury in cell with sample

statements are given in Section 8. Warning statements are

Hg

Hg

V = sample volume, cm

S

given in 9.1.4, 9.1.7, and 9.1.11.

V = specific sample volume

Hg

V = particle volume

2. Referenced Documents

P

W = weight mercury reservoir after filling burette with

b

2.1 ASTM Standards:

sample

D3766 Terminology Relating to Catalysts and Catalysis

W = mass of mercury reservoir after filling burette with-

b'

E177 Practice for Use of the Terms Precision and Bias in

out sample

ASTM Test Methods

3.3 Symbols for Helium Pycnometry:

This test method is under the jurisdiction of ASTM Committee D32 on

Catalysts and is the direct responsibility of Subcommittee D32.02 on Physical-

V = volume of sample cell and associated tubing, cm

C

Mechanical Properties. 3

V = reference volume, cm

R

CurrenteditionapprovedMay1,2012.PublishedJuly2012.Originallyapproved

He

V = sample volume, cm

S

in 2002. Last previous edition approved in 2007 as D6761–07. DOI: 10.1520/

V = volume of calibration cylinder, cm

D6761-07R12.

Cyl

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

V = volume of calibration standard, cm

STD

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

V = specific sample volume

He

Standards volume information, refer to the standard’s Document Summary page on

P' = pressure in empty sample cell, psig or pascals

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6761 − 07 (2012)

P' = pressure in empty sample cell, after the reference

volume has been included in the system, psig or

pascals

P = pressure in sample cell with sample or calibration

standard before the reference volume has been

included in the system, psig or pascals

P = pressure with sample or calibration standard in the

sample cell, after the reference volume has been

included in the system, psig or pascals

W = tare weight of sample cup, g

W = mass of sample + tare weight of sample cup, g

W = mass of sample, g

P.V. = pore volume

4. Summary of Test Method

4.1 The total pore volume of a catalyst or catalyst carrier is

determined as the difference between the particle volume and

the true volume, measured by mercury intrusion and helium

pycnometry, respectively. The particle volume is determined

by mercury intrusion at ambient pressure and the true volume

is determined by helium displacement at pressures above

ambient.

5. Significance and Use

5.1 This test method provides for the measurement of

volume of pores that are in the range of catalytic importance

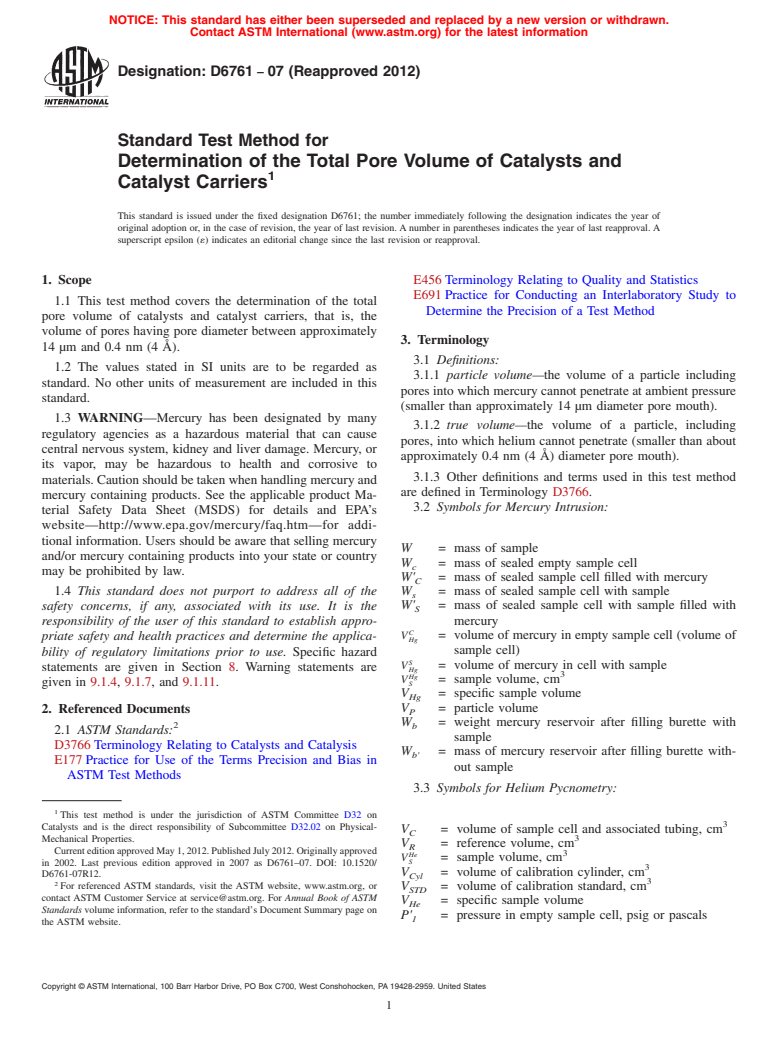

FIG. 1 Schematic Diagram of Burette

and possibly for adsorption processes. This test method re-

quires the use of mercury in order to perform the measure-

ments.

reservoir, should be narrow enough so as to prevent drops of

6. Apparatus

mercury from becoming lost if the reservoir is removed for

6.1 For Mercury Intrusion: weighing.

6.1.1 Chamber, capable of holding the sample cell (com- 6.2.2 Burette, a calibrated narrow bore tube ending in a

monly referred to as a penetrometer), which contains the curved tip in the sample cell to prevent fine particles from

sample. This chamber must be capable of being evacuated and passing into the burette. There is a clear mark on the burette at

contain enough mercury to fill the penetrometer. 23 cm above the curved tip.

6.1.2 Glass Sample Cell (penetrometer), having a wide base 6.2.3 Manifold, with a splash bulb and appropriate needle

and narrow bore stem. If the sample is powder, the penetrom- valves for choosing either vacuum or vent.

etershouldhaveaprovisioninthebasetopreventfineparticles 6.2.4 Mercury Reservoir with Lid, capable of containing the

from passing into the stem when the cell is evacuated. The amount of mercury necessary to fill the sample cell and burette

penetrometer must have the capability of being sealed. while the tip of the sample cell valve is still submerged in

6.1.3 Vacuum Pump, capable of attaining pressures of less mercury. A weighing bottle of 5 cm diameter and 3 cm height

is suitable.

than 0.05 torr.

6.1.4 Valve, for choosing vacuum and vent, for evacuation 6.2.5 Vacuum Pump, capable of attaining pressures of 0.05

torr.

of the sample cell and filling the sample cell, respectively.

6.1.5 Valve, for rapid evacuation or venting of the system. 6.2.6 Cold Trap, or other method or device to prevent

6.1.6 Valve, for controlled evacuation or venting. mercury vapor from being vented into the laboratory through

6.1.7 Cold Trap, or other method or device to prevent the vacuum pump and to prevent contaminants from entering

mercury vapor from being vented into the laboratory through the vacuum pump.

the vacuum pump and to prevent contaminants from entering

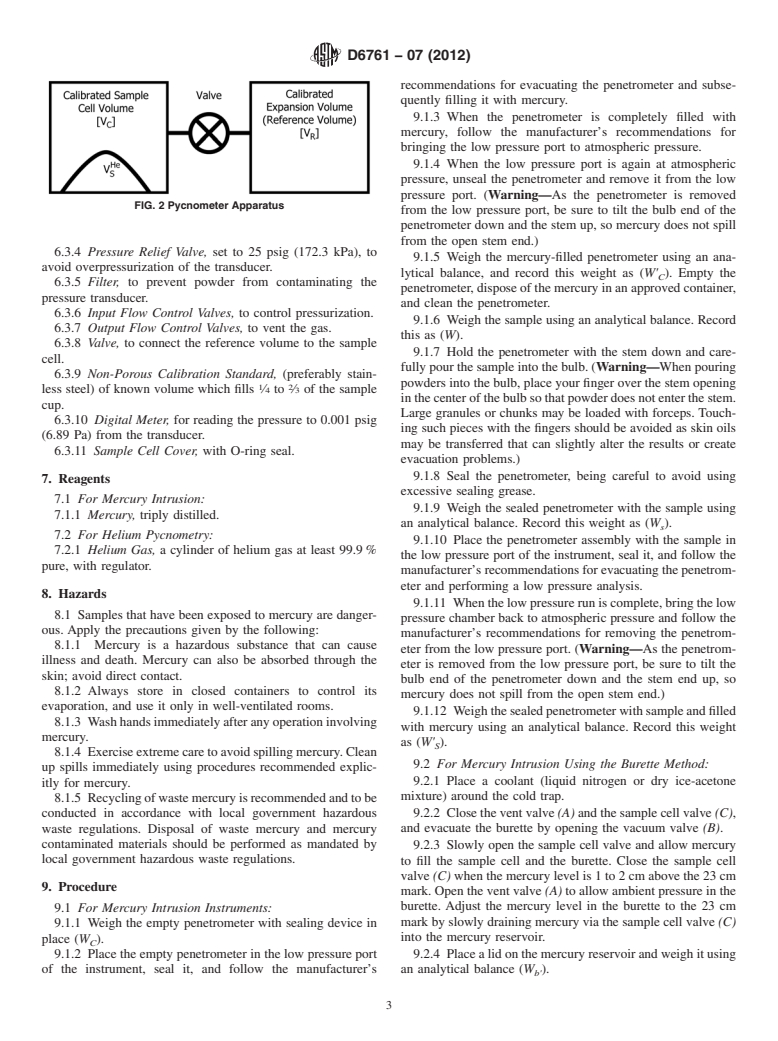

6.3 For Helium Pycnometry—A schematic diagram of the

the vacuum pump.

pycnometer apparatus is shown in Fig. 2. It should be con-

6.1.8 Pressure-Measuring Device, capable of reading in the

structed from metal and have the following features:

range 0 to 1000 torr or higher.

6.3.1 Sample Cell, having a volume suitable for the desired

6.1.9 Balance, measuring to the nearest 1 mg (60.001 g).

sample size and calibrated to the nearest 0.1 cm . This volume

6.2 For Mercury Intrusion with a Burette—A schematic is indicated in Fig. 2.

diagram of the burette is shown in Fig. 1. It has the following 6.3.2 Reference Volume (V ), a precisely calibrated volume

R

features: known to the nearest 0.02 cm .

6.2.1 Glass Sample Cell, with a needle valve suitable for 6.3.3 Pressure Transducer, (0 to 25 psig or 0 to 172.3 kPa)

handling mercury. The tip, which is submerged in the mercury with minimum volume displacement and linear within 0.1 %.

D6761 − 07 (2012)

recommendations for evacuating the penetrometer and subse-

quently filling it with mercury.

9.1.3 When the penetrometer is completely filled with

mercury, follow the manufacturer’s recommendations for

bringing the low pressure port to atmospheric pressure.

9.1.4 When the low pressure port is again at atmospheric

pressure, unseal the penetrometer and remove it from the low

pressure port. (Warning—As the penetrometer is removed

FIG. 2 Pycnometer Apparatus

from the low pressure port, be sure to tilt the bulb end of the

penetrometer down and the stem up, so mercury does not spill

from the open stem end.)

6.3.4 Pressure Relief Valve, set to 25 psig (172.3 kPa), to

9.1.5 Weigh the mercury-filled penetrometer using an ana-

avoid overpressurization of the transducer.

lytical balance, and record this weight as (W' ). Empty the

C

6.3.5 Filter, to prevent powder from contaminating the

penetrometer, dispose of the mercury in an approved container,

pressure transducer.

and clean the penetrometer.

6.3.6 Input Flow Control Valves, to control pressurization.

9.1.6 Weigh the sample using an analytical balance. Record

6.3.7 Output Flow Control Valves, to vent the gas.

this as (W).

6.3.8 Valve, to connect the reference volume to the sample

9.1.7 Hold the penetrometer with the stem down and care-

cell.

fully pour the sample into the bulb. (Warning—When pouring

6.3.9 Non-Porous Calibration Standard, (preferably stain-

powders into the bulb, place your finger over the stem opening

1 2

less steel) of known volume which fills ⁄4 to ⁄3 of the sample

inthecenterofthebulbsothatpowderdoesnotenterthestem.

cup.

Large granules or chunks may be loaded with forceps. Touch-

6.3.10 Digital Meter, for reading the pressure to 0.001 psig

ing such pieces with the fingers should be avoide

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.