ASTM D4645-87(1997)

(Test Method)Standard Test Method for Determination of the In-Situ Stress in Rock Using the Hydraulic Fracturing Method

Standard Test Method for Determination of the In-Situ Stress in Rock Using the Hydraulic Fracturing Method

SCOPE

1.1 This test method covers the determination of the in-situ state of stress in rock by hydraulic fracturing. Note 1-Hydraulic fracturing for stress determination is also referred to as hydrofracturing, and sometimes as minifracing. Hydraulic fracturing and hydrofracturing may also refer to fracturing of the rock by fluid pressure for the purpose of altering rock properties, such as permeability and porosity.

1.2 Hydraulic fracturing is the only widely accepted field method available for in situ stress measurements at depths greater than 50 m. It can be used in drill holes of any diameter.

1.3 Hydraulic fracturing can also be used in short holes for which other stress measuring methods, such as overcoring, are also available. The advantage of hydraulic fracturing is that it yields stresses averaged over a few square metres (the size of the induced hydraulic fracture) rather than over grain size areas, as in the case of overcoring techniques.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4645 – 87 (Reapproved 1997)

Standard Test Method for

Determination of the In-Situ Stress in Rock Using the

Hydraulic Fracturing Method

This standard is issued under the fixed designation D 4645; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope induced hydrofracture after the test interval pressure has been

allowed to return to its initial condition.

1.1 This test method covers the determination of the in-situ

2.1.4 shut-in pressure (or ISIP (instantaneous shut-in

state of stress in rock by hydraulic fracturing.

pressure))—the pressure reached when the induced hydrofrac-

NOTE 1—Hydraulic fracturing for stress determination is also referred

ture closes back after pumping is stopped.

to as hydrofracturing, and sometimes as minifracing. Hydraulic fracturing

2.1.5 vertical and horizontal principal stresses—the three

and hydrofracturing may also refer to fracturing of the rock by fluid

principal stresses in situ are assumed to act one in the vertical

pressure for the purpose of altering rock properties, such as permeability

direction and the other two in the horizontal plane.

and porosity.

1.2 Hydraulic fracturing is the only widely accepted field

3. Summary of Test Method

method available for in situ stress measurements at depths

3.1 A section of the borehole is isolated by pressurizing two

greater than 50 m. It can be used in drill holes of any diameter.

inflatable rubber packers. The fluid pressure in the sealed-off

1.3 Hydraulic fracturing can also be used in short holes for

interval between the two packers is raised by pumping fluid

which other stress measuring methods, such as overcoring, are

into it at a controlled rate until a fracture occurs in the borehole

also available. The advantage of hydraulic fracturing is that it

wall. Pumping is stopped and the pressure in the interval is

yields stresses averaged over a few square metres (the size of

allowed to stabilize. The pressure is then reduced to the pore

the induced hydraulic fracture) rather than over grain size

pressure level of the rock formation, and the pressurization

areas, as in the case of overcoring techniques.

process is repeated several times maintaining the same flow

1.4 The values stated in SI units are to be regarded as the

rate. Additional pressure cycles can be conducted at different

standard.

flow rates. The magnitudes of the principal stresses are

1.5 This standard does not purport to address all of the

calculated from the various pressure readings. The orientation

safety problems, if any, associated with its use. It is the

of the fracture is detected in order to determine the orientation

responsibility of the user of this standard to establish appro-

of the transverse principal stresses. A typical pressure versus

priate safety and health practices and determine the applica-

time, flow rate versus time record for a test interval is shown in

bility of regulatory limitations prior to use.

Fig. 1.

2. Terminology

4. Significance and Use

2.1 Definitions of Terms Specific to This Standard:

4.1 Limitations:

2.1.1 breakdown (or critical) pressure—the pressure re-

4.1.1 The depth of measurement is limited only by the

quired to induce a hydraulic fracture in a previously intact test

length of the test hole.

interval.

4.1.2 Presently, the results of the hydraulic fracturing

2.1.2 in-situ stress—rock stress measured in situ (as op-

method can be interpreted in terms of in-situ stresses only if the

posed to by remote sensing).

boreholes are approximately parallel to one of the three

2.1.3 secondary breakdown (or fracture reopening, or re-

principal in-situ stresses. Unless evidence to the contrary

frac) pressure—the pressure required to reopen a previously

exists, vertical boreholes are assumed to be parallel to one of

the in-situ principal stresses.

4.1.3 When the principal stress parallel to the borehole axis

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

is not the least principal stress, only the two other principal

and Rock and is the direct responsibility of Subcommittee D18.12 on Rock

stresses can be determined directly from the test. If the

Mechanics.

Current edition approved March 9, 1987. Published May 1987. minimum stress acts along the borehole axis, fractures both

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4645

NOTE 1—In this test the flow rate was maintained constant during the first three cycles. In the fourth cycle a very slow flow rate was maintained such

that the top level of the pressure–time curve could be considered as the upper limit for the shut-in pressure.

FIG. 1 Typical Pressure − Time, Flow Rate − Time Records During Hydrofracturing

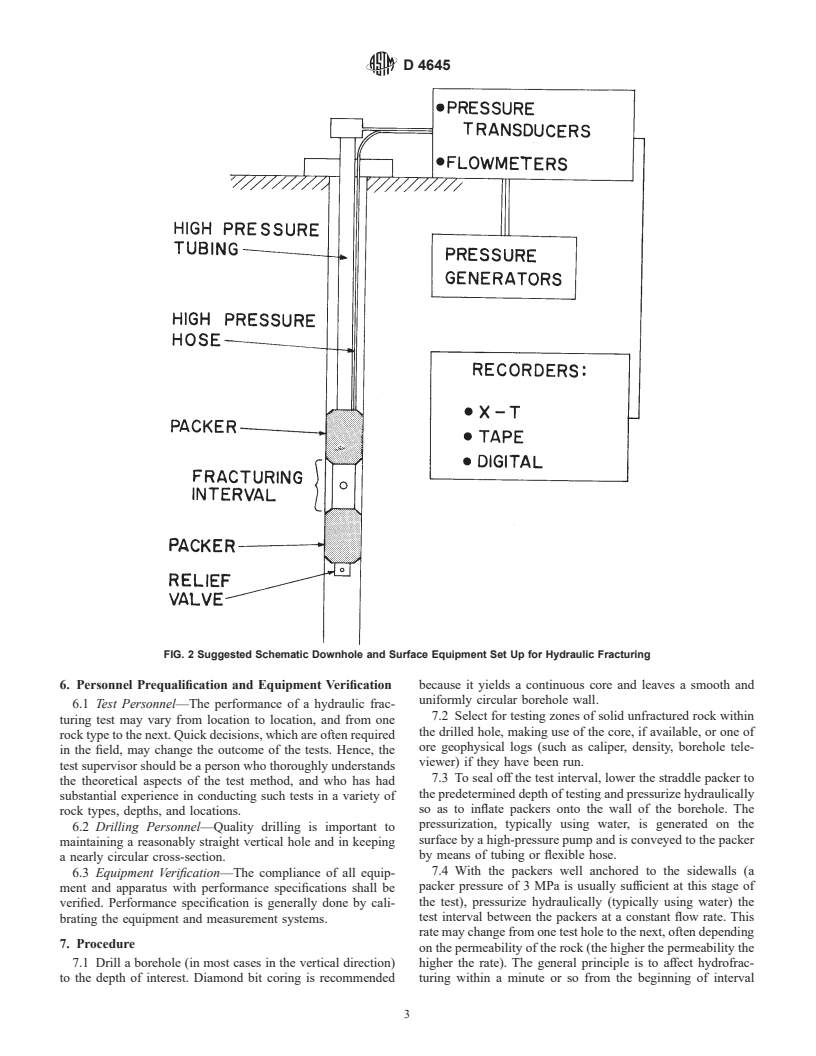

parallel and perpendicular to the axis of the borehole are strapped to the outside of the tubing facilitates packer infla-

sometimes induced by the test, allowing for the determination tion). The hose or the tubing, or both, are connected hydrau-

of all three principal stresses.

lically at one end to pumps or pressure generators (0.70 MPa,

4.1.4 In the unlikely event that the induced fracture changes 0 to 25 L/min are recommended ratings), and at the other to the

orientation away from the borehole, its expression in the

straddle packer and the test interval between the packers (Fig.

borehole wall cannot be used in stress determinations.

2). It has been found that pump capacities similar to those

4.2 Assumptions:

given here can overcome almost any common rock permeabil-

4.2.1 The rock tested is assumed to be linearly elastic,

ity and facilitate pressurization.

homogeneous, and isotropic. Any excessive departure from

5.4 Pressure Transducers and Flow Meter—Pressure trans-

these assumptions could affect the results.

ducers (10 to 70 MPa) are used to monitor the test interval

4.2.2 Vertical boreholes are assumed to be substantially

pressure either on the surface or at the test depth (or both). In

parallel to one of the in-situ principal stresses, since it has been

some setups, the packer pressure is also monitored in the same

established from many geological observations and stress

way as the test interval. A flow meter is used to monitor the

measurements by other methods that in most cases one of the

flow rate of fluid into the test interval. The sensing devices feed

principal stresses is vertical to subvertical.

into multichannel analog time-base recorders for real-time

4.3 Hydraulic fracturing determination of in-situ stresses

continuous permanent recording. Additional options available

can be complicated by rock matrix porosity, naturally occur-

are analog-data tape recording and digital computer recording

ring fractures, the presence of nearby underground openings,

for the storage of test pressure and flow rate information which

and local variations in the stress field.

can later be used to provide a thorough analysis of the test data.

5.5 Hydrofracture Delineation Equipment:

5. Apparatus

5.5.1 Impression Packer—The presence and orientation of

5.1 Tripod or Drilling Rig—Equipment for lowering the

the induced hydrofracture is commonly recorded by the use of

hydraulic fracturing tool into and lifting it from the test hole is

an impression packer, which is an inflatable packer with an

necessary. To facilitate the lowering and lifting of the down-

outer layer of very soft semicured rubber. An orienting device,

hole hydrofracturing tool, a tripod or a drilling rig is set up on

in the form of a magnetic borehole surveying tool or a

top of the test hole. When high-pressure tubing or drilling pipes

gyroscopic borehole surveying tool, is used to determine the

(rods) are used for lowering the tool, it is necessary to use a

direction and inclination of the hydrofracture traced on the

drilling rig with a derrick and hoist capable of lifting the

impression packer (Fig. 3).

combined weight of the pipe and instruments. When a

5.5.2 Borehole Televiewer—An alternative to the oriented

wireline-flexible hose system is used for hydrofracturing, a

impression packer is the borehole televiewer, which is a sonic

well-designed tripod capable of carrying the weight of the

logging tool that takes an oriented acoustic picture of the

testing tool, wireline, and hoses is employed.

borehole wall. This tool is considerably faster than the impres-

5.2 Straddle Packer—Borehole sealing is accomplished by

sion packer because it can take readings from an entire test hole

two inflatable rubber packers, spaced apart a distance equal to

at least six hole diameters, and interconnected mechanically in one trip. The impression packer requires retrieval after each

test so that the outer cover can be properly marked or replaced

and hydraulically to form one unit called the straddle packer.

5.3 High-Pressure Tubing or Hose—Packer and test- before lowering the tool to the next zone. However, the

borehole televiewer is considerably more expensive to own or

interval pressurization is accomplished either by a high-

pressure tubing (drilling rod is often a good substitute) or by rent, does not always discern hydrofractures that have closed

tightly after the pressurization stage of the test, and requires a

high-pressure hose, or by a combination of the two (where

tubing is used to pressurize the interval, and the hose, which is fluid filled borehole.

D 4645

FIG. 2 Suggested Schematic Downhole and Surface Equipment Set Up for Hydraulic Fracturing

6. Personnel Prequalification and Equipment Verification because it yields a continuous core and leaves a smooth and

uniformly circular borehole wall.

6.1 Test Personnel—The performance of a hydraulic frac-

7.2 Select for testing zones of solid unfractured rock within

turing test may vary from location to location, and from one

the drilled hole, making use of the core, if available, or one of

rock type to the next. Quick decisions, which are often required

ore geophysical logs (such as caliper, density, borehole tele-

in the field, may change the outcome of the tests. Hence, the

viewer) if they have been run.

test supervisor should be a person who thoroughly understands

7.3 To seal off the test interval, lower the straddle packer to

the theoretical aspects of the test method, and who has had

the predetermined depth of testing and pressurize hydraulically

substantial experience in conducting such tests in a variety of

so as to inflate packers onto the wall of the borehole. The

rock types, depths, and locations.

pressurization, typically using water, is generated on the

6.2 Drilling Personnel—Quality drilling is important to

surface by a high-pressure pump and is conveyed to the packer

maintaining a reasonably straight vertical hole and in keeping

by means of tubing or flexible hose.

a nearly circular cross-section.

7.4 With the packers well anchored to the sidewalls (a

6.3 Equipment Verification—The compliance of all equip-

packer pressure of 3 MPa is usually sufficient at this stage of

ment and apparatus with performance specifications shall be

the test), pressurize hydraulically (typically using water) the

verified. Performance specification is generally done by cali-

test interval between the packers at a constant flow rate. This

brating the equipment and measurement systems.

rate may change from one test hole to the next, often depending

7. Procedure

on the permeability of the rock (the higher the permeability the

7.1 Drill a borehole (in most cases in the vertical direction) higher the rate). The general principle is to affect hydrofrac-

to the depth of interest. Diamond bit coring is recommended turing within a minute or so from the beginning of interval

D 4645

FIG. 3 Suggested Schematic Downhole and Surface Equipment Set Up for Taking a Packer Impression of the

Hydraulic Fracture

pressure rise. Throughout the interval pressurization, maintain straddle packer assembly can then either be moved to the next

packer pressure at a level of about 2 MPa higher than the test zone or pulled out of the borehole.

interval to ensure that no leak-offs occur. As the rock hydrof-

7.7 The most common tool for determining hydraulic frac-

ractures, a critical (or breakdown) pressure is reached. If

turing orientation is the oriented impression packer. Lower the

pumping is then stopped without venting the hydraulic line, the

packer on the drill-rod or wireline to the test interval after

pressure will suddenly drop and settle at a lower level called

hydrofracturing, and inflate to a pressure higher than the

the shut-in pressure. Repeated cycling of the pressurization

secondary breakdown pressure or the shut-in pressure (which-

procedure using the same flow rate will yield the secondary

ever is larger). This ensures that the packer will slightly open

breakdown pressure (the pressure required to reopen a preex-

the hydrofracture and enable the soft rubber covering to take a

isting hydrofracture), and additional values of the shut-in

good imprint of the fracture. A magnetic compass or a

pressure.

gyroscopic borehole surveying tool is used to determine the

7.5 Continuously record the entire pressurization process

azimuth of a fixed point on the packer. After some 30 to 60 min

both as pressure versus time and as flow rate versus time.

of pressurization, deflate the impression packer and retrieve.

7.6 At the conclusion of the test, vent the packer pressure to

Trace the fracture impression and determine its orientation

allow the packers to return to their original diameter. The entire

D 4645

with respect to the fixed point on the packer so that it can also pointing the shut-in pressure on the pressure–time curves are

be oriented with respect to north. described by Zoback and Haimson.

8.2.3 The tensile strength (T) is not a constant parameter and

varies with loading rate, specimen size, grain size, and mode of

8. Calculation

testing. There is no direct way of determining T in the test hole.

8.1 General—The calculation of in-situ principal stresses

However, when it can be assumed that the hydrofractured rock

given here is for the commonly used vertical test holes. The

closes back completely once the fluid pressure is brought back

pressure−time record, such as the one shown in Fig. 1, is used

to the original pore pressure level, the pressure required to

to obtain the test results required for the calculation; knowl-

reopen the fracture in the second pressurization cycle (fracture

edge of the attitude

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.