ASTM E341-96(2002)

(Practice)Standard Practice for Measuring Plasma Arc Gas Enthalpy by Energy Balance

Standard Practice for Measuring Plasma Arc Gas Enthalpy by Energy Balance

SIGNIFICANCE AND USE

The purpose of this practice is to measure the total or stagnation gas enthalpy of a plasma-arc gas stream in which nonreactive gases are heated by passage through an electrical discharge device during calibration tests of the system.

The plasma arc represents one heat source for determining the performance of high temperature materials under simulated hyperthermal conditions. As such the total or stagnation enthalpy is one of the important parameters for correlating the behavior of ablation materials.

The most direct method for obtaining a measure of total enthalpy, and one which can be performed simultaneously with each material test, if desired, is to perform an energy balance on the arc chamber. In addition, in making the energy balance, accurate measurements are needed since the efficiencies of some plasma generators are low (as low as 15 to 20 % or less in which case the enthalpy depends upon the difference of two quantities of nearly equal magnitude). Therefore, the accuracy of the measurements of the primary variables must be high, all energy losses must be correctly taken into account, and steady-state conditions must exist both in plasma performance and fluid flow.

In particular it is noted that total enthalpy as determined by the energy balance technique is most useful if the plasma generator design minimizes coring affects. If nonuniformity exists the enthalpy determined by energy balance gives only the average for the entire plasma stream, whereas the local enthalpy experienced by a model in the core of the stream may be much higher. More precise methods are needed to measure local variations in total enthalpy.

SCOPE

1.1 This practice covers the measurement of total gas enthalpy of an electric-arc-heated gas stream by means of an overall system energy balance. This is sometimes referred to as a bulk enthalpy and represents an average energy content of the test stream which may differ from local values in the test stream.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E341–96 (Reapproved 2002)

Standard Practice for

Measuring Plasma Arc Gas Enthalpy by Energy Balance

This standard is issued under the fixed designation E341; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

EnergyIn 2EnergyOut 5EnergytoGas (1)

1. Scope

n p

1.1 This practice covers the measurement of total gas

¯ ¯

E I 2 Q 2 W C ~DT 2DT ! 2 M H

( (

CR p 0 1 H O j j

H O 2 i

2 i

enthalpy of an electric-arc-heated gas stream by means of an i 51 j 51

overallsystemenergybalance.Thisissometimesreferredtoas

5Energytogas

abulkenthalpyandrepresentsanaverageenergycontentofthe

test stream which may differ from local values in the test

where:

stream.

C = water, specific heat,

p

1.2 This standard does not purport to address all of the

E = plasma arc voltage,

safety concerns, if any, associated with its use. It is the

H = exhaust gas enthalpy,

g

responsibility of the user of this standard to establish appro-

H = inlet gas enthalpy,

in

priate safety and health practices and determine the applica-

H = heat of vaporization corresponding to the ma-

j

bility of regulatory limitations prior to use.

terial M,

j

I = plasma arc current,

2. Summary of Test Method

M = mass loss rate of electrode insulator, interior

j

2.1 A measure of the total or stagnation gas enthalpy of

metal surface, etc.

plasma-arc heated gases (nonreacting) is based upon the

Q = energy convected and radiated from external

CR

following measurements:

surface of plasma generator,

2.1.1 Energy input to the plasma arc,

DT = T − T = water temperature rise during

0 0 0

H2O 2 1

2.1.2 Energy losses to the plasma arc hardware and cooling

plasma arc operation,

water, and

DT = T −T =water temperature rise before plasma

1 2 1

H2O

2.1.3 Gas mass flow.

arc operation,

2.2 The gas enthalpy is determined numerically by dividing

T = water exhaust temperature during plasma arc

the gas mass flow into the net power input to the plasma arc operation,

(power to plasma arc minus the energy losses). T = inlet water temperature during plasma arc op-

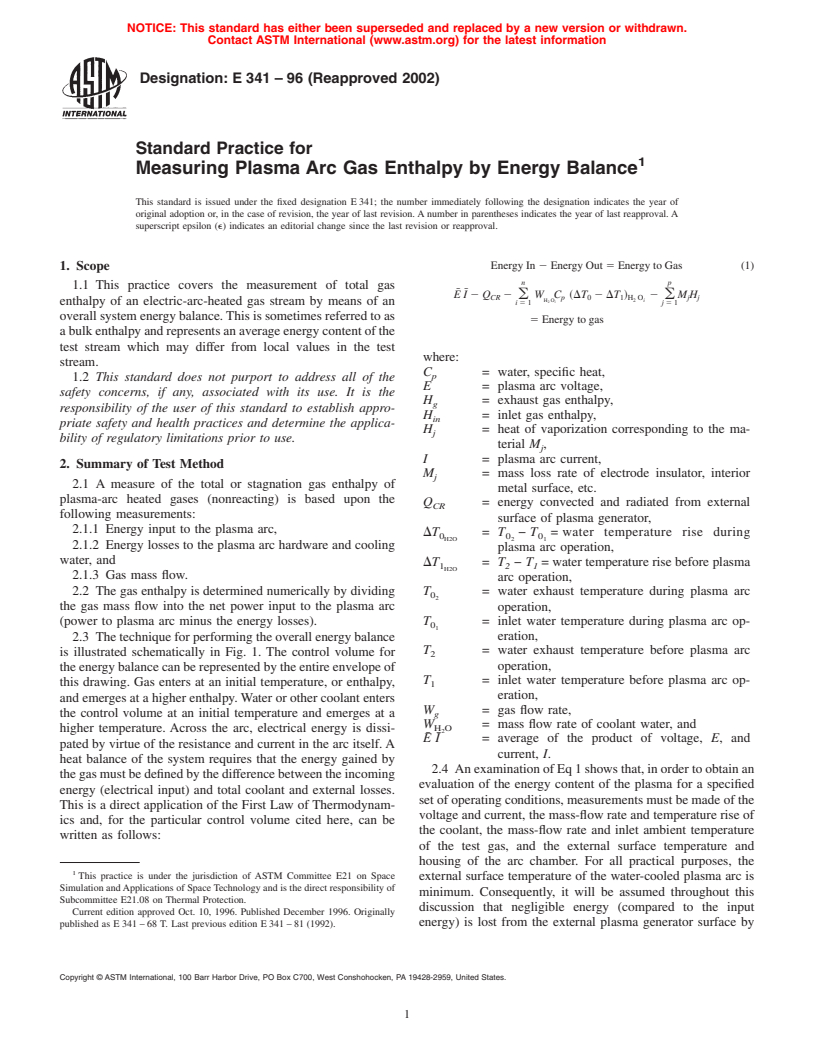

2.3 Thetechniqueforperformingtheoverallenergybalance eration,

T = water exhaust temperature before plasma arc

is illustrated schematically in Fig. 1. The control volume for

operation,

theenergybalancecanberepresentedbytheentireenvelopeof

T = inlet water temperature before plasma arc op-

this drawing. Gas enters at an initial temperature, or enthalpy,

eration,

andemergesatahigherenthalpy.Waterorothercoolantenters

W = gas flow rate,

the control volume at an initial temperature and emerges at a g

W = mass flow rate of coolant water, and

H O

higher temperature. Across the arc, electrical energy is dissi- 2

¯ ¯

E I = average of the product of voltage, E, and

pated by virtue of the resistance and current in the arc itself.A

current, I.

heat balance of the system requires that the energy gained by

2.4 AnexaminationofEq1showsthat,inordertoobtainan

thegasmustbedefinedbythedifferencebetweentheincoming

evaluation of the energy content of the plasma for a specified

energy (electrical input) and total coolant and external losses.

setofoperatingconditions,measurementsmustbemadeofthe

This is a direct application of the First Law of Thermodynam-

voltage and current, the mass-flow rate and temperature rise of

ics and, for the particular control volume cited here, can be

the coolant, the mass-flow rate and inlet ambient temperature

written as follows:

of the test gas, and the external surface temperature and

housing of the arc chamber. For all practical purposes, the

This practice is under the jurisdiction of ASTM Committee E21 on Space

external surface temperature of the water-cooled plasma arc is

Simulation andApplications of SpaceTechnology and is the direct responsibility of

minimum. Consequently, it will be assumed throughout this

Subcommittee E21.08 on Thermal Protection.

discussion that negligible energy (compared to the input

Current edition approved Oct. 10, 1996. Published December 1996. Originally

energy) is lost from the external plasma generator surface by

published as E341–68 T. Last previous edition E341–81(1992).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E341

FIG. 1 Schematic Energy Balance Method for Determining Gas

Enthalpy

convectiveorradiativemechanismsandthattheinternallossof in which case the enthalpy depends upon the difference of two

electrode or plasma generator material is small compared with quantities of nearly equal magnitude). Therefore, the accuracy

theenergyinput.Inaddition,assomeplasmageneratorsutilize of the measurements of the primary variables must be high, all

magneticfieldsintheirdesign,themagneticfieldcoilelectrical energy losses must be correctly taken into account, and

power and ohmic-heating dissipation should be included in the steady-state conditions must exist both in plasma performance

over-all heat balance. Precautions should be taken to assure and fluid flow.

that only a negligible portion of magnetic energy is being 3.4 In particular it is noted that total enthalpy as determined

dissipated in hardware not within the heat balance circuit. For by the energy balance technique is most useful if the plasma

the purposes of this discussion, the magnetic field power input generator design minimizes coring affects. If nonuniformity

and loss aspects have been omitted because of their unique exists the enthalpy determined by energy balance gives only

applicability to specific plasma generator designs. the average for the entire plasma stream, whereas the local

2.5 The energy balance is given by Eq 2 when these factors enthalpyexperiencedbyamodelinthecoreofthestreammay

are taken into account: be much higher. More precise methods are needed to measure

local variations in total enthalpy.

n

¯

EI 2 W C ~DT 2DT ! (2)

(

H O p 0 1 H O

2 i 2 i

i 51

4. Apparatus

4.1 General—The apparatus shall consist of the plasma-arc

The exhaust enthalpy, H , of the effluent as defined by Eq 1

g

facility and the necessary instrumentation to measure the

and 2 is a measure of the average total (stagnation) enthalpy at

power input to the arc, gas stream and coolant flow rates, inlet

the nozzle exit plane of the plasma-arc heater. This enthalpy

gas temperature and net coolant temperature rise of the plasma

does not necessarily apply to the plasma downstream of the

generator hardware. Although the recommended instrumenta-

nozzle exit plane.

tion accuracies are state-of-the-art values, higher accuracy

instruments (than those recommended) may be required for

3. Significance and Use

low efficiency plasma generators.

3.1 The purpose of this practice is to measure the total or

4.2 Input Energy Measurements—The energy input term,

stagnation gas enthalpy of a plasma-arc gas stream in which

EI, to a large degree may be time dependent. Fluctuations in

nonreactive gases are heated by passage through an electrical

the power input can produce errors as large as 50% under

discharge device during calibration tests of the system.

certain conditions. The magnitude of the error will depend on

3.2 Theplasmaarcrepresentsoneheatsourcefordetermin-

theamplitudeoftheunsteadycomparedwiththesteadyportion

ing the performance of high temperature materials under

of the current and voltage and also on the instantaneous phase

simulated hyperthermal conditions. As such the total or stag-

relationship between current and voltage. The power input

nation enthalpy is one of the important parameters for corre-

portion term should be written:

lating the behavior of ablation materials.

t

3.3 The most direct method for obtaining a measure of total

¯

enthalpy,andonewhichcanbeperformedsimultaneouslywith EI 51/t EIdt (3)

*

each material test, if desired, is to perform an energy balance

on the arc chamber. In addition, in making the energy balance, Asaconsequenceeachplasmageneratorshouldmakeuseof

accurate measurements are needed since the efficiencies of oscilloscopic voltage-current traces during operation in order

some plasma generators are low (as low as 15 to 20% or less to ascertain the time variation of the voltage-current input. If

E341

these traces show significant unsteadiness it is recommended be adhered to in the calibration and preparation of temperature

that additional methods of input power measurements be sensors. The bulk or average temperature of the coolant shall

pursued, such as an integrating device if available. In order to be measured at the inlet and output lines of each cooled unit.

measurepowerdirectly,awattmeterascitedbyDawes(1) can The error in measurement of temperature difference between

be employed. As a precaution in the use of the wattmeter, inlet and outlet shall be not more than 61 %. The water

reversed readings of current and voltage should be taken and temperature-indicating devices shall be placed as close as

the average of the two readings used. For those plasma practical to the plasma arc in the inlet and outlet lines. No

generator facilities which operate under known and steady additional apparatus shall be between the temperature sensor

input power the use of a voltmeter and ammeter is recom- and the plasma arc. The temperature measurements shall be

mended owing to their high degree of accuracy. recorded continuously. Ref (2) lists a variety of commercially

4.2.1 Voltage Measurement—The determination of power available temperature sensors. During the course of operation

input to the plasma generator requires the measurement of the oftheplasmaarc,cares

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.