ASTM E457-08(2020)

(Test Method)Standard Test Method for Measuring Heat-Transfer Rate Using a Thermal Capacitance (Slug) Calorimeter

Standard Test Method for Measuring Heat-Transfer Rate Using a Thermal Capacitance (Slug) Calorimeter

SIGNIFICANCE AND USE

4.1 The purpose of this test method is to measure the rate of thermal energy per unit area transferred into a known piece of material (slug) for purposes of calibrating the thermal environment into which test specimens are placed for evaluation. The calorimeter and holder size and shape should be identical to that of the test specimen. In this manner, the measured heat transfer rate to the calorimeter can be related to that experienced by the test specimen.

4.2 The slug calorimeter is one of many calorimeter concepts used to measure heat transfer rate. This type of calorimeter is simple to fabricate, inexpensive, and readily installed since it is not water-cooled. The primary disadvantages are its short lifetime and relatively long cool-down time after exposure to the thermal environment. In measuring the heat transfer rate to the calorimeter, accurate measurement of the rate of rise in back-face temperature is imperative.

4.3 In the evaluation of high-temperature materials, slug calorimeters are used to measure the heat transfer rate on various parts of the instrumented models, since heat transfer rate is one of the important parameters in evaluating the performance of ablative materials.

4.4 Regardless of the source of thermal energy to the calorimeter (radiative, convective, or a combination thereof) the measurement is averaged over the calorimeter surface. If a significant percentage of the total thermal energy is radiative, consideration should be given to the emissivity of the slug surface. If non-uniformities exist in the input energy, the heat transfer rate calorimeter would tend to average these variations; therefore, the size of the sensing element (that is, the slug) should be limited to small diameters in order to measure local heat transfer rate values. Where large ablative samples are to be tested, it is recommended that a number of calorimeters be incorporated in the body of the test specimen such that a heat transfer rate distribution across...

SCOPE

1.1 This test method describes the measurement of heat transfer rate using a thermal capacitance-type calorimeter which assumes one-dimensional heat conduction into a cylindrical piece of material (slug) with known physical properties.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 1: For information see Test Methods E285, E422, E458, E459, and E511.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E457 − 08 (Reapproved 2020)

Standard Test Method for

Measuring Heat-Transfer Rate Using a Thermal Capacitance

(Slug) Calorimeter

This standard is issued under the fixed designation E457; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E458Test Method for Heat of Ablation

E459Test Method for Measuring Heat Transfer Rate Using

1.1 This test method describes the measurement of heat

a Thin-Skin Calorimeter

transfer rate using a thermal capacitance-type calorimeter

E511TestMethodforMeasuringHeatFluxUsingaCopper-

which assumes one-dimensional heat conduction into a cylin-

Constantan Circular Foil, Heat-Flux Transducer

drical piece of material (slug) with known physical properties.

1.2 The values stated in SI units are to be regarded as

3. Summary of Test Method

standard. No other units of measurement are included in this

3.1 The measurement of heat transfer rate to a slug or

standard.

thermal capacitance type calorimeter may be determined from

NOTE 1—For information see Test Methods E285, E422, E458, E459,

the following data:

and E511.

3.1.1 Density and specific heat of the slug material,

1.3 This standard does not purport to address all of the

3.1.2 Length or axial distance from the front face of the

safety concerns, if any, associated with its use. It is the

cylindrical slug to the back-face thermocouple,

responsibility of the user of this standard to establish appro-

3.1.3 Slope of the temperature—time curve generated by

priate safety, health, and environmental practices and deter-

the back-face thermocouple, and

mine the applicability of regulatory limitations prior to use.

3.1.4 Calorimeter temperature history.

1.4 This international standard was developed in accor-

3.2 The heat transfer rate is thus determined numerically by

dance with internationally recognized principles on standard-

multiplyingthedensity,specificheat,andlengthoftheslugby

ization established in the Decision on Principles for the

the slope of the temperature–time curve obtained by the data

Development of International Standards, Guides and Recom-

acquisition system (see Eq 1).

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.3 The technique for measuring heat transfer rate by the

thermal capacitance method is illustrated schematically in Fig.

2. Referenced Documents

1.Theapparatusshownisatypicalslugcalorimeterwhich,for

2.1 ASTM Standards:

example, can be used to determine both stagnation region heat

E285Test Method for Oxyacetylene Ablation Testing of

transfer rate and side-wall or afterbody heat transfer rate

Thermal Insulation Materials

values.Theannularinsulatorservesthepurposeofminimizing

E422Test Method for Measuring Heat Flux Using a Water-

heat transfer to or from the body of the calorimeter, thus

Cooled Calorimeter

approximating one-dimensional heat flow. The body of the

calorimeter is configured to establish flow and should have the

same size and shape as that used for ablation models or test

This test method is under the jurisdiction of ASTM Committee E21 on Space

specimens.

Simulation andApplications of SpaceTechnology and is the direct responsibility of

Subcommittee E21.08 on Thermal Protection. 3.3.1 For the control volume specified in this test method, a

Current edition approved Nov. 1, 2020. Published December 2020. Originally

thermal energy balance during the period of initial linear

approvedin1972.Lastpreviouseditionapprovedin2015asE457–08(2015).DOI:

temperatureresponsewhereheatlossesareassumednegligible

10.1520/E0457-08R20.

can be stated as follows:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

EnergyReceivedbytheCalorimeter frontface

~ !

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5EnergyConductedAxiallyIntotheSlug

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E457 − 08 (2020)

FIG. 1 Schematic of a Thermal Capacitance (Slug) Calorimeter

q 5 ρC l ∆T/∆τ 5 MC /A ∆T/∆τ (1) where:

~ ! ~ !~ !

c p p

k = thermal conductivity of slug material, W/m·K

where:

q = q that would be measured at the back-face of the

indicated

q˙ = calorimeter heat transfer rate, W/m ,

c

slug by Eq 1, W/m

ρ = density of slug material, kg/m ,

q = constant q at the front-face of the slug begin-

input input

C = average specific heat of slug material during the

p 2

ning at τ=0,W/m

temperature rise (∆T), J/kg·K,

l = length or axial distance from front face of slug to the

3.3.3 Although the goal of good slug calorimeter design is

thermocouple location (back-face), m,

to minimize heat losses, there can be heating environments,

∆T =(T − T)=calorimeter slug temperature rise during

f i such as very high heat fluxes, where even a good slug

exposure to heat source (linear part of curve), K,

calorimeter design cannot meet the recommended 5 % maxi-

∆τ =(τ − τ)=timeperiodcorrespondingto∆Ttemperature

f i

mum heat loss criterion of 6.1. Also, this criterion only deals

rise, s,

with heat losses measured during the cooling phase, not losses

M = mass of the cylindrical slug, kg,

duringtheheatingphase,whichcanbegreaterthanthecooling

A = cross-sectional area of slug, m .

losses. Under these circumstances, significant heat losses from

In order to determine the steady-state heat transfer rate with

slug to holder during the heating phase, as well as other

athermalcapacitance-typecalorimeter,Eq1mustbesolvedby

possible decaying processes such as a drop in surface

using the known properties of the slug material (for example,

catalycity, can cause the Temperature-Time slope to decrease

densityandspecificheat)—thelengthoftheslug,andtheslope

significantly more than can be accounted for by the increasing

(linear portion) of the temperature–time curve obtained during

heat capacity with temperature of the Copper slug alone,

the exposure to a heat source.The initial and final temperature

makingitimportantthattheslopebetakenearlyintheprocess

transient effects must be eliminated by using the initial linear

before the losses lower the slope too much, introducing more

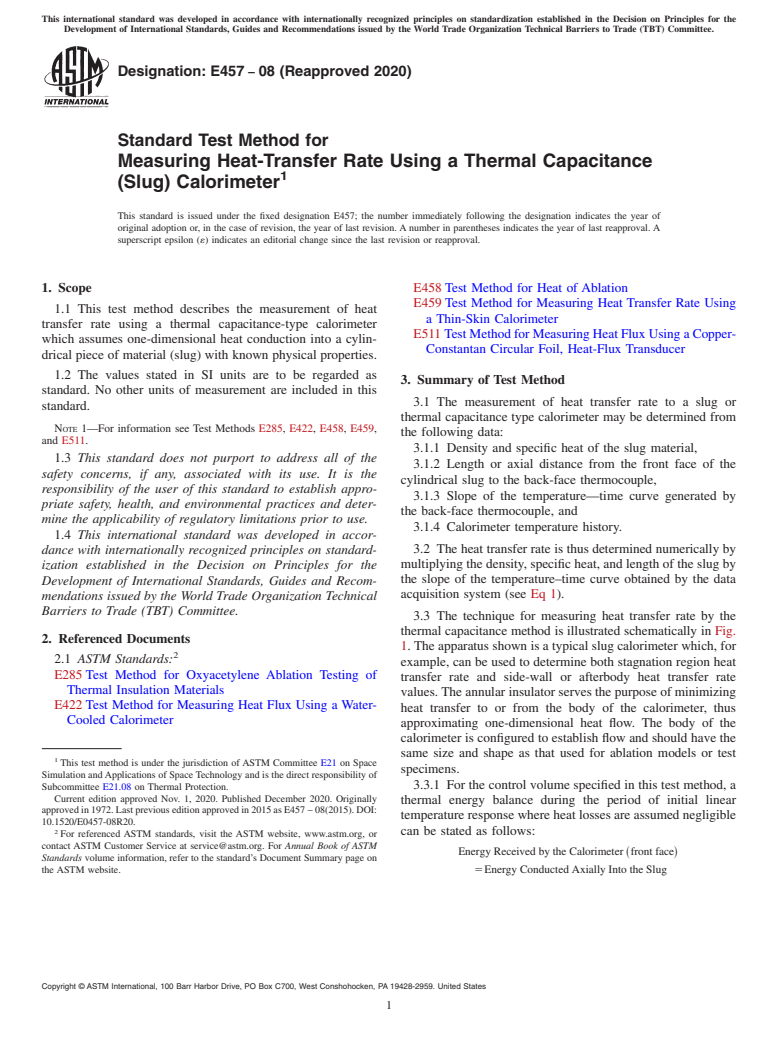

portion of the curve (see Fig. 2).

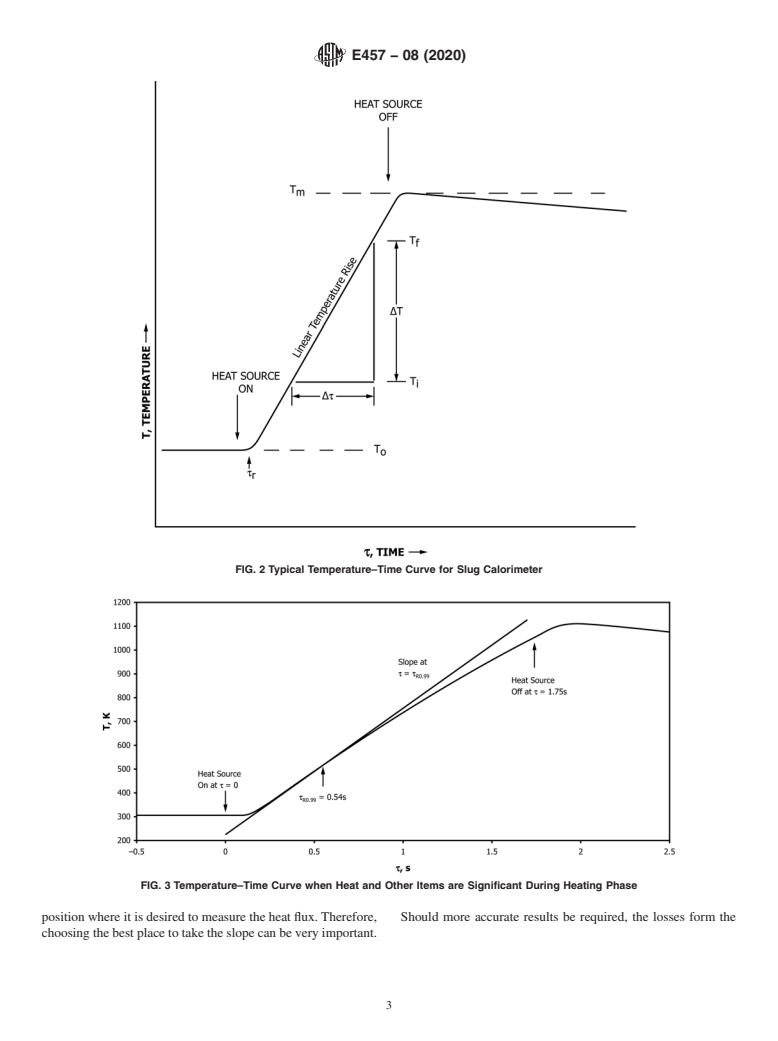

error to the downside on the heat flux calculated (see Fig. 3).

3.3.2 In order to calculate the initial response time for a

The degree of losses affect the exact position where the best

given slug, Eq 2 may be used. This equation is based on the

slope begins to occur, but typically it should be expected at

idealization of zero heat losses from slug to its holder.

about time τ = τ calculated by Eq 2 for q /q = 0.99,

R indicated input

which value of τ is abbreviated as τ . Fig. 2 and Fig. 3

l ρC 2 R R0.99

p

τ 5 ln (2)

R 2 assume that “heat source on” is a step function. This is an

kπ q indicated

S D

1 2

idealization, but the reality can be significantly different. For

q input

example, in some cases a calorimeter may experience a higher

heat flux prior to reaching its final position in the heat source,

which can cause the initial maximum slope to be higher than

“Thermophysical Properties of High Temperature Solid Materials,” TPRC,

Purdue University, or “Handbook of Thermophysical Properties,” Tolukian and

what is wanted for the calculation of the heat flux at the final

Goldsmith, MacMillan Press, 1961.

position. Therefore, it is important to note that “zero” time, to

Ledford, R. L., Smotherman,W. E., and Kidd, C.T., “Recent Developments in

which τ is added to determine where to start looking for

Heat-Transfer Rate, Pressure, and Force Measurements for Hotshot Tunnels,” R0.99

AEDC-TR-66-228 (AD645764), January 1967. the desired slope, is when the calorimeter has reached its final

E457 − 08 (2020)

FIG. 2 Typical Temperature–Time Curve for Slug Calorimeter

FIG. 3 Temperature–Time Curve when Heat and Other Items are Significant During Heating Phase

positionwhereitisdesiredtomeasuretheheatflux.Therefore, Should more accurate results be required, the losses form the

choosingthebestplacetotaketheslopecanbeveryimportant.

E457 − 08 (2020)

slugshouldbemodeledandaccountedforbyacorrectionterm short lifetime and relatively long cool-down time after expo-

in the energy balance equation. suretothethermalenvironment.Inmeasuringtheheattransfer

3.3.4 For maximum linear test time (temperature–time ratetothecalorimeter,accuratemeasurementoftherateofrise

curve)withinanallowedsurfacetemperaturelimit,therelation in back-face temperature is imperative.

shownasEq3maybeusedforacalorimeterwhichisinsulated

4.3 In the evaluation of high-temperature materials, slug

by a gap at the back face.

calorimeters are used to measure the heat transfer rate on

τ 50.48ρlC ~∆T /q˙ ! (3) various parts of the instrumented models, since heat transfer

max,opt. p frontface

rate is one of the important parameters in evaluating the

where:

performance of ablative materials.

∆T = the calorimeter final front face temperature

front face

4.4 Regardless of the source of thermal energy to the

minus the initial front face (ambient)

calorimeter (radiative, convective, or a combination thereof)

temperature, T .

o

the measurement is averaged over the calorimeter surface. If a

3.3.5 Eq3isbasedontheoptimumlengthoftheslugwhich

significant percentage of the total thermal energy is radiative,

can be obtained by applying Eq 4 as follows:

consideration should be given to the emissivity of the slug

l 53 k ∆T /5q˙ (4) surface. If non-uniformities exist in the input energy, the heat

opt. frontface c

transfer rate calorimeter would tend to average these varia-

3.4 Tominimizesideheatingorsideheatlosses,thebodyis

tions; therefore, the size of the sensing element (that is, the

separated physically from the calorimeter slug by means of an

slug) should be limited to small diameters in order to measure

insulating gap or a low thermal diffusivity material, or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.