ASTM E459-22

(Test Method)Standard Test Method for Measuring Heat Transfer Rate Using a Thin-Skin Calorimeter

Standard Test Method for Measuring Heat Transfer Rate Using a Thin-Skin Calorimeter

SIGNIFICANCE AND USE

5.1 This test method may be used to measure the net heat transfer rate to a metallic or coated metallic surface for a variety of applications, including:

5.1.1 Measurements of aerodynamic heating when the calorimeter is placed into a flow environment, such as a wind tunnel or an arc jet; the calorimeters can be designed to have the same size and shape as the actual test specimens to minimize heat transfer corrections;

5.1.2 Heat transfer measurements in fires and fire safety testing;

5.1.3 Laser power and laser absorption measurements; as well as,

5.1.4 X-ray and particle beam (electrons or ions) dosimetry measurements.

5.2 The thin-skin calorimeter is one of many concepts used to measure heat transfer rates. It may be used to measure convective, radiative, or combinations of convective and radiative (usually called mixed or total) heat transfer rates. However, when the calorimeter is used to measure radiative or mixed heat transfer rates, the absorptivity and reflectivity of the surface should be measured over the expected radiation wavelength region of the source, and as functions of temperature if possible.

5.3 In 6.6 and 6.7, it is demonstrated that lateral heat conduction effects on a local measurement can be minimized by using a calorimeter material with a low thermal conductivity. Alternatively, a distribution of the heat transfer rate may be obtained by placing a number of thermocouples along the back surface of the calorimeter.

5.4 In high temperature or high heat transfer rate applications, the principal drawback to the use of thin-skin calorimeters is the short exposure time necessary to ensure survival of the calorimeter such that repeat measurements can be made with the same sensor. When operation to burnout is necessary to obtain the desired heat flux measurements, thin-skin calorimeters are often a good choice because they are relatively inexpensive to fabricate.

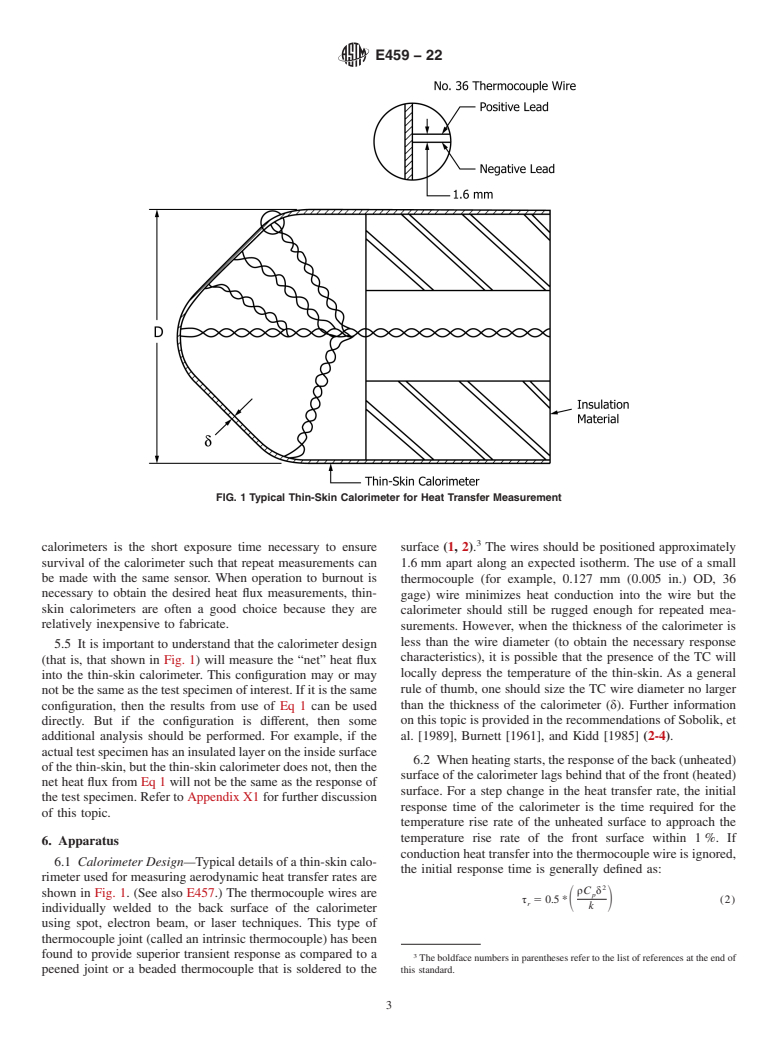

5.5 It is important to understand that the calorimeter design (th...

SCOPE

1.1 This test method covers the design and use of a thin metallic calorimeter for measuring heat transfer rate (also called heat flux). Thermocouples are attached to the unexposed surface of the calorimeter. A one-dimensional heat flow analysis is used for calculating the heat transfer rate from the temperature measurements. Applications include aerodynamic heating, laser and radiation power measurements, and fire safety testing.

1.2 Advantages:

1.2.1 Simplicity of Construction—The calorimeter may be constructed from a number of materials. The size and shape can often be made to match the actual application. Thermocouples may be attached to the metal by spot, electron beam, or laser welding.

1.2.2 Heat transfer rate distributions may be obtained if metals with low thermal conductivity, such as some stainless steels or Inconel 600, are used.

1.2.3 The calorimeters can be fabricated with smooth surfaces, without insulators or plugs and the attendant temperature discontinuities, to provide more realistic flow conditions for aerodynamic heating measurements.

1.2.4 The calorimeters described in this test method are relatively inexpensive. If necessary, they may be operated to burn-out to obtain heat transfer information.

1.3 Limitations:

1.3.1 At higher heat flux levels, short test times are necessary to ensure calorimeter survival.

1.3.2 For applications in wind tunnels or arc-jet facilities, the calorimeter must be operated at pressures and temperatures such that the thin-skin does not distort under pressure loads. Distortion of the surface will introduce measurement errors.

1.3.3 Interpretation of the heat flux estimated may require additional analysis if the thin-skin calorimeter configuration is different from the test specimen.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4.1 Exception—The values ...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E459 − 22

Standard Test Method for

Measuring Heat Transfer Rate Using a Thin-Skin

1

Calorimeter

This standard is issued under the fixed designation E459; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 Units—The values stated in SI units are to be regarded

as standard. No other units of measurement are included in this

1.1 This test method covers the design and use of a thin

standard.

metallic calorimeter for measuring heat transfer rate (also

1.4.1 Exception—The values given in parentheses are for

called heat flux). Thermocouples are attached to the unexposed

information only.

surface of the calorimeter. A one-dimensional heat flow analy-

1.5 This standard does not purport to address all of the

sis is used for calculating the heat transfer rate from the

safety concerns, if any, associated with its use. It is the

temperature measurements. Applications include aerodynamic

responsibility of the user of this standard to establish appro-

heating, laser and radiation power measurements, and fire

priate safety, health, and environmental practices and deter-

safety testing.

mine the applicability of regulatory limitations prior to use.

1.2 Advantages:

1.6 This international standard was developed in accor-

1.2.1 Simplicity of Construction—The calorimeter may be

dance with internationally recognized principles on standard-

constructed from a number of materials. The size and shape can

ization established in the Decision on Principles for the

often be made to match the actual application. Thermocouples

Development of International Standards, Guides and Recom-

may be attached to the metal by spot, electron beam, or laser

mendations issued by the World Trade Organization Technical

welding.

Barriers to Trade (TBT) Committee.

1.2.2 Heat transfer rate distributions may be obtained if

metals with low thermal conductivity, such as some stainless

2. Referenced Documents

steels or Inconel 600, are used.

2

2.1 ASTM Standards:

1.2.3 The calorimeters can be fabricated with smooth

E176 Terminology of Fire Standards

surfaces, without insulators or plugs and the attendant tempera-

E230 Specification for Temperature-Electromotive Force

ture discontinuities, to provide more realistic flow conditions

(emf) Tables for Standardized Thermocouples

for aerodynamic heating measurements.

E235 Specification for Type K and Type N Mineral-

1.2.4 The calorimeters described in this test method are

Insulated, Metal-Sheathed Thermocouples for Nuclear or

relatively inexpensive. If necessary, they may be operated to

for Other High-Reliability Applications

burn-out to obtain heat transfer information.

E456 Terminology Relating to Quality and Statistics

1.3 Limitations:

E3057 Test Method for Measuring Heat Flux Using Direc-

1.3.1 At higher heat flux levels, short test times are neces-

tional Flame Thermometers with Advanced Data Analysis

sary to ensure calorimeter survival.

Techniques

1.3.2 For applications in wind tunnels or arc-jet facilities,

E457 Test Method for Measuring Heat-Transfer Rate Using

the calorimeter must be operated at pressures and temperatures

a Thermal Capacitance (Slug) Calorimeter

such that the thin-skin does not distort under pressure loads.

Distortion of the surface will introduce measurement errors.

3. Terminology

1.3.3 Interpretation of the heat flux estimated may require

3.1 Definitions—Refer to Terminologies E176 and E456 for

additional analysis if the thin-skin calorimeter configuration is

definitions of terms used in this test method.

different from the test specimen.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee E21 on Space

Simulation and Applications of Space Technology and is the direct responsibility of

2

Subcommittee E21.08 on Thermal Protection. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1972. Last previous edition approved in 2016 as E459 – 05(2016). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E0459-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E459 − 22

3.2.1 absorbed heat flux, n—incident r

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E459 − 05 (Reapproved 2016) E459 − 22

Standard Test Method for

Measuring Heat Transfer Rate Using a Thin-Skin

1

Calorimeter

This standard is issued under the fixed designation E459; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the design and use of a thin metallic calorimeter for measuring heat transfer rate (also called heat flux).

Thermocouples are attached to the unexposed surface of the calorimeter. A one-dimensional heat flow analysis is used for

calculating the heat transfer rate from the temperature measurements. Applications include aerodynamic heating, laser and

radiation power measurements, and fire safety testing.

1.2 Advantages:

1.2.1 Simplicity of Construction—The calorimeter may be constructed from a number of materials. The size and shape can often

be made to match the actual application. Thermocouples may be attached to the metal by spot, electron beam, or laser welding.

1.2.2 Heat transfer rate distributions may be obtained if metals with low thermal conductivity, such as some stainless steels, steels

or Inconel 600, are used.

1.2.3 The calorimeters can be fabricated with smooth surfaces, without insulators or plugs and the attendant temperature

discontinuities, to provide more realistic flow conditions for aerodynamic heating measurements.

1.2.4 The calorimeters described in this test method are relatively inexpensive. If necessary, they may be operated to burn-out to

obtain heat transfer information.

1.3 Limitations:

1.3.1 At higher heat flux levels, short test times are necessary to ensure calorimeter survival.

1.3.2 For applications in wind tunnels or arc-jet facilities, the calorimeter must be operated at pressures and temperatures such that

the thin-skin does not distort under pressure loads. Distortion of the surface will introduce measurement errors.

1.3.3 Interpretation of the heat flux estimated may require additional analysis if the thin-skin calorimeter configuration is different

from the test specimen.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1

This test method is under the jurisdiction of ASTM Committee E21 on Space Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.08 on Thermal Protection.

Current edition approved April 1, 2016April 1, 2022. Published April 2016May 2022. Originally approved in 1972. Last previous edition approved in 20112016 as

E459 – 05 (2011).(2016). DOI: 10.1520/E0459-05R16.10.1520/E0459-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E459 − 22

1.4.1 Exception—The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E176 Terminology of Fire Standards

E230 Specification for Temperature-Electromotive Force (emf) Tables for Standardized Thermocouples

E235 Specification for Type K and Type N Mineral-Insulated, Metal-Sheathed Thermocouples for Nuclear or for Other

High-Reliability Applications

E456 Terminology Relating to Quality and Statistics

E3057 Test Method for Measuring Heat Flux Using Directional Flame Thermometers with Advanced Data Analysis Techniques

E457 Test Method for Measuring Heat-Transfer Rate Using a Thermal Capacitance (Slug) Calorimeter

3. Terminology

3.1 Definitions—Refer to Terminologies E176 and E456 for definitions of terms used in this test method.

3.2 Definitions of Terms Specific to This Standard:

2

3.2.1 absorbed heat flux, n—incident radiative heat flux less the reflected r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.