ASTM E124-94(2022)

(Specification)Standard Specification for Weighing and Drying Apparatus for Microchemical Analysis

Standard Specification for Weighing and Drying Apparatus for Microchemical Analysis

ABSTRACT

This specification covers the general requirements for the components that comprise the apparatus used for the weighing and drying operations in the laboratory practice of microchemical analysis. The components covered here are the following: combustion boats; weighing bottles, cup, and tubes; spatulas; forceps; tare flasks; metal cooling block; metal crucible container with glass cover; and micro glass desiccator with metal insert.

SCOPE

1.1 This specification covers apparatus used for weighing and drying operations in microchemical laboratory practice.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents may be approximate.

Note 1: This specification was originally developed by the Committee on Microchemical Apparatus, Division of Analytical Chemistry, American Chemical Society.2

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E124 −94 (Reapproved 2022)

Standard Specification for

Weighing and Drying Apparatus for Microchemical Analysis

This standard is issued under the fixed designation E124; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Combustion Boats

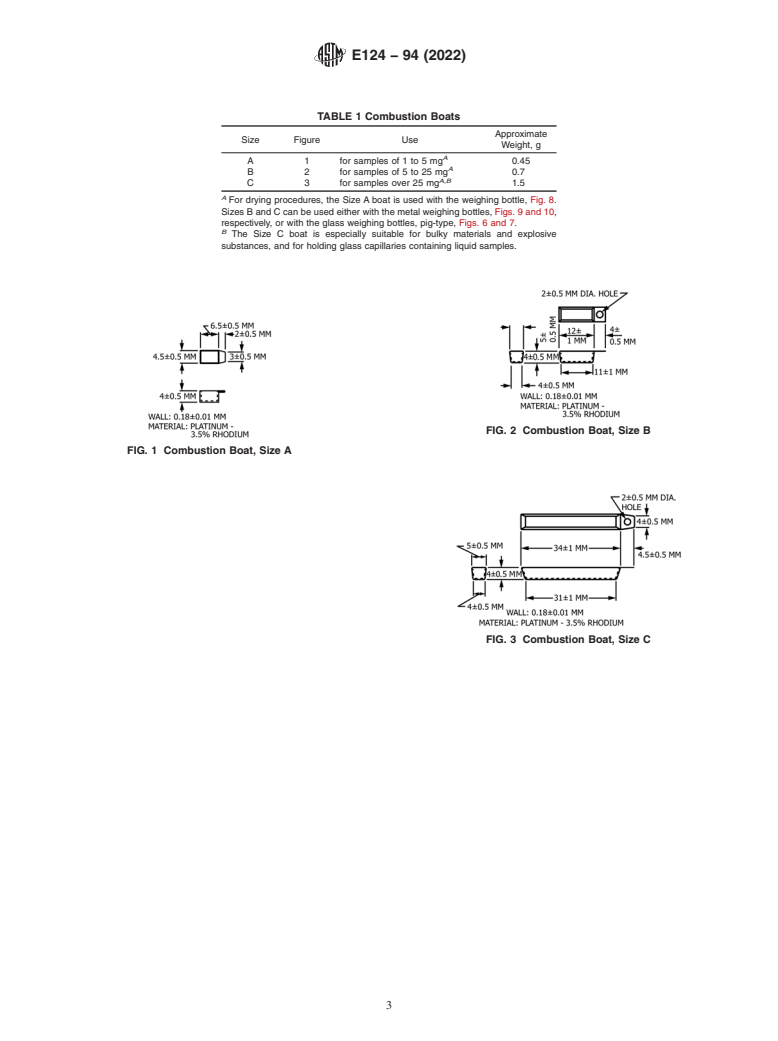

3.1 Combustion boats of three sizes shall conform to the

1.1 This specification covers apparatus used for weighing

requirements in Table 1 and Fig. 1, Fig. 2, and Fig. 3. These

and drying operations in microchemical laboratory practice.

boats shall be made of platinum-rhodium alloy containing

1.2 The values stated in inch-pound units are to be regarded

3.5 % rhodium.

as the standard. The metric equivalents may be approximate.

4. Weighing Bottles

NOTE 1—This specification was originally developed by the Committee

on MicrochemicalApparatus, Division ofAnalytical Chemistry,American

4.1 Weighing bottles of seven capacities shall conform to

Chemical Society.

the requirements in Table 2 and Figs. 4-9, inclusive.

1.3 This international standard was developed in accor-

5. Weighing Cup

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5.1 The weighing cup shall conform to the requirements

Development of International Standards, Guides and Recom-

shown in Fig. 11, and shall be made of platinum-rhodium alloy

mendations issued by the World Trade Organization Technical

containing 3.5 % rhodium. The cup is designed to be used as a

Barriers to Trade (TBT) Committee.

sample container to fit into the weighing bottle shown in Fig.

5, and is useful for weighing hygroscopic materials.

2. Referenced Documents

3 6. Weighing Tubes

2.1 ASTM Standards:

6.1 Weighing tubes of three types shall conform to the

E671 Specification for Maximum Permissible Thermal Re-

sidual Stress in Annealed Glass Laboratory Apparatus requirements shown in Fig. 12, Fig. 13, and Fig. 14. These

tubes should preferably be made of soda-lime glass.

E920 Specification for Commercially Packaged Laboratory

Apparatus

7. Spatulas

E921 Specification for Export Packaged Laboratory Appa-

ratus

7.1 Spatulas of four types, and preferably made of stainless

E1133 Practice for Performance Testing of Packaged Labo-

steel, shall conform to the following requirements:

ratory Apparatus for United States Government Procure-

7.1.1 TypeA(Fig. 15)—This spatula is generally useful.The

ments

top can be used for crushing crystals and the bent blade for

E1157 Specification for Sampling and Testing of Reusable

scraping containers.

Laboratory Glassware

7.1.2 TypeB(Fig. 16)—This spatula has a flat bent portion

at one end and a V-shaped scoop at the other end. It is

particularly useful for weighing samples.

1 7.1.3 TypeC(Fig.17)—Thisspatulaissuitableforthelarger

This specification is under the jurisdiction of ASTM Committee E41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on samples commonly encountered in semimicro and preparative

Laboratory Ware and Supplies.

work.IthasaU-shapedscoopatoneendandaV-shapedscoop

Current edition approved Jan. 1, 2022. Published February 2022. Originally

at the other end. The spatula can be used to add shot or beads

approvedin1956.Lastpreviouseditionapprovedin2016asE124 – 94(2016).DOI:

to tare flasks and for measuring and introducing solid reagent

10.1520/E0124-94R22.

See the “1949 Report on Recommended Specifications for Microchemical

into combustion tubes.

Apparatus, Carbon-Hydrogen, Dumas Nitrogen, Sulfur and Halogen,” Analytical

7.1.4TypeD(Fig. 18)—This spatula is useful in many

Chemistry, Vol 21, December 1949, p. 1555; and the “1953 Report on Recom-

microchemical applications.

mended Specifications for Microchemical Apparatus, Weighing and Drying,”

Analytical Chemistry, Vol 26, July 1954, p. 1186.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 8. Forceps

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.1 Forceps of two types, made of nickel-plated steel, shall

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. conform to the following requirements:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E124−94 (2022)

8.1.1 ForcepswithPlatinum—5%RutheniumTips(Fig.19) 12. Micro Glass Desiccator with Metal Insert

The pin serves as a stop to prevent the forceps from being

12.1 The micro glass desiccator shall conform to the re-

depressed to such an extent that the tips can open, allowing the

quirements shown in Fig. 26. It shall consist of a glass

held object to drop. When pressed together, the tips make

desiccator with cover and an aluminum insert which shall hold

1 1

contact for a distance of ⁄4 to ⁄2 in. (6.4 to 12.7 mm).

securely the metal cooling block, Fig. 24. This combination

serves the same purpose as that described in Section 11, but

NOTE 2—Depending upon the intended use, other materials may be

substituted for the platinum alloy. Thec construction and over-all dimen-

permits the additional use of drying agents of other chemicals

sions should be identical with those shown in Fig. 19.

in the bottom container.

8.1.2 Forceps with Conical Tapered Holders (Fig. 20)—

13. Drying Apparatus

These forceps shall be made of spring steel.They are useful for

13.1 The drying apparatus shall be of theAbderhalden type

handling weighing tubes, absorption tubes, filter tubes, etc.

and shall conform to the requirements shown in Fig. 27.

9. Tare Flasks

NOTE 3—The shape of the tube attached to the ball joint, in the

desiccator bulb, is intended to prevent desiccant from being carried over

9.1 Tare flasks of three types, made of soda-lime glass, shall

into the sample when the vacuum is broken. A cap for the ball joint and

conformtotherequirementsshowninFig.21,Fig.22,andFig.

stopper for the standard taper 40/50 joint may be used to protect the

23. The serial numbers shall be etched on the flasks.

desiccant

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.