ASTM F585-16(2021)

(Guide)Standard Guide for Insertion of Flexible Polyethylene Pipe Into Existing Sewers

Standard Guide for Insertion of Flexible Polyethylene Pipe Into Existing Sewers

SIGNIFICANCE AND USE

4.1 The procedures described in this guide are intended as a design and review aid for use by the design engineer in conjunction with manufacturer's recommendations for installing a polyethylene pipe using the insertion method.

SCOPE

1.1 This guide describes design and selection considerations and installation procedures for the rehabilitation of sanitary and storm sewers by the insertion of solid wall or profile wall or corrugated polyethylene pipe into an existing pipe and along its existing line and grade. The procedures in this guide are intended to minimize traffic disruption, surface damage, surface restoration and interruption of service.

1.2 The polyethylene piping product manufacturer should be consulted to determine the polyethylene piping product’s suitability for insertion renewal as described in this guide.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. See 6.1, 7.1, and 8.1 for additional safety precautions.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F585 − 16 (Reapproved 2021)

Standard Guide for

Insertion of Flexible Polyethylene Pipe Into Existing Sewers

ThisstandardisissuedunderthefixeddesignationF585;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* F1804 Practice for Determining Allowable Tensile Load for

Polyethylene (PE) Gas Pipe During Pull-In Installation

1.1 Thisguidedescribesdesignandselectionconsiderations

F2620 Practice for Heat Fusion Joining of Polyethylene Pipe

andinstallationproceduresfortherehabilitationofsanitaryand

and Fittings

storm sewers by the insertion of solid wall or profile wall or

2.2 Other Documents:

corrugatedpolyethylenepipeintoanexistingpipeandalongits

PPI Material Handling Guide

existing line and grade. The procedures in this guide are

intended to minimize traffic disruption, surface damage, sur-

3. Terminology

face restoration and interruption of service.

3.1 Definitions—Definitions are in accordance with Termi-

1.2 The polyethylene piping product manufacturer should

nology F412, unless otherwise specified.

be consulted to determine the polyethylene piping product’s

4. Significance and Use

suitability for insertion renewal as described in this guide.

1.3 The values stated in inch-pound units are to be regarded 4.1 The procedures described in this guide are intended as a

design and review aid for use by the design engineer in

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only conjunction with manufacturer’s recommendations for install-

ing a polyethylene pipe using the insertion method.

and are not considered standard.

1.4 This standard does not purport to address all of the

5. Design and Selection Considerations

safety concerns, if any, associated with its use. It is the

5.1 General Guidelines:

responsibility of the user of this standard to establish appro-

5.1.1 Host Pipe Condition Assessment—Prior to the selec-

priate safety, health, and environmental practices and deter-

tion of polyethylene pipe size and installation procedure,

mine the applicability of regulatory limitations prior to use.

measures should be taken to determine in detail the condition

See 6.1, 7.1, and 8.1 for additional safety precautions.

of the host (original) sewer piping. A detailed examination

1.5 This international standard was developed in accor-

should determine if the host sewer piping is structurally

dance with internationally recognized principles on standard-

sufficient, and that any joint offsets or other host pipe defects

ization established in the Decision on Principles for the

will permit polyethylene pipe insertion.

Development of International Standards, Guides and Recom-

5.1.2 The presence of obstructions should be determined

mendations issued by the World Trade Organization Technical

(see 6.3). Protrusions of lateral or service piping into the host

Barriers to Trade (TBT) Committee.

sewer pipe, root growths, sedimentation, mineral deposits, or

2. Referenced Documents any combination of such obstructions, may require remedial

2 work prior to inserting the polyethylene pipe.

2.1 ASTM Standards:

5.1.3 To ensure against interference during insertion, the

F412 Terminology Relating to Plastic Piping Systems

minimumannularclearancebetweenthepolyethylenepipeOD

F1417 Practice for Installation Acceptance of Plastic Non-

and the host pipe ID should be 10 % of the host pipe ID or 2

pressure Sewer Lines Using Low-Pressure Air

in. (50 mm) whichever is less. Greater annular clearance is

acceptable. Outside diameter information should be obtained

This guide is under the jurisdiction ofASTM Committee F17 on Plastic Piping

from the polyethylene pipe manufacturer.

Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

5.1.4 The number of insertion excavations should be kept to

Current edition approved April 1, 2021. Published April 2021. Originally

a minimum and should coincide with areas where problems

approved in 1978. Last previous edition approved in 2016 as F585 – 16. DOI:

10.1520/F0585-16R21.

have been detected in the existing sewer (see Section 7).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

the ASTM website. Irving, TX 75062, http://www.plasticpipe.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F585 − 16 (2021)

5.1.5 Solid wall or profile wall or corrugated polyethylene 5.3.3 Point Excavation Encasement—At all points where

pipe may be assembled at the time of insertion using heat the polyethylene pipe has been exposed, such as at excavations

fusion in accordance with Practice F2620, integral bell and for polyethylene pipe insertion, or for service connections, or

spigot joints, or mechanical connections as appropriate for the excavations at other points where structurally unsound host

pipe is removed, the polyethylene pipe, fittings, and service

polyethylene piping product.

connections should be encased in embedment that provides

5.1.6 In all cases, the hydraulic capacity of the pipeline

structural support for the polyethylene pipe. Polyethylene pipe

should be assessed by an engineer to insure the reduction in

embedment design information is available from organizations

flowareafromaninsertedpipeordeteriorationordeformation,

such as the Plastics Pipe Institute. If the annulus is not filled

or both, of the host pipe does not adversely impact the

(5.3.2), stabilized embedment material should be used to seal

hydraulic capacity or flow characteristics of the storm or

the ends of the excavation against embedment migration into

sanitary sewer.

the annulus. Stabilized embedment material is at least 6 in.

NOTE 1—It should be noted, in many instances, the pipe being

(150 mm) of concrete, or cement-stabilized sand, or other

retrofitted is not designed to flow at 100 percent capacity, which may

stable high-density material as specified by the design engi-

provide additional options for downsizing of the inserted pipe.

neer. Preparations for placing of the encasement material

5.2 Ancillary materials—Mechanical fasteners, sealants, include the removal of debris and soil along each side of the

grouts and other materials that are or are likely to be exposed host pipe down to the spring line. After the encasement

to sanitary sewage, sewage gases or other corrosive elements material has been placed and accepted by the design engineer,

of the sanitary sewer environment should be resistant to backfill is placed and compacted to the required finished grade

deleterious effects of the sanitary sewer environment. Sealants, in accordance with the design engineer’s specifications. At

grouts and other materials must be selected with the ability to serviceconnections,careshouldbetakentoensurecompaction

adequately cure in underwater, sewage or other corrosive of earth beneath the lateral service pipe in order to reduce

environments. subsidence that can cause bending at the lateral connection.

5.3.4 Host Pipe Deterioration—Structural deterioration of

5.3 External Loading—Areas where the host pipe is or may

thehostpipemaycontinueafterthepolyethylenepipehasbeen

be structurally compromised, or where some or the entire host

installed. Uneven or concentrated point loading on the poly-

pipe had been removed will subject the polyethylene pipe to

ethylene pipe or subsidence of the soil above the host pipe may

external loads. Information about the resistance of polyethyl-

occur if the host pipe collapses or if large parts of the host pipe

ene pipe (pipe stiffness (PS) or ring stiffness constant (RSC),

fallintotheannulusbetweenthehostpipeandthepolyethylene

and buckling resistance) to external hydrostatic and earth loads

pipe. This can be avoided by filling the annular space between

shouldbeobtainedfromthepipemanufacturer,andisavailable

the inside diameter of the host pipe and the outside diameter of

in someASTM polyethylene pipe specifications. Design infor-

the polyethylene pipe. See 5.3.2.

mation about the external load collapse resistance of polyeth-

5.4 Axial Bending:

ylene pipe is available in Handbooks and Technical Notes

5.4.1 Solid wall polyethylene pipe is relatively flexible such

published by the Plastics Pipe Institute.

that the barrel of the pipe may be curved during installation. It

5.3.1 Hydraulic Loads—When the ground water level may

will accommodate reasonable irregularities in line and grade.

be above the polyethylene pipe, the ground water level and its

Excessive pipe barrel bending during handling and installation

duration should be estimated by the design engineer, and the

that may cause the pipe to kink should be avoided. Axial

polyethylene pipe should be designed to withstand the esti-

(longitudinal) bends induced during the insertion step, in

mated external hydrostatic pressure without collapsing.

transporting pipe lengths from assembly sites to job sites, or

5.3.2 Filling the Annulus—Filling the annulus between the

permanent bends to accommodate line or grade changes,

host pipe and the polyethylene pipe with a cementitious grout

should not be less than the minimum bending radius in Table

or other structurally stable material increases the resistance of

1. The bending radius is the inside radius of curvature.

the polyethylene pipe to external hydrostatic or structural load,

and may improve the overall external load capacity of the host

pipe. Flexible pipe such as polyethylene pipe relies in part on

materials that surround the pipe for external structural load

TABLE 1 Minimum Bending Radii for Solid Wall Pipe

resistance. Flexible pipe ring stiffness and the stiffness of

Dimension Ratio, DR Minimum Bending Radius

materials surrounding the flexible pipe act together to support <9 20×PipeOD

>9 to 13.5 25 × Pipe OD

external loads. Structurally stable fill materials are materials

>13.5 to 21 27 × Pipe OD

that remain in place and resist movement from the rise and fall

>21 to 26 34 × Pipe OD

>26 to 32.5 42 × Pipe OD

of groundwater around the pipeline. Fill materials may be able

>32.5 52 × Pipe OD

to penetrate into cracks and voids in the host pipe, and in

Fitting, Flange or MJ Adapter in 100×PipeOD

A

combinationwiththeinsertedpolyethylenepipeprovidepartial

Bend

structural rehabilitation. Host pipe condition assessment per

A

Because fittings, flange and MJ Adapter connections are rigid compared to the

5.1.1 should identify if filling the annulus is needed for pipe, the minimum bend radius is 100 times the pipe OD when a fitting flange or

MJ adapter is present in the bend. The bend radius should be limited to 100 × OD

structural reasons. Hydraulic load analysis per 5.3.1 should

for a distance of about 5 times the pipe OD on either side of the fitting, flange or

identify if filling the annulus is needed for hydraulic load

MJ adapter location.

resistance.

F585 − 16 (2021)

5.4.2 Axial bending of bell and spigot joined or coupled 6.3 Remove obstructions, debris, and protruding service

profile wall or corrugated polyethylene pipe is generally lines that interfere with inserting the polyethylene pipe.

limited by the allowable angular displacement of bell and

6.4 Before the insertion operation, it may be desirable to

spigot or spigot and coupling joints. The manufacturer should

pass a test-head of the same diameter as the polyethylene pipe

be contacted for information.

throughthehostpipetoensurefreepassage.Test-headsmaybe

madefromashortsectionofthepolyethylenepipewithpulling

5.5 Installation Force and Length:

5.5.1 Butt fusion joined solid wall polyethylene pipes are cables attached to both ends so that the test head may be pulled

back out if blocked by an obstruction. After passing the test

typically installed by pulling the polyethylene pipe into the

host pipe. The length of polyethylene pipe to be inserted by head through the host pipe, the test head should be inspected

for damage.

pulling in will seldom be limited by the strength of the pipe

itself. Pulling load limitations will usually be in the load

7. Excavation

capacity of the winch and cable and the length of the pulling

7.1 Excavation Safety—Observe all local, state, or federal

cable. Smaller diameter pipe 24 in. (610 mm) or less can

regulationsforexcavationsafetytogetherwithotherapplicable

usually be handled with winches having about 12-tons-force

laws and ordinances covering public and private access, and

(110-KN) pulling capacity. Higher capacity pulling equipment,

the protection and safety of the public and property.

or a combination of pulling and pushing may be applicable to

larger pipe, longer lengths, where the host pipe is in poor

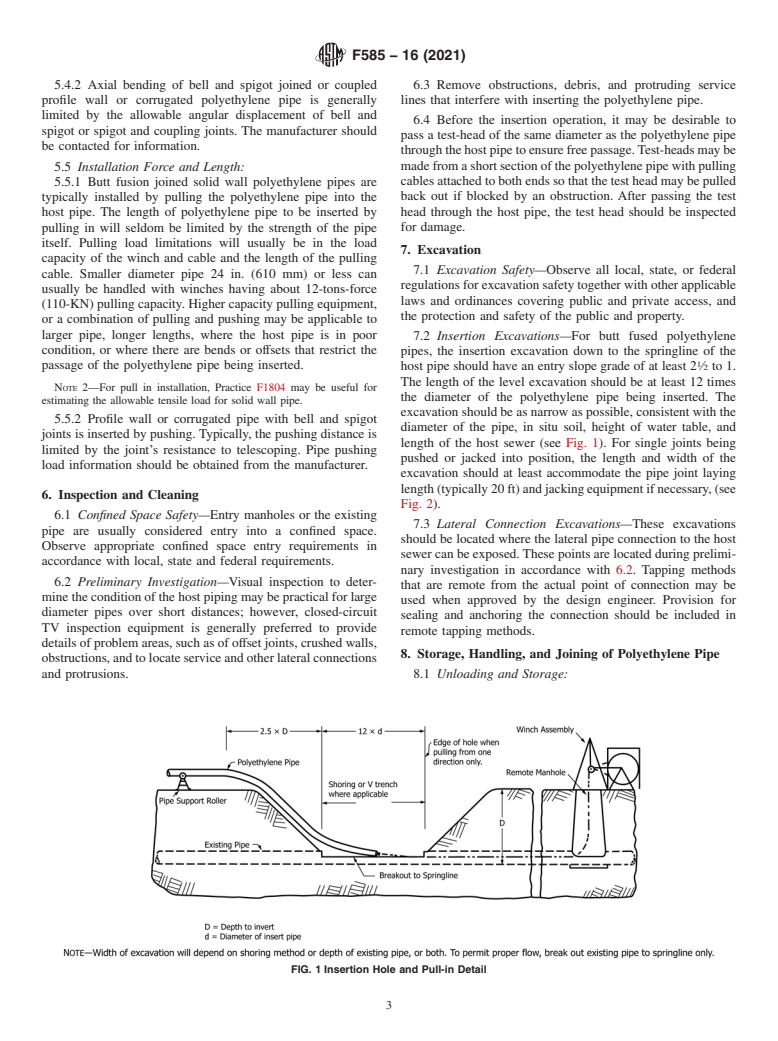

7.2 Insertion Excavations—For butt fused polyethylene

condition, or where there are bends or offsets that restrict the

pipes, the insertion excavation down to the springline of the

passage of the polyethylene pipe being inserted.

host pipe should have an entry slope grade of at least 2 ⁄2 to 1.

The length of the level excavation should be at least 12 times

NOTE 2—For pull in installation, Practice F1804 may be useful for

the diameter of the polyethylene pipe being inserted. The

estimating the allowable tensile load for solid wall pipe.

excavation should be as narrow as possible, consistent with the

5.5.2 Profile wall or corrugated pipe with bell and spigot

diameter of the pipe, in situ soil, height of water table, and

joints is inserted by pushing. Typically, the pushing distance is

length of the host sewer (see Fig. 1). For single joints being

limited by the joint’s resistance to telescoping. Pipe pushing

pushed or jacked into position, the length and width of the

load information should be obtained from the manufacturer.

excavation should at least accommodate the pipe joint laying

length(typically20ft)andjackingequipmentifnecessary,(see

6. Inspection and Cleaning

Fig. 2).

6.1 Confined Space Safety—Entry manholes or the existing

7.3 Lateral Connection Excavations—These excavations

pipe are usually considered entry into a confined space.

should be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.