ASTM F1417-11a(2015)

(Practice)Standard Practice for Installation Acceptance of Plastic Non-pressure Sewer Lines Using Low-Pressure Air

Standard Practice for Installation Acceptance of Plastic Non-pressure Sewer Lines Using Low-Pressure Air

SIGNIFICANCE AND USE

4.1 This low-pressure air testing practice detects damaged piping or improper jointing by measuring the rate at which air under pressure escapes from an isolated section of sewer.

4.2 The rate of air loss indicates the presence or absence of damaged piping or leaking joints. This practice is not intended to show total system water leakage limits and shall not be used as a quantitative measure of leakage under service conditions for infiltration or exfiltration.

Note 1: A finding of acceptable air loss specified in this practice can be interpreted as an installation acceptance test in lieu of infiltration or exfiltration testing.

4.3 This practice provides assurance of initial condition and quality of workmanship of properly-installed sewer pipe.

SCOPE

1.1 This practice provides procedures for testing non-pressure plastic pipe sewer lines, using low-pressure air to prove the integrity of the installed material and the construction procedures. Two procedures are included to find the rate of air leakage—the constant-pressure method and the time-pressure drop method.

1.2 This practice is performed on lines after all connections and service laterals have been plugged and braced adequately to withstand the test pressure. The time between completion of the backfill operation and low-pressure air testing may be specified by the approving authority.

1.3 This practice is used as a preliminary test, which enables the installer to show the condition of a buried line prior to final backfill, paving, and other construction activities.

1.4 This practice is applicable to all non-pressure sewer lines made of thermoplastic pipe, reinforced thermosetting resin (RTRP) pipe, and reinforced plastic mortar (RPM) pipe, defined in Terminology D883, D1600, and F412.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 5.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1417 − 11a (Reapproved 2015)

Standard Practice for

Installation Acceptance of Plastic Non-pressure Sewer Lines

Using Low-Pressure Air

This standard is issued under the fixed designation F1417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C828 Test Method for Low-Pressure Air Test of Vitrified

Clay Pipe Lines

1.1 This practice provides procedures for testing non-

C924 Practice for Testing Concrete Pipe Sewer Lines by

pressure plastic pipe sewer lines, using low-pressure air to

Low-Pressure Air Test Method (Withdrawn 2013)

provetheintegrityoftheinstalledmaterialandtheconstruction

D883 Terminology Relating to Plastics

procedures. Two procedures are included to find the rate of air

D1600 Terminology forAbbreviatedTerms Relating to Plas-

leakage—the constant-pressure method and the time-pressure

tics

drop method.

D2122 Test Method for Determining Dimensions of Ther-

1.2 This practice is performed on lines after all connections

moplastic Pipe and Fittings

and service laterals have been plugged and braced adequately

D3567 Practice for Determining Dimensions of “Fiberglass”

to withstand the test pressure. The time between completion of

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

the backfill operation and low-pressure air testing may be

Fittings

specified by the approving authority.

F412 Terminology Relating to Plastic Piping Systems

1.3 Thispracticeisusedasapreliminarytest,whichenables 2.2 Uni-Bell PVC Pipe Association Standard:

the installer to show the condition of a buried line prior to final

UNI-B-6 Recommended Practice for Low-PressureAirTest-

backfill, paving, and other construction activities. ing of Installed Sewer Pipe

1.4 This practice is applicable to all non-pressure sewer

3. Summary of Practice

lines made of thermoplastic pipe, reinforced thermosetting

3.1 Thesectionofthelinetobetestedisplugged.Air,atlow

resin (RTRP) pipe, and reinforced plastic mortar (RPM) pipe,

pressure, is introduced into the plugged line. The line passes

defined in Terminology D883, D1600, and F412.

the test if the rate of air leakage, as measured by a constant-

1.5 The values stated in inch-pound units are to be regarded

pressure method or a time-pressure drop method. The rate of

as standard. The values given in parentheses are mathematical

air leakage may be determined by using Table 1 or Table 2,or

conversions to SI units that are provided for information only

calculated by use of the equations in Section 9.

and are not considered standard.

1.6 This standard does not purport to address all of the

4. Significance and Use

safety problems, if any, associated with its use. It is the

4.1 This low-pressure air testing practice detects damaged

responsibility of the user of this standard to establish appro-

piping or improper jointing by measuring the rate at which air

priate safety and health practices and determine the applica-

under pressure escapes from an isolated section of sewer.

bility of regulatory limitations prior to use. For specific

4.2 The rate of air loss indicates the presence or absence of

precautionary statements, see Section 5.

damaged piping or leaking joints. This practice is not intended

2. Referenced Documents to show total system water leakage limits and shall not be used

2 as a quantitative measure of leakage under service conditions

2.1 ASTM Standards:

for infiltration or exfiltration.

NOTE 1—A finding of acceptable air loss specified in this practice can

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

be interpreted as an installation acceptance test in lieu of infiltration or

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

exfiltration testing.

Current edition approved Aug. 1, 2015. Published November 2015. Originally

approved in 1992. Last previous edition approved in 2011 as F1417–11a. DOI:

10.1520/F1417-11AR15.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Uni-Bell PVC Pipe Association, 2711 Lyndon B. Johnson

the ASTM website. Freeway, Suite 1000, Dallas, TX 75234, http://www.uni-bell.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1417 − 11a (2015)

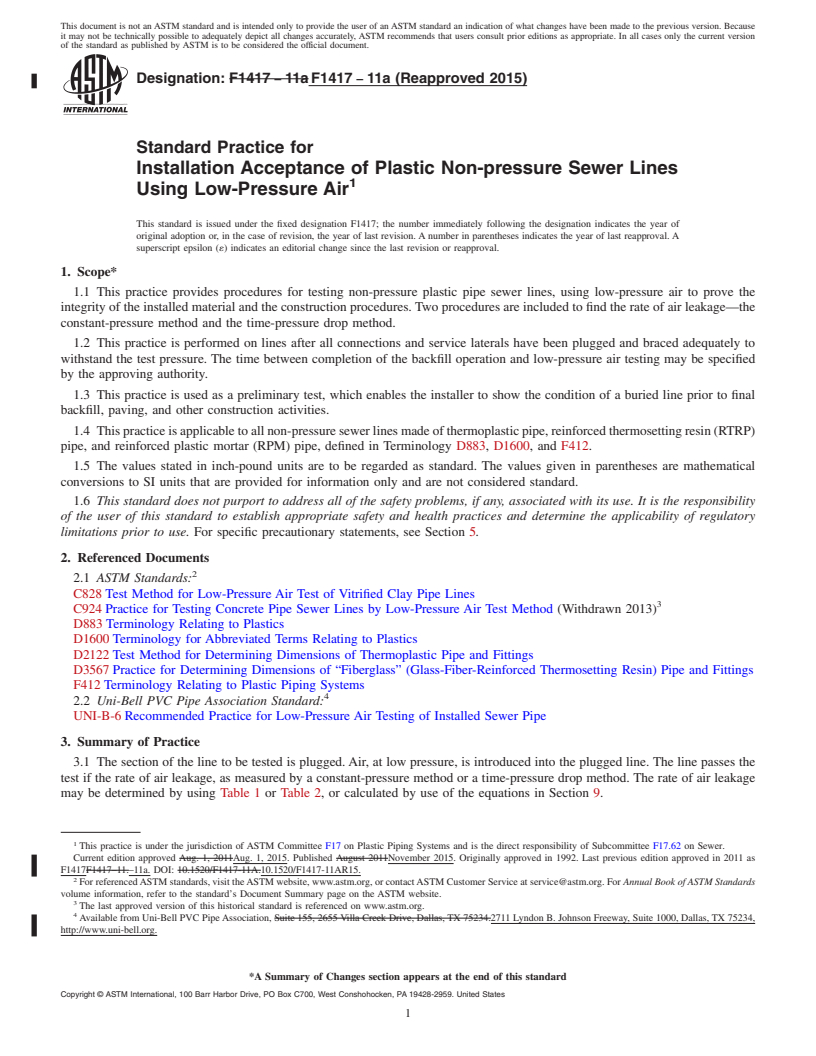

TABLE 1 Minimum Time for a 1.0-psig Pressure Drop for Size and Length of Pipe forQ = 0.0015

NOTE 1—See Practice UNI-B-6.

NOTE 2—Consult with pipe and appurtenance manufacturer for maximum test pressure for pipe size greater than 30 in. in diameter.

Length Specification Time for Length (L) Shown, min:s

Pipe Minimum Time for

for

100 ft 150 ft 200 ft 250 ft 300 ft 350 ft 400 ft 450 ft

Diameter, Time, Longer

Minimum

in. min:s Length, s

Time, ft

4 3:46 597 0.380 L 3:46 3:46 3:46 3:46 3:46 3:46 3:46 3:46

6 5:40 398 0.854 L 5:40 5:40 5:40 5:40 5:40 5:40 5:42 6:24

8 7:34 298 1.520 L 7:34 7:34 7:34 7:34 7:36 8:52 10:08 11:24

10 9:26 239 2.374 L 9:26 9:26 9:26 9:53 11:52 13:51 15:49 17:48

12 11:20 199 3.418 L 11:20 11:20 11:24 14:15 17:05 19:56 22:47 25:38

15 14:10 159 5.342 L 14:10 14:10 17:48 22:15 26:42 31:09 35:36 40:04

18 17:00 133 7.692 L 17:00 19:13 25:38 32:03 38:27 44:52 51:16 57:41

21 19:50 114 10.470 L 19:50 26:10 34:54 43:37 52:21 61:00 69:48 78:31

24 22:40 99 13.674 L 22:47 34:11 45:34 56:58 68:22 79:46 91:10 102:33

27 25:30 88 17.306 L 28:51 43:16 57:41 72:07 86:32 100:57 115:22 129:48

30 28:20 80 21.366 L 35:37 53:25 71:13 89:02 106:50 124:38 142:26 160:15

33 31:10 72 25.852 L 43:05 64:38 86:10 107:43 129:16 150:43 172:21 193:53

36 34:00 66 30.768 L 51:17 76:55 102:34 128:12 153:50 179:29 205:07 230:46

42 39:48 57 41.883 L 69:48 104:42 139:37 174:30 209:24 244:19 279:13 314:07

48 45:34 50 54.705 L 91:10 136:45 182:21 227:55 273:31 319:06 364:42 410:17

54 51:02 44 69.236 L 115:24 173:05 230:47 288:29 346:11 403:53 461:34 519:16

60 56:40 40 85.476 L 142:28 213:41 284:55 356:09 427:23 498:37 569:50 641:04

TABLE 2 Minimum Time for a 0.5-psig Pressure Drop for Size and Length of Pipe forQ = 0.0015

NOTE 1—Consult with pipe and appurtenance manufacturer for maximum test pressure for pipe size greater than 30 in. in diameter.

Length Specification Time for Length (L) Shown, min:s

Pipe Minimum Time for

for

100 ft 150 ft 200 ft 250 ft 300 ft 350 ft 400 ft 450 ft

Diameter, Time, Longer

Minimum

in. min:s Length, s

Time, ft

4 1:53 597 0.190 L 1:53 1:53 1:53 1:53 1:53 1:53 1:53 1:53

6 2:50 398 0.427 L 2:50 2:50 2:50 2:50 2:50 2:50 2:51 3:12

8 3:47 298 0.760 L 3:47 3:47 3:47 3:47 3:48 4:26 5:04 5:42

10 4:43 239 1.187 L 4:43 4:43 4:43 4:57 5:56 6:55 7:54 8:54

12 5:40 199 1.709 L 5:40 5:40 5:42 7:08 8:33 9:58 11:24 12:50

15 7:05 159 2.671 L 7:05 7:05 8:54 11:08 13:21 15:35 17:48 20:02

18 8:30 133 3.846 L 8:30 9:37 12:49 16:01 19:14 22:26 25:38 28:51

21 9:55 114 5.235 L 9:55 13:05 17:27 21:49 26:11 30:32 34:54 39:16

24 11:20 99 6.837 L 11:24 17:57 22:48 28:30 34:11 39:53 45:35 51:17

27 12:45 88 8.653 L 14:25 21:38 28:51 36:04 43:16 50:30 57:42 64:54

30 14:10 80 10.683 L 17:48 26:43 35:37 44:31 53:25 62:19 71:13 80:07

33 15:35 72 12.926 L 21:33 32:19 43:56 53:52 64:38 75:24 86:10 96:57

36 17:00 66 15.384 L 25:39 38:28 51:17 64:06 76:55 89:44 102:34 115:23

42 19:54 57 20.942 L 34:54 52:21 69:49 87:15 104:42 122:10 139:37 157:04

48 22:47 50 27.352 L 45:35 68:23 91:11 113:58 136:46 159:33 182:21 205:09

54 25:31 44 34.618 L 57:42 86:33 115:24 144:15 173:05 201:56 230:47 259:38

60 28:20 40 42.738 L 71:14 106:51 142:28 178:05 213:41 249:18 284:55 320:32

4.3 This practice provides assurance of initial condition and 5.4 Time Measuring Equipment—A stopwatch or watch

quality of workmanship of properly-installed sewer pipe. with a second hand or digital readout in minutes and seconds

with an accuracy of 0.1.s.

5. Apparatus

6. Safety Precautions

5.1 Plugs—Mechanical or pneumatic type.

6.1 This low-pressure air testing practice may be dangerous

5.2 Air Compressor—A properly calibrated portable, oil-

to personnel if, through lack of understanding or carelessness,

free air source with a singular control panel containing a main

a line is over-pressurized or plugs/caps are installed or re-

shut-off valve, pressure-regulating valve, 9-psig pressure-relief

strained improperly. It is extremely important that the various

valve, input pressure gauge, and a continuous monitoring

plugsbeproperlyinstalled,restrainedandbracedtopreventthe

pressuregaugehavingapressurerangefrom0psitoatleast10

suddenexpulsionofapoorlyinstalledorpartiallyinflatedplug.

psi with minimum divisions of 0.10 psi and an accuracy of

Observe the following minimum safety precautions:

60.04 psi.

6.1.1 Duringtesting,nooneshallbeallowedinmanholesor

5.3 Rotameter, standard CFM reading with an accuracy of in the possible path of a suddenly expelled cap or plug.

62%. 6.1.2 Install and restrain all caps and plugs securely.

F1417 − 11a (2015)

6.1.3 When lines are tested, it is mandatory that all the caps cubic feet per minute is read directly by a rotameter. Convert

and plugs shall be braced as an added safety factor. this air-flow rate to actual cubic feet per minute of air leaking

6.1.4 Do not over-pressurize the lines. Do not exceed 9.0 from the test section by using the absolute pressure and

psig. temperature in the test section. The requirements for air loss

under the constant pressure method shall be considered satis-

NOTE 2—The axial force on a plug at 9 psig internal pressure isF=P

fied if the air loss does not exceed the specified leakage rate in

π D /4 lb, where D is the inside diameter in inches. For example, the axial

cubic feet per minute per square foot of internal pipe surface

force on an 30-in. plug at 9.0 psig maximum allowable pressure is over

6 300 lb. Restraint systems must be designed to handle these forces with

area.

adequate safety factors. Every effort should be made to maintain backfill

8.2.2 Time-Pressure Drop Method—Air is slowly intro-

over the pipe during air testing.

duced into the test section, until the air pressure is raised to

6.1.5 Aregulatororreliefvalvesetnohigherthan9psishall

approximately4.0psiandthetestsectionisstabilizedasin8.1.

be included on all pressurizing equipment.

Disconnect the air supply and decrease the pressure to 3.5 psi

before starting the test. Determine pressure drap time per

7. Preparation of the Line

8.2.2.1 and 8.2.2.2.

7.1 Clean the section of sewer line to be tested by flushing

8.2.2.1 1.0 psig pressure drop—Determinethetimerequired

or other means prior to conducting the low-pressure air test.

for the pressure to drop from 3.5 psi to 2.5 psi, and compare

This cleaning serves to eliminate debris and produce consistent

this interval to the minimum time for the pipe diameter and the

results.

length per Table 1. If the rate of air loss is greater than or equal

totheminimumtimeforthepipediameterandlengthperTable

8. Procedures

1, the installation is acceptable.

8.1 Isolatethesectionofsewerlinetobetestedbyinflatable 8.2.2.2 0.5 psig pressure drop—Determinethetimerequired

stoppers or other suitable test plugs or caps. for the pressure to drop from 3.5 psi to 3.0 psi, and compare

8.1.1 Theendsofallbranches,laterals,tees,wyes,andstubs this interval to the minimum time for the pipe diameter and

included in the test section shall be plugged or capped to length per Table 2. If the rate of air loss is greater than or equal

prevent air leakage.All plugs and caps shall be securely braced totheminimumtimeforthepipediameterandlengthperTable

to prevent blow-out. One of the plugs or caps shall have an 2, the installation is acceptable.

inlet tap, or other provision for connecting an air hose to a

NOTE 4—The time-pressure drop method assumes an atmospheric

portable air control source.

pressure of 14.7 psia. Locations of high altitude need compensation for

8.1.2 Connecttheairhosetotheinlettapandtotheportable

variation in atmospheric pressure to maintain the same air leakage test

air source and control equipment. The air equipment shall criteria.

consist of necessary valves and pressure gages to control an

8.3 Upon completion of the test, open the bleeder valve and

oil-freeairsource,tocontroltherateatwhichairflowsintothe

allow all air to escape. Caps and plugs shall not be removed

test section, and to enable monitoring of the air pressure within

until all air pressure in the test section has been reduced to

the test section.

atmospheric pressure.

8.1.3 Add air slowly to the test section until the pressure

inside the test section reaches 4.0 psig.

9. Test Time Calculations

8.1.4 After the pressure of 4.0 psig is obtained, regulate the

9.1 Test Time Criteria—No test section shall be accepted if

air supply so that the pressure is maintained between 3.5 to 4.0

air loss is more than a specified leakage rate (in cubic feet per

psig for at least 2 min. Depending on air/ground temperature

minute per square foot) determined by the approving authority.

conditions, the internal air temperature will stabilize in equi-

librium with the temperature of the pipe walls. The pressure

9.2 Calculate all test times by the following equation:

will normally drop slightly until equilibrium is obtained;

T 5 0.085 DK/Q

however, a minimum of 3.5 psig is required.

where:

8.2 After equilibrium is obtained, determine the rate of air

T = shortest time allowed for the air pressure to drop 1.0

lossbyeithertheconstantpressuremethodorthetime-pressure

psig, s,

drop method.

K = 0.000419 DL but not less than 1.0,

NOTE 3—All test pressures are measured as gauge pressure, which is

Q = leak rate in cubic feet/minute/square feet of internal

any pressure greater than atmospheric pressure. Since water produces a

surface = 0.0015 CFM/SF,

pressure of 0.43 psi for every foot of depth, air test pressures must be

D = measured average inside diameter of sewer pipe (see

increased to offset the depth of ground water over the sewer line. If the

Test Method D2122 and Practice D3567), in., and

groundwaterlevelis2ftormoreabovethetopofthepipeattheupstream

L = length of test section, ft.

end, or if the air pressure required for the test is greater than 9-psi gauge,

this air testing practice should not be used. Before this air testing practice

Table 1 contains the specified minimum times required for a

is used, the ground water level should b

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1417 − 11a F1417 − 11a (Reapproved 2015)

Standard Practice for

Installation Acceptance of Plastic Non-pressure Sewer Lines

Using Low-Pressure Air

This standard is issued under the fixed designation F1417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice provides procedures for testing non-pressure plastic pipe sewer lines, using low-pressure air to prove the

integrity of the installed material and the construction procedures. Two procedures are included to find the rate of air leakage—the

constant-pressure method and the time-pressure drop method.

1.2 This practice is performed on lines after all connections and service laterals have been plugged and braced adequately to

withstand the test pressure. The time between completion of the backfill operation and low-pressure air testing may be specified

by the approving authority.

1.3 This practice is used as a preliminary test, which enables the installer to show the condition of a buried line prior to final

backfill, paving, and other construction activities.

1.4 This practice is applicable to all non-pressure sewer lines made of thermoplastic pipe, reinforced thermosetting resin (RTRP)

pipe, and reinforced plastic mortar (RPM) pipe, defined in Terminology D883, D1600, and F412.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautionary statements, see Section 5.

2. Referenced Documents

2.1 ASTM Standards:

C828 Test Method for Low-Pressure Air Test of Vitrified Clay Pipe Lines

C924 Practice for Testing Concrete Pipe Sewer Lines by Low-Pressure Air Test Method (Withdrawn 2013)

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D3567 Practice for Determining Dimensions of “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

2.2 Uni-Bell PVC Pipe Association Standard:

UNI-B-6 Recommended Practice for Low-Pressure Air Testing of Installed Sewer Pipe

3. Summary of Practice

3.1 The section of the line to be tested is plugged. Air, at low pressure, is introduced into the plugged line. The line passes the

test if the rate of air leakage, as measured by a constant-pressure method or a time-pressure drop method. The rate of air leakage

may be determined by using Table 1 or Table 2, or calculated by use of the equations in Section 9.

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

Current edition approved Aug. 1, 2011Aug. 1, 2015. Published August 2011November 2015. Originally approved in 1992. Last previous edition approved in 2011 as

F1417F1417–11.–11a. DOI: 10.1520/F1417-11A.10.1520/F1417-11AR15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from Uni-Bell PVC Pipe Association, Suite 155, 2655 Villa Creek Drive, Dallas, TX 75234.2711 Lyndon B. Johnson Freeway, Suite 1000, Dallas, TX 75234,

http://www.uni-bell.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1417 − 11a (2015)

TABLE 1 Minimum Time for a 1.0 psig 1.0-psig Pressure Drop for Size and Length of Pipe for Q = 0.0015

NOTE 1—See Practice UNI-B-6.

NOTE 2—Consult with pipe and appurtenance manufacturer for maximum test pressure for pipe size greater than 30 in. in diameter.

Length Specification Time for Length (L) Shown, min:s

Pipe Minimum Time for

for

100 ft 150 ft 200 ft 250 ft 300 ft 350 ft 400 ft 450 ft

Diameter, Time, Longer

Minimum

in. min:s Length, s

Time, ft

4 3:46 597 0.380 L 3:46 3:46 3:46 3:46 3:46 3:46 3:46 3:46

6 5:40 398 0.854 L 5:40 5:40 5:40 5:40 5:40 5:40 5:42 6:24

8 7:34 298 1.520 L 7:34 7:34 7:34 7:34 7:36 8:52 10:08 11:24

10 9:26 239 2.374 L 9:26 9:26 9:26 9:53 11:52 13:51 15:49 17:48

12 11:20 199 3.418 L 11:20 11:20 11:24 14:15 17:05 19:56 22:47 25:38

15 14:10 159 5.342 L 14:10 14:10 17:48 22:15 26:42 31:09 35:36 40:04

18 17:00 133 7.692 L 17:00 19:13 25:38 32:03 38:27 44:52 51:16 57:41

21 19:50 114 10.470 L 19:50 26:10 34:54 43:37 52:21 61:00 69:48 78:31

24 22:40 99 13.674 L 22:47 34:11 45:34 56:58 68:22 79:46 91:10 102:33

27 25:30 88 17.306 L 28:51 43:16 57:41 72:07 86:32 100:57 115:22 129:48

30 28:20 80 21.366 L 35:37 53:25 71:13 89:02 106:50 124:38 142:26 160:15

33 31:10 72 25.852 L 43:05 64:38 86:10 107:43 129:16 150:43 172:21 193:53

36 34:00 66 30.768 L 51:17 76:55 102:34 128:12 153:50 179:29 205:07 230:46

42 39:48 57 41.883 L 69:48 104:42 139:37 174:30 209:24 244:19 279:13 314:07

48 45:34 50 54.705 L 91:10 136:45 182:21 227:55 273:31 319:06 364:42 410:17

54 51:02 44 69.236 L 115:24 173:05 230:47 288:29 346:11 403:53 461:34 519:16

60 56:40 40 85.476 L 142:28 213:41 284:55 356:09 427:23 498:37 569:50 641:04

TABLE 2 Minimum Time for a 0.5 psig 0.5-psig Pressure Drop for Size and Length of Pipe for Q = 0.0015

NOTE 1—Consult with pipe and appurtenance manufacturer for maximum test pressure for pipe size greater than 30 in. in diameter.

Length Specification Time for Length (L) Shown, min:s

Pipe Minimum Time for

for

100 ft 150 ft 200 ft 250 ft 300 ft 350 ft 400 ft 450 ft

Diameter, Time, Longer

Minimum

in. min:s Length, s

Time, ft

4 1:53 597 0.190 L 1:53 1:53 1:53 1:53 1:53 1:53 1:53 1:53

6 2:50 398 0.427 L 2:50 2:50 2:50 2:50 2:50 2:50 2:51 3:12

8 3:47 298 0.760 L 3:47 3:47 3:47 3:47 3:48 4:26 5:04 5:42

10 4:43 239 1.187 L 4:43 4:43 4:43 4:57 5:56 6:55 7:54 8:54

12 5:40 199 1.709 L 5:40 5:40 5:42 7:08 8:33 9:58 11:24 12:50

15 7:05 159 2.671 L 7:05 7:05 8:54 11:08 13:21 15:35 17:48 20:02

18 8:30 133 3.846 L 8:30 9:37 12:49 16:01 19:14 22:26 25:38 28:51

21 9:55 114 5.235 L 9:55 13:05 17:27 21:49 26:11 30:32 34:54 39:16

24 11:20 99 6.837 L 11:24 17:57 22:48 28:30 34:11 39:53 45:35 51:17

27 12:45 88 8.653 L 14:25 21:38 28:51 36:04 43:16 50:30 57:42 64:54

30 14:10 80 10.683 L 17:48 26:43 35:37 44:31 53:25 62:19 71:13 80:07

33 15:35 72 12.926 L 21:33 32:19 43:56 53:52 64:38 75:24 86:10 96:57

36 17:00 66 15.384 L 25:39 38:28 51:17 64:06 76:55 89:44 102:34 115:23

42 19:54 57 20.942 L 34:54 52:21 69:49 87:15 104:42 122:10 139:37 157:04

48 22:47 50 27.352 L 45:35 68:23 91:11 113:58 136:46 159:33 182:21 205:09

54 25:31 44 34.618 L 57:42 86:33 115:24 144:15 173:05 201:56 230:47 259:38

60 28:20 40 42.738 L 71:14 106:51 142:28 178:05 213:41 249:18 284:55 320:32

4. Significance and Use

4.1 This low-pressure air testing practice detects damaged piping or improper jointing by measuring the rate at which air under

pressure escapes from an isolated section of sewer.

4.2 The rate of air loss indicates the presence or absence of damaged piping or leaking joints. This practice is not intended to

show total system water leakage limits and shall not be used as a quantitative measure of leakage under service conditions for

infiltration or exfiltration.

NOTE 1—A finding of acceptable air loss specified in this practice can be interpreted as an installation acceptance test in lieu of infiltration or exfiltration

testing.

4.3 This practice provides assurance of initial condition and quality of workmanship of properly-installed sewer pipe.

5. Apparatus

5.1 Plugs—Mechanical or pneumatic type.

5.2 Air Compressor—A properly calibrated portable, oil-free air source with a singular control panel containing a main shut-off

valve, pressure-regulating valve, 9 psig 9-psig pressure-relief valve, input pressure gauge, and a continuous monitoring pressure

gauge having a pressure range from 0 psi to at least 10 psi with minimum divisions of 0.10 psi and an accuracy of 6 0.04 60.04

psi.

F1417 − 11a (2015)

5.3 Rotameter, standard CFM reading with an accuracy of 6 2 %. 62 %.

5.4 Time measuring equipment—Measuring Equipment—A stopwatch or watch with a second hand or digital readout in minutes

and seconds with an accuracy of 0.1.s.

6. Safety Precautions

6.1 This low-pressure air testing practice may be dangerous to personnel if, through lack of understanding or carelessness, a line

is over-pressurized or plugs/caps are installed or restrained improperly. It is extremely important that the various plugs be properly

installed, restrained and braced to prevent the sudden expulsion of a poorly installed or partially inflated plug. Observe the

following minimum safety precautions:

6.1.1 During testing, no one shall be allowed in manholes or in the possible path of a suddenly expelled cap or plug.

6.1.2 Install and restrain all caps and plugs securely.

6.1.3 When lines are tested, it is mandatory that all the caps and plugs shall be braced as an added safety factor.

6.1.4 Do not over-pressurize the lines. Do not exceed 9.0 psig.

NOTE 2—The axial force on a plug at 9 psig internal pressure is F = P π D /4 lb, where D is the inside diameter in inches. For example, the axial force

on an 30-in. plug at 9.0 psig maximum allowable pressure is over 6 300 6 300 lb. Restraint systems must be designed to handle these forces with adequate

safety factors. Every effort should be made to maintain backfill over the pipe during air testing.

6.1.5 A regulator or relief valve set no higher than 9 psi shall be included on all pressurizing equipment.

7. Preparation of the Line

7.1 Clean the section of sewer line to be tested by flushing or other means prior to conducting the low-pressure air test. This

cleaning serves to eliminate debris and produce consistent results.

8. Procedures

8.1 Isolate the section of sewer line to be tested by inflatable stoppers or other suitable test plugs or caps.

8.1.1 The ends of all branches, laterals, tees, wyes, and stubs included in the test section shall be plugged or capped to prevent

air leakage. All plugs and caps shall be securely braced to prevent blow-out. One of the plugs or caps shall have an inlet tap, or

other provision for connecting an air hose to a portable air control source.

8.1.2 Connect the air hose to the inlet tap and to the portable air source and control equipment. The air equipment shall consist

of necessary valves and pressure gages to control an oil-free air source, to control the rate at which air flows into the test section,

and to enable monitoring of the air pressure within the test section.

8.1.3 Add air slowly to the test section until the pressure inside the test section reaches 4.0 psig.

8.1.4 After the pressure of 4.0 psig is obtained, regulate the air supply so that the pressure is maintained between 3.5 to 4.0 psig

for at least 2 min. Depending on air/ground temperature conditions, the internal air temperature will stabilize in equilibrium with

the temperature of the pipe walls. The pressure will normally drop slightly until equilibrium is obtained; however, a minimum of

3.5 psig is required.

8.2 After equilibrium is obtained, determine the rate of air loss by either the constant pressure method or the time-pressure drop

method.

NOTE 3—All test pressures are measured as gauge pressure, which is any pressure greater than atmospheric pressure. Since water produces a pressure

of 0.43 psi for every foot of depth, air test pressures must be increased to offset the depth of ground water over the sewer line. If the ground water level

is 2 ft or more above the top of the pipe at the upstream end, or if the air pressure required for the test is greater than 9-psi gauge, this air testing practice

should not be used. Before this air testing practice is used, the ground water level should be lowered by pumping or dewatering.

8.2.1 Constant Pressure Method—Add air until the internal air pressure of the test section is raised to 4.0 psig and the test

section is stabilized as in 8.1. Reduce pressure to 3.5 psig to run the constant pressure test. The air-flow rate in standard cubic feet

per minute is read directly by a rotameter. Convert this air-flow rate to actual cubic feet per minute of air leaking from the test

section by using the absolute pressure and temperature in the test section. The requirements for air loss under the constant pressure

method shall be considered satisfied if the air loss does not exceed the specified leakage rate in cubic feet per minute per square

foot of internal pipe surface area.

8.2.2 Time-Pressure Drop Method—Air is slowly introduced into the test section, until the air pressure is raised to approximately

4.0 psi and the test section is stabilized as in 8.1. Disconnect the air supply and decrease the pressure to 3.5 psi before starting the

test. Determine pressure drap time per 8.2.2.1 and 8.2.2.2.

8.2.2.1 1.0 psig pressure drop—Determine the time required for the pressure to drop from 3.5 psi to 2.5 psi, and compare this

interval to the minimum time for the pipe diameter and the length per Table 1. If the rate of air loss is greater than or equal to the

minimum time for the pipe diameter and length per Table 1, the installation is acceptable.

8.2.2.2 0.5 psig pressure drop—Determine the time required for the pressure to drop from 3.5 psi to 3.0 psi, and compare this

interval to the minimum time for the pipe diameter and length per Table 2. If the rate of air loss is greater than or equal to the

minimum time for the pipe diameter and length per Table 2, the installation is acceptable.

NOTE 4—The time-pressure drop method assumes an atmospheric pressure of 14.7 psia. Locations of high altitude need compensation for variation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.