ASTM D2625-94(2003)

(Test Method)Standard Test Method for Endurance (Wear) Life and Load-Carrying Capacity of Solid Film Lubricants (Falex Pin and Vee Method)

Standard Test Method for Endurance (Wear) Life and Load-Carrying Capacity of Solid Film Lubricants (Falex Pin and Vee Method)

SIGNIFICANCE AND USE

This test method differentiates between bonded solid lubricants with respect to their wear life and load-carrying capacity. If the test conditions are changed, wear life may change and relative ratings of the bonded solid film lubricants may be different.

SCOPE

1.1 This test method covers the determination of the endurance (wear) life and load-carrying capacity of dry solid film lubricants in sliding steel-on-steel applications.

1.2 The values stated in SI units are to be regarded as the standard except where equipment is supplied using inch-pound units and would then be regarded as standard. The metric equivalents of inch-pound units given in such cases in the body of the standard may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D2625–94 (Reapproved 2003)

Standard Test Method for

Endurance (Wear) Life and Load-Carrying Capacity of Solid

Film Lubricants (Falex Pin and Vee Method)

This standard is issued under the fixed designation D2625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope MIL-P-16232F Phosphate Coatings, Heavy, Manganese or

2 Zinc Base (for Ferrous Metals)

1.1 This test method covers the determination of the

2.3 Other Standards:

endurance (wear) life and load-carrying capacity of dry solid

42USC7671a Clean Air Act Ammendments of 1990

film lubricants in sliding steel-on-steel applications.

Federal Test Methods791a, Methods3807 and3812

1.2 The values stated in SI units are to be regarded as the

standardexceptwhereequipmentissuppliedusinginch-pound

3. Terminology

units and would then be regarded as standard. The metric

3.1 Definitions:

equivalentsofinch-poundunitsgiveninsuchcasesinthebody

3.1.1 dry solid film lubricants—dry coatings consisting of

of the standard may be approximate.

lubricating powders in a solid matrix bonded to one or both

1.3 This standard does not purport to address all of the

surfaces to be lubricated.

safety concerns, if any, associated with its use. It is the

3.2 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

3.2.1 direct load, n—the load that is applied linearly,

priate safety and health practices and determine the applica-

bisecting the angle of the vee block corrected to either the

bility of regulatory limitations prior to use.

800-lbf (3550-N) gage reference or the 3000-lbf (13300-N)

2. Referenced Documents gage reference.

3.2.1.1 Discussion—This load is equivalent to the true load

2.1 ASTM Standards:

times the cos 42°.

B16/B16M Specification for Free-Cutting Brass Rod, Bar

3.2.2 endurance (wear) life—the length of test time before

and Shapes for Use in Screw Machines

failure under a constant loaded condition, in minutes, in which

F22 Test Method for Hydrophobic Surface Films by the

the applied test lubricant performs its function.

Water-Break Test

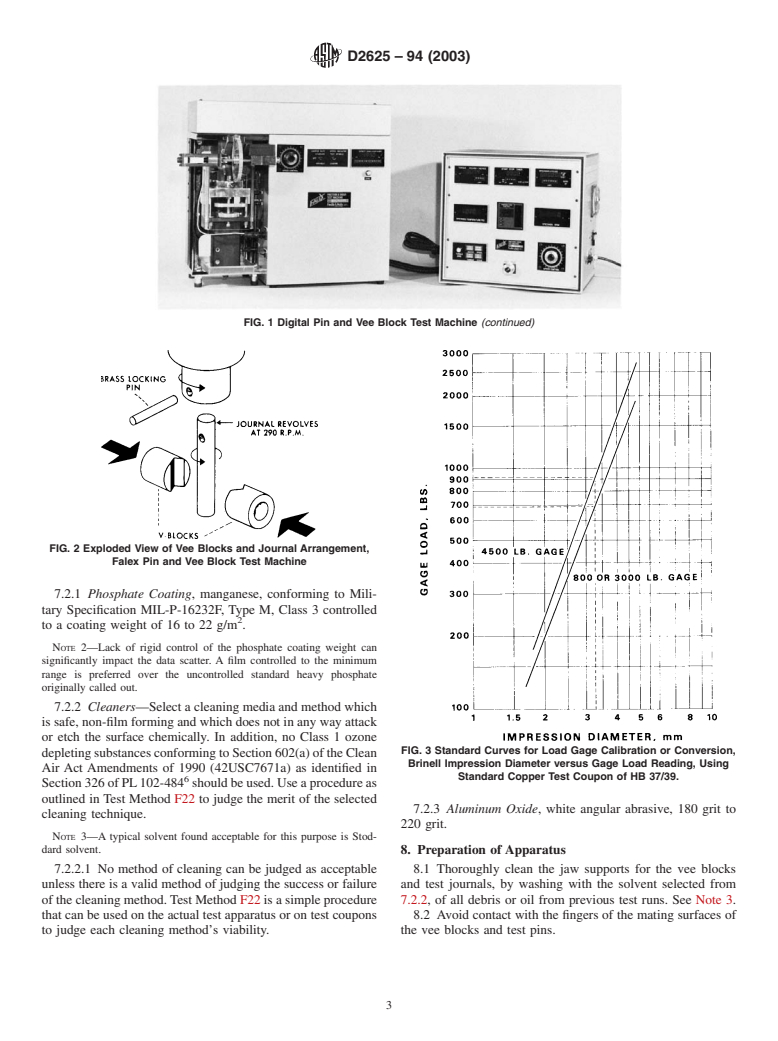

4 3.2.3 gage load, n—the value obtained from the gage while

2.2 U.S. Military Specifications:

running the test after being corrected to the standard curve

MIL-L-8937

using the calibration procedure for the 4500-lbf (20000-N)

reference gage.

This test method is under the jurisdiction of ASTM Committee D02 on

3.2.3.1 Discussion—The gage reading is irrespective of the

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

particular gage used, and corrections are made by comparison

D02.L0 on Industrial Lubricants.

totheBrinellballimpressiondiametersonastandardreference

Current edition approved Nov. 1, 2003. Published November 2003. Originally

approved in 1967. Last previous edition approved in 1998 as D2625–94 (1998).

copper test coupon with a Rockwell hardness range of HB37

DOI: 10.1520/D2625-94R03. 6

to HB39. An electronic calibration instrument is available

Reference may be made to Coordinating Research Council, Inc. (CRC) Report

which can be used in place of the copper coupon.

No.419,“DevelopmentofResearchTechniqueforMeasuringWearLifeofBonded

Solid Lubricant Coatings for Airframes, Using the Falex Tester.” Also to Military

Specification MIL-L-8937 (ASG), Jan. 22, 1963, and Methods3807 and3812 of

Federal Test Method Standard No. 791a. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The Falex Pin and Vee Block Test machine available from Falex Corp., 1020

Standards volume information, refer to the standard’s Document Summary page on Airpark Dr., Sugar Grove, IL60554 has been found satisfactory for this purpose.A

the ASTM website. new model of this machine has been available since 1983. Certain operating

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, procedures are different for this new model. Consult instruction manual of machine

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098. for this information.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2625–94 (2003)

FIG. 1 Schematic Diagram of Falex Pin and Vee Block Test Machine

3.2.4 load carrying capacity—the highest indicated load 6.2 Required for Calibration of Load Gage:

sustained for a minimum of 1 min. 6.2.1 Standardized Test Coupon, soft, annealed copper HB

37/39.

4. Summary of Test Method 6

6.2.2 Allen Screw, with attached 10-mm Brinell ball.

4.1 The endurance test (Procedure A) consists of running

6.2.3 Back-up Plug.

two stationary steel vee block specimens loaded to a predeter-

6.2.4 Brinell Microscope, or equivalent.

mined value against a rotating steel pin specimen. The endur-

6.2.5 Rule, steel, 150 mm (6 in.) long.

ance (wear) life is determined when the torque increases by 10

6.2.6 Timer, graduated in minutes and seconds.

in·lbf (1.13 N·m).

6.3 Required for Application of Dry Solid Film Lubricants-

4.2 The load-carrying capacity test (Procedure B) consists

(see Annex A1):

of running two stationary steel vee block specimens against a

6.3.1 Desiccator, for storing test parts. The bottom of the

rotating steel pin, increasing the load on the pin until a sharp

desiccator shall be filled with desiccant to maintain approxi-

increase (10 in·lbf (1.13 N·m)) in steady-state torque or pin

mately 50% relative humidity. (Not required if parts can be

breakage is experienced. Prior to both tests, the solid film

stored in a fume-free room at 50 6 5% relative humidity.)

lubricant is deposited on the surfaces of the test specimens.

6.3.2 Forced-Circulation Oven, capable of maintaining a

temperature of 149 6 5°C (300 6 10°F).

5. Significance and Use

6.3.3 Micrometer, reading 0 to 25 6 0.0025 mm (0 to 1 6

5.1 This test method differentiates between bonded solid

0.0001 in.), with a one-ball anvil.

lubricants with respect to their wear life and load-carrying

6.3.4 Vapor Degreasing Bath.

capacity. If the test conditions are changed, wear life may

change and relative ratings of the bonded solid film lubricants

7. Reagents and Materials

may be different.

7.1 Required for Procedures A and B:

6. Apparatus 7.1.1 Eight Standard Vee Blocks, 96 6 1° angle, heat

9 9

treatedto1.24 310 to1.38 310 Pa(180000to200000psi)

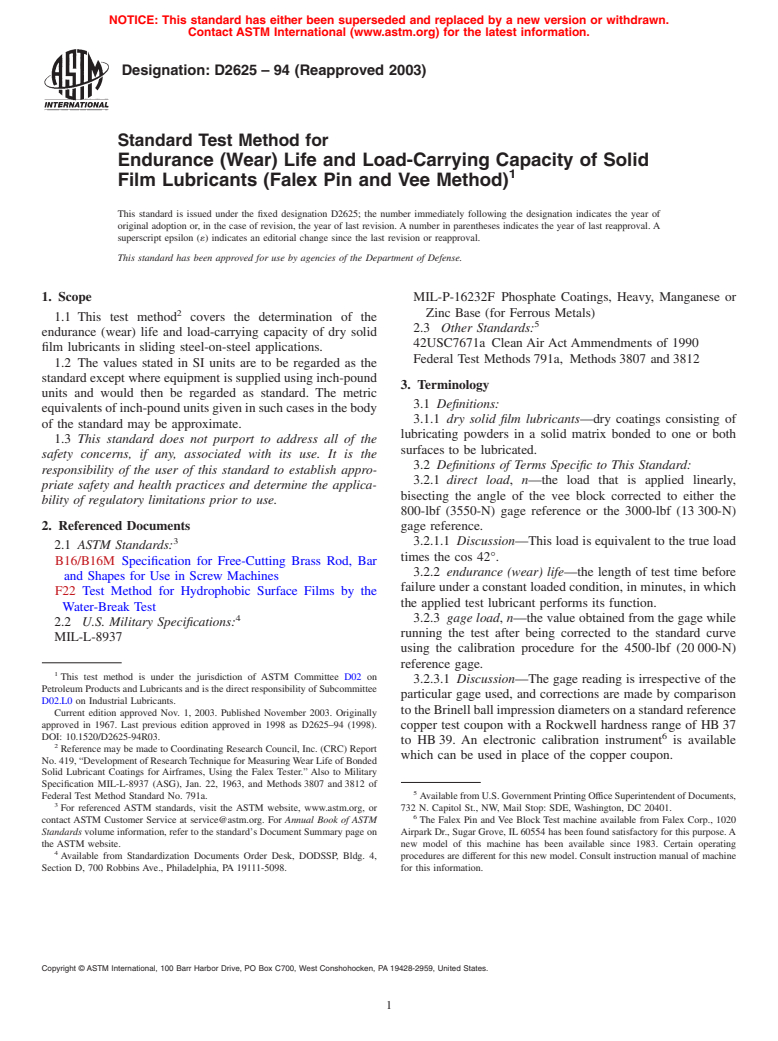

6.1 Falex Pin and Vee Block Test Machine, illustrated in

tensile strength; or standard coined vee blocks, 96 6 1° angle,

Fig. 1 and Fig. 2.

of AISI C-1137 steel as an alternative, with a Rockwell

6.1.1 Load Gage, 4500-lbf (20 000-N) range, or 3000-lbf

−7

hardness of HRC 20 to 24 and surface finish of 1.3 310 to

(13300-N) direct-reading gage. An 800-lbf (3550-N) direct-

−7

2.5 310 m (5 to 10 µin.), rms.

reading load gage may be used for Procedure A, but does not

7.1.2 Four Standard Test Pins, 6.35-mm ( ⁄4-in.) outside

have a high enough load range for Procedure B.

diameter by 31.75 mm (1 ⁄4 in.) long, heat treated to

NOTE 1—Primary figures for loads are shown for the 4500-lbf 9

1.24 310 to 1.38 310 Pa (180000 to 200000 psi) ultimate

(20000-N) gage. Equivalent readings on either 800 or 3000-lbf (3550 or

hardness; or Standard No. 8 Pins of AISI 3135 steel as an

13300-N) direct-reading gages are shown in parentheses and can be

alternative, with a hardness of HRB 87 to 91, on a ground, flat

obtained from the curve in Fig. 3.

surface (or approximately HRB 80 to 83 on the round), and a

6.1.2 Optional—An automatic cutoff, torque recorder, and

−7 −7

surfacefinishof1.3 310 to2.5 310 m(5to10µin.)rms.

timer may be used in place of the standard indicating torque

7.1.3 Locking (Shear) Pin, ⁄2 H Brass, conforming to

gage.

Specification B16/B16M.

7.2 Required for Application of Dry Solid Film Lubricant-

Available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554. (see Annex A1):

D2625–94 (2003)

FIG. 1 Digital Pin and Vee Block Test Machine (continued)

FIG. 2 Exploded View of Vee Blocks and Journal Arrangement,

Falex Pin and Vee Block Test Machine

7.2.1 Phosphate Coating, manganese, conforming to Mili-

tary Specification MIL-P-16232F, Type M, Class 3 controlled

to a coating weight of 16 to 22 g/m .

NOTE 2—Lack of rigid control of the phosphate coating weight can

significantly impact the data scatter. A film controlled to the minimum

range is preferred over the uncontrolled standard heavy phosphate

originally called out.

7.2.2 Cleaners—Selectacleaningmediaandmethodwhich

issafe,non-filmformingandwhichdoesnotinanywayattack

or etch the surface chemically. In addition, no Class 1 ozone

FIG. 3 Standard Curves for Load Gage Calibration or Conversion,

depletingsubstancesconformingtoSection602(a)oftheClean

Brinell Impression Diameter versus Gage Load Reading, Using

Air Act Amendments of 1990 (42USC7671a) as identified in

Standard Copper Test Coupon of HB 37/39.

Section326ofPL102-484 shouldbeused.Useaprocedureas

outlined in Test Method F22 to judge the merit of the selected

7.2.3 Aluminum Oxide, white angular abrasive, 180 grit to

cleaning technique.

220 grit.

NOTE 3—A typical solvent found acceptable for this purpose is Stod-

dard solvent. 8. Preparation of Apparatus

7.2.2.1 No method of cleaning can be judged as acceptable 8.1 Thoroughly clean the jaw supports for the vee blocks

unless there is a valid method of judging the success or failure and test journals, by washing with the solvent selected from

ofthecleaningmethod.TestMethodF22isasimpleprocedure 7.2.2, of all debris or oil from previous test runs. See Note 3.

that can be used on the actual test apparatus or on test coupons 8.2 Avoid contact with the fingers of the mating surfaces of

to judge each cleaning method’s viability. the vee blocks and test pins.

D2625–94 (2003)

measurements represent the same points. Average the three

measurements of each impression and record.

9.1.9 Plot the four impression readings versus gage load

readingsonlog-logpaper(K&E467080orequivalent).Ifthey

do not plot as an approximately straight line, repeat steps

9.1.4-9.1.8. A standard curve of impression diameter versus

gage reading is shown in Fig. 3. If the indentation diameter,

plotted as above, is lower or higher than that shown on the

standard curve, determine the actual load necessary to produce

the indentation diameter that will correspond to that shown on

the standard curve.

NOTE 4—A full-size standard calibration curve, plotted on log-log

paper and similar to Fig. 3 but with finer subdivision lines included,

should be used for accurate calibration.

9.2 Calibration Procedure with 800 or 3000-lbf (3550 or

13 300-N) Direct-Reading Load Gage:

9.2.1 Use the same procedure as with the 4500-lbf

FIG. 4 Schematic Drawing of Calibration Accessories for Falex

Pin and Vee Block Test Machine (20000-N) gage above, except obtain impressions at gage

readings of 300, 500, 700, and 800 lbf (1330, 2220, 3100, and

3550 N) on the 800-lbf (3550-N) gage; or at 300, 700, 1100,

8.3 Avoid atmospheric contamination such as cigarette

and 1700 lbf (1330, 3100, 4880, and 7550 N) on the 3000-lbf

smoke, as this can adversely affect the test results.

(13300-N)gage.Plottheimpressionreadingsversusgageload

9. Calibration of Load Gage readings, as in 9.1.9, with similar adjustments to the load in

order to produce indentation diameter that corresponds to the

9.1 Calibration Procedure with 4500-lbf (20 000-N) Load

indentation diameter on the standard curve.

Gage:

9.1.1 Remove the Allen set screw and 12.70-mm ( ⁄2-in.)

10. Procedure A

ball from the left jaw socket (Fig. 4).

9.1.2 InsertthespecialAllenscrewwiththeattached10-mm 10.1 Insertthesolidfilmcoatedveeblocksintherecessesof

Brinell ball into the working face of the left jaw.Adjust so that the load jaws.

the ball projects about 4 mm ( ⁄32 in.) from face of the jaw. 10.2 Mount the solid film coated pin in the test shaft and

9.1.3 Insert the back-up plug in the counterbore of the insert a new brass shear pin as shown in Fig. 1 and Fig. 2.

right-hand jaw. Adjust so that the plug projects about 0.8 mm 10.3 Swing the arms inward so that the vee blocks contact

( ⁄32 in.) from the face. the test pin in such a way that the vee grooves are aligned with

9.1.4 Support the standard test coupon so that the upper the pin’s major axis as shown in Fig. 2. Check this alignment

edge of the coupon is about 2.5 mm ( ⁄32 in.) below the upper visually. Place the automatic loading mechanism with attached

surface of the jaws. Place a steel rule across the face of the load gage on the load arms and turn the ratched wheel by hand

jaws.AdjusttheAllenscrewwiththeattached10-mmballuntil until the test parts are securely seated, indicated by a slight

the face of the jaws are parallel to the steel rule with the test upward movement of the load gage needle. At this point the

coupon in position for indentation. torque gage should read zero or be adjusted to read zero.

9.1.5 With the test coupon in position for the first impres-

10.4 Start the motor and engage the automatic loading

sion, place the load gage assembly on the lever arms. ratchet until a gage load of 300 lbf (1330 N) is reached

9.1.6 Placetheloadingarmontheratchetwheelandactuate (approximately 265 lbf (1170 N) on the direct-reading gage).

the motor.Allow the motor to run until the load gage indicates Removetheloadapplyingarmandcontinuerunning(at290 6

aloadof300lbf(1330N).Aslighttakeupontheratchetwheel 10 r/min) for 3 min, then increase the load to 500 lbf (2220 N)

is required to hold the load due to the ball sinking into the test (approximately 410 lbf (1820 N) on the direct-reading gage)

coupon.Afterthe300-lbf(1330-N)loadisobtained,holdfor1 using the load applying arm, and run for 1 min.

min for the indentation to form. 10.5 Increaseloadto750lbf(3330N)(590lbf(2620N)on

9.1.7 Turn off the machine and back off the load until the the direct-reading gage) and run for 1 min. Then increase the

test coupon is free of the jaws. Advance the test coupon load to 1000 lbf (4450 N) (765 lbf (3400 N) on the direct-

approximately 9.5 mm ( ⁄8 in.) (additional indentations should reading gage). Maintain this load and measure the time until

be separated by a minimum distance of 2.5 3the diameter of failure. Load should be maintained by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.