ASTM B249/B249M-00

(Specification)Standard Specification for General Requirements for Wrought Copper and Copper-Alloy Rod, Bar, Shapes and Forgings

Standard Specification for General Requirements for Wrought Copper and Copper-Alloy Rod, Bar, Shapes and Forgings

SCOPE

1.1 This specification establishes the general requirements common to wrought copper and copper alloy rod, bar, shapes, and forgings which shall apply to Specifications B 16/B 16M, B 21/B 21M, B 98/B 98M, B 124/B 124M, B 138/B 138M, B 139/B 139M, B 140/B 140M, B 150, B 151/B 151M, B 196/B 196M, B 283, B 301/B 301M, B 371, B 411/B 411M, B 441, B 453/B 453M, B 455, and B 570 to the extent referenced therein.

1.2 The chemical composition, physical and mechanical properties, and all other requirements not included in this specification are prescribed in the product specification.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in inch-pounds units or SI units are to be regarded separately in the standard. Within the text the SI values are given in brackets. The values stated in each system of units are not exact equivalents; each system is independent of the other. Combining values from the two systems may result in nonconformance with the specification.

Note 1—Requirements for flat wire (defined as flat products up to and including 0.188 in. thick and up to 1 1/4 in. in width, with all surfaces rolled or drawn, without having been slit, sheared or sawed) including square, furnished in coils or straight lengths, or on spools, reels, or bucks are described by the wire Specifications B 206/B 206M and B 272.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 249/B 249M – 00

Standard Specification for

General Requirements for Wrought Copper and Copper-

Alloy Rod, Bar, Shapes and Forgings

This standard is issued under the fixed designation B 249/B 249M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * B 98/B 98 M Specification for Copper-Silicon Alloy Rod,

Bar, and Shapes

1.1 This specification establishes the general requirements

B 124 Specification for Copper and Copper-Alloy Forging

common to wrought copper and copper alloy rod, bar, shapes,

Rod, Bar, and Shapes

and forgings which shall apply to Specifications B 16, B 21,

B 138 Specification for Manganese Bronze Rod, Bar, and

B 98, B 124, B 138, B 139, B 140/B 140M, B 150, B 151,

Shapes

B 196, B 283, B 301, B 371, B 411, B 441, B 453, B 455, and

B 139 Specification for Phosphor Bronze Rod, Bar, and

B 570 to the extent referenced therein.

Shapes

1.2 The chemical composition, physical and mechanical

B 140/B 140M Specification for Copper-Zinc-Lead

properties, and all other requirements not included in this

(Leaded Red Brass or Hardware Bronze) Rod, Bar, and

specification are prescribed in the product specification.

Shapes

1.3 This standard does not purport to address all of the

B 150 Specification for Aluminum Bronze Rod, Bar, and

safety concerns, if any, associated with its use. It is the

Shapes

responsibility of the user of this standard to establish appro-

B 151 Specification for Copper-Nickel-Zinc Alloy (Nickel

priate safety and health practices and determine the applica-

Silver) and Copper-Nickel Rod and Bar

bility of regulatory limitations prior to use.

B 154 Test Method for Mercurous Nitrate Test for Copper

1.4 The values stated in inch-pounds units or SI units are to

and Copper Alloys

be regarded separately in the standard. Within the text the SI

B 187 Specification for Copper Bar, Bus Bar, Rod and

values are given in brackets. The values stated in each system

Shapes

of units are not exact equivalents; each system is independent

B 193 Test Method for Resistivity of Electrical Conductor

of the other. Combining values from the two systems may

Materials

result in nonconformance with the specification.

B 194 Specification for Copper-Beryllium Alloy Plate,

NOTE 1—Requirements for flat wire (defined as flat products up to and 3

Sheet, Strip and Rolled Bar

including 0.188 in. thick and up to 1 ⁄4 in. in width, with all surfaces rolled

B 196 Specification for Copper-Beryllium Alloy Rod and

or drawn, without having been slit, sheared or sawed) including square,

Bar

furnished in coils or straight lengths, or on spools, reels, or bucks are

B 206/B 206M Specification for Copper-Nickel-Zinc Alloy

described by the wire Specifications B 206 and B 272.

(Nickel Silver) Wire and Copper-Nickel Alloy Wire

2. Referenced Documents

B 272 Specification for Flat Copper Products With Finished

(Rolled or Drawn) Edges (Flat Wire and Strip)

2.1 The following documents of the issue in effect on date

B 283 Specification for Copper and Copper-Alloy Die Forg-

of material purchase form a part of this specification to the

ings

extent referenced herein:

B 301 Specification for Free-Cutting Copper Rod and Bar

2.2 ASTM Standards:

B 371 Specification for Copper-Zinc-Silicon Alloy Rod

B 16 Specification for Free-Cutting Brass Rod, Bar, and

B 411 Specification for Copper-Nickel-Silicon Alloy Rod

Shapes for Use in Screw Machines

and Bar

B 21 Specification for Naval Brass Rod, Bar, and Shapes

B 441 Specification for Copper-Cobalt-Beryllium (UNS

C17500) and Copper-Nickel-Beryllium (UNS C17510)

This specification is under the jurisdiction of ASTM Committee B0-5 on

Rod and Bar

Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.02

B 453 Specification for Copper-Zinc-Lead Alloy (Leaded

on Rod, Bar, Shapes, and Forgings .

Brass) Rod

Current edition approved May 10, 2000. Published July 2000. Originally

published as B 249 – 51 T. Last previous edition B 249 – 94a.

B 455 Specification for Copper-Zinc-Lead Alloy (Leaded

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cations SB-249 in Section II of that Code.

3 4

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 02.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 249/B 249M

Brass) Extruded Shapes 3.1.2.2 bus rod, n—solid round and regular polygons of six

B 570 Specification for Copper-Beryllium Alloy (UNS and eight sides.

C17000 and C17200) Forgings and Extrusions

3.1.2.3 bus shape, n—a solid section other than regular rod,

B 577 Test Methods for Detection of Cuprous Oxide (Hy- bar, plate, sheet, strip, or flat wire, and may be of oval, half

drogen Embrittlement Susceptibility) in Copper

oval, half round, triangular, pentagonal, or of any special

B 846 Terminology for Copper and Copper Alloys cross-section.

B 858M Test Method for Determination of Susceptibility to

3.1.3 capable of, adj—possessing the required properties or

Stress Corrosion Cracking in Copper Alloys Using an

characteristics, or both, necessary to conform to specification

Ammonia Vapor Test

requirement(s) when subjected to specified test(s).

D 4855 Practice for Comparing Test Methods

3.1.4 coil, n—a length of the product wound into a series of

E 3 Practice for Preparation of Metallographic Specimens

connected turns. The unqualified term as applied to “flat wire”

E 8 Test Methods for Tension Testing of Metallic Materials

refers to a coil in which the product is spirally wound, with the

E 8M Test Methods for Tension Testing of Metallic Mate-

successive layers one atop the other (sometimes called a

rials [Metric]

“roll”).

E 18 Test Methods for Rockwell Hardness and Rockwell

3.1.4.1 coil, level or traverse wound, n—a coil in which the

Superficial Hardness of Metallic Materials

turns are positioned into layers parallel to the axis of the coil

E 29 Practice for Using Significant Digits in Test Data to

such that successive turns in a given layer are next to one

Determine Conformance with Specifications

another.

E 53 Methods for Chemical Analysis of Copper

3.1.4.2 coil, level or traverse wound on a reel or spool, n—a

E 54 Test Methods for Chemical Analysis of Special

coil in which the turns are positioned into layers on a reel or

Brasses and Bronzes

spool parallel to the axis of the reel or spool such that

E 62 Test Methods for Chemical Analysis of Copper and

successive turns in a given layer are next to one another.

Copper Alloys (Photometric Methods)

3.1.4.3 coil, stagger wound, n—a coil in which the turns are

E 75 Test Methods for Chemical Analysis of Copper-Nickel

positioned into layers approximately parallel to the axis of the

and Copper-Nickel-Zinc Alloys

coil, but not necessarily with the fixed regularity of a level or

E 76 Test Method for Chemical Analysis of Nickel-Copper

traverse wound coil.

Alloys

3.1.5 length, n—straight pieces of the product.

E 112 Test Methods for Determining Average Grain Size

3.1.5.1 lengths, ends, n—straight pieces, shorter than the

E 118 Test Methods for Chemical Analysis of Copper-

nominal length, left over after cutting the product into mill

Chromium Alloys

lengths, stock lengths, or specific lengths. They are subject to

E 121 Test Methods for Chemical Analysis of Copper-

minimum length and maximum weight requirements.

Tellurium Alloys

3.1.5.2 lengths, mill, n—straight lengths, including ends,

E 255 Practice for Sampling Copper and Copper Alloys for

that can be conveniently manufactured in the mill. Full length

Determination of Chemical Composition

pieces are usually 10 or 12 ft [3000 or 3600 mm] and subject

E 290 Test Method for Semi-Guided Bend Test for Ductility

to established length tolerances.

of Metallic Materials

3.1.5.3 lengths, multiple, n—straight lengths of integral

E 478 Test Methods for Chemical Analysis of Copper

multiples of a base length, with suitable allowance for cutting

Alloys

when specified.

E 527 Practice for Numbering Metals and Alloys (UNS)

3.1.5.4 lengths, specific, n—straight lengths that are uni-

3. Terminology

form in length, as specified, and subject to established length

tolerances.

3.1 Definitions:

3.1.5.5 lengths, specific with ends, n—specific lengths, in-

3.1.1 bar, n—a solid rectangular section, or one with

cluding ends.

two-plane parallel surfaces and round or other simple regularly

3.1.5.6 lengths, stock, n—straight lengths that are mill cut

shaped finished edges, up to and including 12 in. [300 mm] in

and stored in advance of orders. They are usually 10 or 12 ft

width and over 0.188 in. [5 mm] in thickness furnished in

[3000 or 3600 mm] and subject to established length toler-

straight lengths or in rolls and with finished edges, either

ances.

rolled, drawn, or extruded.

3.1.2 bus conductor stock, n—a bar, rod, or shape of high 3.1.5.7 lengths, stock with ends, n—stock lengths, including

ends.

conductivity copper used to make electrical conductors.

3.1.2.1 bus bar, n—of solid or square cross-section or a 3.1.6 reel or spool, n—a cylindrical device that has a rim at

solid section with two plane parallel surfaces and round or each end and an axial hole for a shaft or spindle, and on which

other simple regular shaped edges. the product is wound to facilitate handling and shipping.

3.1.7 rod, n—a round, regular hexagonal, or regular octago-

nal solid section furnished in straight lengths (a regular

Annual Book of ASTM Standards, Vol 07.02.

Annual Book of ASTM Standards, Vol 03.01.

hexagonal or a regular octagonal rod is a solid section having

Annual Book of ASTM Standards, Vol 14.02.

equal sides and equal angles).

Annual Book of ASTM Standards, Vol 03.05.

3.1.7.1 rod, piston finish, n—a round rod having a special

Annual Book of ASTM Standards, Vol 03.06.

Annual Book of ASTM Standards, Vol 01.01. surface produced by turning or grinding to close tolerances for

B 249/B 249M

diameter and straightness. diameter of round sections or the distance between parallel

3.1.7.2 rod, shafting, n—a round rod specially manufac- surfaces in the case of other sections, except shapes, shall not

tured to the close straightness tolerances required for use in vary from that specified by more than the amounts specified in

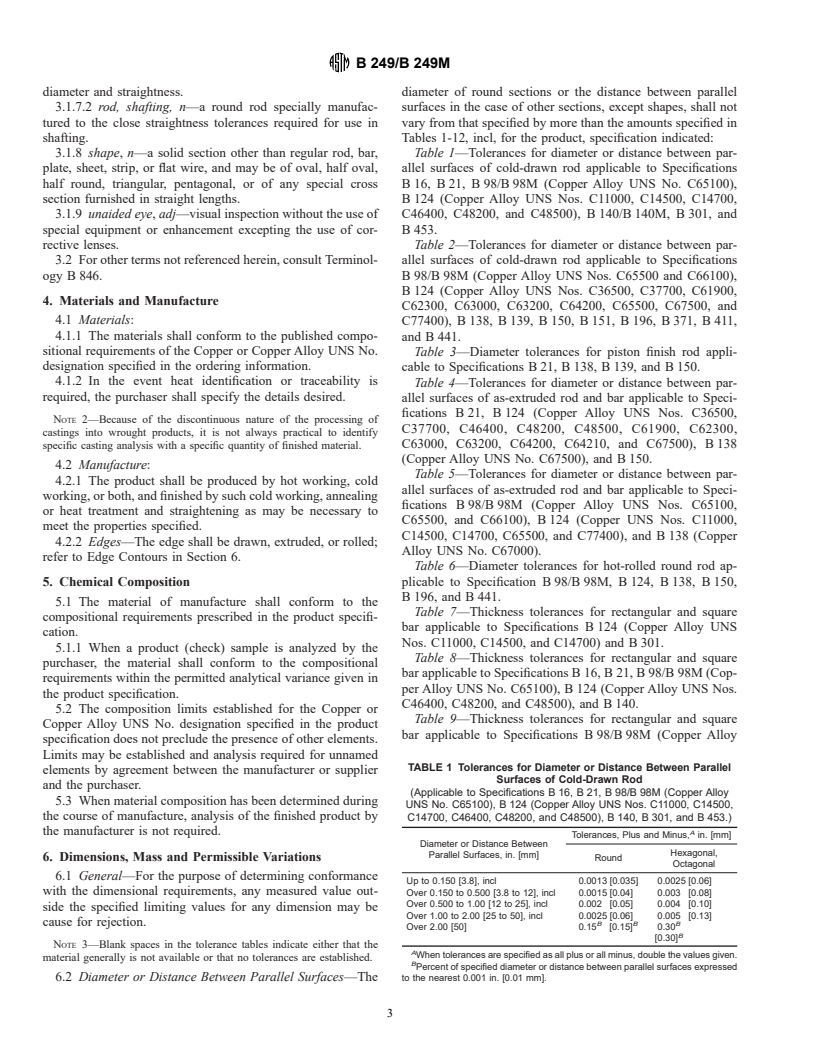

shafting. Tables 1-12, incl, for the product, specification indicated:

3.1.8 shape, n—a solid section other than regular rod, bar, Table 1—Tolerances for diameter or distance between par-

plate, sheet, strip, or flat wire, and may be of oval, half oval, allel surfaces of cold-drawn rod applicable to Specifications

half round, triangular, pentagonal, or of any special cross B 16, B 21, B 98/B 98M (Copper Alloy UNS No. C65100),

section furnished in straight lengths. B 124 (Copper Alloy UNS Nos. C11000, C14500, C14700,

3.1.9 unaided eye, adj—visual inspection without the use of C46400, C48200, and C48500), B 140/B 140M, B 301, and

special equipment or enhancement excepting the use of cor- B 453.

rective lenses. Table 2—Tolerances for diameter or distance between par-

3.2 For other terms not referenced herein, consult Terminol- allel surfaces of cold-drawn rod applicable to Specifications

ogy B 846. B 98/B 98M (Copper Alloy UNS Nos. C65500 and C66100),

B 124 (Copper Alloy UNS Nos. C36500, C37700, C61900,

4. Materials and Manufacture

C62300, C63000, C63200, C64200, C65500, C67500, and

4.1 Materials:

C77400), B 138, B 139, B 150, B 151, B 196, B 371, B 411,

4.1.1 The materials shall conform to the published compo-

and B 441.

sitional requirements of the Copper or Copper Alloy UNS No.

Table 3—Diameter tolerances for piston finish rod appli-

designation specified in the ordering information.

cable to Specifications B 21, B 138, B 139, and B 150.

4.1.2 In the event heat identification or traceability is Table 4—Tolerances for diameter or distance between par-

required, the purchaser shall specify the details desired.

allel surfaces of as-extruded rod and bar applicable to Speci-

fications B 21, B 124 (Copper Alloy UNS Nos. C36500,

NOTE 2—Because of the discontinuous nature of the processing of

C37700, C46400, C48200, C48500, C61900, C62300,

castings into wrought products, it is not always practical to identify

C63000, C63200, C64200, C64210, and C67500), B 138

specific casting analysis with a specific quantity of finished material.

(Copper Alloy UNS No. C67500), and B 150.

4.2 Manufacture:

Table 5—Tolerances for diameter or distance between par-

4.2.1 The product shall be produced by hot working, cold

allel surfaces of as-extruded rod and bar applicable to Speci-

working, or both, and finished by such cold working, annealing

fications B 98/B 98M (Copper Alloy UNS Nos. C65100,

or heat treatment and straightening as may be necessary to

C65500, and C66100), B 124 (Copper UNS Nos. C11000,

meet the properties specified.

C14500, C14700, C65500, and C77400), and B 138 (Copper

4.2.2 Edges—The edge shall be drawn, extruded, or rolled;

Alloy UNS No. C67000).

refer to Edge Contours in Section 6.

Table 6—Diameter tolerances for hot-rolled round rod ap-

5. Chemical Composition plicable to Specification B 98/B 98M, B 124, B 138, B 150,

B 196, and B 441.

5.1 The material of manufacture shall conform to the

Table 7—Thickness tolerances for rectangular and square

compositional requirements prescribed in the product specifi-

bar applicable to Specifications B 124 (Copper Alloy UNS

cation.

Nos. C11000, C14500, and C14700) and B 301.

5.1.1 When a product (check) sample is analyzed by the

Table 8—Thickness tolerances for rectangular and square

purchaser, the material shall conform to the compositional

bar applicable to Specifications B 16, B 21, B 98/B 98M (Cop-

requirements within the permitted analytical variance given in

per Alloy UNS No. C65100), B 124 (Copper Alloy UNS Nos.

the product specification.

C46400, C48200, and C48500), and B 140.

5.2 The composition limits established for the Copper or

Table 9—Thickness tolerances for rectangular and square

Copper Alloy UNS No. designation specified in the product

bar applicable to Specifications B 98/B 98M (Copper Alloy

specification does not preclude the presence of other elements.

Limits may be established and analysis required for unnamed

TABLE 1 Tolerances for Diameter or Distance Between Parallel

elements by agreement between the manufacturer or supplier

Surfaces of Cold-Drawn Rod

and the purchaser.

(Appli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.