ASTM C1019-09

(Test Method)Standard Test Method for Sampling and Testing Grout

Standard Test Method for Sampling and Testing Grout

SIGNIFICANCE AND USE

Grout used in masonry is a fluid mixture of cementitious materials and aggregate with a high water content for ease of placement.

During construction, grout is placed within or between absorptive masonry units. Excess water must be removed from grout specimens in order to provide compressive strength test results more nearly indicative of the grout strength in the wall. In this test method, molds are made from masonry units having the same absorption and moisture content characteristics as those being used in the construction.

This test method is used to either help select grout proportions by comparing test values or as a quality control test for uniformity of grout preparation during construction.

The physical exposure condition and curing of the grout are not exactly reproduced, but this test method does subject the grout specimens to absorption conditions similar to those experienced by grout in the wall.

Note 2—Test results of grout specimens taken from a wall should not be compared to test results obtained with this test method.

SCOPE

1.1 This test method covers procedures for both field and laboratory sampling and compression testing of grout used in masonry construction. Grout for masonry is specified under Specification C 476.

Note 1—The testing agency performing this test method should be evaluated in accordance with Practice C 1093.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1019 – 09

Standard Test Method for

1

Sampling and Testing Grout

This standard is issued under the fixed designation C1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* C1093 Practice for Accreditation of Testing Agencies for

Masonry

1.1 This test method covers procedures for both field and

C1611/C1611M Test Method for Slump Flow of Self-

laboratory sampling and compression testing of grout used in

Consolidating Concrete

masonry construction. Grout for masonry is specified under

Specification C476.

3. Significance and Use

NOTE 1—The testing agency performing this test method should be

3.1 Groutusedinmasonryisafluidmixtureofcementitious

evaluated in accordance with Practice C1093.

materials and aggregate with a high water content for ease of

1.2 The values stated in inch-pound units are to be regarded

placement.

as standard. The values given in parentheses are mathematical

3.1.1 Duringconstruction,groutisplacedwithinorbetween

conversions to SI units that are provided for information only

absorptive masonry units. Excess water must be removed from

and are not considered standard.

grout specimens in order to provide compressive strength test

1.3 This standard does not purport to address all of the

results more nearly indicative of the grout strength in the wall.

safety concerns, if any, associated with its use. It is the

In this test method, molds are made from masonry units having

responsibility of the user of this standard to establish appro-

the same absorption and moisture content characteristics as

priate safety and health practices and determine the applica-

those being used in the construction.

bility of regulatory limitations prior to use.

3.2 This test method is used to either help select grout

proportionsbycomparingtestvaluesorasaqualitycontroltest

2. Referenced Documents

for uniformity of grout preparation during construction.

2

2.1 ASTM Standards:

3.3 The physical exposure condition and curing of the grout

C39/C39M Test Method for Compressive Strength of Cy-

are not exactly reproduced, but this test method does subject

lindrical Concrete Specimens

the grout specimens to absorption conditions similar to those

C143/C143M Test Method for Slump of Hydraulic-Cement

experienced by grout in the wall.

Concrete

NOTE 2—Test results of grout specimens taken from a wall should not

C476 Specification for Grout for Masonry

be compared to test results obtained with this test method.

C511 Specification for Mixing Rooms, Moist Cabinets,

Moist Rooms, and Water Storage Tanks Used in the

4. Apparatus

Testing of Hydraulic Cements and Concretes

4.1 Maximum-Minimum Thermometer.

C617 Practice for Capping Cylindrical Concrete Specimens

4.2 Straightedge, a steel straightedge not less than 6 in.

C1064/C1064M Test Method for Temperature of Freshly

1

(152.4 mm) long and not less than ⁄16 in. (1.6 mm) in

Mixed Hydraulic-Cement Concrete

thickness.

4.3 Tamping Rod, a nonabsorbent rod, either round or

5

square in cross section nominally ⁄8 in. (15.9 mm) in dimen-

1

This test method is under the jurisdiction ofASTM Committee C12 on Mortars

sion with ends rounded to hemispherical tips of the same

and Grouts for Unit Masonry and is the direct responsibility of Subcommittee

diameter. The rod shall be a minimum length of 12 in. (304.8

C12.02 on Research and Methods of Test.

mm).

Current edition approved Jan. 1, 2009. Published February 2009. Originally

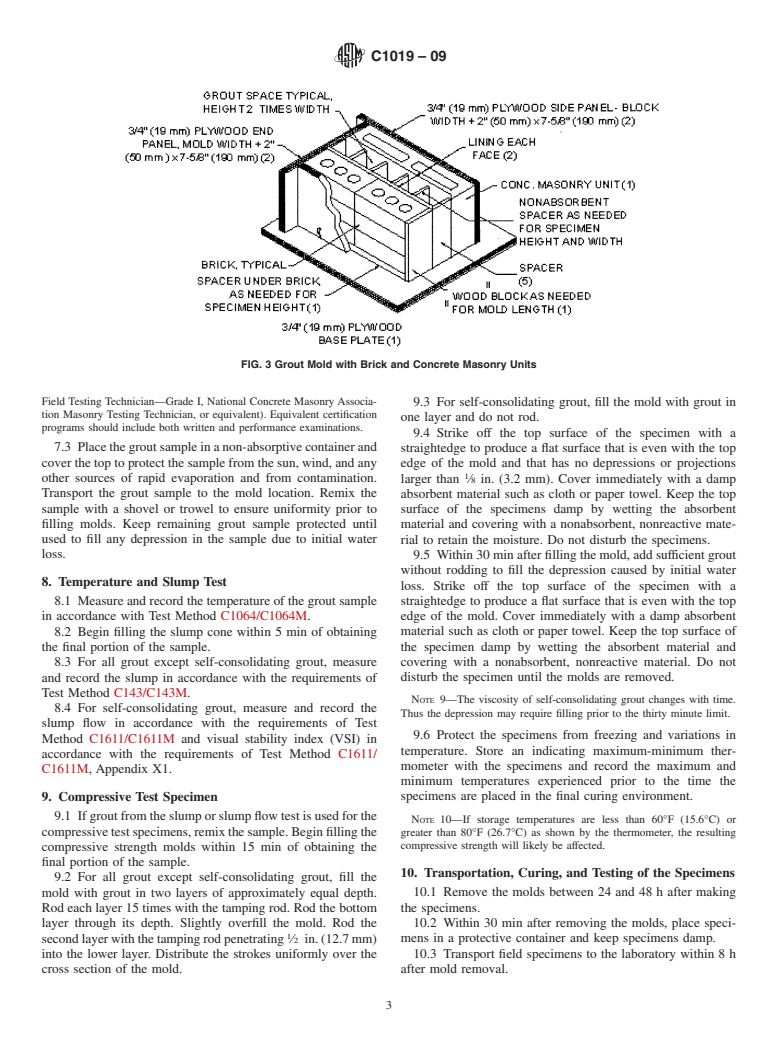

4.4 Nonabsorbent Blocks and Spacers, nonabsorbent, rigid

approved in 1984. Last previous edition approved in 2008 as C1019 – 08a. DOI:

10.1520/C1019-09.

squares and rectangles with side dimensions so as to achieve

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the desired grout specimen side dimensions and of sufficient

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

quantity or thickness to yield the desired grout specimen

Standards volume information, refer to the standard’s Document Summary page on

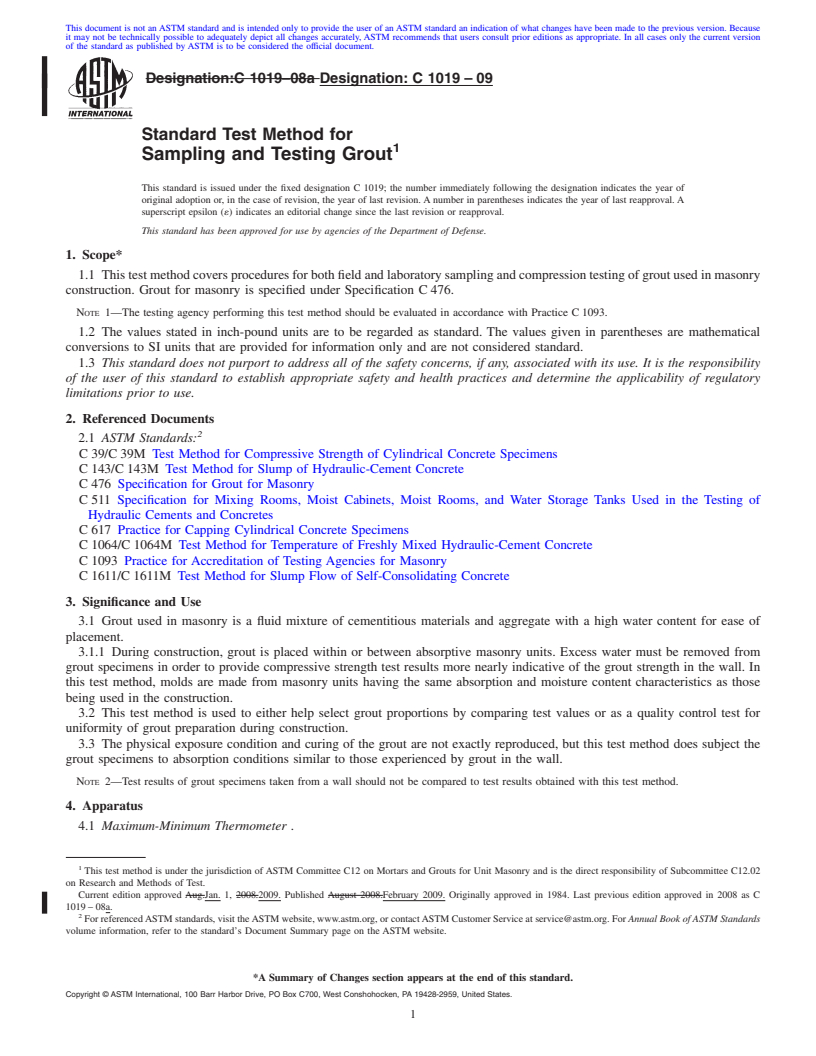

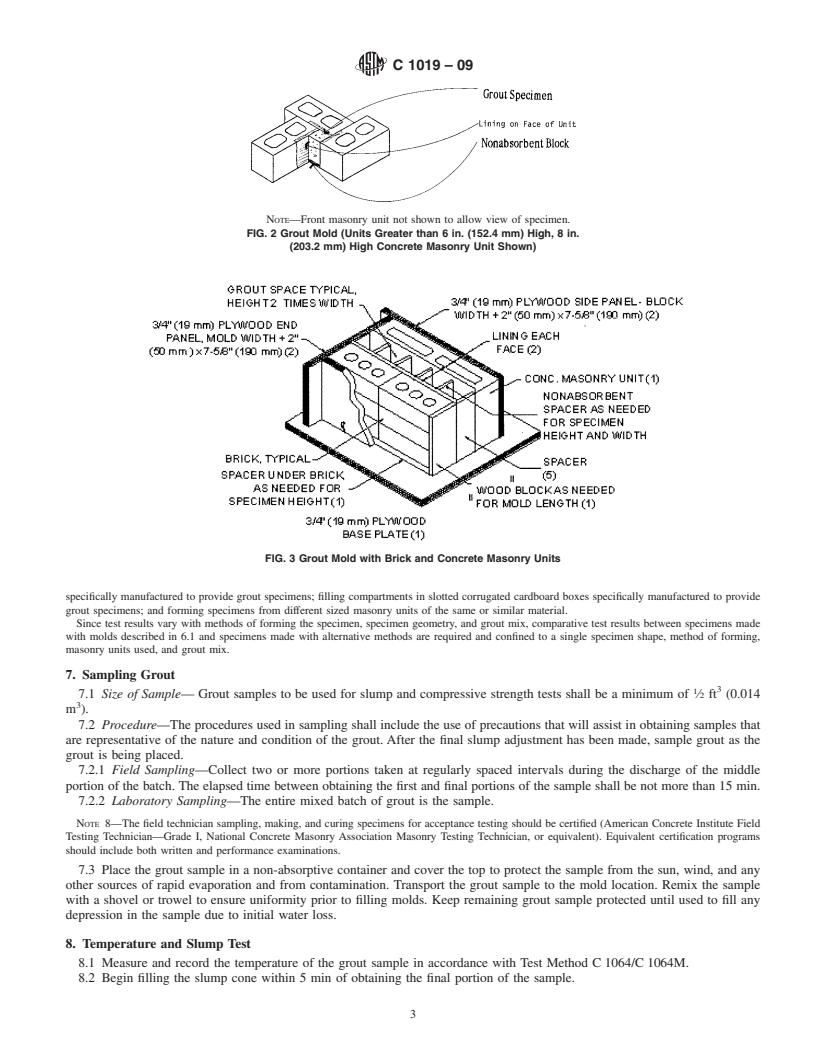

the ASTM website. height, as shown in Fig. 1, Fig. 2, and Fig. 3.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1019 – 09

stacking masonry units of the same type and moisture condi-

tion as those being used in the construction. The surface of the

unit in contact with the grout specimen shall not have been

previously used to mold speci

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C 1019–08a Designation: C 1019 – 09

Standard Test Method for

1

Sampling and Testing Grout

This standard is issued under the fixed designation C 1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thistestmethodcoversproceduresforbothfieldandlaboratorysamplingandcompressiontestingofgroutusedinmasonry

construction. Grout for masonry is specified under Specification C 476.

NOTE 1—The testing agency performing this test method should be evaluated in accordance with Practice C 1093.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 39/C 39M Test Method for Compressive Strength of Cylindrical Concrete Specimens

C 143/C 143M Test Method for Slump of Hydraulic-Cement Concrete

C 476 Specification for Grout for Masonry

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of

Hydraulic Cements and Concretes

C 617 Practice for Capping Cylindrical Concrete Specimens

C 1064/C 1064M Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete

C 1093 Practice for Accreditation of Testing Agencies for Masonry

C 1611/C 1611M Test Method for Slump Flow of Self-Consolidating Concrete

3. Significance and Use

3.1 Grout used in masonry is a fluid mixture of cementitious materials and aggregate with a high water content for ease of

placement.

3.1.1 During construction, grout is placed within or between absorptive masonry units. Excess water must be removed from

grout specimens in order to provide compressive strength test results more nearly indicative of the grout strength in the wall. In

this test method, molds are made from masonry units having the same absorption and moisture content characteristics as those

being used in the construction.

3.2 This test method is used to either help select grout proportions by comparing test values or as a quality control test for

uniformity of grout preparation during construction.

3.3 The physical exposure condition and curing of the grout are not exactly reproduced, but this test method does subject the

grout specimens to absorption conditions similar to those experienced by grout in the wall.

NOTE 2—Test results of grout specimens taken from a wall should not be compared to test results obtained with this test method.

4. Apparatus

4.1 Maximum-Minimum Thermometer .

1

This test method is under the jurisdiction of ASTM Committee C12 on Mortars and Grouts for Unit Masonry and is the direct responsibility of Subcommittee C12.02

on Research and Methods of Test.

Current edition approved Aug.Jan. 1, 2008.2009. Published August 2008.February 2009. Originally approved in 1984. Last previous edition approved in 2008 as C

1019 – 08a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 1019 – 09

1

4.2 Straightedge, a steel straightedge not less than 6 in. (152.4 mm) long and not less than ⁄16 in. (1.6 mm) in thickness.

5

4.3 TampingRod,anonabsorbentrod,eitherroundorsquareincrosssectionnominally ⁄8in.(15.9mm)indimensionwithends

rounded to hemispherical tips of the same diameter. The rod shall be a minimum length of 12 in. (304.8 mm).

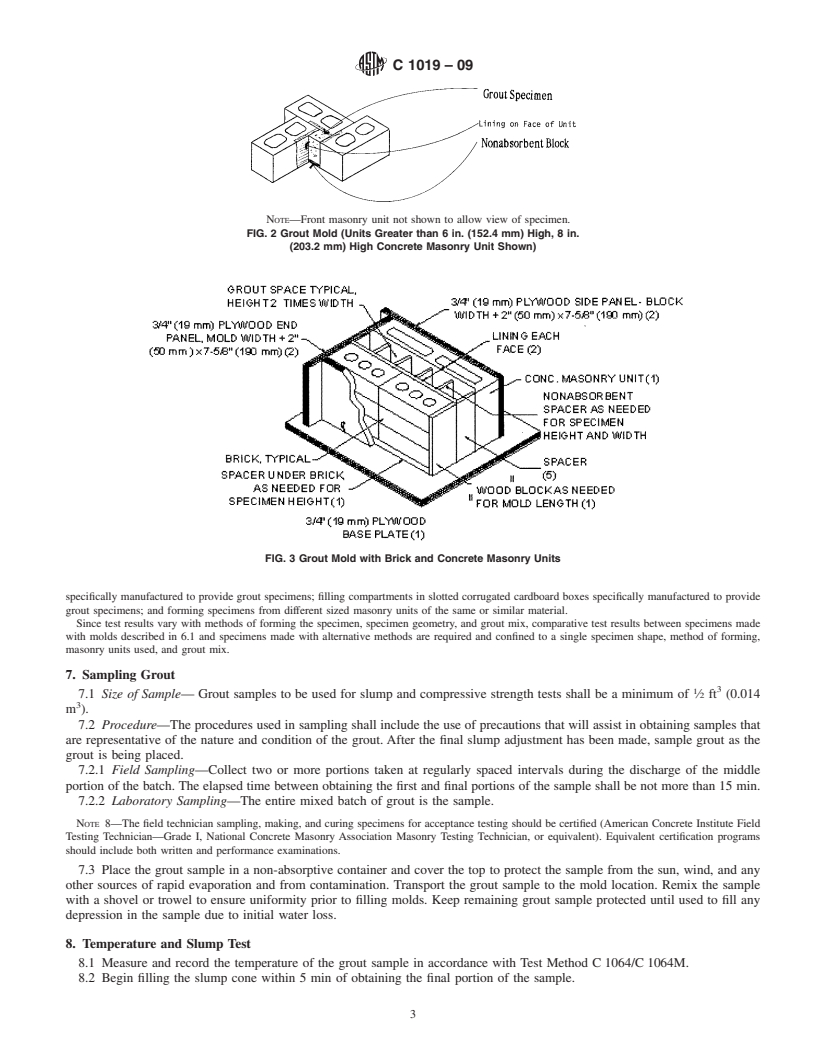

4.4 Nonabsorbent Blocks and Spacers , nonabsorbent, rigid squares and rectangles with side dimensions so as to achieve the

desired grout specimen side dimensions and of sufficient quantity or thickness to y

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C 1019–08a Designation: C 1019 – 09

Standard Test Method for

1

Sampling and Testing Grout

This standard is issued under the fixed designation C 1019; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thistestmethodcoversproceduresforbothfieldandlaboratorysamplingandcompressiontestingofgroutusedinmasonry

construction. Grout for masonry is specified under Specification C 476.

NOTE 1—The testing agency performing this test method should be evaluated in accordance with Practice C 1093.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C 39/C 39M Test Method for Compressive Strength of Cylindrical Concrete Specimens

C 143/C 143M Test Method for Slump of Hydraulic-Cement Concrete

C 476 Specification for Grout for Masonry

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of

Hydraulic Cements and Concretes

C 617 Practice for Capping Cylindrical Concrete Specimens

C 1064/C 1064M Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete

C 1093 Practice for Accreditation of Testing Agencies for Masonry

C 1611/C 1611M Test Method for Slump Flow of Self-Consolidating Concrete

3. Significance and Use

3.1 Grout used in masonry is a fluid mixture of cementitious materials and aggregate with a high water content for ease of

placement.

3.1.1 During construction, grout is placed within or between absorptive masonry units. Excess water must be removed from

grout specimens in order to provide compressive strength test results more nearly indicative of the grout strength in the wall. In

this test method, molds are made from masonry units having the same absorption and moisture content characteristics as those

being used in the construction.

3.2 This test method is used to either help select grout proportions by comparing test values or as a quality control test for

uniformity of grout preparation during construction.

3.3 The physical exposure condition and curing of the grout are not exactly reproduced, but this test method does subject the

grout specimens to absorption conditions similar to those experienced by grout in the wall.

NOTE 2—Test results of grout specimens taken from a wall should not be compared to test results obtained with this test method.

4. Apparatus

4.1 Maximum-Minimum Thermometer .

1

This test method is under the jurisdiction of ASTM Committee C12 on Mortars and Grouts for Unit Masonry and is the direct responsibility of Subcommittee C12.02

on Research and Methods of Test.

Current edition approved Aug.Jan. 1, 2008.2009. Published August 2008.February 2009. Originally approved in 1984. Last previous edition approved in 2008 as C

1019 – 08a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 1019 – 09

1

4.2 Straightedge, a steel straightedge not less than 6 in. (152.4 mm) long and not less than ⁄16 in. (1.6 mm) in thickness.

5

4.3 TampingRod,anonabsorbentrod,eitherroundorsquareincrosssectionnominally ⁄8in.(15.9mm)indimensionwithends

rounded to hemispherical tips of the same diameter. The rod shall be a minimum length of 12 in. (304.8 mm).

4.4 Nonabsorbent Blocks and Spacers , nonabsorbent, rigid squares and rectangles with side dimensions so as to achieve the

desired grout specimen side dimensions and of sufficient quantity or thickness to y

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.