ASTM D6416/D6416M-01

(Test Method)Standard Test Method for Two-Dimensional Flexural Properties of Simply Supported Sandwich Composite Plates Subjected to a Distributed Load

Standard Test Method for Two-Dimensional Flexural Properties of Simply Supported Sandwich Composite Plates Subjected to a Distributed Load

SCOPE

1.1 This test method determines the two-dimensional flexural properties of sandwich composite plates subjected to a distributed load. The test fixture uses a relatively large square panel sample which is simply supported all around and has the distributed load provided by a water-filled bladder. This type of loading differs from the procedure of Test Method C393, where concentrated loads induce one-dimensional, simple bending in beam specimens.

1.2 This test method is applicable to composite structures of the sandwich type which involve a relatively thick layer of core material bonded on both faces with an adhesive to thin-face sheets composed of a denser, higher-modulus material, typically, a polymer matrix reinforced with high-modulus fibers.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: D 6416/D 6416M – 01

Standard Test Method for

Two-Dimensional Flexural Properties of Simply Supported

Sandwich Composite Plates Subjected to a Distributed

1

Load

This standard is issued under the fixed designation D 6416/D 6416M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 393 TestMethodforFlexuralPropertiesofFlatSandwich

2

Constructions

1.1 This test method determines the two-dimensional flex-

D 792 TestMethodsforDensityandSpecificGravity(Rela-

ural properties of sandwich composite plates subjected to a

3

tive Density) and Density of Plastics by Displacement

distributed load. The test fixture uses a relatively large square

D 2584 Test Method for Ignition Loss of Cured Reinforced

panel sample which is simply supported all around and has the

4

Resins

distributedloadprovidedbyawater-filledbladder.Thistypeof

D 2734 Test Method for Void Content of Reinforced Plas-

loading differs from the procedure of Test Method C 393,

4

tics

where concentrated loads induce one-dimensional, simple

D 3171 Test Method for Constituent Content of Composite

bending in beam specimens.

2

Materials

1.2 This test method is applicable to composite structures of

D 3878 Terminology for High-Modulus Reinforcing Fibers

thesandwichtypewhichinvolvearelativelythicklayerofcore

2

and Their Composites

material bonded on both faces with an adhesive to thin-face

5

E4 Practices for Force Verification of Testing Machines

sheets composed of a denser, higher-modulus material, typi-

E6 Terminology Relating to Methods of Mechanical Test-

cally, a polymer matrix reinforced with high-modulus fibers.

5

ing

1.3 The values stated in either SI units or inch-pound units

E 251 Test Methods for Performance Characteristics of

are to be regarded separately as standard. Within the text the

5

Metallic Bonded Resistance Strain Gages

inch-pound units are shown in brackets. The values stated in

E 1237 Guide for Installing Bonded Resistance Strain

each system are not exact equivalents; therefore, each system

5

Gages

must be used independently of the other. Combining values

2.2 ASTM Adjunct:

from the two systems may result in nonconformance with the

Sandwich Plate Test Fixture and Hydromat Pressure Blad-

standard.

6

der, ASTM D 6416/D 6416M

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Terminology D 3878 defines terms relating to high-

priate safety and health practices and determine the applica-

modulus fibers and their composites. Terminology C 274

bility of regulatory limitations prior to use.

defines terms relating to structural sandwich constructions.

2. Referenced Documents TerminologyE6 defines terms relating to mechanical testing.

In the event of a conflict between terms, Terminology D 3878

2.1 ASTM Standards:

2

shall have precedence over the other terminology standards.

C 274 Terminology of Structural Sandwich Constructions

3.2 Definitions of Terms Specific to This Standard:

C 365 Test Methods for Flatwise Compressive Strength of

2

Sandwich Cores

3

Annual Book of ASTM Standards, Vol 08.01.

1 4

This test method is under the jurisdiction of ASTM Committee D30 on Annual Book of ASTM Standards, Vol 08.02.

5

Composite Materials and is the direct responsibility of Subcommittee D30.09 on Annual Book of ASTM Standards, Vol 03.01.

6

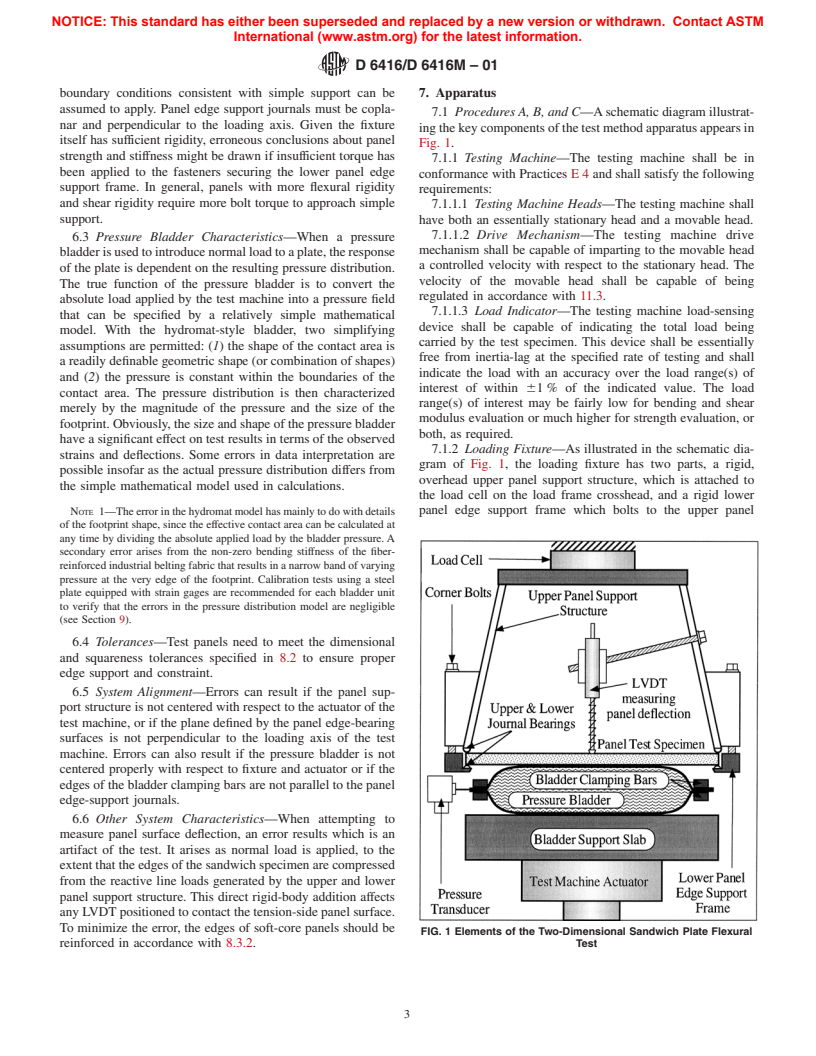

Sandwich Construction. Detailed drawings for the fabrication of the 500–mm test fixture and pressure

Current edition approved March 10, 2001. Published May 2001. bladder shown in Fig. 3 and Fig. 4 are available from ASTM Headquarters. Order

2

Annual Book of ASTM Standards, Vol 15.03. Adjunct No. ADJD6416.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D 6416/D 6416M – 01

3.2.1 bending stiffness, n—the sandwich property which moving the platens of the test frame. The test measures the

resists bending deflections. two-dimensional flexural response of a sandwich composite

3.2.2 core, n—a centrally located layer of a sandwich plate in terms of deflections and strains when subjected to a

construction, usually low density, which separates and stabi- well-defined distributed load.

lizes the facings and transmits shear between the facings and 4.2 Panel deflection at load is monitored by a cent

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.