ASTM D720-91(2004)e1

(Test Method)Standard Test Method for Free-Swelling Index of Coal

Standard Test Method for Free-Swelling Index of Coal

SIGNIFICANCE AND USE

This test method, in addition to indicating the caking properties of a coal when burned as a fuel, can be used to give a broad indication of the degree of oxidation of a coal.

SCOPE

1.1 This test method is a small-scale test for obtaining information regarding the free-swelling properties of a coal. The results may be used as an indication of the caking characteristic of the coal when burned as a fuel. This test is not recommended as a method for the determination of expansion of coals in coke ovens.

1.2 Breathing of asbestos dust is hazardous. Asbestos and asbestos products present demonstrated health risks for users and for those with whom they come into contact. In addition to other precautions, when working with asbestos-cement products, minimize the dust that results. For information on the safe use of chrysoltile asbestos, refer to, Safe Use of Chrysotile Asbestos: A Manual on Preventive and Control Measures.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation: D720 – 91 (Reapproved 2004)

Standard Test Method for

Free-Swelling Index of Coal

This standard is issued under the fixed designation D720; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Section 1.2 was editorially inserted in March 2005.

1. Scope 2. Referenced Documents

2 4

1.1 This test method is a small-scale test for obtaining 2.1 ASTM Standards:

information regarding the free-swelling properties of a coal. D2013 Practice for Preparing Coal Samples for Analysis

The results may be used as an indication of the caking

3. Significance and Use

characteristic of the coal when burned as a fuel.This test is not

recommended as a method for the determination of expansion 3.1 This test method, in addition to indicating the caking

properties of a coal when burned as a fuel, can be used to give

of coals in coke ovens.

1.2 Warning—Breathing of asbestos dust is hazardous. a broad indication of the degree of oxidation of a coal.

Asbestos and asbestos products present demonstrated health

4. Apparatus

risksforusersandforthosewithwhomtheycomeintocontact.

4.1 This test method can be made with either electric or gas

In addition to other precautions, when working with asbestos-

heating. When using electric heating, the results obtained must

cement products, minimize the dust that results. For informa-

be the same as those obtained when using the gas heating

tion on the safe use of chrysoltile asbestos, refer to, Safe Use

method. The apparatus common to both electric and gas

of Chrysotile Asbestos: A Manual on Preventive and Control

methods shall consist of the following:

Measures.

4.1.1 Crucible, translucent silica, low-form, with a flat,

1.3 The values stated in SI units are to be regarded as the

close-fitting silica ring-handle lid and an extra pierced lid for

standard. The values given in parentheses are for information

use in determining the crucible temperature, conforming to the

only.

following requirements:

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the Weight, g 11.0 to 12.75

External height, mm 26 6 0.5

responsibility of the user of this standard to establish appro-

External diameter at top, mm 41 6 0.75

priate safety and health practices and determine the applica-

Internal diameter at base, min, mm 11

bility of regulatory limitations prior to use. Capacity (approximate), cm 17

4.1.2 Sight Tube, as shown in Fig. 1, for viewing the coke

buttons so that the effect of parallax will be eliminated. Make

This test method is under the jurisdiction of ASTM Committee D05 on Coal

and Coke and is the direct responsibility of Subcommittee D05.15 on Metallurgical

the tube of any rigid and preferably opaque material and

Properties of Coal and Coke.

support vertically on a ring stand.

Current edition approved April 1, 2004. Published May 2004. Originally

4.1.3 Thermocouple and Potentiometer.

approved in 1943. Last previous edition approved in 1999 as D720 – 91 (1999).

4.1.4 Weight, 500 g.

DOI: 10.1520/D0720-91R04E01.

This test method is an adaptation of the Crucible Swelling Test for Coal of the

4.2 The electric apparatus shall consist of the following:

British Standards Institution. For information concerning the experimental work on

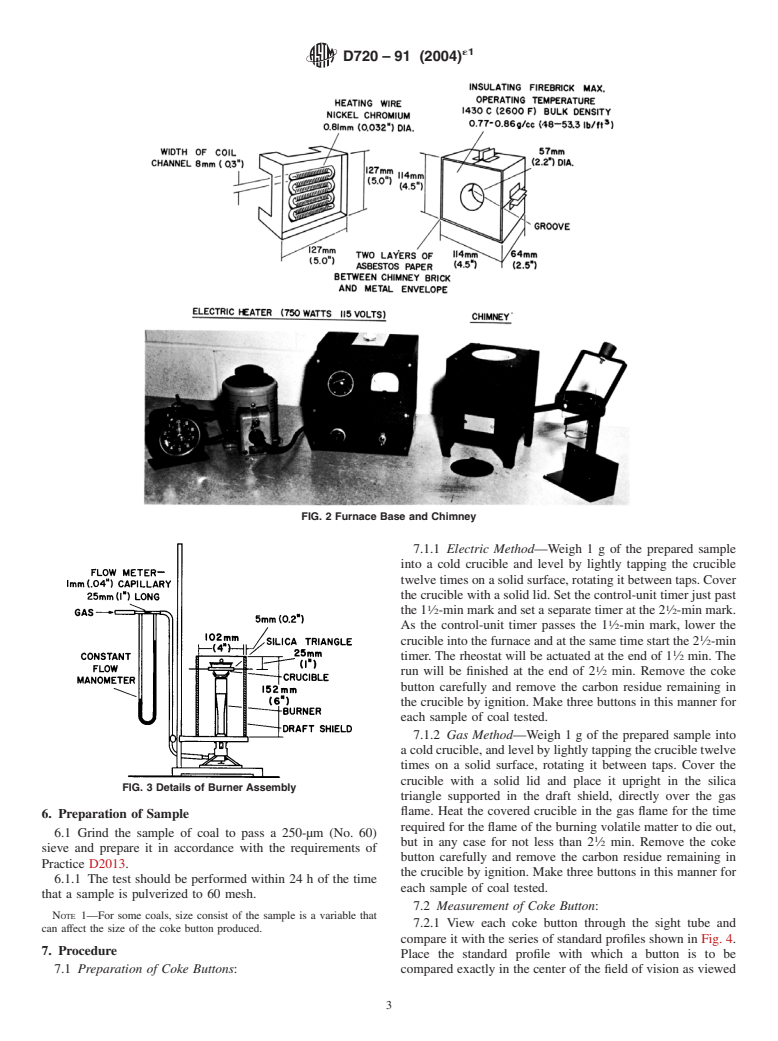

4.2.1 Furnace, consisting of a base, a heating element, and

which this adaptation is based, see paper by Ostborg, H. N., Limbacker, H. R., and

a chimney. The unit is shown in Fig. 2.

Sherman, R.A., “An Experimental Investigation of the British Standard Method for

the Crucible Swelling Test for Coal,” Proceedings,Am. Soc. Testing Mats., Vol 42,

1042, p. 851. See also a paper by Selvig, W.A., and Ode, W. H., “An Investigation

of a Laboratory Test for Determination of the Free-Swelling Index of Coal,” U.S. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Bureau of Mines Report of Investigation 4238, Revision of R. I. 3989, 1948. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ChrysotileInstitute1200,McGillCollegeSuite1640Montreal,QuebecCanada Standards volume information, refer to the standard’s Document Summary page on

H3B 4G7 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D720 – 91 (2004)

distance between the base of the crucible and the top of the

burner grid may be adjusted by raising or lowering the draft

shield. Make the triangular crucible support from three pieces

of translucent silica tubing each 63 mm (2.5 in.) in length, 6 to

6.5 mm (0.24 to 0.26 in.) in external diameter, and mounted on

chromium-nickel wire so that the diameter of the inscribed

circle is approximately 32 mm (1.26 in.). The twisted ends of

the triangle may be joined together by a loop of wire to

facilitate removal of the hot crucible.

4.3.2 Flowmeter—A capillary flowmeter with water ma-

nometer placed in the gas line before the burner as a guide to

the control of the rate of gas flow (Fig. 3).

5. Calibration

5.1 Electric Furnace:

5.1.1 Turn the main power switch on and set the timer to the

HOLD position. Adjust the variable transformer so that the

FIG. 1 Sight Tube

ammeter reads 5.8 A. Allow at least 45 min for the furnace

temperature to reach equilibrium.

1 1

5.1.2 Set the timer just beyond the 1 ⁄2-min mark. At 1 ⁄2

4.2.1.1 Chimney—Fig. 2 shows the chimney design. Make

min, lower an empty crucible with pierced lid into the furnace.

the unit from firebrick and coat with firebrick bonding mortar.

Measure the temperature at the inside base of the crucible with

Maintain the chimney under compression by a sheet-metal

a thermocouple and a potentiometer. The unprotected junction

envelope (Fig. 2) to prevent cracking. Make the envelope in

of the thermocouple must be in contact with the inside base of

four pieces, each piece covering a corner. The pieces shall

thecrucible.Attheendof1 ⁄2min,thetemperatureshouldread

overlap at the center of the flat faces and be held together by

800 6 10°C (1472 6 18°F).Adjust the variable transformer as

bolts and springs. Place two layers of asbestos paper between

necessary to provide this temperature.

the chimney brick and the envelope. Cut two grooves in the

5.1.3 A temperature of 820 6 5°C (1508 6 9°F) must be

upper inside chimney walls to accommodate the crucible

support. In cases in which the furnace is located in a drafty attained at the end of 2 ⁄2 min. The second timer shall be used

here. The control unit rheostat must be properly adjusted to

area, it is advisable to shield the chimney to prevent large

fluctuations in furnace temperature. reduce the heating rate at the end of 2 ⁄2 min. If the rheostat is

set initially so that at the end of 1 ⁄2 min the ammeter reading

4.2.2 Crucible Support—A convenient crucible support

is reduced by 0.6 or 0.7A, the specified temperature at the end

consists of a cradle support made from nickel-chromium wire

of 2 ⁄2 min should be attained. Several trials will no doubt be

suspended from a metal ring. The height of the support inside

1 1

necessary before the proper temperatures at 1 ⁄2 and 2 ⁄2 min

the furnace can be adjusted by loosening the two screws that

are reached; however, the information given above provides a

hold the wire legs of the support in place.

general guide for calibration. The silica crucible and cover

4.2.3 Electric Controls, consisting of a rheostat, an a-c

must be at room temperature before each calibration run.

ammeter, and two timers. These components shall conform to

the following specifications: 5.1.4 After each calibration attempt or sample run, switch

the timer to the HOLD position, and allow about 1 min for the

Ammeter a-c, 0 to 10-A range

Rheostat 100 W, 10 V

furnace to reach equilibrium.

Variable transformer 7.4 A, 120 V

5.2 Gas Burner:

Timer mechanical, 0–5 min minimum span, with a hold

position, and electrical contact closed during 5.2.1 With the burner assembly arranged as shown in Fig. 3,

timing cycle

and with an empty crucible in position, light the burner about

15 min before making a determination to allow the draft shield

4.2.3.1 One timer shall actuate the rheostat, at a predeter-

mined setting, after 1 ⁄2 min of operation. Preset the rheostat to to rise to an equilibrium temperature.

reduce the rate of heating of the furnace so that a temperature 5.2.2 After placing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.