ASTM C115-96a(2003)

(Test Method)Standard Test Method for Fineness of Portland Cement by the Turbidimeter

Standard Test Method for Fineness of Portland Cement by the Turbidimeter

SIGNIFICANCE AND USE

The purpose of this test method is to determine whether or not the hydraulic cement under test meets the Wagner turbidimetric fineness requirements of the applicable hydraulic cement specification for which the test is being made. Fineness of the cement component is only one of the many characteristics that influence the strength capabilities of concrete.

SCOPE

1.1 This test method covers determination of the fineness of portland cement as represented by a calculated measure of specific surface, expressed as square centimetres of total surface area per gram, or square metres of total surface area per kilogram, of cement, using the Wagner turbidimeter.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in SI units are to regarded as the standard. The inch-pound equivalents may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C115 – 96a (Reapproved 2003)

Standard Test Method for

Fineness of Portland Cement by the Turbidimeter

This standard is issued under the fixed designation C115; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of the cement component is only one of the many character-

istics that influence the strength capabilities of concrete.

1.1 This test method covers determination of the fineness of

portland cement as represented by a calculated measure of

4. Apparatus

specific surface, expressed as square centimetres of total

4.1 Nature of Apparatus—TheWagnerturbidimeterconsists

surfaceareapergram,orsquaremetresoftotalsurfaceareaper

2 essentially of a source of light maintained at constant intensity

kilogram, of cement, using the Wagner turbidimeter.

and adjusted so that approximately parallel rays of light pass

1.2 This standard does not purport to address all of the

through a suspension of the cement to be tested and impinge

safety concerns, if any, associated with its use. It is the

upon the sensitive plate of a photoelectric cell. The current

responsibility of the user of this standard to establish appro-

generated in the cell is measured by means of a microammeter

priate safety and health practices and determine the applica-

and the indicated reading is a measure of the turbidity of the

bility of regulatory limitations prior to use.

suspension. General considerations indicate that turbidity is in

1.3 The values stated in SI units are to regarded as the

turn a measure of the surface area of the suspended sample of

standard. The inch-pound equivalents may be approximate.

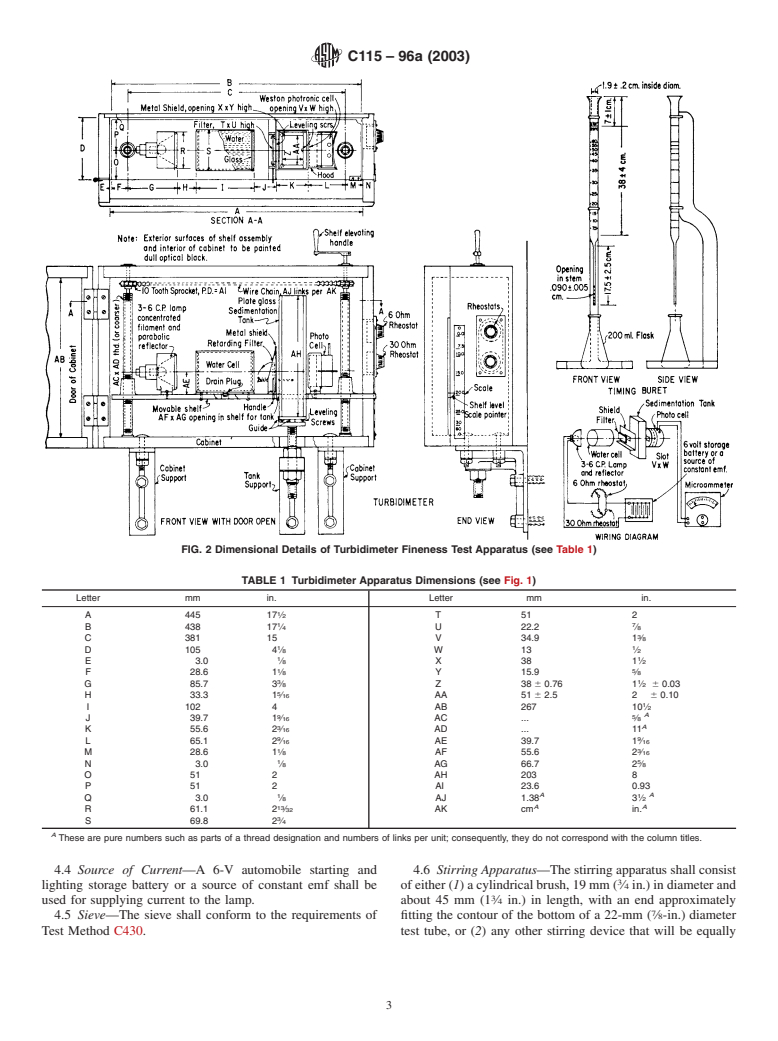

cement. The apparatus shall consist specifically of the parts

2. Referenced Documents described in 4.2-4.7 and shall be constructed in accordance

with the detailed design and dimensional requirements shown

2.1 ASTM Standards:

in Fig. 1 and Table 1, except that the case may be either of

C114 Test Methods for Chemical Analysis of Hydraulic

wood or of metal.

Cement

4.2 Turbidimeter, mounted in a suitable wood or metal case

C430 TestMethodforFinenessofHydraulicCementbythe

including the following features:

45-µm (No. 325) Sieve

4.2.1 Source of Light—The source of light (Fig. 1) shall

C670 Practice for Preparing Precision and Bias Statements

consist of a concentrated-filament electric lamp of between 3

for Test Methods for Construction Materials

and 6 cd operated by a source of constant emf. The lamp shall

3. Significance and Use be mounted rigidly in the socket. A clean, bright parabolic

metallic reflector shall be rigidly mounted behind the lamp,

3.1 The purpose of this test method is to determine whether

focused so that approximately parallel rays of light will pass

or not the hydraulic cement under test meets the Wagner

through the sedimentation tank and impinge upon the photo-

turbidimetric fineness requirements of the applicable hydraulic

electric cell. The light intensity shall be regulated by two

cementspecificationforwhichthetestisbeingmade.Fineness

rheostats of approximately 6 and 30 V, respectively, and they

shall possess such characteristics that uniform changes in light

ThistestmethodisunderthejurisdictionofASTMCommitteeC01onCement intensitymaybeobtainedoverthefullrangeofresistance.The

and is the direct responsibility of Subcommittee C01.25 on Fineness.

rheostats shall be mounted in parallel with each other and in

Current edition approved July 10, 2003. Published September 2003. Originally

series with the lamp.

approved in 1934. Last previous edition approved in 1996 as C115–96a. DOI:

4.2.2 Heat-Absorbing Device—The light shall pass through

10.1520/C0115-96AR03.

This turbidimeter was developed by L. A. Wagner, Research Associate of the

a suitable heat absorbing device before entering the sedimen-

Cement Reference Laboratory, National Institute of Standards and Technology,

tation tank in order that radiant heat from the beam shall be

Washington, DC. A description of the apparatus and the original mathematical

absorbed, the device being either (1) a water cell or (2)a

derivationsofformulasusedaregiveninthepaper:Wagner,L.A.,“ARapidMethod

specialheat-absorbingglassfilter.Thewatercellshallbemade

for the Determination of the Specific Surface of Portland Cement,” Proceedings,

ASTM, ASTEA, Vol 33, Part II, 1933, p. 553.

from 76-mm (3-in.) outside diameter seamless brass tubing,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3-mm ( ⁄8-in.) thick wall, 102-mm (4 in.) in length with glass

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

windows sealed in the ends. The cell shall contain a hole for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. filling with distilled water. The hole shall be sealed with a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C115 – 96a (2003)

4.2.6 Shield—Ametallicshieldhavingaslot16mm( ⁄8in.)

in height by 38 mm (1 ⁄2 in.) in width, as indicated in Fig. 1,

shall be placed between the heat absorbing device and the

sedimentation tank.

4.2.7 Elevating Device—The source of the light, the heat-

absorbingdevice,thephotoelectriccell,theretardingfilter,and

the shield shall be mounted on a movable shelf which may be

raised or lowered by two connected lead screws, and which

Microammeter Internal Resistance = 90 V

Shunt Equivalent Resistance:

may be readily and accurately adjusted so that the turbidity of

470 3 100

470 V in parallel with 100V5 5 82 V

the suspension may be determined at any desired depth. The

470 1 100

Meter & Shunt Equivalent + Resistance:

center of the light source, the heat absorbing device, the

90 3 82

90 V in parallel with 82V5 5 43 V

photocell, the center of the slots of the metal shield, and the

90 1 82

Series Resistance = 90 − 43 = 47 V

hood shall be on a straight line which is parallel to the shelf.

FIG. 1 Illustrated Example of D’Arsonval Meter Circuit for I

r

The sedimentation tank shall be mounted on a base which is

Determination

independentoftherestoftheapparatussothatthetankshallbe

free from vibration caused by moving the shelf. Care shall be

taken that the shelf shall be level at all points of elevation and

metalplug.Thecell,whenmountedonthemovableshelf,may

thatthetankshallbenormaltotheshelf.Thedistancebetween

have the plug in either the top or bottom position. The

thetankandtheedgesoftheopeningintheshelfshallvarynot

heat-absorbing device shall be so arranged that essentially all

more than ⁄64 in. (0.4 mm) between the “30–50” and “0”

rays of light entering the sedimentation tank shall first pass

positions. The level of the light beam with reference to the

through the heat-absorbing device.

surface of the suspension shall be indicated by a pointer which

4.2.3 Retarding Filter—A light-retarding glass or other

will travel along a scale mounted on the cabinet. The zero of

device shall be provided that will reduce the intensity of light

thescaleshallindicatethatpositionatwhichthecenterlinesof

fromthatcorrespondingto100µAtoareadingof20to30µA.

the slots for the light beam are at the same elevation as the

The light intensity shall be uniformly retarded over the entire

surface of the liquid in the tank when filled to the 335-mL

area of that portion of the cell which is exposed to light during

level. The lines on the scale to be marked 7.5, 10, 15, 20, 25,

a test. The retarding filter shall be mounted in a carrier on the

and 30–50, shall be located at distances from the zero mark

shieldandshallbecapableofbeingswungoutofthelightpath

equaltosuspensiondepthvalues, h,inTable2.Thescale,when

by means of a handle.

comparedwithastandardscaleaccuratetowithin0.1mmatall

4.2.4 Sedimentation Tank—The sedimentation tank shall be

points,shallnotshowadeviationatanypointgreaterthan0.25

3 1

either(1)constructedof5to6-mm( ⁄16to ⁄4-in.)plateglassor

mmandshallindicatethepositionsatwhichthepointershould

borosilicate glass cemented or sealed together to form a

be located when turbidity readings for these values of h are

rectangular tank, or (2) a molded glass tank having walls

taken. The interior of the turbidimeter cabinet and the exterior

approximately 5-mm ( ⁄16 in.) thick with plane surfaces. The

surfaces of the shelf, the parabolic reflector, the heat absorbing

insidedimensionsoftherectangulartankshallbe51mmby38

device, the shield, and the photoelectric cell hood shall be

mm by 203 mm (2 in. by 1 ⁄2 in. by 8 in.) in height. The

painted with a dull flat black paint.

permissiblevariationontheinsidedimensionsofthetankshall

be 62.5 mm (0.1 in.) in length and 60.76 mm (0.03 in.) in NOTE 1—The requirement of the 0 to 50 markings on the scale shall

apply only to new Wagner Turbidimeters and not to equipment in use

width.The 51-mm faces of the tank shall be equidistant within

which meets the other requirements of this method.

0.25 mm (0.1 in.) at all points. A mark shall be placed on the

side of the tank to indicate a volumetric content of 335 mL,

4.3 Microammeters:

which is the level to which the tank will be filled in a test. A

4.3.1 D’Arsonval-Type Microammeters shall have a range

tank filled to the mark with clear kerosine and placed in the

from 0 to 50 µA and shall be readable to 0.1 µA. New

turbidimeter light beam shall yield uniform microammeter

microammeters shall be accurate to 60.5% of full scale value

readings, within 60.1 µA, for the entire usable portion of the

at any part of the scale value at any part of the scale at 77°F

tank.

(25°C). For microammeters, in use, the accuracy shall be the

4.2.5 Photoelectric Cell—Themeansofmeasuringthelight

sameasfornewinstrumentsexceptthattheaccuracyat40and

intensity shall be a sensitive photoelectric cell connected

50µAshallbe 61%offullscale.Theinternalresistanceofthe

directly to a microammeter. A hood with a horizontal slot 13

microammeter shall be between 50 and 150 V . The microam-

1 3

mm ( ⁄2 in.) in height by 35 mm (1 ⁄8 in.) in width shall be

meter shall not be mounted upon a working surface containing

mountedoverthephotoelectriccell.Thefrontofthehoodshall

or consisting of iron or steel, or near other magnetic influence.

be 25 61mm(1 6 ⁄16 in.) in front of the face of the cell.The

4.3.2 Digital Microammeter:

face of the photocell shall be parallel to the tank faces within

0.5 mm (0.02 in.).

NOTE 2—A meter with a range of 199.9 µA is satisfactory for use and

enables the operator to read the theoretical I directly without supplemen-

tarydevices.Thehighinternalresistanceofthedigitalmicroammeterdoes

not affect the linearity of readings at the light intensity levels encountered

Weston Photronic type, Model 594YY is acceptable. in a Wagner turbidimetric determination of fineness.

C115 – 96a (2003)

FIG. 2 Dimensional Details of Turbidimeter Fineness Test Apparatus (see Table 1)

TABLE 1 Turbidimeter Apparatus Dimensions (see Fig. 1)

Letter mm in. Letter mm in.

A 445 17 ⁄2 T51 2

1 7

B 438 17 ⁄4 U 22.2 ⁄8

C 381 15 V 34.9 1 ⁄8

1 1

D 105 4 ⁄8 W13 ⁄2

1 1

E3.0 ⁄8 X38 1 ⁄2

1 5

F 28.6 1 ⁄8 Y 15.9 ⁄8

3 1

G 85.7 3 ⁄8 Z38 6 0.76 1 ⁄2 6 0.03

H 33.3 1 ⁄16 AA 51 6 2.5 2 6 0.10

I 102 4 AB 267 10 ⁄2

A

9 5

J 39.7 1 ⁄16 AC . ⁄8

A

K 55.6 2 ⁄16 AD . 11

9 9

L 65.1 2 ⁄16 AE 39.7 1 ⁄16

1 3

M 28.6 1 ⁄8 AF 55.6 2 ⁄16

1 5

N3.0 ⁄8 AG 66.7 2 ⁄8

O 51 2 AH 203 8

P 51 2 AI 23.6 0.93

A A

1 1

Q3.0 ⁄8 AJ 1.38 3 ⁄2

13 A A

R 61.1 2 ⁄32 AK cm in.

S 69.8 2 ⁄4

A

These are pure numbers such as parts of a thread designation and numbers of links per unit; consequently, they do not correspond with the column titles.

4.4 Source of Current—A 6-V automobile starting and 4.6 Stirring Apparatus—The stirring apparatus shall consist

lighting storage battery or a source of constant emf shall be ofeither(1)acylindricalbrush,19mm( ⁄4in.)indiameterand

used for supplying current to the lamp. about 45 mm (1 ⁄4 in.) in length, with an end approximately

4.5 Sieve—The sieve shall conform to the requirements of fitting the contour of the bottom of a 22-mm ( ⁄8-in.) diameter

Test Method C430. test tube, or (2) any other stirring device that will be equally

C115 – 96a (2003)

TABLE 2 Values of h, d, and h/d to be Used in Calibration of the

7.1.1.1 For calibration of the buret scale use a kerosine

Turbidimeter Apparatus

having a known viscosity and density for the temperature at

Particle Depth of h/d

which the calibration is to be made. Density and viscosity of

Diameter, d,µm Suspension, h,cm

the kerosine should be determined. Calculate the times of flow

50 15 0.00600

from the buret that correspond to the times of settling for the

45 15 0.00741

different sized particles, from the following equation:

40 15 0.00938

35 15 0.01224

t 5[1,837,000h/~r 2r !# 3 ~h/d ! (1)

1 2

30 15 0.01667

25 13.1 0.0210

where:

20 10 0.0250

15 6.6 0.0293

t = time of settling, or time of flow, s,

10 3.3 0.0330

h = viscosity of kerosine at the temperature of calibra-

7.5 2.1 0.0373

tion, P,

3 3

r = density of cement particles, Mg/m (g/cm )=3.15 for

portland cement (Note 4),

efficient in dispersion as measured by specific surface deter-

r = density of kerosine, Mg/m at the temperature of

minations on a standard sample. The stirring apparatus shall

calibration,

rotate at a speed of approximately 3500 r/min.

h = depth of suspension to level of light, cm, and

4.7 Timing Buret—The time of settling for the different-

d = diameter of particle, µm.

sized particles shall be obtained by use of a buret from which

Values of h/d are given in Table 2.

kerosine is allowed to flow. The buret shall consist of a glass

7.1.1.2 Fill the buret with kerosine at the calibrating tem-

tube having a capillary tube fused into the lower end. The

perature, start a timing clock at the instant the kerosine in the

upper end of the large tube shall be flared to serve as a funnel

buret drains past the zero line, and mark on the buret the levels

for introducing kerosine into the tube.The buret shall conform

reached by the draining kerosine for each of the time intervals,

to the limiting dimensions given in Table 3. The graduation

t, calculated as described above. At these marks, etch perma-

linesontheburetshallbecompletecircles.AfiltermadeofNo.

nent lines and numbers on the buret indicating the correspond-

325 (45-µm) wire cloth shall be used with the timing buret and

ing diameters (Note 5).The construction and the graduation of

a cover shall be placed over the top of the buret when it is not

theburetshallbesuchthata

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.