ASTM B845-97(2013)e1

(Guide)Standard Guide for Mixed Flowing Gas (MFG) Tests for Electrical Contacts

Standard Guide for Mixed Flowing Gas (MFG) Tests for Electrical Contacts

SIGNIFICANCE AND USE

4.1 Preservation of a conducting surface on electrical contact is vital to the continued functioning of such contacts. Contamination of the surface with insulating layers formed by corrosion processes is one potential hazard. Laboratory testing of contacts in MFG tests is used to assess the effectiveness of design features and materials.

4.2 MFG tests are used in development studies of processes and materials for contacts. For example, coupon specimens may be exposed to MFG tests to evaluate new contact materials, layers of new coating materials on a supporting substrate, reduced coating thicknesses, or protective surface treatments.

4.3 MFG tests are also employed to test the durability of a finished product with respect to atmospheric corrosion. For example, finished connectors may be exposed to a MFG test and their performances compared against each other or against a set of fixed requirements. Relays or switch contacts may be exposed in the operated and non-operated conditions to compare performance.

4.4 MFG tests are useful for determining the effectiveness of connector housings and shrouds as barriers to ingress of atmospheric corrodants to the contact surfaces. These tests can also be used to assess the screening of the metal-to-metal contact areas of mated connectors.

4.5 MFG tests are employed as qualification tests to determine connector failure rates in application environments for which correlation between test and application has previously been established.

4.6 This guide provides test conditions which are to be applied in conjunction with Practice B827 which defines the required test operation and certification procedures, tolerances, and reporting requirements. Where the test specifier requires certifications or tolerances different than those provided in Practice B827, the required certifications or tolerances shall be part of the test specification. Differences from the specifications in Practice B827 shall be reported in the test re...

SCOPE

1.1 The techniques described in this guide pertain to mixed flowing gas (MFG) tests containing species that are applied to evaluate devices containing electrical contacts such as slip rings, separable connectors, electromechanical relays or switch contacts. These techniques may be relevant to other devices, but it is the responsibility of the user to determine suitability prior to testing.

1.2 The MFG tests described in this guide are designed to accelerate corrosive degradation processes. These accelerations are designed such that the degradation occurs in a much shorter time period than that expected for such processes in the intended application environment of the device being tested. Application environments can vary continuously from benign to aggressively corrosive. Connectors and contacts within closed electronic cabinets may be affected by an environment of different severity than the environment on the outside of such cabinets. In general, indoor environments are different than outdoor environments. The MFG tests described herein, being discrete embodiments of specific corrosive conditions, cannot be representative of all possible application environments. It is the responsibility of the test specifier to assure the pertinence of a given test condition to the specifier's application condition.

1.3 The MFG tests described herein are not designed to duplicate the actual intended application environment of the device under test. An extended bibliography that provides information which is useful to test specifiers to assist them in selecting appropriate test methods is included in this guide. The bibliography covers the scope from application condition characterization, single and multiple gas effects, and material and product effects to key application and test variables as well as discussions of atmospheric corrosion processes.

1.4 The values stated in SI units are to be regarded as standard. No other uni...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: B845 − 97 (Reapproved 2013)

Standard Guide for

Mixed Flowing Gas (MFG) Tests for Electrical Contacts

This standard is issued under the fixed designation B845; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Footnote 3 was corrected editorially in October 2014.

1. Scope 1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 The techniques described in this guide pertain to mixed

standard.

flowing gas (MFG) tests containing species that are applied to

1.5 This standard does not purport to address all of the

evaluate devices containing electrical contacts such as slip

safety concerns, if any, associated with its use. It is the

rings, separable connectors, electromechanical relays or switch

responsibility of the user of this standard to become familiar

contacts. These techniques may be relevant to other devices,

with all hazards including those identified in the appropriate

but it is the responsibility of the user to determine suitability

Material Safety Data Sheet (MSDS) for this product/material

prior to testing.

as provided by the manufacturer, to establish appropriate

1.2 The MFG tests described in this guide are designed to safety and health practices, and determine the applicability of

accelerate corrosive degradation processes. These accelera- regulatory limitations prior to use.

tions are designed such that the degradation occurs in a much

2. Referenced Documents

shorter time period than that expected for such processes in the

intended application environment of the device being tested.

2.1 ASTM Standards:

Application environments can vary continuously from benign B542 Terminology Relating to Electrical Contacts and Their

to aggressively corrosive. Connectors and contacts within Use

B808 TestMethodforMonitoringofAtmosphericCorrosion

closed electronic cabinets may be affected by an environment

of different severity than the environment on the outside of Chambers by Quartz Crystal Microbalances

B810 Test Method for Calibration ofAtmospheric Corrosion

such cabinets. In general, indoor environments are different

Test Chambers by Change in Mass of Copper Coupons

than outdoor environments. The MFG tests described herein,

B825 Test Method for Coulometric Reduction of Surface

being discrete embodiments of specific corrosive conditions,

Films on Metallic Test Samples

cannot be representative of all possible application environ-

B826 Test Method for Monitoring Atmospheric Corrosion

ments. It is the responsibility of the test specifier to assure the

Tests by Electrical Resistance Probes

pertinence of a given test condition to the specifier’s applica-

B827 Practice for Conducting Mixed Flowing Gas (MFG)

tion condition.

Environmental Tests

1.3 The MFG tests described herein are not designed to

2.2 Other Documents:

duplicate the actual intended application environment of the

EIA-364B-TP65 Mixed Industrial Gas Test Procedure

device under test. An extended bibliography that provides

IEC Standard 68-2–42 Basic Environmental Testing

information which is useful to test specifiers to assist them in

Procedures,TestK SulphurDioxideTestforContactsand

c

selecting appropriate test methods is included in this guide.

Connections

The bibliography covers the scope from application condition

IEC Standard 68-2–43 Basic Environmental Testing

characterization, single and multiple gas effects, and material

Procedures, Test K Hydrogen Sulfide Test for Contacts

d

and product effects to key application and test variables as well

and Connections

as discussions of atmospheric corrosion processes.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This guide is under the jurisdiction of ASTM Committee B02 on Nonferrous Standards volume information, refer to the standard’s Document Summary page on

Metals and Alloys and is the direct responsibility of Subcommittee B02.11 on the ASTM website.

Electrical Contact Test Methods. Available from IHS, 15 Inverness Way East, Englewood, CO 80112, http://

Current edition approved Aug. 1, 2013. Published August 2013. Originally www.global.ihs.com.

ε2 4

approved in 1993. Last previous edition approved in 2008 as B845 – 97 (2008) . Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/B0845-97R13E01. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

B845 − 97 (2013)

IEC Technical Trend Document 68-2–60 TTD Environmen- part of the test specification. Differences from the specifica-

tal Testing, Corrosion Tests in Artificial Atmosphere at tions in Practice B827 shall be reported in the test report

Very Low Concentration of Polluting Gas(es) provided by the test operator to the test specifier. Specification

IEC 68-2–60 (second edition) Environmental Testing—Part of one of the test conditions defined in this document in the

2: Tests—test Ke: Flowing mixed gas corrosion test, 1995 form of a statement such as, “Parts shall be tested in accor-

IEEE P1156.1 Environmental Specifications for Computer dance with ASTM B845 Method Z.”, implicitly requires test

Modules (Draft 4 June 10, 1992—unapproved) condition, Z, applied according to Practice B827.

3. Terminology

5. Procedure

3.1 Terms relevant to this guide are defined in Terminology

5.1 Decide upon a test plan appropriate for the contacts

B542 except as noted in the following section.

being evaluated. Consider test parameters such as

preconditioning, performance measurement and other evalua-

3.2 Other term:

tion techniques, and experimental controls.

3.2.1 mixed flowing gas test, n—a laboratory test conducted

in air that flows through a test chamber in which the

5.2 Select a MFG test and exposure length appropriate for

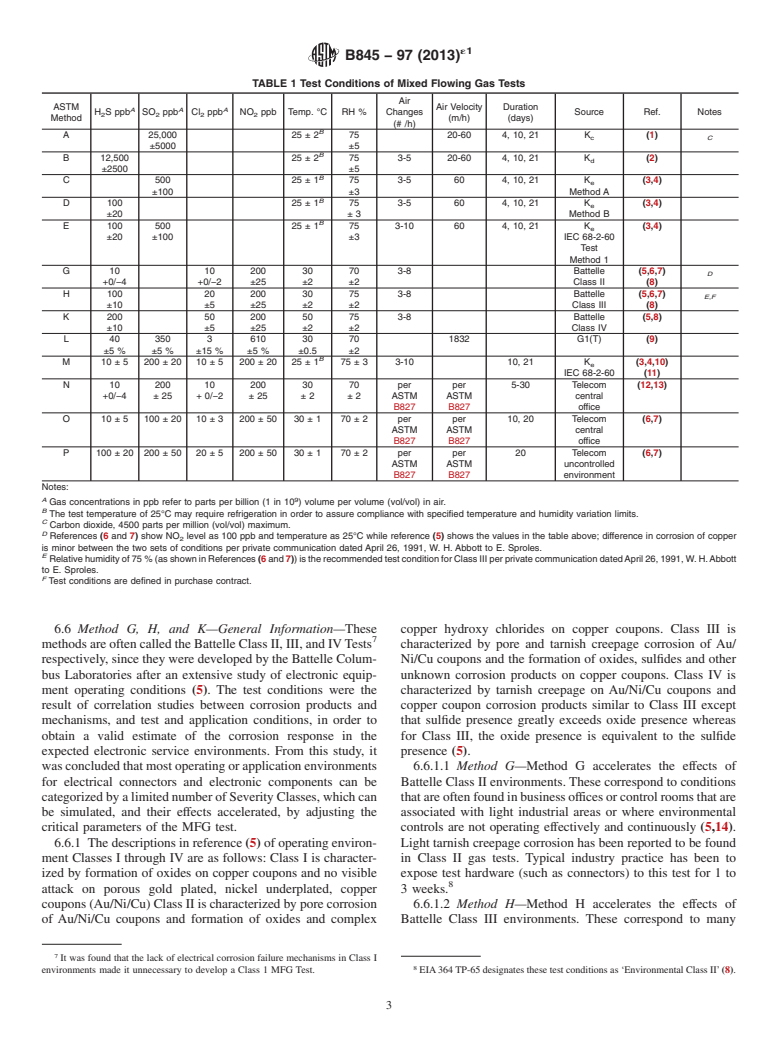

temperature, relative humidity, concentrations of gaseous the parts being evaluated. Table 1 lists a number of such tests

pollutants, and other critical variables are carefully defined,

that have been documented in the technical literature.The next

monitored and controlled. section provides brief discussions of the origins and intended

purpose of each of the methods.

4. Significance and Use

6. Abstracts of Methods

4.1 Preservation of a conducting surface on electrical con-

tact is vital to the continued functioning of such contacts.

6.1 Method A—Method A was originally developed as a

Contamination of the surface with insulating layers formed by

highly accelerated test to stress equipment that might be

corrosion processes is one potential hazard. Laboratory testing

exposed to environments with high levels of air pollution from

of contacts in MFG tests is used to assess the effectiveness of

combustion of high sulfur coal (1). The method is included in

design features and materials.

this list for completeness. It is generally not considered

realistic for evaluation of electronic equipment for the vast

4.2 MFG tests are used in development studies of processes

majority of applications. Typical exposure time is 4, 10 or 21

and materials for contacts. For example, coupon specimens

days, depending upon the specification for the product under

may be exposed to MFG tests to evaluate new contact

test.

materials, layers of new coating materials on a supporting

substrate, reduced coating thicknesses, or protective surface

6.2 Method B—Method B was originally developed as a

treatments.

European standard, and has largely been replaced by methods

with lower levels of sulfur bearing gases (2). The method is

4.3 MFG tests are also employed to test the durability of a

included in this list for completeness. It is generally not

finished product with respect to atmospheric corrosion. For

considered realistic for evaluation of electronic equipment for

example, finished connectors may be exposed to a MFG test

thevastmajorityofapplications.Typicalexposuretimeis4,10

and their performances compared against each other or against

or 21 days, depending upon the specification for the product

a set of fixed requirements. Relays or switch contacts may be

under test.

exposed in the operated and non-operated conditions to com-

pare performance.

6.3 Method C—Method C was developed in Europe as an

alternative to Method A in response to requests for a less

4.4 MFG tests are useful for determining the effectiveness

aggressive test that would simulate exposures in less aggres-

of connector housings and shrouds as barriers to ingress of

sive environments (3,4). Method C may simulate the majority

atmospheric corrodants to the contact surfaces. These tests can

of usage environments better than MethodA.Typical exposure

also be used to assess the screening of the metal-to-metal

time is 4, 10 or 21 days depending upon the specification for

contact areas of mated connectors.

the product under test.

4.5 MFG tests are employed as qualification tests to deter-

6.4 Method D—Method D was developed in Europe as an

mine connector failure rates in application environments for

alternative to Method B for the same reasons cited in the above

which correlation between test and application has previously

discussion of Method C (3,4).Typical exposure time is 4, 10 or

been established.

21 days, depending upon the specification for the product

4.6 This guide provides test conditions which are to be

under test.

applied in conjunction with Practice B827 which defines the

6.5 MethodE—MethodEwasdevelopedinEuropeasafirst

required test operation and certification procedures, tolerances,

step toward a test containing more than one pollutant gas (3,4).

and reporting requirements. Where the test specifier requires

Typical exposure time is 4, 10 or 21 days depending upon the

certifications or tolerances different than those provided in

specification for the product under test.

Practice B827, the required certifications or tolerances shall be

5 6

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), The boldface numbers in parentheses refer to a list of references at the end of

445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org. this guide.

´1

B845 − 97 (2013)

TABLE 1 Test Conditions of Mixed Flowing Gas Tests

Air

ASTM Air Velocity Duration

A A A

H S ppb SO ppb Cl ppb NO ppb Temp. °C RH % Changes Source Ref. Notes

2 2 2 2

Method (m/h) (days)

(# /h)

B

A 25,000 25±2 75 20-60 4, 10, 21 K (1)

c C

±5000 ±5

B

B 12,500 25±2 75 3-5 20-60 4, 10, 21 K (2)

d

±2500 ±5

B

C 500 25±1 75 3-5 60 4, 10, 21 K (3,4)

e

±100 ±3 Method A

B

D 100 25±1 75 3-5 60 4, 10, 21 K (3,4)

e

±20 ±3 Method B

B

E 100 500 25±1 75 3-10 60 4, 10, 21 K (3,4)

e

±20 ±100 ±3 IEC 68-2-60

Test

Method 1

G10 10 200 30 70 3-8 Battelle (5,6,7)

D

+0/−4 +0/−2 ±25 ±2 ±2 Class II (8)

H 100 20 200 30 75 3-8 Battelle (5,6,7)

E,F

±10 ±5 ±25 ±2 ±2 Class III (8)

K 200 50 200 50 75 3-8 Battelle (5,8)

±10 ±5 ±25 ±2 ±2 Class IV

L40 350 3 610 30 70 1832 G1(T) (9)

±5 % ±5 % ±15 % ±5 % ±0.5 ±2

B

M 10±5 200±20 10±5 200±20 25±1 75 ± 3 3-10 10, 21 K (3,4,10)

e

IEC 68-2-60 (11)

N10 200 10 200 30 70 per per 5-30 Telecom (12,13)

+0/−4 ±25 + 0/−2 ±25 ±2 ±2 ASTM ASTM central

B827 B827 office

O 10±5 100±20 10±3 200±50 30±1 70±2 per per 10, 20 Telecom (6,7)

ASTM ASTM central

B827 B827 office

P 100±20 200±50 20±5 200±50 30±1 70±2 per per 20 Telecom (6,7)

ASTM ASTM uncontrolled

B827 B827 environment

Notes:

A 9

Gas concentrations in ppb refer to parts per billion (1 in 10 ) volume per volume (vol/vol) in air.

B

The test temperature of 25°C may require refrigeration in order to assure compliance with specified temperature and humidity variation limits.

C

Carbon dioxide, 4500 parts per million (vol/vol) maximum.

D

References (6 and 7) show NO level as 100 ppb and temperature as 25°C while reference (5) shows the values in the table above; difference in corrosion of copper

is minor between the two sets of conditions per private communication dated April 26, 1991, W. H. Abbott to E. Sproles.

E

Relative humidity of 75 % (as shown in References (6 and 7)) is the recommended test condition for Class III per private communication dated April 26, 1991, W. H. Abbott

to E. Sproles.

F

Test conditions are defined in purchase contract.

6.6 Method G, H, and K—General Information—These copper hydroxy chlorides on copper coupons. Class III is

methodsareoftencalledtheBattelleClassII,III,andIVTests characterized by pore and tarnish creepage corrosion of Au/

respectively, since they were developed by the Battelle Colum- Ni/Cu coupons and the formation of oxides, sulfides and other

bus Laboratories after an extensive study of electronic equip- unknown corrosion products on copper coupons. Class IV is

ment operating conditions (5). The test conditions were the characterized by tarnish creepage on Au/Ni/Cu coupons and

result of correlation studies between corrosion products and copper coupon corrosion products similar to Class III except

mechanisms, and test and application conditions, in order to that sulfide presence greatly exceeds oxide presence whereas

obtain a valid estimate of the corrosion response in the for Class III, the oxide presence is equivalent to the sulfide

expected electronic service environments. From this study, it presence (5).

wasconcludedthatmostoperatingorapplicationenvironments 6.6.1.1 Method G—Method G accelerates the effects of

for electrical connectors and electronic components can be Battelle Class II environments. These correspond to conditions

categorizedbyalimitednumberofSeverityClasses,whichcan thatareoftenfoundinbusinessofficesorcontrolroomsthatare

be simulated, and their effects accelerated, by adjusting the associated with light industrial areas or where environmental

critical parameters of the MFG test. controls are not operating effectively and continuously (5,14).

6.6.1 The descriptions in reference (5) of operating environ- Light tarnish creepage corrosion has been reported to be found

ment Classes I through IV are as follows: Class I is character- in Class II gas tests. Typical industry practice has been to

ized by formation of oxides on copper coupons and no visible expose test hardware (such as connectors) to this test for 1 to

attack on porous gold plated, nickel underplated, copper 3 weeks.

coupons(Au/Ni/Cu)ClassIIischaracterizedbyporecorrosion 6.6.1.2 Method H—Method H accelerates the effects of

of Au/Ni/Cu coupons and formation of oxides and complex Battelle Class III environm

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B845 − 97 (Reapproved 2013) B845 − 97 (Reapproved 2013)

Standard Guide for

Mixed Flowing Gas (MFG) Tests for Electrical Contacts

This standard is issued under the fixed designation B845; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Footnote 3 was corrected editorially in October 2014.

1. Scope

1.1 The techniques described in this guide pertain to mixed flowing gas (MFG) tests containing species that are applied to

evaluate devices containing electrical contacts such as slip rings, separable connectors, electromechanical relays or switch contacts.

These techniques may be relevant to other devices, but it is the responsibility of the user to determine suitability prior to testing.

1.2 The MFG tests described in this guide are designed to accelerate corrosive degradation processes. These accelerations are

designed such that the degradation occurs in a much shorter time period than that expected for such processes in the intended

application environment of the device being tested. Application environments can vary continuously from benign to aggressively

corrosive. Connectors and contacts within closed electronic cabinets may be affected by an environment of different severity than

the environment on the outside of such cabinets. In general, indoor environments are different than outdoor environments. The

MFG tests described herein, being discrete embodiments of specific corrosive conditions, cannot be representative of all possible

application environments. It is the responsibility of the test specifier to assure the pertinence of a given test condition to the

specifier’s application condition.

1.3 The MFG tests described herein are not designed to duplicate the actual intended application environment of the device

under test. An extended bibliography that provides information which is useful to test specifiers to assist them in selecting

appropriate test methods is included in this guide. The bibliography covers the scope from application condition characterization,

single and multiple gas effects, and material and product effects to key application and test variables as well as discussions of

atmospheric corrosion processes.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B542 Terminology Relating to Electrical Contacts and Their Use

B808 Test Method for Monitoring of Atmospheric Corrosion Chambers by Quartz Crystal Microbalances

B810 Test Method for Calibration of Atmospheric Corrosion Test Chambers by Change in Mass of Copper Coupons

B825 Test Method for Coulometric Reduction of Surface Films on Metallic Test Samples

B826 Test Method for Monitoring Atmospheric Corrosion Tests by Electrical Resistance Probes

B827 Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

This guide is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.11 on Electrical

Contact Test Methods.

ε2

Current edition approved Aug. 1, 2013. Published August 2013. Originally approved in 1993. Last previous edition approved in 2008 as B845 – 97 (2008) . DOI:

10.1520/B0845-97R13.10.1520/B0845-97R13E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

B845 − 97 (2013)

2.2 Other Documents:

EIA-364B-TP65 Mixed Industrial Gas Test Procedure

IEC Standard 68-2–42 Basic Environmental Testing Procedures, Test K Sulphur Dioxide Test for Contacts and Connections

c

IEC Standard 68-2–43 Basic Environmental Testing Procedures, Test K Hydrogen Sulfide Test for Contacts and Connections

d

IEC Technical Trend Document 68-2–60 TTD Environmental Testing, Corrosion Tests in Artificial Atmosphere at Very Low

Concentration of Polluting Gas(es)

IEC 68-2–60 (second edition) Environmental Testing—Part 2: Tests—test Ke: Flowing mixed gas corrosion test, 1995

IEEE P1156.1 Environmental Specifications for Computer Modules (Draft 4 June 10, 1992—unapproved)

3. Terminology

3.1 Terms relevant to this guide are defined in Terminology B542 except as noted in the following section.

3.2 Other term:

3.2.1 mixed flowing gas test, n—a laboratory test conducted in air that flows through a test chamber in which the temperature,

relative humidity, concentrations of gaseous pollutants, and other critical variables are carefully defined, monitored and controlled.

4. Significance and Use

4.1 Preservation of a conducting surface on electrical contact is vital to the continued functioning of such contacts.

Contamination of the surface with insulating layers formed by corrosion processes is one potential hazard. Laboratory testing of

contacts in MFG tests is used to assess the effectiveness of design features and materials.

4.2 MFG tests are used in development studies of processes and materials for contacts. For example, coupon specimens may

be exposed to MFG tests to evaluate new contact materials, layers of new coating materials on a supporting substrate, reduced

coating thicknesses, or protective surface treatments.

4.3 MFG tests are also employed to test the durability of a finished product with respect to atmospheric corrosion. For example,

finished connectors may be exposed to a MFG test and their performances compared against each other or against a set of fixed

requirements. Relays or switch contacts may be exposed in the operated and non-operated conditions to compare performance.

4.4 MFG tests are useful for determining the effectiveness of connector housings and shrouds as barriers to ingress of

atmospheric corrodants to the contact surfaces. These tests can also be used to assess the screening of the metal-to-metal contact

areas of mated connectors.

4.5 MFG tests are employed as qualification tests to determine connector failure rates in application environments for which

correlation between test and application has previously been established.

4.6 This guide provides test conditions which are to be applied in conjunction with Practice B827 which defines the required

test operation and certification procedures, tolerances, and reporting requirements. Where the test specifier requires certifications

or tolerances different than those provided in Practice B827, the required certifications or tolerances shall be part of the test

specification. Differences from the specifications in Practice B827 shall be reported in the test report provided by the test operator

to the test specifier. Specification of one of the test conditions defined in this document in the form of a statement such as, “Parts

shall be tested in accordance with ASTM B845 Method Z.”, implicitly requires test condition, Z, applied according to Practice

B827.

5. Procedure

5.1 Decide upon a test plan appropriate for the contacts being evaluated. Consider test parameters such as preconditioning,

performance measurement and other evaluation techniques, and experimental controls.

5.2 Select a MFG test and exposure length appropriate for the parts being evaluated. Table 1 lists a number of such tests that

have been documented in the technical literature. The next section provides brief discussions of the origins and intended purpose

of each of the methods.

6. Abstracts of Methods

6.1 Method A—Method A was originally developed as a highly accelerated test to stress equipment that might be exposed to

environments with high levels of air pollution from combustion of high sulfur coal (1). The method is included in this list for

completeness. It is generally not considered realistic for evaluation of electronic equipment for the vast majority of applications.

Typical exposure time is 4, 10 or 21 days, depending upon the specification for the product under test.

Available from Electronic Industries Alliance (EIA), 2500 Wilson Blvd., Arlington, VA 22201, http://www.eia.org.IHS, 15 Inverness Way East, Englewood, CO 80112,

http://www.global.ihs.com.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

The boldface numbers in parentheses refer to a list of references at the end of this guide.

´1

B845 − 97 (2013)

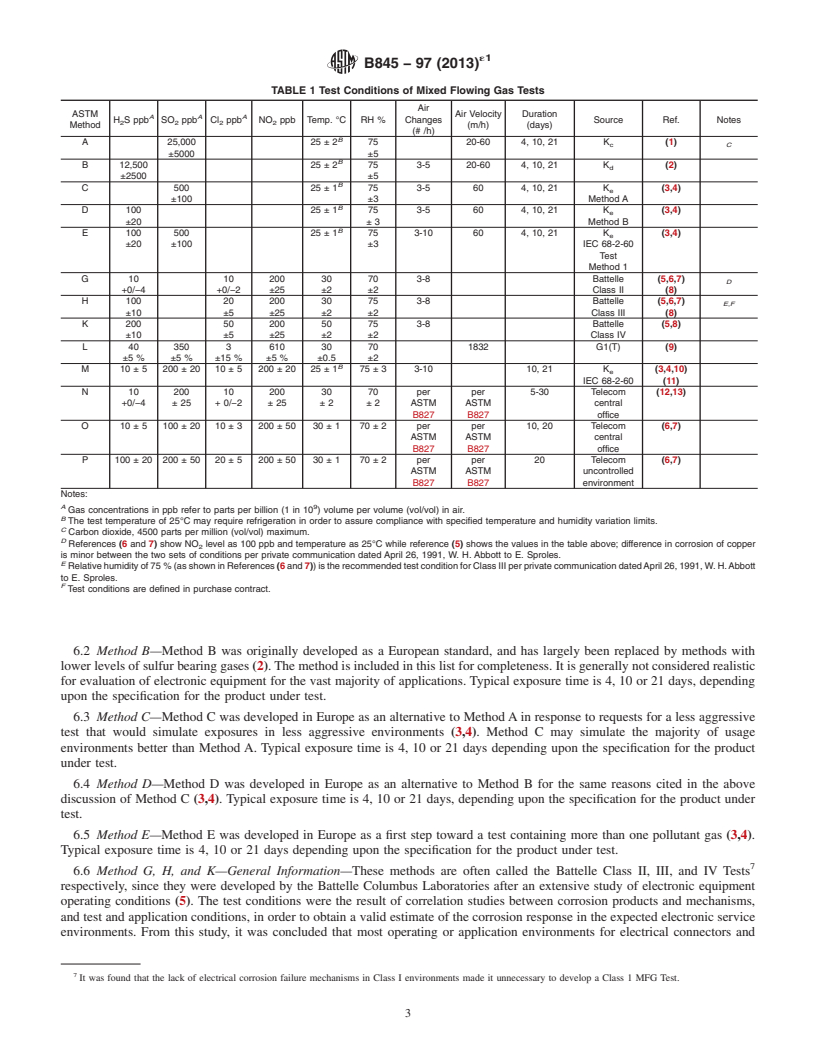

TABLE 1 Test Conditions of Mixed Flowing Gas Tests

Air

ASTM Air Velocity Duration

A A A

H S ppb SO ppb Cl ppb NO ppb Temp. °C RH % Changes Source Ref. Notes

2 2 2 2

Method (m/h) (days)

(# /h)

B

A 25,000 25 ± 2 75 20-60 4, 10, 21 K (1)

c C

±5000 ±5

B

B 12,500 25 ± 2 75 3-5 20-60 4, 10, 21 K (2)

d

±2500 ±5

B

C 500 25 ± 1 75 3-5 60 4, 10, 21 K (3,4)

e

±100 ±3 Method A

B

D 100 25 ± 1 75 3-5 60 4, 10, 21 K (3,4)

e

±20 ± 3 Method B

B

E 100 500 25 ± 1 75 3-10 60 4, 10, 21 K (3,4)

e

±20 ±100 ±3 IEC 68-2-60

Test

Method 1

G 10 10 200 30 70 3-8 Battelle (5,6,7)

D

+0/−4 +0/−2 ±25 ±2 ±2 Class II (8)

H 100 20 200 30 75 3-8 Battelle (5,6,7)

E,F

±10 ±5 ±25 ±2 ±2 Class III (8)

K 200 50 200 50 75 3-8 Battelle (5,8)

±10 ±5 ±25 ±2 ±2 Class IV

L 40 350 3 610 30 70 1832 G1(T) (9)

±5 % ±5 % ±15 % ±5 % ±0.5 ±2

B

M 10 ± 5 200 ± 20 10 ± 5 200 ± 20 25 ± 1 75 ± 3 3-10 10, 21 K (3,4,10)

e

IEC 68-2-60 (11)

N 10 200 10 200 30 70 per per 5-30 Telecom (12,13)

+0/−4 ± 25 + 0/−2 ± 25 ± 2 ± 2 ASTM ASTM central

B827 B827 office

O 10 ± 5 100 ± 20 10 ± 3 200 ± 50 30 ± 1 70 ± 2 per per 10, 20 Telecom (6,7)

ASTM ASTM central

B827 B827 office

P 100 ± 20 200 ± 50 20 ± 5 200 ± 50 30 ± 1 70 ± 2 per per 20 Telecom (6,7)

ASTM ASTM uncontrolled

B827 B827 environment

Notes:

A 9

Gas concentrations in ppb refer to parts per billion (1 in 10 ) volume per volume (vol/vol) in air.

B

The test temperature of 25°C may require refrigeration in order to assure compliance with specified temperature and humidity variation limits.

C

Carbon dioxide, 4500 parts per million (vol/vol) maximum.

D

References (6 and 7) show NO level as 100 ppb and temperature as 25°C while reference (5) shows the values in the table above; difference in corrosion of copper

is minor between the two sets of conditions per private communication dated April 26, 1991, W. H. Abbott to E. Sproles.

E

Relative humidity of 75 % (as shown in References (6 and 7)) is the recommended test condition for Class III per private communication dated April 26, 1991, W. H. Abbott

to E. Sproles.

F

Test conditions are defined in purchase contract.

6.2 Method B—Method B was originally developed as a European standard, and has largely been replaced by methods with

lower levels of sulfur bearing gases (2). The method is included in this list for completeness. It is generally not considered realistic

for evaluation of electronic equipment for the vast majority of applications. Typical exposure time is 4, 10 or 21 days, depending

upon the specification for the product under test.

6.3 Method C—Method C was developed in Europe as an alternative to Method A in response to requests for a less aggressive

test that would simulate exposures in less aggressive environments (3,4). Method C may simulate the majority of usage

environments better than Method A. Typical exposure time is 4, 10 or 21 days depending upon the specification for the product

under test.

6.4 Method D—Method D was developed in Europe as an alternative to Method B for the same reasons cited in the above

discussion of Method C (3,4). Typical exposure time is 4, 10 or 21 days, depending upon the specification for the product under

test.

6.5 Method E—Method E was developed in Europe as a first step toward a test containing more than one pollutant gas (3,4).

Typical exposure time is 4, 10 or 21 days depending upon the specification for the product under test.

6.6 Method G, H, and K—General Information—These methods are often called the Battelle Class II, III, and IV Tests

respectively, since they were developed by the Battelle Columbus Laboratories after an extensive study of electronic equipment

operating conditions (5). The test conditions were the result of correlation studies between corrosion products and mechanisms,

and test and application conditions, in order to obtain a valid estimate of the corrosion response in the expected electronic service

environments. From this study, it was concluded that most operating or application environments for electrical connectors and

It was found that the lack of electrical corrosion failure mechanisms in Class I environments made it unnecessary to develop a Class 1 MFG Test.

´1

B845 − 97 (2013)

electronic components can be categorized by a limited number of Severity Classes, which can be simulated, and their effects

accelerated, by adjusting the critical parameters of the MFG test.

6.6.1 The descriptions in reference (5) of operating environment Classes I through IV are as follows: Class I is characterized

by formation of oxides on copper coupons and no visible attack on porous gold plated, nickel underplated, copper coupons

(Au/Ni/Cu) Class II is characterized by pore corrosion of Au/Ni/Cu coupons and formation of oxides and complex copper hydroxy

chlorides on copper coupons. Class III is characterized by pore and tarnish creepage corrosion of Au/Ni/Cu coupons and the

formation of oxides, sulfides and other unknown corrosion products on copper coupons. Class IV is characterized by tarnish

creepage on Au/Ni/Cu coupons and copper coupon corros

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.