ASTM D3981-09a(2024)e1

(Specification)Standard Specification for Polyethylene Films Made from Medium-Density Polyethylene for General Use and Packaging Applications

Standard Specification for Polyethylene Films Made from Medium-Density Polyethylene for General Use and Packaging Applications

ABSTRACT

This specification covers unpigmented, unsupported, sheet or tubular, medium-density polyethylene films intended for general uses and packaging applications. The film shall be made from homopolymer polyethylene, copolymer polyethylene commonly referred to as low-pressure polyethylene, or blends of homopolymers and copolymers that include ethylene/vinyl-acetate copolymers. The specimens shall be conditioned before testing in the standard laboratory temperature. Tests shall be conducted to determine the physical properties of the specimens which shall conform to the following physical requirements: secant modulus or stiffness; kinetic coefficient of friction; optical properties such as clarity, gloss, and haze; surface treatment level or wetting tension; impact resistance; tensile strength and elongation at break; heat sealability; and odor level.

SCOPE

1.1 This specification covers unpigmented, unsupported, sheet or tubular, medium-density polyethylene films (hereafter referred to as film or films) from resins having densities in the range from 926.0 to 938.0 kg/m3 (0.926 to 0.938 g/cm3), inclusive, as measured on molded plaques.

1.2 This specification is applicable to homopolymer polyethylene but is not restricted to it.

1.3 This specification is also applicable to films made from copolymer polyethylene commonly referred to in industry as low-pressure polyethylene.

1.4 This specification is also applicable to films made from blends of homopolymers and copolymers, including ethylene/vinyl-acetate copolymers.

1.5 This specification allows for the use of recycled polyethylene film or resin as feedstock, in whole or in part, as long as all the requirements of this specification are met and as long as any specific requirements as governed by the producer and end user are also met (see Note 1).

Note 1: Guide D7209 contains terminology and definitions relating to recycled plastics.

1.6 Special care must be exercised if this specification is applied to colored or pigmented films. This specification does not address specific problems associated with coloring, such as, quantity and quality of pigment dispersion, optical properties, and increase in density. These and other areas must be taken into account by mutual agreement between the supplier and the purchaser.

1.7 The thickness of the films covered by this specification range from 25 to 100 μm (0.001 to 0.004 in.), inclusive. The maximum width of the sheet or lay-flat is 3.05 m (120 in.).

1.8 This specification does not cover oriented heat-shrinkable films.

1.9 This specification defines the levels of various physical properties from which specifications for specific films are to be described. The levels of physical properties required by a film for a given application are selected from Section 6 and the corresponding tables. However, Sections 7.2 – 7.5 relating to tolerances shall apply without change to all film falling within the scope indicated by the title and 1.1 – 1.4.

1.10 This specification covers dimensional tolerances, classification, intrinsic quality requirements, and test methods. The dimensional tolerances include thickness, width, and length or yield. Classification defines types, classes, surfaces, and finishes. The intrinsic quality requirements include density, workmanship, impact strength, tensile strength, heat sealability, and odor, as well as the classification properties for stiffness, coefficient of friction, optical properties, and surface treatment. A sampling method is included.

1.11 The values stated in SI units are to be regarded as standard. The values in parentheses are given for information only.

1.12 The following precautionary caveat pertains only to the test methods portion, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate s...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D3981 − 09a (Reapproved 2024)

Standard Specification for

Polyethylene Films Made from Medium-Density Polyethylene

for General Use and Packaging Applications

This standard is issued under the fixed designation D3981; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Reapproved with editorial changes to Section 1 in February 2024.

1. Scope 1.7 The thickness of the films covered by this specification

range from 25 to 100 μm (0.001 to 0.004 in.), inclusive. The

1.1 This specification covers unpigmented, unsupported,

maximum width of the sheet or lay-flat is 3.05 m (120 in.).

sheet or tubular, medium-density polyethylene films (hereafter

referred to as film or films) from resins having densities in the 1.8 This specification does not cover oriented heat-

3 3

range from 926.0 to 938.0 kg/m (0.926 to 0.938 g/cm ), shrinkable films.

inclusive, as measured on molded plaques.

1.9 This specification defines the levels of various physical

1.2 This specification is applicable to homopolymer poly- properties from which specifications for specific films are to be

ethylene but is not restricted to it. described. The levels of physical properties required by a film

for a given application are selected from Section 6 and the

1.3 This specification is also applicable to films made from

corresponding tables. However, Sections 7.2 – 7.5 relating to

copolymer polyethylene commonly referred to in industry as

tolerances shall apply without change to all film falling within

low-pressure polyethylene.

the scope indicated by the title and 1.1 – 1.4.

1.4 This specification is also applicable to films made from

1.10 This specification covers dimensional tolerances,

blends of homopolymers and copolymers, including ethylene/

classification, intrinsic quality requirements, and test methods.

vinyl-acetate copolymers.

The dimensional tolerances include thickness, width, and

1.5 This specification allows for the use of recycled poly-

length or yield. Classification defines types, classes, surfaces,

ethylene film or resin as feedstock, in whole or in part, as long

and finishes. The intrinsic quality requirements include density,

as all the requirements of this specification are met and as long

workmanship, impact strength, tensile strength, heat

as any specific requirements as governed by the producer and

sealability, and odor, as well as the classification properties for

end user are also met (see Note 1).

stiffness, coefficient of friction, optical properties, and surface

treatment. A sampling method is included.

NOTE 1—Guide D7209 contains terminology and definitions relating to

recycled plastics.

1.11 The values stated in SI units are to be regarded as

1.6 Special care must be exercised if this specification is

standard. The values in parentheses are given for information

applied to colored or pigmented films. This specification does

only.

not address specific problems associated with coloring, such as,

1.12 The following precautionary caveat pertains only to the

quantity and quality of pigment dispersion, optical properties,

test methods portion, Section 10, of this specification: This

and increase in density. These and other areas must be taken

standard does not purport to address all of the safety concerns,

into account by mutual agreement between the supplier and the

if any, associated with its use. It is the responsibility of the user

purchaser.

of this standard to establish appropriate safety, health, and

environmental practices and determine the applicability of

regulatory limitations prior to use.

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, NOTE 2—There is no known ISO equivalent to this standard.

and Molded Products.

1.13 This international standard was developed in accor-

Current edition approved Feb. 1, 2024. Published March 2024. Originally

dance with internationally recognized principles on standard-

approved in 1981. Last previous edition approved in 2016 as D3981 – 09a(2016).

DOI: 10.1520/D3981-09AR24E01. ization established in the Decision on Principles for the

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D3981 − 09a (2024)

Development of International Standards, Guides and Recom- 3. Terminology

mendations issued by the World Trade Organization Technical

3.1 Unless otherwise indicated the terminology used in this

Barriers to Trade (TBT) Committee.

specification is in accordance with definitions given in Termi-

nology D883.

2. Referenced Documents

2 4. Classification

2.1 ASTM Standards:

4.1 The medium-density film is, by this specification, clas-

D792 Test Methods for Density and Specific Gravity (Rela-

sified by Types: 0, 1, 2, and 3; Surfaces: 0, 1, 2, and 3; Classes:

tive Density) of Plastics by Displacement

0, 1, 2, and 3; and Finishes: 1, 2, 3, and 4. These classifications

D882 Test Method for Tensile Properties of Thin Plastic

Sheeting are described in detail in 6.1.

D883 Terminology Relating to Plastics

5. Materials

D1003 Test Method for Haze and Luminous Transmittance

of Transparent Plastics 5.1 The film shall be made from a homopolymer

D1505 Test Method for Density of Plastics by the Density-

polyethylene, copolymer polyethylene (see Note 5), or blends

Gradient Technique of homopolymers or copolymers, or both, so that it meets the

D1709 Test Methods for Impact Resistance of Plastic Film

density and other film requirements listed herein.

by the Free-Falling Dart Method

NOTE 5—From a polyethylene, polyethylene plastic, or an ethylene

D1894 Test Method for Static and Kinetic Coefficients of

plastic as defined in Terminology D883.

Friction of Plastic Film and Sheeting (Withdrawn 2023)

5.2 The film shall be made from resins having a density

D1898 Practice for Sampling of Plastics (Withdrawn 1998)

3 3

between 926.0 and 938.0 kg/m (0.926 and 0.938 g/cm ),

D2103 Specification for Polyethylene Film

inclusive.

D2457 Test Method for Specular Gloss of Plastic Films and

5.3 The film shall be natural in color (essentially colorless)

Solid Plastics

unless a color has been agreed upon between the supplier and

D2578 Test Method for Wetting Tension of Polyethylene and

the purchaser. If colored, the quality and uniformity of coloring

Polypropylene Films

shall be by agreement between the supplier and the purchaser.

D4321 Test Method for Package Yield of Plastic Film

Also, if added colorants or pigments are used in an amount

(Withdrawn 2024)

such that some film properties are affected, this shall be taken

D4703 Practice for Compression Molding Thermoplastic

Materials into Test Specimens, Plaques, or Sheets into account by mutual agreement between the supplier and the

purchaser.

D4883 Test Method for Density of Polyethylene by the

Ultrasound Technique

6. Physical Requirements

D4976 Specification for Polyethylene Plastics Molding and

Extrusion Materials

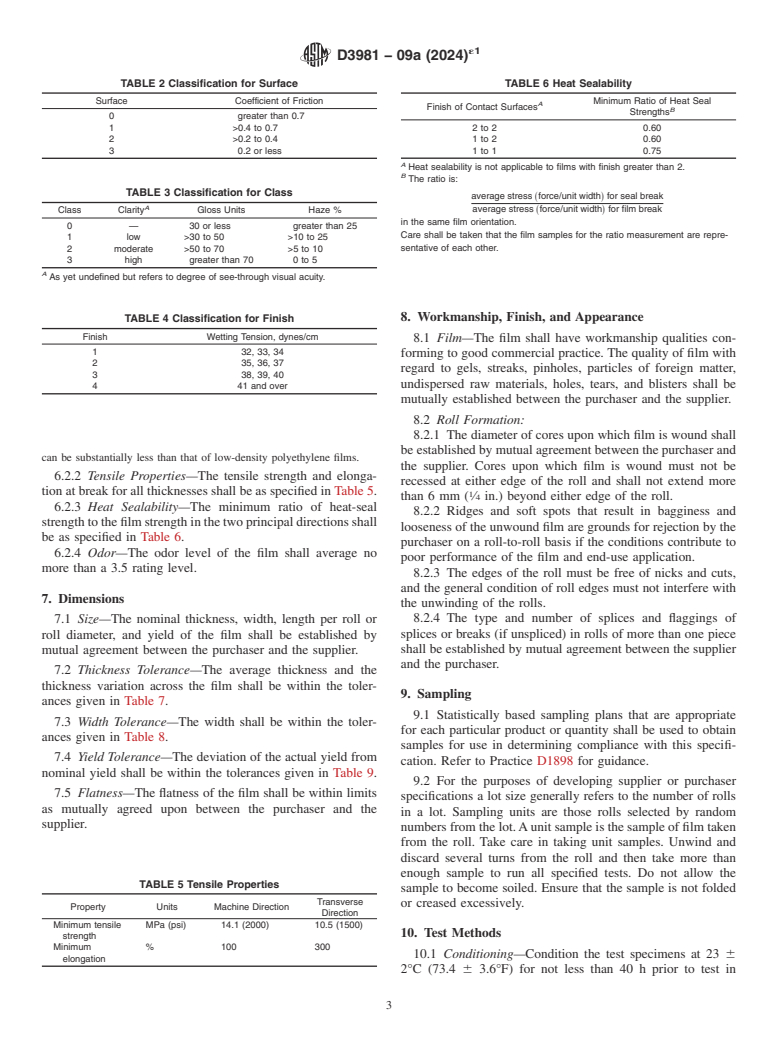

6.1 Classification Properties:

D6988 Guide for Determination of Thickness of Plastic Film 6.1.1 Type—The 1 % secant modulus for all thicknesses of

Test Specimens

film shall be as specified in Table 1 for Types 0, 1, 2, and 3.

D7209 Guide for Waste Reduction, Resource Recovery, and 6.1.2 Surface—The kinetic coefficient of friction shall be as

Use of Recycled Polymeric Materials and Products (With-

specified in Table 2 for Surfaces 0, 1, 2, and 3.

drawn 2015) 6.1.3 Class—The optical properties shall be as specified in

E1870 Test Method for Odor and Taste Transfer from Table 3 of Classes 0, 1, 2, and 3. The three optical properties

Polymeric Packaging Film of clarity, gloss, and haze do not always correlate. The

particular property of most importance for the specific appli-

NOTE 3—Relevant government regulations also apply to this specifica-

cation shall be established and the value for this property shall

tion.

then govern, in case of any inconsistency.

NOTE 4—If this product is intended for packaging foods, medicines,

6.1.4 Finish—The surface treatment level of the film shall

drugs, and cosmetics it is subject to applicable regulations of the Food and

Drug Administration or the Department of Agriculture and must comply be as specified in Table 4 for Finishes 1, 2, 3, and 4.

with such regulations. If it is necessary to comply with regulations of other

6.2 Other Physical Properties:

government agencies, such as the Consumer Product Safety Commission,

6.2.1 Impact Resistance—Impact resistance of the film shall

Environmental Protection Agency, Department of Transportation, Federal

Trade Commission, etc., such compliance shall be arranged between the

be established by mutual agreement between the supplier and

purchaser and the seller prior to placing an order.

the purchaser if this property is required.

F88 Test Method for Seal Strength of Flexible Barrier

NOTE 6—Dart-impact resistance of medium-density polyethylene films

Materials

TABLE 1 Classification for Type

Type 1 % Secant Modulus, MPa (psi)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

0 170 (25 000) or less

Standards volume information, refer to the standard’s Document Summary page on

1 >170 to 240 (25 000 to 35 000)

the ASTM website.

2 >240 to 345 (35 000 to 50 000)

The last approved version of this historical standard is referenced on 3 greater than 345 (50 000)

www.astm.org.

´1

D3981 − 09a (2024)

TABLE 2 Classification for Surface TABLE 6 Heat Sealability

Surface Coefficient of Friction Minimum Ratio of Heat Seal

A

Finish of Contact Surfaces

B

Strengths

0 greater than 0.7

1 >0.4 to 0.7 2 to 2 0.60

2 >0.2 to 0.4 1 to 2 0.60

3 0.2 or less 1 to 1 0.75

A

Heat sealability is not applicable to films with finish greater than 2.

B

The ratio is:

TABLE 3 Classification for Class

average stress force/unit width for seal break

s d

A

average stress sforce/unit widthd for film break

Class Clarity Gloss Units Haze %

in the same film orientation.

0 — 30 or less greater than 25

Care shall be taken that the film samples for the ratio measurement are repre-

1 low >30 to 50 >10 to 25

sentative of each other.

2 moderate >50 to 70 >5 to 10

3 high greater than 70 0 to 5

A

As yet undefined but refers to degree of see-through visual acuity.

8. Workmanship, Finish, and Appearance

TABLE 4 Classification for Finish

Finish Wetting Tension, dynes/cm

8.1 Film—The film shall have wo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.