ASTM D3839-94a

(Practice)Standard Practice for Underground Installation of "Fiberglass" (Glass-Fiber- Reinforced Thermosetting-Resin) Pipe

Standard Practice for Underground Installation of "Fiberglass" (Glass-Fiber- Reinforced Thermosetting-Resin) Pipe

SCOPE

1.1 This practice establishes procedures for the burial of pressure and nonpressure "fiberglass" (glass-fiber-reinforced thermosetting-resin) pipe in many typically encountered soil conditions. Included are recommendations for trenching, placing pipe, joining pipe, placing and compacting backfill, and monitoring deflection levels. Guidance for installation of fiberglass pipe in subaqueous conditions is not included.

1.2 Product standards for fiberglass pipe encompass a wide range of product variables. Diameters range from 1 in. to 12 ft and pipe stiffness range from 9 to over 72 psi with internal pressure ratings up to several thousand pound-force per square inch. This standard does not purport to consider all of the possible combinations of pipe, soil types, and natural ground conditions that may occur. The recommendations in this practice may need to be modified or expanded to meet the needs of some installation conditions. In particular, fiberglass pipe with diameters of a few inches are generally so stiff that they are frequently installed in accordance with different guidelines. Consult with the pipe manufacturer for guidance on which practices are applicable to these particular pipes.

1.3 The scope of this practice excludes product-performance criteria such as a minimum pipe stiffness, maximum service deflection, or long-term strength. Such parameters may be contained in product standards or design specifications, or both, for fiberglass pipe. It is incumbent upon the specified product manufacturer or project engineer to verify and ensure that the pipe specified for an intended application, when installed in accordance with procedures outlined in this practice, will provide a long-term, satisfactory performance in accordance with criteria established for that application. Note 1-There is no similar or equivalent ISO standard. Note 2-A discussion of the importance of deflection and a presentation of a simplified method to approximate field deflections are given in AWWA C950.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 3839 – 94a

Standard Practice for

Underground Installation of “Fiberglass” (Glass-

FiberReinforced Thermosetting-Resin) Pipe

This standard is issued under the fixed designation D 3839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.1 This practice establishes procedures for the burial of

priate safety and health practices and determine the applica-

pressure and nonpressure “fiberglass” (glass-fiber-reinforced

bility of regulatory limitations prior to use.

thermosetting-resin) pipe in many typically encountered soil

conditions. Included are recommendations for trenching, plac-

2. Referenced Documents

ing pipe, joining pipe, placing and compacting backfill, and

2.1 ASTM Standards:

monitoring deflection levels. Guidance for installation of

D 8 Terminology Relating to Materials for Roads and Pave-

fiberglass pipe in subaqueous conditions is not included.

ments

1.2 Product standards for fiberglass pipe encompass a wide

D 653 Terminology Relating to Soil, Rock, and Contained

range of product variables. Diameters range from 1 in. to 12 ft

Fluids

and pipe stiffness range from 9 to over 72 psi with internal

D 698 Test Method for Laboratory Compaction Character-

pressure ratings up to several thousand pound-force per square

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

inch. This standard does not purport to consider all of the

kN-m/m))

possible combinations of pipe, soil types, and natural ground

D 883 Terminology Relating to Plastics

conditions that may occur. The recommendations in this

D 1556 Test Method for Density and Unit Weight of Soil in

practice may need to be modified or expanded to meet the

Place by the Sand-Cone Method

needs of some installation conditions. In particular, fiberglass

D 2167 Test Method for Density and Unit Weight of Soil in

pipe with diameters of a few inches are generally so stiff that

Place by the Rubber Balloon Method

they are frequently installed in accordance with different

D 2216 Test Method for Laboratory Determination of Water

guidelines. Consult with the pipe manufacturer for guidance on

(Moisture) Content of Soil and Rock

which practices are applicable to these particular pipes.

D 2321 Practice for Underground Installation of Flexible

1.3 The scope of this practice excludes product-

Thermoplastic Pipe for Sewers and Other Gravity-Flow

performance criteria such as a minimum pipe stiffness, maxi-

Applications

mum service deflection, or long-term strength. Such param-

D 2487 Classification of Soils for Engineering Purposes

eters may be contained in product standards or design

D 2488 Practice for Description of Soils (Visual-Manual

specifications, or both, for fiberglass pipe. It is incumbent upon

Procedure)

the specified product manufacturer or project engineer to verify

D 2922 Test Methods for Density of Soil and Soil-

and ensure that the pipe specified for an intended application,

Aggregate in Place by Nuclear Methods (Shallow Depth)

when installed in accordance with procedures outlined in this

D 3017 Test Method for Moisture Content of Soil and

practice, will provide a long-term, satisfactory performance in

Soil-Aggregate in Place by Nuclear Methods (Shallow

accordance with criteria established for that application.

Depth)

NOTE 1—There is no similar or equivalent ISO standard.

D 4253 Test Methods for Maximum Index Density and Unit

NOTE 2—A discussion of the importance of deflection and a presenta-

Weight of Soils Using a Vibratory Table

tion of a simplified method to approximate field deflections are given in

D 4254 Test Method for Minimum Index Density and Unit

AWWA C 950.

Weight of Soils and Calculation of Relative Density

1.4 This standard does not purport to address all of the

D 4318 Test Method for Liquid Limit, Plastic Limit, and

Plasticity Index of Soils

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Annual Book of ASTM Standards, Vol 04.03.

Piping Systems and Chemical Equipment. Annual Book of ASTM Standards, Vol 04.08.

Current edition approved June 15, 1994. Published August 1994. Originally Annual Book of ASTM Standards, Vol 08.01.

published as D 3839 – 79. Last previous edition D 3839 – 94. Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3839

D 4564 Test Method for Density of Soil in Place by the

Sleeve Method

D 4643 Method for Determination of Water (Moisture)

Content of Soil by the Microwave Oven Method

D 4914 Test Method for Density of Soil and Rock in Place

by the Sand Replacement Method in a Test Pit

D 4944 Test Method for Field Determination of Water

(Moisture) Content of Soil by the Calcium Carbide Gas

Pressure Tester Method

D 4959 Test Method for Determination of Water (Moisture)

Content of Soil by Direct Heating Method

D 5030 Test Methods for Density and Unit Weight of Soil

and Rock in Place by the Water Replacement Method in a

Test Pit

D 5080 Test Method for Rapid Determination of Percent

Compaction

F 412 Terminology Relating to Plastic Piping Systems

2.2 Other Standards:

AASHTO American Association of State Highway and

Transportation Officials Standard Specifications for High-

way Bridges

AWWA C 950 American Water Works Association Standard

Specification for Fiberglass Pressure Pipe

FIG. 1 Trench Cross-Section Terminology

3. Terminology

3.1 Definitions: neering related material, as an integral part of a man-made

3.1.1 General—Unless otherwise indicated, definitions are

product, structure, or system.

in accordance with Terminologies D 8, D 653, D 883, and 3.2.8 haunching—backfill material placed on top of the

F 412. bedding and under the springline of the pipe; the term

3.2 Definitions of Terms Specific to This Standard: Descrip- haunching only pertains to soil directly beneath the pipe (see

tions of Terms Specific to This Standard: Fig. 1).

3.2.1 bedding—backfill material placed and compacted in 3.2.9 initial backfill—backfill material placed at the sides of

the bottom of the trench or on the foundation to provide a the pipe and up to 6 to 12 in. (150 to 300 mm) over the top of

uniform material on which to lay the pipe. the pipe, including the haunching.

3.2.2 deflection—any change in the inside diameter of the 3.2.10 manufactured aggregates—aggregates that are prod-

pipe resulting from installation or imposed loads, or both; ucts or by-products of a manufacturing process, or natural

deflection may be either vertical or horizontal and is usually aggregates that are reduced to their final form by a manufac-

reported as a percentage of the base (undeflected) inside pipe turing process such as crushing.

diameter. 3.2.11 maximum standard proctor density—the maximum

3.2.3 engineer—the engineer in responsible charge of the dry unit weight of soil compacted at optimum moisture

work or his duly recognized or authorized representative. content, as obtained by laboratory test in accordance with Test

3.2.4 fiberglass pipe—a tubular product containing glass- Method D 698.

fiber reinforcements embedded in or surrounded by cured 3.2.12 native (in situ) soil—natural soil in which a trench is

thermosetting resin; the composite structure may contain

excavated for pipe installation or on which a pipe and

aggregate, granular, or platelet fillers, thixotropic agents, pig- embankment are placed.

ments, or dyes; thermoplastic or thermosetting liners or coat-

3.2.13 open-graded aggregate—an aggregate that has a

ings may be included. particle-size distribution such that, when compacted, the re-

3.2.5 final backfill—backfill material placed from the top of

sulting voids between the aggregate particles, expressed as a

the initial backfill to the ground surface. percentage of the total space occupied by the material, are

3.2.6 foundation—backfill material placed and compacted relatively large.

in the bottom of the trench to replace over-excavated material 3.2.14 optimum moisture content—the moisture content of

or to stabilize the trench-bottom in case of unsuitable ground soil at which its maximum density is obtained. (See Test

conditions, or both (see Fig. 1). Method D 698.)

3.2.7 geotextile—any permeable textile material used with 3.2.15 pipe zone embedment—all backfill around the pipe;

foundation, soil, earth, rock, or any other geotechnical engi- this includes the bedding, haunching, and initial backfill.

3.2.16 processed aggregates—aggregates which are

screened or washed or mixed or blended to produce a specific

Annual Book of ASTM Standards, Vol 04.09.

7 particle-size distribution.

Available from AASHTO, Denver, CO.

Available from AWWA, Washington, DC. 3.2.17 relative density—a measure of the density of a

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3839

granular soil based on the actual density of the soil “relative” owners, and inspection organizations involved in the construc-

to the soil in its loosest state and the soil in its densest state (see tion of buried fiberglass pipelines. As with any practice,

Terminology D 653 for a precise definition) as obtained by modifications may be required for specific job conditions, or

laboratory testing in accordance with Test Methods D 4253 and for special local or regional conditions. Recommendations for

D 4254. inclusion of this practice in contract documents for a specific

3.2.18 soil stiffness—a property of soil, generally repre- project are given in Appendix X1.

sented numerically by a modulus of deformation that indicates

5. Materials

the relative amount of deformation that will occur under a

5.1 Classification—Soil types used or encountered in bury-

given load.

ing pipes include those classified in Table 1 and natural,

3.2.19 split installation—an installation in which the initial

manufactured, and processed aggregates. The soil classifica-

backfill consists of two different materials; the primary backfill

tions are grouped into soil-stiffness categories (SC) in Table 2

must extend from the top of the bedding to a depth of at least

based on the typical soil stiffness when compacted. Soil-

0.7 times the diameter and the secondary backfill extends from

stiffness Category 1 indicates a soil that generally provides the

the top of the primary backfill to the top of the initial backfill.

highest soil stiffness at any given percentage of maximum

4. Significance and Use

Proctor density, and a soil that provides a given soil stiffness

4.1 This practice is for use by designers and specifiers, with the least compactive effort. Each higher-number soil-

manufacturers, installation contractors, regulatory agencies, stiffness category provides successively less soil stiffness at a

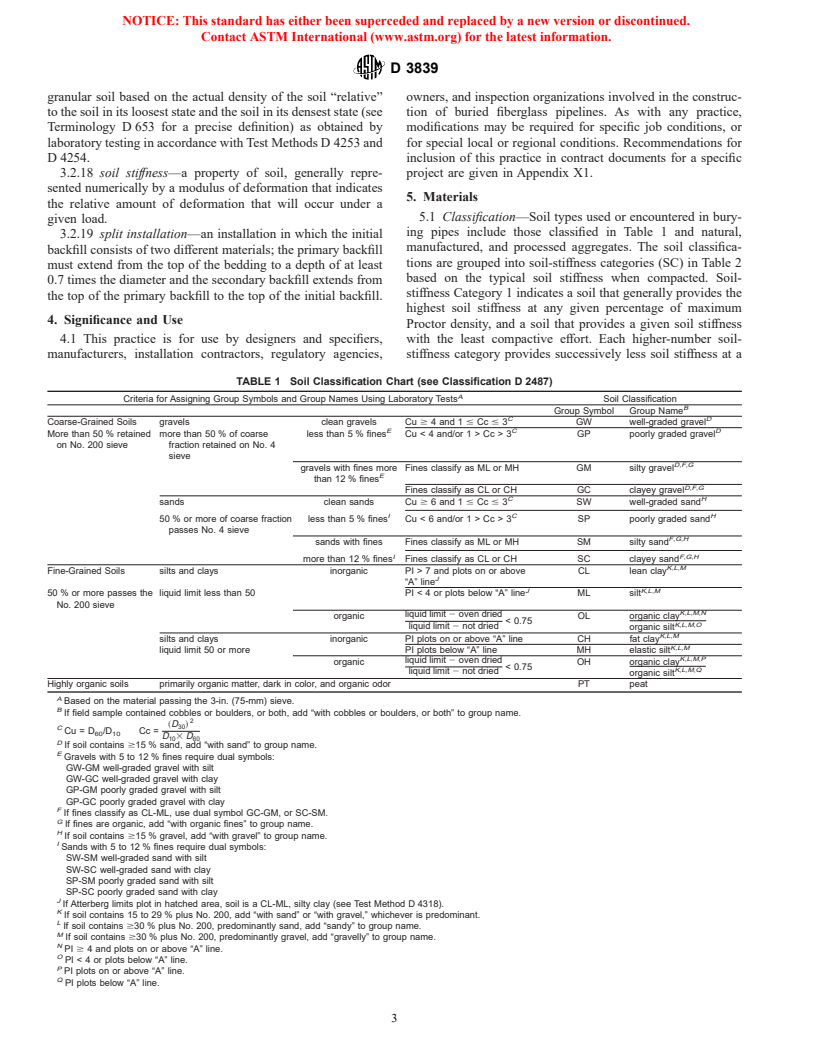

TABLE 1 Soil Classification Chart (see Classification D 2487)

A

Criteria for Assigning Group Symbols and Group Names Using Laboratory Tests Soil Classification

B

Group Symbol Group Name

C D

Coarse-Grained Soils gravels clean gravels Cu $ 4 and 1 # Cc # 3 GW well-graded gravel

E C D

More than 50 % retained more than 50 % of coarse less than 5 % fines Cu < 4 and/or1>Cc>3 GP poorly graded gravel

on No. 200 sieve fraction retained on No. 4

sieve

D,F,G

gravels with fines more Fines classify as ML or MH GM silty gravel

E

than 12 % fines

D,F,G

Fines classify as CL or CH GC clayey gravel

C H

sands clean sands Cu $ 6 and 1 # Cc # 3 SW well-graded sand

I C H

50 % or more of coarse fraction less than 5 % fines Cu < 6 and/or1>Cc>3 SP poorly graded sand

passes No. 4 sieve

F,G,H

sands with fines Fines classify as ML or MH SM silty sand

I F,G,H

more than 12 % fines Fines classify as CL or CH SC clayey sand

K,L,M

Fine-Grained Soils silts and clays inorganic PI > 7 and plots on or above CL lean clay

J

“A” line

J K,L,M

50 % or more passes the liquid limit less than 50 PI<4or plots below “A” line ML silt

No. 200 sieve

K,L,M,N

liquid limit 2 oven dried

organic OL organic clay

< 0.75

K,L,M,O

liquid limit 2 not dried

organic silt

K,L,M

silts and clays inorganic PI plots on or above “A” line CH fat clay

K,L,M

liquid limit 50 or more PI plots below “A” line MH elastic silt

K,L,M,P

liquid limit 2 oven dried

organic OH organic clay

< 0.75

K,L,M,Q

liquid limit 2 not dried

organic silt

Highly organic soils primarily organic matter, dark in color, and organic odor PT peat

A

Based on the material passing the 3-in. (75-mm) sieve.

B

If field sample contained cobbles or boulders, or both, add “with cobbles or boulders, or both” to group name.

~D !

C

Cu=D /D Cc =

60 10

D 3 D

10 60

D

If soil contains $15 % sand, add “with sand” to group name.

E

Gravels with 5 to 12 % fines require dual symbols:

GW-GM well-graded gravel with silt

GW-GC well-graded gravel with clay

GP-GM poorly graded gravel with silt

GP-GC poorly graded gravel with clay

F

If fines classify as CL-ML, use dual symbol GC-GM, or SC-SM.

G

If fines are organic, add “with organic fines” to group name.

H

If soil contains $15 % gravel, add “with gravel” to group name.

I

Sands with 5 to 12 % fines require dual symbols:

SW-SM well-graded sand with silt

SW-SC well-graded sand with clay

SP-SM poorly graded sand with silt

SP-SC poorly graded sand with clay

J

If Atterberg limits plot in hatched area, soil is a CL-ML, silty clay (see Test Method D 4318).

K

If soil contains 15 to 29 % plus No. 200, add “with sand” or “with gravel,” whichever is predominant.

L

If soil contains $30 % plus No. 200, predominantly sand, add “sandy” to group name.

M

If soil contains $30 % plus No. 200, predominantly gravel, add “gravelly” to group name.

N

PI $ 4 and plots on or above “A” line.

O

PI<4or plots below “A” line.

P

PI plots on or above “A” line.

Q

PI plots below “A” line.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3839

TABLE 2 Soil-Stiffness Categories

when used for foundation, emb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.